Beruflich Dokumente

Kultur Dokumente

Static Frequency Convertor

Hochgeladen von

Rahul ChoubeyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Static Frequency Convertor

Hochgeladen von

Rahul ChoubeyCopyright:

Verfügbare Formate

GE Energy

Rev. : B

Page : 1/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

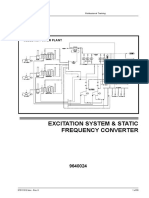

1. SYSTEM DESIGN

1.1. PURPOSE

Gas Turbine need starting equipment to accelerate from standstill and follow a preset

speed-time profile as required by the ignition and start-up procedure. Once the Gas

Turbine can deliver enough torque, further acceleration up to the synchronous speed is

accomplished by the turbine itself and the starting equipment is no more necessary.

The Synchronous Generator, fed by a suitable variable-voltage / variable-frequency power

source, can be used as a variable speed electric motor to start the Gas Turbine.

The variable-frequency power source is usually a thyristor converter: a static equipment

that, fed from the network, can supply the Synchronous Machine with finely controlled

voltage and frequency, so that the aforesaid speed-time profile can be accured followed.

The converter equipment, known as Load Commutated Inverter ( LCI ), has gained wide

acceptance also in pumping storage stations and as industrial drive, due to its ability to

reach high power and/or high speed levels, and because of the robustness of the LCI.

The simplified schematic diagram of the drive system is shown on Fig. 1. It shows the

overall system including the Gas-Turbine (GT), the Starter Equipment, the Filed Exciter

(SE) .

At start-up the Generator is disconnected from the medium voltage (m.v.) Main Bus and is

supplied by the Starter Equipment that takes the power from the m.v. Auxiliary Bus

through the converter transformer ST.

L

D.C. LINK

K’ K” MS GT

ST

SN

SE

FIG.1.1

The Field Exciter regulates the Generator flux as required by the voltage rating limits of

the power converter, as recalled in the next paragraph.

When producing power the generator is connected to the main Bus and the Starter C.B. is

open. The Field Exciter regulates the generator flux to comply with the active and reactive

power requirements of the power station.

More details of the Starter Equipment include :

a ) current and voltage transformer that are used to acquire the converter input and

output current and voltage values as well as the value of the generator field current.

b) the Control equipment that is the Digital Control Module ( with the Converter

Interface and the PLC interface ).

c) the PLC that implements the drive logic and connects field signals

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 2/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.2 DESCRIPTION OF THE EQUIPMENT

1.2.1 Medium voltage dry type cast resin step down transformer

Fig. 1.2.1-1 MEDIUM VOLTAGE TRANSFORMER

The three phase type transformer shall be installed between a M.V. three-phase supply

line and a static converter . The transformer shall supply a rectifier bridge - six pulse, total

controlled, thyristor based Graetz bridge operating at fixed frequency

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 3/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The transformer is ready to start.

Only the electrical connections between cables and connections bars of the primary

winding are to be performed.

It is appropriate to perform the fixing of the M.V. and L.V terminals and the connection

bars of the tapings using the following values of the fixing torque:

The transformer is endowed of N° 3 thermal sensors (PT100Ω), if not otherwise

requested, position one for each low-voltage winding and connect it to the displaying and

data management device that has two level of intervention (alarm and break down), the

following values are recommended for their calibration:

Insulation T Alarm T Break down

class (°C) (°C)

B 100 120

F 120 140

H 145 165

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 4/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.2.1-2 THERMAL SENSOR Fig. 1.2.1-3 DYSPLAY AND DATA

MANAGEMENT DEVICE

When the transformer is fitted up with a hausing there is no need to keep the insulation

distance while it is already kept between the transformer and the housing.

In the installation cabin it is necessary to perform openings for air inlet on the same level

of the floor for receiving the fresh air and to perform openings on the apposite side on

the upper side near the roof for outlet of the warm air.

During the operations of connections and installation of the transformer it is possible that

some tools, bolts and or washers have been inserted accidentally in the cooling ducts of

the windings or left on the transformer. Since it is necessary to clean up the transformer

accurately so that once the transformer is under voltage does not happen failures due to

the presence of strange objects

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 5/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.2.2 Medium voltage switchboards

Metal enclosed switchboard for indoor installation are made of standardized units employed

in the transformer cabins, to control and protect lines, transformers, motors and capacitors,

and usually in the M.V. electrical distribution.

Metal enclosed switchboards are constructed in standard and internal arc versions (in

compliance with IEC 298 Equipment AA ).

Legend

6

5

Aux. contacts box

4 Sf6 off-load switch

and earth switch

Operating mechanism

for open/close Sf6 off-load

switch and earth switch

Incoming line

M.V. circuit breaker

Inspection windows

Fig. 1.2.2 MEDIUM VOLTAGE SWITCHBOARDS

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 6/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.2.2.1 Main characteristics

The switchboards have the following characteristics:

Dimensions

the switchboard can be placed against the wall, since the front side is easily

accessible

Max service continuity and reliability

the internal metallic segregations, which separate the cubicles, allow the personnel

to replace fuses, circuit breaker, CT etc., even when the main bus bars are on

voltage.

Easy installation and connection

the units are assembled in the factory and tested before shipping, therefore they

need only to be fixed to the floor on site and then, coupled together and connected

to the external circuits.

Versatility and flexibility

any technical requirement of extension on already installed switchboards can be met

easily with any electrical layout to be carried out

Easy operation and maintenance

the front side switchboard inspection windows, the isolation and withdrawing of

circuit breakers and disconnectors allow a quick check-up and a long lasting

maintenance.

Surface treatments

the cubicles are carried out by prior zinc-plated steel sheets UNI EN 10142 and

sheets UNI EN 10111, then they are degreased and passivated. The external part is

powder painted in RAL 7030 grey with orange peel bright effect. On request, other

colours are at disposal.

Personnel safety

guaranteed by the following measures:

earthed enclosure and earthed equipments’ and components’ bulk.

continuity of protection circuits.

IP3x protection for enclosure and IP2x for the cubicles diaphragms against

contacts with part on voltage or in movement.

use of insulating safe materials, with creepage distances suitable for much

polluted environment.

1.2.2.2 Compartments

The switchboards are realised by joining the different types of standardised

compartments.

Each compartment generally consist of:

- a bus-bar cubicle

- a feeder – circuit-breaker cubicle

- an instrument cubicle

The bus-bar cubicle and the feeder – circuit-breaker cubicle are segregated from the

structure of the rotating disconnecting switch.

The instrument cubicle, with all the auxiliary circuits, is segregated from the bus-bar

cubicle by means of a metal partition.

The compartments are factory wired; to complete installation on site it is necessary simply

to connection the power and external auxiliary connections.

All the operating manoeuvres are carried out on the front of the switchboard with the

doors closed; doors must however be opened for maintenance purposes and/or when

replacing parts.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 7/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Bus-Bar Cubicle

The bus-bars are realised in copper flat bar and fixed to the terminals of the line

disconnecting switch or switch-disconnector, according to the type of compartment in

question; the bus-bars pass from one compartment to another directly, without the use

of baffle plates, forming a continuous duct.

