Beruflich Dokumente

Kultur Dokumente

A Vision For The Refinery of 2030

Hochgeladen von

Félix AlorOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Vision For The Refinery of 2030

Hochgeladen von

Félix AlorCopyright:

Verfügbare Formate

Originally appeared in:

May 2019, pgs 23-24.

Used with permission.

Executive RON BECK, DIRECTOR OF MARKETING STRATEGY

Viewpoint Aspen Technology, Boston, Massachusetts

A vision for the refinery of 2030

Momentum towards efficiency is petitors. Integrated systems and visual

driving integration from oil production interfaces show them how their indi-

to finished goods, while a recognition vidual and collective actions impact cus-

of the need for a positive environmental tomer delivery and satisfaction, as well

image for the energy industry is driving as how to optimize the asset to meet de-

innovation in carbon capture and new mand profitably.

uses for performance chemicals to reach Following the lead of Amazon’s busi-

a carbon-neutral balance. ness model, the connected supply chain

Sustainability initiatives are steering of the 2030 refinery ties together its sup-

refiners to implement ambitious pro- ply chain with its operations, planning

grams to reduce both energy and water and trading, and sources solutions and

use in refining and chemicals. Global applies powerful artificial intelligence

cybersecurity concerns are driving inno- (AI)-assisted analytics to understand

vation to enable digital transformation, the business opportunities presented by

while simultaneously protecting the demand changes.

safety and integrity of strategic assets. Business management, sales and

trading use these analytics to find the

RON BECK is the Director of marketing strategy

Strategic choices. How do you posi- business levers that give them market

at AspenTech. He has been responsible tion a refinery in the next 10 yr to make advantage.

for engineering product marketing, Aspen the right capital investments for change

Economic Evaluation and Aspen B asic but be increasingly flexible? Will digi- Optimized production driven by

Engineering. He has more than 25 yr of tal technologies be transformative in trading and the economically op-

experience in providing software solutions to

the process industries and 15 yr of experience

providing refiners a strategic cost and timum plan. The refinery of 2030 will

in chemical engineering technology margin advantage? Can digital trans- operate with knowledge worker “pods”

commercialization. Mr. Beck has authored formation make flattened refining orga- comprising planners, optimization ex-

papers on key industry topics and has presented nizations exciting destinations for the perts, operators and reliability experts.

at several public industry events. He is a “best and the brightest” graduates—the Planning and scheduling will be fully

graduate of Princeton University in New Jersey.

future key people resources? How can integrated, with the planner supported

organizations reduce cyber vulnerabil- by an AI expert dashboard displaying

ity and, simultaneously, increase agility economic, sales, sustainability and op-

The refining business needs to change and innovation? erations trade-offs. Creation of the best

dramatically over the next decade. Re- schedule will be fully autonomous.

finery executives worldwide are tuned to The vision. The refinery of 2030 will be Prescriptive maintenance systems

the signals of change, but some are not very different from the refinery of 2019. will flag to the planner and reliabil-

sure of the best course of action. What At its core, the multibillion-dollar physi- ity expert situations that could interrupt

are the challenges? How will technol- cal asset—conversion, storage and sepa- achieving the production plan, along

ogy disrupt the hydrocarbon processing ration units—will still be there. People with alternatives for traders to purchase

business? What is the path forward for will still drive refining, but in different optimum crudes and operators to main-

future success? jobs. However, it will become an intel- tain operations at the best possible asset

ligent, flexible and adaptive plant. utilization, safety and profitability.