Feeder Circuit-Breaker Cubicle

Access to the feeder circuit-breaker cubicle is provided through the door on the front of

the compartment. ( See Fig. 1.2.2.2-1 , 1.2.2.2-2)

The cubicle houses an ABB SACE HAD SF6 circuit-breaker in fixed or plug-in versions

fitted if necessary with on board current transformer, a line disconnecting switch, an earth

switch and the terminals for connection of the Medium Voltage cables.

The cubicle may also contain the following components:

- current transformer (in addition or as an alternative to those already installed on

board)

- voltage transformers

- capacitive voltage dividers

The window on the door of the cubicle makes it possible to inspect and check the position

of the disconnecting switches.

FRONT Internal Schema

View layout

Fig. 1.2.2.2-1 FEEDER CIRCUIT-BREAKER CUBICLE

250

2250

1150 1400

Fig. 1.2.2.2-2 FEEDER CIRCUIT-BREAKER CUBICLE

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 8/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Instrument Cubicle

The instrument cubicle is mounted in the auxiliary circuit drawer, above the feeder circuit-

breaker cubicle and in front of the bus-bar cubicle.

This cubicle contains all the low voltage equipment generally used, in particular the

following.

- terminal boards, raceways and cables for connection of the auxiliary circuits of the

cubicle and the other compartments of the switchboard

- auxiliary accessories of the circuit-breaker and cubicle ( metering instruments,

protection relays, control and signalling devices, fuses, protection circuit-breakers of

the auxiliary relays etc. )

1.2.2.3 Circuit breakers

The circuit breakers used in Switchboards are ABB SACE SF6 series HD4R circuit

breakers suitable for up to 1250 A at 24 kV (see figure 1.2.2.3).

They are ideal for the protection and control of transformers and distribution lines as well

as for motor control and protection.

The circuit breaker is supplied in fixed version.

The HD4/... circuit-breakers are constructed using the separate pole technique. They are

insulated in sulphur hexafluoride, for indoor installation, and are pressure systems sealed

for operating life (IEC 60056 and CEI 17-1 Standards).

In addition to the accessories supplied, the circuit breaker may also be fitted

with a key lock (open or closed position).

The three poles, the operating mechanism and any optional accessories are mounted on

a sturdy support frame.

Protection is guaranteed by the current transformers installed on the circuit breaker

together with the ABB SACE electronic release switches PR521.

For the electrical characteristics, please refer to the technical catalogue.

1 closing pushbutton

2 opening pushbutton

3 mechanical signalling device

for circuit-breaker open/closed

4 manual operating mechanism

1

5 mechanical signalling device 2

for closing springs 3

4

6 operation counter

5

6

Fig. 1.2.2.3 HD4R SF6 CIRCUIT-BREAKER

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 9/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.2.2.4 SF6 switch-disconnector / earthing switch

SF6 switch-disconnector / earthing switch includes a complete range of isolating and

disconnecting equipment, insulated in SF6 (which is also the arc quenching medium), with

respective operating mechanisms, that are described below.

These are two appliances in a single stainless steel parallelepiped hermetically welded

casing filled with SF6 at very low pressure to extinguish the electric arc and to insulate the

live components (between the phases and to earth) of the equipment housed in the

enclosure (see fig.1.2.2.4).

Fig. 1.2.2.4 – SF6 switch-disconnector / earthing switch

Epoxy resin bushings positioned on the upper and bottom surfaces ensure the electric

connection of the internal equipment consisting of a three-pole switch-disconnector and a

three-pole earthing switch with making capacity.

The operations of the two appliances is carried out by a special operating mechanism

(independent from the operator) installed on the front of the enclosure that permits placing

the internal equipment on the three positions shown by fig. 1.2.2.4a as follows:

Line close – Earth open;

Earth and line open;

Earth closed – line open

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 10/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.2.2.4a – operating mechanism

In addition to the operating mechanism, the front of the enclosure has a wide window that

Permits seeing the position of the internal equipment very clearly, the sealed filling plug

(vacuum and SF6 filling) and the moving shaft of the mobile contacts.

The safety valve for internal overpressure is installed on the back of the enclosure.

The hermetic seal of the enclosure against gas leaks (more than 30 years) is guaranteed

by means of toroidal O-rings on the external contact points.

The bushings may be equipped with capacitive dividers for connection to the voltage

detecting devices on the front of the operating mechanism.

N.B. The enclosure may be filled with sulphur hexa-fluoride, after emptying, only by

IMESA workshops.

SF6 line side isolator-earthing switch

The SF6 Line-Earthing switch is operated by means of a manual mechanism

dependent on the operator.

SF6 earthing switch

The Earthing switch is operated by means of of a manual mechanism dependent

on the operator.

SF6 insulated three-pole bushing

The resin bushing insulators are connected between the inlet and outlet by means

of a through bar. The explosion valve for internal overpressure is installed on the

back while only the SF6 filling tap is mounted on the front.

1.2.2.5 Earth

All the steel structural parts are connected together by means of special nuts and screws

designed to guarantee efficient electrical contact between the parts.

The doors are connected to earth by means of flexible copper strands having an

appropriate cross-section.

A 30 x 5 mm copper bus-bar connects the entire switchboard longitudinally to earth the

switchboard; the earth connections of the main equipment (disconnecting switch, line

disconnecting switch, current transformers, voltage transformers etc.) are branched on

each compartment.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 11/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.2.3. Static starter section

1.2.3.1. Product description

The static starter consist of 3 separated compartment ( See Fig.1.2.3 ) that contain:

a) POWER COMPARTMENT

- + 11 Compartment D.C. link smoothing reactor and earth switch

- + 12 Compartment Power thyristors module

b) AUXILIARY & CONTROL COMPARTMENT

- + 21 Compartment Control and auxiliary circuit

c) POWER DISTRIBUTION COMPARTMENT

- + 31 Compartment Disconnecting Switch (feeder exit)

+.11 +.12

DC LINK CONVERTER

2300

1200

2000 1000

Power Board +11 +12 Control Board +21 Disconnecting

(front) (front) Switch +31

(front)

Fig. 1.2.3 OVERALL DIMENSIONS BOARDS

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 12/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

a) Power Compartment

Main power components are the following :

-a1) Power thyristors module ( =G01 -GF01 )

-a2) D.C. link smoothing reactor ( =H01 -LL01 )

Feed transformer is not included in starter board.

-a1) Power Thyristors Module

The two bridges mentioned below are provided in this module :

rectifier stage, located in the lower part, inverter stage located in upper part

( See Fig.1.2.3a )

=G01.GF01

U V W

=H01.LL01

L1 L2 L3

Fig. 1.2.3a POWER MODULES ELECTRICAL DIAGRAM

The module consist of by three stacks on 4 levels with factory pre-charged

clamps ( See fig. 1.2.3b ) ;

these stacks are located inside a stell structure based on four wheels, to facilitate

extraction from board.

Each thyristor is protected by a R - C circuit ( snubber ) to damp commutation over -

voltages.

The R - C groups and pulse transformers ( that are used to amplify thyristors ignition

signals ) are mounted on insulating supports and located in front of the stacks ( See

fig.1.2.3c ); in this way a compact structure has been obtained; moreover, clamps pre -

charged stacks allows thyristor substitution on the spot in case of fault so that no stack as

to be disassembled and sent to the factory for replacement . The module is forced

ventilation cooling type ( see fig. 1.2.3d ). and it is located in the central upper part

compartment Nr +12 ( see fig. 1.2.3e ).