The signs of change. The uptake of Using AI-assisted advanced process

hybrid, electric and high-efficiency ve- Demand-driven decision making. control (APC), the integrated plan and

hicles, along with the pace of renewable The refinery of 2030 thrives by being schedule will autonomously provide

power, are key variables in forecasting fully demand-driven, with decisions closed-loop optimization. By 2030, data

hydrocarbon fuels demand. The market made quickly at the appropriate level. sensors will be pervasive, but new real-

for petrochemical feedstocks depends Across the management chain, knowl- time analytics deployed at the edge will

both on economic growth in Asia and, edgeable workers in the 2030 refinery provide process stream compositions,

conversely, a strong push to avoid non- will take actions based on their impact and catalyst nanosensors will drive better

recyclable plastics. on satisfying demand better than com- control over process performance. These

Hydrocarbon Processing | MAY 2019

Executive Viewpoint

technologies will drive the APC and un- Taking people out of dangerous/re- worker in the refinery will have imme-

derlying control to operate through dy- mote areas. The further development diate visibility into the impacts of their

namically adjusted setpoints to achieve of sensors, prescriptive maintenance AI tactical and strategic decisions on en-

and exceed operations. solutions, unit analytics, etc., will pro- terprise sustainability metrics and key

vide the intelligence to understand phys- performance indicators. Online optimi-

Smart units/equipment: Hardware ical asset conditions, trends, risks and zation models will constantly optimize

embedded APC and models. Major emergencies, obviating most of the need both energy and water use in the asset

process units and equipment in the re- to send people into the plant to inspect and throughout the value chain. Person-

finery of 2030 will be smart plant build- equipment and units for issues. AI-en- nel will keep a running scoreboard of

ing blocks. This built-in intelligence will abled virtual solutions will be able to not sustainability “points” the workers can

greatly improve the ability of the refinery only plan but also manage startup and earn recognition for when their actions

to operate at process operating limits. It shutdown procedures largely remotely. help the enterprise improve its sustain-

will also be a critical element of asset Advances in plant robotics solutions will ability investment standing.

flexibility. The asset owner will use this enable performance of many tasks with-

intelligence as an AI-based decision tool out sending people into danger. Executive risk-based visibility. En-

to model plant reconfiguration to shift This concept is far beyond, and an terprise-wide, next-generation risk mod-

product suites based on demand, to ex- alternative view to, the concept of “3D els provide a dashboard in the executive

ecute the reconfiguration rapidly, and to augmented reality.” Conversely, it is the suite to assess an increase or reduction

reconfigure the monitoring and control process and intelligent reliability, plan- of risk being undertaken by different

models for operating optimization. ning and execution systems that will businesses, and capital and operational

The next-generation prescriptive drastically reduce the need for people to expenditures budgetary decisions. Cy-

maintenance system will not only flag enter dangerous areas at dangerous times. ber defensive capabilities and warnings

future failure modes for equipment and will be built into every layer of the future

units, but also will link to the planning Sustainability oversight. The refinery digital refinery. These concepts will help

and process models to propose operat- of 2030 will only exist in an even more the refinery of 2030 play a key role in the

ing changes that will delay or eliminate stringent “social license to operate” en- sustainable, highly-diversified and inte-

the future failure risk. vironment. Every decision-maker and grated energy enterprise of the future.

Electronic and single printed copies for distribution with permission to AspenTech from Hydrocarbon Processing

May © 2019 Gulf Publishing Company

MAY 2019 | HydrocarbonProcessing.com

Das könnte Ihnen auch gefallen

- Hydrotreating Amine Treating & Sulphur Recovery: PetroDokument8 SeitenHydrotreating Amine Treating & Sulphur Recovery: PetroIlham HakimNoch keine Bewertungen

- Introdiction To Engineering PDFDokument295 SeitenIntrodiction To Engineering PDFAyebareNoch keine Bewertungen

- Simulation Result Comparison-LPG Plant JambiDokument1 SeiteSimulation Result Comparison-LPG Plant JambiMadeMaryasaRobedNoch keine Bewertungen

- Biogreen Solutions Limited-Bgsl: Green Product Ideas For ExportDokument64 SeitenBiogreen Solutions Limited-Bgsl: Green Product Ideas For Exportncr_thazzardsNoch keine Bewertungen

- AIMMS Tutorial BeginnersDokument46 SeitenAIMMS Tutorial Beginnerstryinghard18Noch keine Bewertungen

- Engineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentDokument26 SeitenEngineering Proposal and Quotation: 50T/D Continuous Refining Workshop EquipmentMuhammad aliNoch keine Bewertungen

- CFC 1criterionbrochureDokument19 SeitenCFC 1criterionbrochureSuraj Amin100% (1)

- SMA - Enterprise Risk Management - Frameworks, Elements, and IntegrationDokument29 SeitenSMA - Enterprise Risk Management - Frameworks, Elements, and Integrationalvarez kameNoch keine Bewertungen

- Attock Refinery Limited (Annual Report 2007)Dokument124 SeitenAttock Refinery Limited (Annual Report 2007)Monis Ali100% (1)

- CHAPTER VI - Oil & Gas DownstreamDokument70 SeitenCHAPTER VI - Oil & Gas DownstreamRUFFALYN FINCALERONoch keine Bewertungen

- Linear Program 1Dokument52 SeitenLinear Program 1ChaOs_Air75% (4)

- Scheduling Crude Oil Loading and UnloadingDokument32 SeitenScheduling Crude Oil Loading and UnloadingnckpourlasNoch keine Bewertungen

- Poeb108 RaviDokument8 SeitenPoeb108 RaviMuhammad GaneshaNoch keine Bewertungen

- Bio Energy Presentation of Bio FuelDokument31 SeitenBio Energy Presentation of Bio FuelDeep GreyNoch keine Bewertungen

- Wenzhou Bangcheng Grain and Oil Machinery Co.,Ltd: 20T/D Soybean & Sunflower Oil Full Continuous Refinery Plant QuotationDokument3 SeitenWenzhou Bangcheng Grain and Oil Machinery Co.,Ltd: 20T/D Soybean & Sunflower Oil Full Continuous Refinery Plant QuotationMuhammad aliNoch keine Bewertungen

- AT-07338-BRO-Aspen GDOT brochure-OLEFINS-2021-1112Dokument7 SeitenAT-07338-BRO-Aspen GDOT brochure-OLEFINS-2021-1112Zeeshan AlamNoch keine Bewertungen

- Marketing Plan For Petrotrin Entry Into ULSD Market - 04707759 - Seon CharlesDokument52 SeitenMarketing Plan For Petrotrin Entry Into ULSD Market - 04707759 - Seon CharlesSeon CharlesNoch keine Bewertungen

- LP-Staffing & BlendingDokument15 SeitenLP-Staffing & BlendingJobayer Islam TunanNoch keine Bewertungen

- Classification of Crude OilDokument3 SeitenClassification of Crude OilY. Dutt50% (4)

- Linear Programming Techniques for Optimizing Paint Product Mix in NigeriaDokument10 SeitenLinear Programming Techniques for Optimizing Paint Product Mix in NigeriaHarsh SaxenaNoch keine Bewertungen

- Indofood Agri-Resources - IndoAgri Ar2013Dokument162 SeitenIndofood Agri-Resources - IndoAgri Ar2013Appie Koekange100% (1)

- Engineering Dreams: A Career in Any Stream of Engineering Is Equally Fruitful and RewardingDokument4 SeitenEngineering Dreams: A Career in Any Stream of Engineering Is Equally Fruitful and RewardingRamPrasadMeenaNoch keine Bewertungen

- Study and Evaluation For Different Types of Sudanese Crude Oil PropertiesDokument4 SeitenStudy and Evaluation For Different Types of Sudanese Crude Oil PropertiesInternational Journal of Research in Engineering and ScienceNoch keine Bewertungen

- Neste Oil: Esa Kokko Guillermo Avila Jürgen Suls Teresa Luoma-AhDokument13 SeitenNeste Oil: Esa Kokko Guillermo Avila Jürgen Suls Teresa Luoma-Ahmemoavila71Noch keine Bewertungen

- Neste Oil Company PresentationDokument49 SeitenNeste Oil Company PresentationXianchi ZhangNoch keine Bewertungen