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 13/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

[front view]

Fig. 1.2.3d POWER MODULE

Fig. 1.2.3c R-C T.I. GROUP

Fig. 1.2.3b

FOUR LEVEL

STACK

[side view]

[front view]

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 14/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

FRONT REAR

Fig. 1.2.3e Nr. +12 COMPARTMENT FRONT and SIDE

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 15/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

a2) Dc link smoothing reactor

The reactor has the function to limit current waviness in the intermediate continuous

current circuit, it is usually made of an air cooled iron core. It is located in compartment

Nr. +11

( See fig.1.2.3f ).

It is equipped with a maximum temperature sensor.

=G3.D01 –XV01

=G3.D01 –XV01

=G3.L04 –BP01 =G3.L04 –BP01

=G1.H01 –LL01

=G1.J01 –QT01

=G1.H01 –LL01

=G3.Y01 –EH02

1000

Fig. 1.2.3f Nr +11 COMPARTMENT FRONT and SIDE VIEW

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 16/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

b) Auxiliary & Control Compartment

Compartment +21 contains all circuits and equipment completing the drive.

They consist of:

b.1) Control panel

b.2) Interface cards and transducers

b.3) PLC and relay circuits interfaced with it

The power supplies of these equipments derive, according to the Client availabilities, from:

Three-phase input line 415V 50Hz for auxiliaries and control

b.1 Control panel

Commonly referred to as control rack, it contains all control electronic cards, and, on the

side door, the local commands. See figure.

Control cards

for inverter

bridge, rectifier

bridge

and speed

Figure – Control rack

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 17/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The control rack is divided as follows:

Frame 1 Power supplies

Frame 2 Control cards for rectifier bridge, inverter bridge of the converter and speed

regulator.

Frame 3 Redundant Control cards for rectifier bridge, inverter bridge of the converter

and speed regulator.

Frame 1

In this frame are assembled all power supplies necessary to generate the various power

supply voltages for the electronic cards.

Frame 2

This frame contains the cards that constitute the control; these cards are Europe 2 standard

size. They can present customizable components varying according to the application. For

this reason the values of these calibrations are reported in the customization sheets of the

project functional diagrams.

. NOTE Before replacing a card, check that all components that can be

calibrated match the system ones.

The control performs the following functions:

- speed regulator

- current regulator

- rectifier bridge phase shifter

- inverter bridge phase shifter

- interface towards converter (pulse generation, analog signal measuring)

- interface towards PLC

- thyristor monitoring (optional)

Frame 3

This frame contains the redundant cards that constitute the control; these cards are Europe

2 standard size. They can present customizable components varying according to the

application. For this reason the values of these calibrations are reported in the

customization sheets of the project functional diagrams

The following table shows a brief description of the cards available on the control.

FRAME 1 CARD NAME DESCRIPTION

- GA10 Power supply, combined with that in GA11 position

75W 15V feeder

position generates the 15Vdc for the control cards Frame 2

- GA11 Power supply, combined with that in GA10 position

75W 15V feeder

position generates the 15Vdc for the control cards Frame 2

- GA20 Power supply, combined with that in GA21 position

75W 15V feeder

position generates the 15Vdc for the control cards Frame 3

- GA21 Power supply, combined with that in GA20 position

75W 15V feeder

position generates the 15Vdc for the control cards Frame 3

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 18/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

FRAME 2/3 CARD NAME DESCRIPTION

Card manufactured by Ansaldo.

It manages the following functions:

– D position AINT02 Analog output among which :

- Current reference

- Speed levels

Card manufactured by Ansaldo.

It manages the following functions:

Inverter bridge angle adjustment

– F position ACPU02

Reference and ramp management

Current adjustment

User interface

Card manufactured by Ansaldo. It monitors the converter

analog quantities and trips at the preset threshold values

generating a hardware protection. It signals, by means of

7 LEDs located on the front panels, the tripped protection.

- H position APROT3 The card manages also all signals necessary to the

pulses enabling; the enabling is signaled by means of 5

green LEDS in the off status. Finally it is used for

generating the exciter current reference for the excitation

system, 3 leds indicate the severals kind of regulation.

Card manufactured by Ansaldo.

It processes the signals coming from the rectifier bridge

– J position AREV11 CTs and PTs, and it processes the three line voltages and

obtains the line frequency. The card holds a front

connector to interface with the terminal board card.

Card manufactured by ASI, current regulator, phase

shifter for 12 pulses rectifier bridge, interface of the

AGIF11 card to receive the commands to the inverter

- L position AGIM11

thyristors bridge. The card produces the logical signals for

firing the thyristors, from the catd 18 optic fibers depart

toward the converter.

Card manufactured by Ansaldo. It processes the signals

coming from the inverter bridge PTs and CTs.

The encoder signal emulator for speed acknowledge.

- N position AREV11 The speed reaction is obtained from the machine voltages

through Hz / V converters.

A front connector is assembled on the card to interface

with the terminal board card.

Card manufactured by ASI., phase shifter of inverter

bridge.

In base to the angle of inverter, the card produces the

logical signals to generate the firing command for the

- P position AGIF11 variable frequency bridge. The card manages the

functionality of recognition of the position of the rotor in

case of start up from zero speed, moreover to reverse

the pulses of the thyristors to have the possibility to work

on 4 quadrants.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 19/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Local commands, lamps and instruments.

For the local management of the drive, on the door of the +13 compartment they are

anticipated the followings commands:

Reset Pushbutton =G3.N02- SB01

Emergency Pushbutton =G3.N02- SB02

Control Selector switch =G3.N02- SB03

There are a series of analogics instruments for the visualization of the principal greatness

Field Current Indicator =G3.U01 - PA01

Converter Input Voltage Indicator (Delta group) =G3.U01 - PV01

Indicator Of The Dc Current Converter =G3.U01 - PA02

Generator Voltage Indicator =G3.U01 - PV02

Set Speed Indicator =G3.U01 - PF01

and a

Operator Panel =G3.N01 – HS01

Temperature transformer monitoring unit =G3.R01 – TH01

The-HS01 text viewer is directly connected to the PLC CPU where all drive alarms and

states can be read (see chapter 1.5.8 for the message list).

-PA01 -PV01 -PA02 -PV02 -PF01

Temperature

Programmable text monitoring unit

viewer

HS01 -TH01

Reset Selector

Pushbutton Switch

-SB01 -SB03

Emergency

Pushbutton

-SB02

Front door cubicle +21

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 20/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

b.2 Interface cards and transducers

The function of the interface cards is that of connecting and adapting all signals coming

from the transducers located in the power compartments and from outside the panel.

All these cards are 24Vdc supplied and are divided as follows:

Cards for digital signals

Cards for analog signals

The cards can present customizable components varying according to the system. For this

reason the values of these calibrations are reported in the customization sheets of the

project functional diagrams.

. NOTE Before replacing a card, check that all components that can be

calibrated match the system ones.

Even if the transducers are not located inside the auxiliary compartment, due to their

connection with the interface cards, they will be described in this section.

Cards for digital signals

This group includes those cards managing the digital signals from and to the control. The

connection of these cards is accomplished through a multi polar cable with a 37 pin

connector, while towards the field it is obtained by means of a screw terminal board.

The following table shows a brief description of the digital cards

CODE CARD NAME DESCRIPTION

Card not manufactured by Ansaldo, connected to the

- AX05 CPD37F AINT02 control card. It consists of :

- AX06 16 digital inputs

16 digital outputs

Used in positive logic to communicate with the PLC.

Card manufactured by ASI, connected to the APROT3

control card, inside the card:

3 output relays with exchange contact, and 9 output

- AX07 signal.

- AX08 8 inputs for positive logic to be customized, each with a

XPROT3

10Ω 0,25W resistance.

14 leds to detect whether the channel is active. Used to

send and receive information from the PLC and the relay

logic.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 21/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Card for monitoring the input breaker status:

CODE CARD NAME DESCRIPTION

Card manufactured by ASI, has two channels: the first one

- AX09 XBA52A used for monitoring the opening coil of input circuit

- AX10 breaker, its operation can be compared to the function of a

contact anticipated on the opening, used for disable the

pulses of converter bridge to open the breaker without

current.

The second is used for the monitoring of the aux. dc

voltage (110V) of the main circuit breaker –Q570/-Q571

The input of the card has to be connected in parallel with the opening command, on the

main coil.

1) When the breaker is close and the opening contacts are open, a current circulate

through the resistors in the coil, this current is enough to activate the optical relay.

When any opening contact from external occurs, the optical relay switch off, and the signal

is sent to SFC control that removes the thyristors pulses immediately. The opening time of

the circuit breaker is enough to have the pulses suppression before, hence the breaker

open always without current.

-x_

-x_

86G SFC

-x_

-x_

YO Opening coil

Note: The card works just when is connected on the main opening coil, not when is used

an auxiliary relay as support to open the circuit breaker.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 22/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Cards for analog signals

This group includes those cards managing the analog signals for the control; the connection

of these cards is accomplished by means of a multi polar cable with a 25 pin connector,

while towards the field it is obtained by means of a screw terminal board.

The following table shows a brief description of the digital cards.

CODE CARD NAME DESCRIPTION

Card manufactured by Ansaldo, connected to the AREV11

control card. J pos., it receives the rectifier bridge CT’s and

- AX01

XREV11 PT’s feedbacks and the external speed set point from DCS.

- AX02

The card AX01 sends also the excitation current set point to

the excitation system.

Card manufactured by Ansaldo, connected to the AREV11

- AX03

XREV11 control card. N pos., it receives the inverter bridge CT’s and

- AX04

PT’s feedbacks and the field current signal.

Transducers

They are divided into current transducers (CT Lem), voltage transducers (magnetic PTs

and lem) and signal transducers.

The current transducers are Hall effect measure transformers assembled on AC side bars

in each converter. As the output signal is in mA, it will suitably processed on the interface

card.

The Hall effect voltage transducers are used on the fixed and variable frequency circuit. As

the output signal is in mA, it will suitably be processed on the interface card.

The function of the signal transducers is that of adapting the signals from and to the control

to the desired value and form.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 23/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The following table shows a brief description of the transducers assembled in the drive.

CODE COMPONENT NAME DESCRIPTION

Current transducer. It detects the AC current

- CT01/02 CT’s Lem

circulating in the rectifier bridge R and S

Compartment 12 2000A/0,4A

power cable phases

Voltage transducer. It detects the voltage

- PT01/02 PT’s Lem

between lines of the rectifier bridge R - T

Compartment 12 2000V/50mA

and T – S phases .

Current transducer. It detects the AC current

- CT05/06 CT’s Lem

circulating in the inverter bridge U and V

Compartment 12 2000A/0,4A

power cable phases..

Voltage transducer. It detects the voltage

- PT05/06 PT’s Lem

between lines of the inverter bridge U-W

Compartment 12 2000V/50mA

and W-V phases.

- UV01 Signal transducer for input coming from the

420mA / 010V

Compartment 21 turbine control (speed reference).

- UV02 Signal transducer for input coming from the

420mA / 010V

Compartment 21 exciter (field current).

- UV03 Signal transducer for output towards the

010V / 420mA

Compartment 21 exciter (excitation current reference).

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 24/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

b.3 PLC and its interfaced relay circuits

All panel input and output signals are galvanically separated by means of 8 relay terminal

board cards as shown in the figure below, except for the commands to the average voltage

switches that use relays with power contacts.

The coils of input cards and power auxiliary relays are equal to 110Vdc, while input cards

and logic relays are equal to 24Vdc.

Input

From / to

110Vdc 24Vdc PLC and

Relay logic

Output

Galvanic separation

Ensured by the interface cards

The PLC used for this application is a GE FANUC type 90-30 series and it consists of:

- 56 digital input points

- 48 output points

boxes can be supplied, as an option, for:

- analog inputs

- MOD – BUS rtu slave communication

Thanks to the PLC all the panel logic and the communication with the supervision system

are developed.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 25/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

FRONT

=G3.U01 -AJ

=G3.U01 –AJ01

=G3.U01 –AJ02

Fig. 1.2.3g Nr +21 COMPARTMENT FRONT

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 26/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

LEFT SIDE RIGHT SIDE

FRONT

FRONT

Fig. 1.2.3h Nr +21 COMPARTMENT SIDE VIEW

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 27/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.2.3m Nr +21 COMPARTMENT - REAR VIEW

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 28/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

c) Power distribution compartment

The disconnecting switch is used to be sure of the electrical insulation between the

generator and the inverter during the stand-by condition.

The disconnector switch work automatically, during the start up sequence and the shut

down, by means of a motor drive electric controller activated with the PLC logic.

The opening and closing command are be ensured through the limit switch assembled on

the panel near the gear motor.

Fig. 1.2.3n Nr +31 COMPARTMENT

The disconnector is equipped with a crank handle used just in case of maintenance.

Any attempt to use the disconnector manually during the SFC operation break off the

sequence.

A safety interlock with generator have to be realized to be sure that every maintenance

operation will be execute in safety condition.

(see operation chapter)

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 29/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.2.3p Nr +31 COMPARTMENT FRONT and SIDE VIEW

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 30/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.3. FUNCTION

1.3.1 Electrical drives

The block diagram of an electrical drive controlled by a power converter is shown in

Fig.1.3.1a. The load is usually a machine designed to accomplish a certain task, for

example a fan, a centrifugal pump, propulsion thrusters, and so constitute a load for the

electrical drive.

POWER

LOAD

LINE THYRISTOR

SOURCE CONVERTER MOTOR

SENSING CONTROL SENSING

UNIT UNIT UNIT

REFERENCE

SIGNAL

Fig. 1.3.1a – Block Diagram of an electrical drive

The requirements of the load can be specified in terms of speed and torque demands. In

order to select a suitable drive for a specific load it is necessary to obtain complete

information about the load requirements,

A motor having speed-torque and speed-current characteristics that suit the load

requirements is chosen. A motor will have characteristics compatible to the load if it

satisfies the speed and torque requirements of the load without exceeding the current

limitation imposed either by the motor rating or the source capacity.