- Cash Flow Estimation and Risk AnalysisDokument24 SeitenCash Flow Estimation and Risk AnalysisSahil GuptaNoch keine Bewertungen

- Producing MDI in the PhilippinesDokument41 SeitenProducing MDI in the PhilippinesJenny SabinoNoch keine Bewertungen

- Lecture-3 Crude Oil PropertiesDokument61 SeitenLecture-3 Crude Oil PropertiesMrHemFun100% (1)

- Twinkle Palm Oil Ventures Set to Redefine Standard Palm Oil ProcessingDokument35 SeitenTwinkle Palm Oil Ventures Set to Redefine Standard Palm Oil ProcessingMumtahinaNoch keine Bewertungen

- Introduction to production, operations management, and their objectivesDokument6 SeitenIntroduction to production, operations management, and their objectivesshreekarainNoch keine Bewertungen

- 2021 Sustainability FinalDokument36 Seiten2021 Sustainability FinalLovely ChoudharyNoch keine Bewertungen

- Petroleum Refining Operations: Key Issues, Advances, and OpportunitiesDokument10 SeitenPetroleum Refining Operations: Key Issues, Advances, and OpportunitiesMarbel VldNoch keine Bewertungen

- Hungrystock CPO OutlookDokument28 SeitenHungrystock CPO OutlooknindyNoch keine Bewertungen

- Palm Oil FractionationDokument2 SeitenPalm Oil FractionationChiew Let Chong0% (1)

- Charles Zishiri's Total Loss Control Case StudyDokument6 SeitenCharles Zishiri's Total Loss Control Case StudyCalleb ZuvaNoch keine Bewertungen

- Oil Price Trends in India and Its DeterminentsDokument16 SeitenOil Price Trends in India and Its DeterminentsDeepthi Priya BejjamNoch keine Bewertungen

- WastewatertreatmentdesignreportfDokument49 SeitenWastewatertreatmentdesignreportfapi-314633288Noch keine Bewertungen

- Ch8 Confidence Interval Estimation Part2 - Suggested Problems SolutionsDokument1 SeiteCh8 Confidence Interval Estimation Part2 - Suggested Problems SolutionsmaxentiussNoch keine Bewertungen

- Case Study Palm Oil Refinery NewDokument2 SeitenCase Study Palm Oil Refinery NewFong Leong Chee 馮亮智100% (2)

- Natural Blush Cosmetics: Setting A Science-Based Carbon Reduction TargetDokument6 SeitenNatural Blush Cosmetics: Setting A Science-Based Carbon Reduction TargetdanielNoch keine Bewertungen

- KBC Viewpoint Optimization Programs Mar18 - USDokument12 SeitenKBC Viewpoint Optimization Programs Mar18 - USjunk multiNoch keine Bewertungen

- Towards A Petroleum Sector Master Plan For Kenya v2Dokument490 SeitenTowards A Petroleum Sector Master Plan For Kenya v2KivutiNoch keine Bewertungen

- Risk Assessment of A Post-Combustion and Amine-BasDokument7 SeitenRisk Assessment of A Post-Combustion and Amine-BasYusdianNoch keine Bewertungen

- Fuel Oil Quality Testing with API Gravity, BSW, and ColorDokument3 SeitenFuel Oil Quality Testing with API Gravity, BSW, and ColorThomas KerlNoch keine Bewertungen

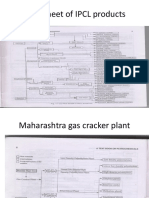

- IPCL chemicals flow sheetDokument51 SeitenIPCL chemicals flow sheetDeekshith KodumuruNoch keine Bewertungen

- Palm Fatty Acid Distillate BiodieselDokument4 SeitenPalm Fatty Acid Distillate Biodieseldwi anggraeniNoch keine Bewertungen

- Case Analysis On IOCLDokument12 SeitenCase Analysis On IOCLRaoul Savio GomesNoch keine Bewertungen