Usually the natural speed-torque characteristic of the motor is not compatible with the load

requirements, for this reason a power converter is interposed between the line source and

the motor. Fig. 1.3.1b shows an example of torque-speed characteristic.

Torque

Speed

Fig. 1.3.1b – Speed torque characteristic of a fan

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 31/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The power converter controls the flow of the power from the source to the motor in such a

way that the motor speed-torque and speed current characteristics are compatible with

the load requirements.

The control of the converter is enclosed in a control unit which operates at much lower

voltage and power levels. The control units consists of micropocessor, PLC, lnear and

digital integrated circuits.

The reference signal (ex. seed setpoint ) adjusts the operating point of the drive and it is

an input for the control unit.

The control unit is electrically isolated from the power converter mainly for two reasons:

a) Without isolation a malfunction in the power converter or in the motor may lead to the

application of the power voltage to the control unit damaging the control and may

attempt the safety of the operator during the drive start up tuning or during the

maintenance.

b) Converter generates harmonics, without isolation the harmonics can enter in the

control and interfere with its operation

The sensing of certain quantities as converter current and voltage, motor speed is usually

required for protection and closed loop regulation (speed regulation loop, current

regulation loop) and metering. The sensing transducers of the power converter electrical

quantities are isolated from the control unit for the reasons stated above.

The complete drive system consisting of the load, motor, power converter, line source and

sensing unit should be considered as an integrated system. The power converter should

be selected to make the motor characteristics suitable the load taking into account the line

supply source and rules governing its use, for example it may be necessary to limit the

current inrush during starting to avoid voltage fluctuations on the supply line.

1.3.2 Fundamental motion equation

Any motor load system can be described by the following fundamental motion equation:

d m

T TL J (2.1)

dt

where :

T [Nm] developed torque of the motor

TL [Nm] load resisting torque, referred to the motor shaft

J [kgm2] moment of the inertia of the motor-load system referred to the motor shaft

m [rad/sec] instantaneous angular velocity of the motor shaft.

Equation (2.1) shows that the torque T developed by the motor is counterbalanced by the

load torque TL and by the dynamic torque Jdm/dt that is called dynamic torque because it

is present only during transient operation.

The drive accelerates or decelerates depending on whether T is greater or less than T L.

During the acceleration period, the motor shall supply not only the load torque T L but an

additional torque Jdm/dt to overcome the inertia of the motor-load system.

In application having a load with large inertia the motor torque must exceed the load torque

by a large amount to have and adequate amount of acceleration, on the other side in

application requiring fast response, the motor torque should be maintained at the highest

value and the motor-load system should be designed to have the lowest inertia.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 32/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

When the speed increases, the kinetic energy of the drive ½ J2m also increases, in

addition to the energy supplied to the load, the motor supplies the kinetic energy. During the

deceleration, the dynamic torque Jdm/dt changes its sign, the motion of the drive is

maintained by extracting energy from the stored kinetic energy. When the load has a high

inertia, the motor should produce a large braking torque (T is negative) to have adequate

deceleration, when it is required a fast rersponse, the braking torque should be maintained

at the highest value and the motor-load system should be designed with the lowest possible

inertia.

When motor torque T and load resistant torque TL are known it is possible to solve Eq. 2.1

in terms of time to get the speed vs time curve from speed 1 to speed 2 :

2

J

t ( ) T ( ) T ( ) d

1

L

(2.2)

Fig. 1.3.2a - Motor-drive Torque and Load Torque for Gas Turbine starter application

Fig. 1.3.2a shows an example of load resistant torque TL, note that when the Gas Turbine is

fired resistant torque changes sign becoming motoring torque, the same figure shows the

motor-drive available torque.

Fig. 1.3.2b – Typical Speed vs Time curve for Gas Turbine starting

Fig. 1.3.2b shows an example of Speed vs Time curve obtained by solving the integral

(2.2).

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 33/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.3.3 Double bridge converter

The fully controlled three-phase bridge with thyristor can function as a rectifier or as an

inverter. The converter can, by suitable control, reverse the polarity of the direct voltage, but

not the direction of the direct current.

Two three-phase bridges decoupled on the dc side by and inductor can interconnect two

three-phase systems of different frequencies and voltages, and provide for an exchange of

energy in the two directions. This double-bridge circuit is known also as dc link converter

(Fig.1.3.3.a).

RECTIFIER DC REACTOR

INVERTER

Idc

LINE Ldc

T4 T6 T2

T1 T3 T5

TCV L1 Lk L1(R) U(R) LU Lk"

CB

L2 Lk L2(S) V(S) LV Lk"

SM FIELD

L3 Lk L3(T) W(T) LW Lk"

T1 T3 T5

SYNCHRONOUS MOTOR f2

SUPPLY f1 T4 T6 T2

Fig. 1.3.3a – Dc Link Converter

The three-phase bridges may also be connected in series. The direct voltage is then

doubled.

At the same time, by using a star-delta transformer connection, it is possible to obtain

twelve-pulse converter operation, with reduction in harmonics (Fig.1.3.3b).

DC REACTOR

RECTIFIER Idc INVERTER

Ldc T4 T6 T2

T1 T3 T5

L1 Lk L1(R)

L2 Lk L2(S)

LINE L3 Lk L3(T) T4 T6 T2

y U(R) LU Lk"

CB

T4 T6 T2 V(S) LV Lk"

TCV SM

D LW Lk"

FIELD

T1 T3 T5

W(T)

d L1 Lk L1(R) T1 T3 T5

L2 Lk L2(S)

L3 Lk L3(T)

T1 T3 T5

T4 T6 T2

Fig. 1.3.3b – Twelve-pulse converter

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 34/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.3.4 Dc link converter

The dc link converter consists of two fully controlled three-phases bridges decoupled by an

inductor in the d.c. circuit. The circuit is known as d.c. link converter, because a direct

current Idc, smoothed by the inductor Ldc, flows between the two bridges (Fig.1.3.4a.)

The operation of the dc link converter is based upon simultaneous current and voltage

loading of both bridges. One bridges functions as a rectifier, the other as an inverter.

RECTIFIER DC REACTOR

INVERTER

Idc

LINE Ldc

T4 T6 T2

T1 T3 T5

TCV L1 Lk L1(R)

VdREC U(R) IMU LU Lk"

CB

L2 Lk IL2 L2(S) V(S) LV Lk"

SM FIELD

L3 Lk L3(T) W(T) IMV LW Lk"

IL3 VdINV

T1 T3 T5

SYNCHRONOUS MOTOR f2

SUPPLY f1 T4 T6 T2

Idc

Fig. 1.3.4a – DC Link Converter Operation

Fig. 1.3.4b – DC Link Load Characteristic

Fig. 1.3.4b illustrates the operation of the fully controlled d.c. link converter in case where

the two three-phase systems are similar (same frequency, voltage and short circuit

reactances).

The operating point of the inverter is taken to be with = 145°.

The delay angle of the rectifier then has to be set at 18° to obtain the required current at the

given voltage.

The rectifier (vdREC) and inverter (vdINV) direct voltage waveforms, the rectifier (VdREC) and

inverter (VdINV) average values (straight lines) and the line (VLST) and motor (VMRS)

alternating voltages are shown on Fig.1.3.4c.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 35/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.3.4c – DC Link Converter Direct Voltages

The dc link current (id) waveform, the average value (Id) of the dc current (straight line), the

line (iLS) and motor (iMR) phase currents are shown on Fig. 1.3.4d.