- Crude Palm OilDokument19 SeitenCrude Palm OilmarpadanNoch keine Bewertungen

- Coconut Oil - WikipediaDokument11 SeitenCoconut Oil - WikipediaYusuf Aliyu UNoch keine Bewertungen

- 2.1-LP Formulation Examples - ExercisesDokument4 Seiten2.1-LP Formulation Examples - Exercisesaminzakaria89Noch keine Bewertungen

- BYCO Report Highlights Oil CompanyDokument17 SeitenBYCO Report Highlights Oil CompanyAliRashidNoch keine Bewertungen

- Nigerian Company Model - Product Mix PDFDokument7 SeitenNigerian Company Model - Product Mix PDFHarsh SaxenaNoch keine Bewertungen

- Oil and Fat Technology Lectures IIIDokument42 SeitenOil and Fat Technology Lectures IIIaulger100% (1)

- Applying flare monitoring to identify major flaring contributorsDokument3 SeitenApplying flare monitoring to identify major flaring contributorsrvkumar61Noch keine Bewertungen

- Petroleum Refining and Economics: Kobbina Awuah (Machinery Engineer/Project Manager, Conocophillips-Bayway Refinery)Dokument21 SeitenPetroleum Refining and Economics: Kobbina Awuah (Machinery Engineer/Project Manager, Conocophillips-Bayway Refinery)GNoch keine Bewertungen

- Improving refinery margins through crude selection and configuration upgradesDokument46 SeitenImproving refinery margins through crude selection and configuration upgradesmujeebmehar100% (2)

- DR Reddy's Laboratories, CTO 2, HyderabadDokument15 SeitenDR Reddy's Laboratories, CTO 2, HyderabadjaydeepsinhNoch keine Bewertungen

- Optimisation Problems (I)Dokument2 SeitenOptimisation Problems (I)Ahasa FarooqNoch keine Bewertungen

- An Ocean of Opportunity: PerspectiveDokument1 SeiteAn Ocean of Opportunity: PerspectiveRoger BustosNoch keine Bewertungen

- Succeeding in The AI Supply Chain RevolutionDokument6 SeitenSucceeding in The AI Supply Chain RevolutionSandeepMahapatraNoch keine Bewertungen

- Alloys DensityDokument4 SeitenAlloys DensityGULA12345Noch keine Bewertungen

- 11 Alloys TM SpanishDokument3 Seiten11 Alloys TM SpanishFélix AlorNoch keine Bewertungen

- Storage Tank Venting Compendium PDFDokument36 SeitenStorage Tank Venting Compendium PDFcrisNoch keine Bewertungen

- Mecanismos de CristalizaciónDokument11 SeitenMecanismos de CristalizaciónFélix AlorNoch keine Bewertungen

- ATM Storage TankDokument10 SeitenATM Storage TanksameerpecNoch keine Bewertungen

- ASME B36.19M Stainless Steel PipesDokument14 SeitenASME B36.19M Stainless Steel Pipesdssscarface50% (2)

- Dae 15 Y764Dokument4 SeitenDae 15 Y764Gerber GarciaNoch keine Bewertungen

- Attachment 1 - Bk12dhz PumpsDokument14 SeitenAttachment 1 - Bk12dhz PumpsluisalonsonucetteranNoch keine Bewertungen

- 2.5 Vol-I, Part-Ii, SCC PDFDokument63 Seiten2.5 Vol-I, Part-Ii, SCC PDFKoushik DeyNoch keine Bewertungen

- FPXDokument18 SeitenFPXRazvan SasuNoch keine Bewertungen

- 11a. Electrical Specifications - GeneralDokument86 Seiten11a. Electrical Specifications - Generalheba777Noch keine Bewertungen

- Understanding Localvolts and DERDokument4 SeitenUnderstanding Localvolts and DERmanojiNoch keine Bewertungen