The two three-phase systems connected by the d.c. link converter can be of quite different

frequencies and short-circuits reactances, and also of unequal voltages.

Fig.1.3.4e shows the currents in the dc link converter fir a case in which the two three-

phase systems have frequency of 50 Hz (rectifier) and 52.5 Hz (inverter). The alternating

currents ILS of the rectifier and IRM of the inverter, and the direct current IDC, are modulated

at six time the frequency of both ac systems (300Hz and 315Hz). If the frequency of the two

ac systems are only slightly different (as in our case), beats are noticeable in the direct

current. In Fig. 1.3.4e is shown the beat frequency which frequency is six time the

difference of the two systems frequency:

Fb 6( Finv Frec ) 6(52.5 50.0) 15 Hz

Fig. 1.3.4d – DC Link Converter Direct Current

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 36/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Fig. 1.3.4e – DC Link Converter Coupling two different frequency systems

1.3.4.1 Power balance in the dc link converter

In the dc link converter with two controlled three-phase bridges and an inductive dc link

(Fig.1.3.4a) the power can transmitted between the two three-phase systems in either

direction. The direction of the power flow is determined by the manner in which the bridges

are controlled. The rectifier side functions as an energy source, the inverter side as a load.

The power transfer takes places between the a.c. voltage sources of the two systems. Only

the fundamental components (first harmonic) of the currents contribute to the power. The

active power (neglecting the losses of the bridges and dc link reactor) is always the same,

but the non-active powers can differ considerably, they depend upon the control angle of

the rectifier and inverter.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 37/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.4 DESCRIPTION OF THE INSTRUMENTATION AND CONTROLS

1.4.1 General

The user’s interface (SSDTERM) is a programme, operating in WINDOWS environment,

that allows the user to set / display the customization parameters of the speed regulator.

The location of the speed regulator cards in the box is as follows:

A C D

ACPU02

CARD

AINT02 Serial Link

CARD

COM1

The serial link cable, identification code 1000079378 + 1000079381, consists of what

follows:

BLACK

05 05 05

06 BLUE 06 06

04 BLACK 04 04

07 GREEN 07 07

03 BLACK 03 03

08 RED 08 08

02 BLACK 02 02

09 WHITE 09 09

01 01 01

CABLE with connector 9 pin MALE - MALE FEMALE ADAPTER

Code 1000079378 Code 1000079381

To climb on on

Side Personal Computer

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 38/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

1.4.2 User’s interface

SSDTERM

General

SSDTERM is a software tool that permits to carry out a fast and effective analysis

of the speed regulator operation state. It is not located permanently in the system

since it is designed for the heaviest diagnostic analyses such as the system

installation. The system is provided with a segment-type LED (ACPU02) for the

following elementary signals:

F The system is set in forward running motor mode.

G The system is set in braked forward running motor mode.

W The system is saving the regulator parameters in EEPROM.

The system is in error mode for AINT02 card is not present, or FLEX

1

programming was unsuccessful.

The system detected a parameter matching error, default parameters must

2 be loaded.

P The system received an external protection signal.

The hardware requirements needed by this tool are as follows:

IBM-compatible personal computer;

VGA graphic display (min. colour1024x760 pixel is suggested);

RS232 38400-baud serial line.

Windows 2000 NT / XP

The installed functions are:

displaying of logic and numeric variable values;

graphic displaying in real time of two numeric variables (Oscilloscope);

editing of specific installation parameters and relevant saving in EEPROM;

uploading and downloading of calibration parameters on ASCII files;

uploading and downloading of all the regulator data (Acpu02) on ASCII files;

on-line help.

If compared with LCD terminal, advantages are:

displaying of more data at the same time (e.g.: 2 windows with 15 variables and 16

flags);

graphic representations without making use of other tools;

file management permitting the data processing and printing even without system;

possible analysis of curves of interest (a posteriors).

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 39/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Description of the diagnostic software

This paragraph deals with the description of the SSDTERM programme in WINDOWS

version; the WINDOWS version keeps its setting and the same functions, yet adopting the

graphical look and the command immediacy that are typical of the execution environment.

The programme can be located on the personal computer in a directory other than the

work one, but all the files managed by the programme will be taken and put in the work

directory.

Conditions to start the programme it is necessary to be in WINDOWS environment and

enter:

Choose the correct COM

port and click CONNECT

PASSWORD : A B C D only to visualize the value

AA BB CC to change the value

Menu

After pressing pushbutton "continue" the following image will be shown on the display:

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 40/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Configuration

The commands available in the Configuration menu are:

It loads the file with .SSD extension chosen among

Open the ones available in the current directory

It saves all the system data and configuration in a file

Save with .SSD extension and name chosen b the user.

It displays the FLASH code existing in the target

If “configuration” is selected by , the following page is shown:

1 2 3

4 5

The CONFIGURATION page permits to get access to parameters, variable and control

states and to preset the oscilloscope functions.

The page is essentially subdivided into 5 windows.

Windows no. 2, 3 can be used to get access and, if necessary, to modify the control

parameters and to display their variables.

Windows no. 4, 5 can be used to get access and, if necessary, to modify the control flags.

Window no. 1 is utilized for oscilloscope function pre-setting.

Navigation in windows no. 2, 3, 4, 5:

In order to be able to move within the interface system, use of what follows can be made

in every window:

either the drop-down menu located or buttons called PgUp and PgDn located

high on the left down on the right

They permit to scroll the

A B various control pages

within which all its

dimensions are contained

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 41/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The groups of variables that can be selected are:

ANALOG.INP.1 Analog inputs of ACPU02 card.

ANALOG.INP.2 Analog inputs of ACPU02 card.

ANALOG.OUTPUT Analog outputs of AINT02 card.

MEASUREMENT Synoptic of variables.

ExtRef + ManRamp External reference by digital input and manual ramps.

AUTOM. RAMP Speed regulator ramps in automatic mode.

CURR.LIMIT.MOT Current limits when the drive is used to drive the motor.

ANGLE REGUL. MOT Angle adjustment of inverter bridge. (motor mode)

CURR.LIMIT.GEN Current limits when the drive is used to recover energy.

ANGLE REGUL.GEN Angle adjustment of inverter bridge. (generator mode)

SPEED REGUL. GAIN Speed regulator gains.

SETUP THRESHOLD Speed threshold setup.

I2T Protection Stator overload protection setup.

EXC CURR.LIM. Rotor thermal protection.

TESTING Test menu.

Dimensions written in black can be only read.

On the contrary, the ones written brown can be modified.

In order to carry out a modification, put the mouse on the relevant cell containing the value

and click with the left button of the mouse.

In this way different windows are shown if a parameter or a flag is being modified.

PARAMETER: The window includes:

parameter denomination, [1]

variation range out of which setting is

not allowed [2]

presently set value [3]

zone intended for the new chosen

value typing in [4]

button(s) to choose the regulator to

1 which the modification has to be sent

2 [5]

3 the button to be utilized to exit the

8 7 function without changing the value

4 [6]

a small keyboard to type in the new

5 value [7]

two + - buttons to modify the

6 parameter value of the lowest

possible value [8]

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 42/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

FLAG: the window includes:

parameter denomination [a]

presently set value [b]

the new settable value [c]

button(s) to choose the regulator to which the modification has to be sent [d]

the button to be utilized to exit the function without changing the value [e]

Navigation in window no. 1::

button to get access are located high on the left:

To eliminate the selected variables

To set the visualization function [C]

To set the oscilloscope function parameters [B]

To set the oscilloscope function variables [A]

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 43/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

[A] Oscilloscope variable setting

This window displays the variables that can be selected for the oscilloscope

(no more than 8 per regulator).

In order to eliminate some parameters, select them pressing on the relevant denomination

with the left button of the mouse (they are pointed out in blue), then press the button with

scissors.

1 In order to input new parameters, select them in the same way in windows

no. 2, 3 and press “conf” button in the top part of the relevant window.

[B] Oscilloscope function parameter setting

This window displays the variables that can be selected for the oscilloscope

(no more than 8 per regulator).

In order to eliminate some parameters, select them pressing on the relevant denomination

with the left button of the mouse (they are pointed out in blue), then press the button with

scissors.

1 In order to input new parameters, select them in the same way in windows

no. 2, 3 and press “conf” button in the top part of the relevant window.

[C] scopE

If “scope” is selected by the following page is shown (fig.5.2.3.4a, b, c):

Clicking on this box i twill

be enable the automatic

stop and save of the

traces

Fig. 5.2.3.4a Example of oscilloscope page [ scopE ]

By this function all the variables existing in the regulator can be displayed in graphic

format.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 44/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The available commands are shown at the display base:

AUTOSCALE NOW

It carries out the automatic setting of the variable scale values ranging between the

minimum and maximum of displaying, the abscissa is set between the lowest and

the highest values among all the dimensions.

MANUAL SET

If the automatic flag is deselected or manual set button is pressed, the ends of axis

Y are set with the two Minimum and Maximum windows.

VAR NAME

It displays all the chosen variables

Making use of the central table below (a row for every dimension) a plot (on/off)

command is associated to every dimension; it is utilized to enable or de-enable its

displaying (at least one of them must be always active). There are two cells to adapt

the signal with an offset and a gain)

INVERTED

The sign of the displayed dimension can be changed clicking on this button.

HISTORY

It creates a buffer in which the data present in scopE are saved.

The buffer dimensions depend on the number of variables and sampling time.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 45/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

PARAMETERS

It permits to change the parameters utilized in scales and diagnostic

Fig. 5.2.3.4b Example of oscilloscope page [ scopE ]

SAVE

It permits to create a file in which the data present in the Historical Buffer can be

saved.

This file can be seen again selecting the History function

Fig. 5.2.3.4c Example of oscilloscope page [ scopE ]

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 46/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

FlaGs

Selecting “Flag” by the following page is displayed.

The menu (Figure 5.2.3.5) permits to display all the inner and input/output logic inner

variables subdivided into 16-bit columns while, at the display base, the selected Flag,

already seen in Configuration menu, is still available.

If the password is enabled, the flags can be modified positioning the cursor on involved

variable that, as only two possible modes are available, can be changed pressing enter.

The only column the values of which can be modified normally is CONTROL; the output

flags can be modified too but only in diagnostic mode (Diag = ON) for the output relay test.

At the display base a help line indicates the available commands:

Press esc to exit the menu.

The code

indicates the

speed regulator

version

Fig. 5.2.3.5 Example of Menu flaGs

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 47/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

History

The menu permits to open one of n saved graphic files.

Selecting “History” by the following page is shown (fig.5.2.3.6a):

Fig. 5.2.3.6a Example of History page

Choose the file to be displayed.

When the file is open, the following page is shown (fig.5.2.3.6b):

Fig. 5.2.3.6b Example of History page

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 48/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

The following commands are available at the display base:

VALUES

It permits to display the numeric value of the chosen dimensions.

In order to help the analysis of recording two bars (a blue and a black one) are

available; they are moved by dragging or pressing black and blue >> ,<< buttons

that are located in the middle.

The value taken by each dimension in correspondence with the bars and the time

distance between the two bars can be seen up on the left.

BARS

Fig. 5.2.3.6c Example of History page

EXPORT

It permits to export the file for printing purpose or sending by e-mail.

Measure

The menu permits to have a graphic indication of the variables:

By means of

mouse

select one or

more of the

following pages

of PC interface:

The variables, that are shown, are the analog input/output of the AINT02 and ACPU02

cards.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 49/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Speed regulator

To understand the several parameters is preferred to introduce the speed regulator. The

speed regulation is carry out inside the control card ACPU02, it can be rappresented as below:

Rive Kp

- + Rico

Reve Ki/s

where:

Rive = internal speed reference

Reve = speed feedback

Kp = proportional gain

Ki =integral gain

Rico = current reference

As you can see on the schematic diagram above, for each analog input signal is possible to set

a filter by the set parameters, this issue will be discussed below.

The regulator is connected with the outside through the cards XREVOX as in the following

scheme:

From the output signal of the transducers, are made the signal to achieve the current reference

(RICO) as output of the speed regulator

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 50/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

A more complete scheme for explain the regulator input is the following:

Live Aut.

Rive

Rico

Rive Regulator

Live Man. Ramp PI

+

RiveReg

StepW

Reve Limcor

Aut Man.

The speed regulator can have two types of reference called Rive and RiveReg. Selecting Rive the

regulator will follow the planned reference, which will be created by the external reference and by

the insertion of the selected ramp. Selecting the reference instead RiveReg will have been

overlapped a step defined by the test parameters (stepW, TimeWsec) . This function is used for

trying the answer of the speed regulator.

StepW

TimeW

T T

Live

Rive

RiveReg

Reve

All the defined parameters are present in the various menus of the list parameters that will be

explained in the following pages. The various parameter pages are:

ANALOG.INP.1 Analog input to the ACPU02 card

ANALOG.INP.2 Analog input to the ACPU02 card

ANALOG.OUTPUT Analog output to the AINT02 card

MEASUREMENT Analog signal measuring

ExtRef + anRamp External reference and manual ramp parameters

AUTO. RAMP Ramp parameters in automatic mode operation

CURRENT LIMIT F Current limit characteristic in the motor operation

ANGLE REGUL. F Inverter firing angle characteristic in the motor operation

CURRENT LIMIT G Current limit characteristic in the generator operation

ANGLE REGUL. G Inverter firing angle characteristic in the generator operation

REGULATOR GAIN Speed regulator gains

SETUP THRESHOLD Signal threshold setting page

I2T protection Termic protection characteristic

Testing Test parameters setting page

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 51/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Here below will be done a more detailed explanation of the various parameters page.