- Medium Voltage Capacitor Bank SpecificationsDokument4 SeitenMedium Voltage Capacitor Bank SpecificationsAlexander WijesooriyaNoch keine Bewertungen

- Ug Zs1 Iom Man Rev.h 2012 06Dokument110 SeitenUg Zs1 Iom Man Rev.h 2012 06yulizard100% (1)

- Maz8120 Zener DDokument7 SeitenMaz8120 Zener Daldo_suviNoch keine Bewertungen

- Improvement in Process Industries by Using Work Study Methods: A Case StudyDokument11 SeitenImprovement in Process Industries by Using Work Study Methods: A Case StudypratikNoch keine Bewertungen

- With Confidence Special Detection Oil & Gas - PDFDokument22 SeitenWith Confidence Special Detection Oil & Gas - PDFTURARAMANoch keine Bewertungen

- World PumpsDokument3 SeitenWorld PumpsMichael WarnerNoch keine Bewertungen

- Ratepayers Coalition Position Statement Opposing Settlement of Xcel Energy's Rush Creek Wind ProjectDokument9 SeitenRatepayers Coalition Position Statement Opposing Settlement of Xcel Energy's Rush Creek Wind ProjectAmy OliverNoch keine Bewertungen

- (Bloomberg Visual Guide Series) Michael C. Thomsett.-Bloomberg Visual Guide To Candlestick Charting-Wiley (2012.)Dokument193 Seiten(Bloomberg Visual Guide Series) Michael C. Thomsett.-Bloomberg Visual Guide To Candlestick Charting-Wiley (2012.)Rodger Zhao100% (6)

- CATALOGUE of PUBLICATIONS COR 24 04 2015Dokument276 SeitenCATALOGUE of PUBLICATIONS COR 24 04 2015krunalNoch keine Bewertungen

- Crystal CallansDokument7 SeitenCrystal Callansapi-10533238Noch keine Bewertungen

- Fichtner PDFDokument76 SeitenFichtner PDFbacuoc.nguyen356Noch keine Bewertungen

- Plant Layout & Piping Design: PL L1 Basic MeduleDokument11 SeitenPlant Layout & Piping Design: PL L1 Basic MeduleAhmad Nabil ElsharkawyNoch keine Bewertungen

- S 2807914Dokument4 SeitenS 2807914Rafat ThongNoch keine Bewertungen

- Exergy BIZWhitepaper v10Dokument30 SeitenExergy BIZWhitepaper v10Vinod JeyapalanNoch keine Bewertungen

- Research Paper Improvement of Power System Stability by Simultaneous AC-DC Power TransmissionDokument6 SeitenResearch Paper Improvement of Power System Stability by Simultaneous AC-DC Power Transmissionmaazsiddiqui.ee7193Noch keine Bewertungen

- MERALCODokument10 SeitenMERALCOKatRobesDeCastroNoch keine Bewertungen

- The External Environment: Opportunities, Threats, Industry Competition, & Competitor AnalysisDokument63 SeitenThe External Environment: Opportunities, Threats, Industry Competition, & Competitor AnalysisLïkïth RäjNoch keine Bewertungen

- DFC Annual Report 2006Dokument46 SeitenDFC Annual Report 2006Klavs RefstrupNoch keine Bewertungen

- Round II Ihub GuidelinesDokument12 SeitenRound II Ihub GuidelinesMdau HalisiNoch keine Bewertungen

- SB PS-Turbo Ver.2.1 enDokument5 SeitenSB PS-Turbo Ver.2.1 engreyhound726415Noch keine Bewertungen

- L1 BEKG2433 Power - System PDFDokument19 SeitenL1 BEKG2433 Power - System PDFAhmad WahiNoch keine Bewertungen

- Hysys WorkbookDokument23 SeitenHysys WorkbookDaniloNoch keine Bewertungen

- Danfoss Scroll CompressorsDokument6 SeitenDanfoss Scroll Compressorsfaizan abbasiNoch keine Bewertungen