Menu: ANALOG. INP1

In the following menu are present the analogical input signals with the relative parameters of

conditioning. Three types of parameters exist essentially:

the input greatness readable represented by [R]

the parameter FS that represents the full scale of the visualization, represented by [W]

the parameter FLT that represents the filter value used on the greatness [W]

The parameters are therefore:

Parameter Name Min/Max Value Typical Value Description

REVE % 0.00 / 650.00 R Speed feedback

LIVE An. % 0.00 / 650.00 R Outest analog speed reference

Continuous current of intermediate

IDC % 0.00 / 650.00 R

circuit

V MOT % 0.00 / 650.00 R Motor voltage

REVE 8V = % 30.00 / 650.00 W 100.00 Percentage for a 8V signal

LIVE 8V = % 30.00 / 650.00 W 100.00 Percentage for a 8V signal

IDC 6V = % 30.00 / 650.00 W 100.00 Percentage for a 6V signal

VMOT 8V = % 30.00 / 650.00 W 100.00 Percentage for a 8V signal

Filter on analog input Parameter x

REVE FLT RP 2 / 9000 W 100

1ms

Filter on analog input Parameter x

REVE FLT CN 1 / 9000 W 10

1ms

Filter on analog input Parameter x

LIVE FLT 1 / 9000 W 10

1ms

Filter on analog input Parameter x

IDC FLT 1 / 9000 W 10

1ms

Filter on analog input Parameter x

VMOT FLT 1 / 9000 W 10

1ms

The analog signal REVE % has two filters:

- REVE FLT RP

- REVE FLT CN

The filter REVE FLT RP is enabled only until the speed is less the 10% of the nominal value, the

REVE FLT CN instead is always enabled.

The parameters called “XXXX 8V=%” are used to change the percentage that correspond to 8V.

Usually at the nominal value for voltage or speed the correspondent analog signals have amplitude

of 8V but sometimes it could be present an offset that could be remove with this parameter.

If the parameter REVE 8V=% is setted to 110%, the 100% will be obtain with an analog signal of

7,2V of amplitude.

For analog signals, that represent current, the nominal value corresponds to a signal that has

amplitude of 6V.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 52/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Menu: ANALOG. INP2

Likewise to the preceding menu also this menu represents analogical input greatness in entry to

the ACPU02. As for the preceding greatness, also in this case there are some parameters used

to set the greatness visualization.

The parameters are therefore:

Parameter Name Min/Max Value Typical Value Description

VDC % 0.00 / 650.00 R DC voltage

IEXC % 0.00 / 650.00 R Motor excitation current

VLINE % 0.00 / 650.00 R Line voltage

POWER % 0.00 / 650.00 R Line frequency

VDC 8V = % 30.00 / 650.00 W 100.00 Percentage for a 8V signal

IEXC 6V = % 30.00 / 650.00 W 100.00 Percentage for a 6V signal

VLINE 8V =% 30.00 / 650.00 W 100.00 Percentage for a 8V signal

POWER 8V =% 30.00 / 650.00 W 100.00 Percentage for a 8V signal

Filter on analog input Parameter x

VDC FLT 1 / 9000 W 10

1ms

Filter on analog input Parameter x

IEXC FLT 1 / 9000 W 10

1ms

Filter on analog input Parameter x

VLINE FLT 1 / 9000 W 10

1ms

Filter on analog input Parameter x

POWER FLT 1 / 9000 W 10

1ms

Likewise to the preceding menu the parameters “XXXX 8V = %” is used to define the

percentage for a 8V signal. These two menus contain the analog input variables of the regulator

and the parameters for their visualization.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 53/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Menu: ANALOG.OUTPUT

Parameter Name Min/Max Value Typical Value Description

RICO % 0.00 / 650.00 R Current reference

LIVE Instr% 0.00 / 650.00 R Speed reference for instrument

Speed reference downstream of the

RIVE out% 0.01 / 650.00 R

ramp

REVE F % 0.01 / 650.00 R Speed feedback

RICO 6V=% 0.00 / 650.00 W 100.00 Percentage for a 8V signal

LIVE 8V=% 0.00 / 650.00 W 106.67 Percentage for a 6V signal

RIVE 8V=% 0.01 / 650.00 W 100.00 Percentage for a 8V signal

REVE F 8V=% 0.01 / 650.00 W 100.00 Percentage for a 8V signal

Filter on analog output Parameter x

RICO Flt 1 / 100 W 10

1ms

Filter on analog output Parameter x

LIVE Flt 1 / 65000 W 10

1ms

Filter on analog output Parameter x

RIVE Flt 1 / 65000 W 10

1ms

Filter on analog output Parameter x

REVE Flt 1 / 65000 W 10

1ms

Instr.Fs V 1 / 65000 W 10 Full scale in Volt of instrument

Instr.FsRpm 1 / 65000 W 4000 Full scale in rpm of instrument

LIVE FS Cal 30.00 / 650.00 R Percentage of 8V of the instrument

The output "Rico Amp" is the reference sent to the current regulator; the other output signals are

used for the instruments or for other diagnostic systems.

For the speed reference instrument there are three parameters:

- Instr. FS V

- Instr. FS rpm

- LIVE FS Cal

With the two inputs (Instr. FS V and Instr. FS rpm) the software calculates the corresponding

percentage (LIVE FS Cal) that has to be insert into the box LIVE 8V=%. If the instrument points to

a wrong number the operator can change the parameter LIVE 8V=%.

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 54/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Menu: MEASUREMENT

Parameter Name Min/Max Value Typical Value Description

LIVE-A % 0.00 / 650.00 R Speed reference in automatic mode

LIVE-M % 0.00 / 650.00 R Speed reference in manual mode

Speed reference utilized by the

LIVE % 0.00 / 650.00 R

regulator

Speed reference downstream of the

RIVE % 0.00 / 650.00 R

ramp

Speed reference downstream of the

RiveReg % 0.00 / 650.00 R

ramp + Step

CURRLIM % 0.00 / 650.00 R Current limit Motor/Generator

ANGLE FV 0 / 6500 R Inverter bridge firing angle

Speed error calculated by the

Errvel % -650.00 / 650.00 R

regulator

Idc/ImLim % 1 / 65000 R Load current per cent

(I-IE/IE) % 1 / 65000 R Rotor current per cent

Motor current limit for stator thermal

Curr.ST.I2T 0.00 / 650.00 R

protection

Motor current limit for rotor thermal

Curr.RT.I2T 0.00 / 650.00 R

protection

Trip ST I2T 0 / 65000 R Signal for motor thermal protection

Trip RT I2T 0 / 65000 R Signal for rotor thermal protection

This menu is used for diagnostic during the operation, in fact all the parameters are readable [R].

All right reserved copyright

E1018_A140_OMMD_Description_B_en Revision : B Date : 19/05/2011

GE Energy

Rev. : B

Page : 55/103

OPERATION AND MAINTENANCE MANUAL

DESCRIPTION

Menu: ExtRef + ManRamp

This menu is used to define the parameters of the ramp in the manual operation, as well as the

external references of speed.

Parameter Name Min/Max Value Typical Value Description

Speed ref. selected by digital input

LIVE E1 % 0.00 / 650.00 W 0.00

04

Speed ref. selected by digital input

LIVE E2 % 0.00 / 650.00 W 0.00

05

Speed ref. selected by digital input

LIVE E3 % 0.00 / 650.00 W 0.00

06

Speed ref. selected by digital input

LIVE E4 % 0.00 / 650.00 W 0.00

07

Hysteresis for oscillation with

IstLIVE E2 % 0.00 / 650.00 W 0.00

LiveE2 selected (Washing)

Hysteresis for oscillation with

IstLIVE E3 % 0.00 / 650.00 W 0.00

LiveE3 selected (Purging)