Beruflich Dokumente

Kultur Dokumente

Ash Handling System

Hochgeladen von

pprasad_g93580 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten16 SeitenAHS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAHS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten16 SeitenAsh Handling System

Hochgeladen von

pprasad_g9358AHS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 16

SUBMITTED BY-

1) Akshay Kumar Yaday (R630211006)

2) Amay Jain (R630211007)

3) Aniket Bhattacharya (R630211008)

4) Animesh Gupta (R630211009)

5) Anukriti (R630211011)

Ash

Ash is the residue remaining after the coal

is incinerated.

Composition of Ash:

- SiO2 .Al2O3.Fe2O3.CaO. MgO

Ash Handling System

The ash handling system handles the ash by

bottom ash handling system, coarse ash

handling system, fly ash handling system, ash

disposal system up to the ash disposal area and

water recovery system from ash pond and

Bottom ash overflow.

Parts of Ash Handling System

Bottom Ash Handling System

Coarse Ash (Economizer Ash) handling

system

Air Pre Heater ash handling system

Fly ash handling system

Ash slurry disposal system

Bottom Ash Handling System

Bottom ash resulting from the

combustion of coal in the

boiler falls into the over

ground, refractory lined, water

impounded, maintained level,

double V-Section type/ W type

steel- fabricated bottom ash

hopper having a hold up

volume to store bottom ash and

economizer ash of maximum

allowable condition with the

rate specified. The slurry

formed is transported to slurry

sump through pipes.

Coarse Ash (Economizer Ash)

handling System

Ash generated in Economizer hoppers is evacuated

continuously through flushing boxes.

Continuous generated Economizer slurry is fed by

gravity into respective bottom ash hopper pipes with

necessary slope.

Air Pre Heater ash handling system

Ash generated from

APH hoppers is

evacuated once in a

shift by vacuum

conveying system

connected with the

ESP hopper vacuum

conveying system.

Fly Ash Handling System

Fly ash is considered to be collected in ESP Hoppers.

Fly ash from electrostatic precipitators or fabric bag filters (or

sometimes both), located at the outlet of the furnace and before

the induced draft fan, is extracted by Vacuum Pumps.

•Electrostatic precipitators or fabric bag filters (or sometimes

both) located at the outlet of the furnace and before the

induced draft fan.

•Generally, the fly ash is pneumatically transported to storage

silos for subsequent transport by trucks or railroad cars

Figure: Fly-Ash Washing

The ways of fly ash utilization include

•Concrete production, as a substitute material for Portland

cement and sand

•Embankments and other structural fills (usually for road

construction)

Waste stabilization and solidification.

•Cement clinkers production - (as a substitute material for clay)

•Mine reclamation

•Stabilization of soft soils

•As Aggregate substitute material (e.g. for brick production)

•Mineral filler in asphaltic concrete

•Agricultural uses: soil amendment, fertilizer, cattle feeders, soil

stabilization in stock feed yards, and agricultural stakes

•Loose application on rivers to melt ice

•Loose application on roads and parking lots for ice control

•Other applications include cosmetics, toothpaste, kitchen

counter tops, floor and ceiling tiles, bowling balls, etc

Ash Slurry Disposal System

Bottom Ash slurry, Fly ash slurry and the Coarse

Ash slurry shall be pumped from the common ash

slurry sump up to the dyke area which is located at a

distance from Slurry pump house.

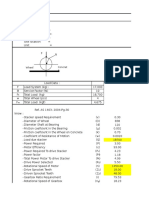

Requirement of Ash Handling

System

In Thermal Power Plant’s coal is generally

used as fuel and hence the ash is produced

as the byproduct of Combustion.

Ash generated in power plant is about 30-

40% of total coal consumption and hence

the system is required to handle Ash for

its proper utilization or disposal.

Das könnte Ihnen auch gefallen

- T.E. Mechanical (A-4) MONIL DOSHI-0815054 KIRAN PATIL - 1125027 JIGAR SHAH - 0815045Dokument19 SeitenT.E. Mechanical (A-4) MONIL DOSHI-0815054 KIRAN PATIL - 1125027 JIGAR SHAH - 0815045wahyuNoch keine Bewertungen

- Air CannonDokument9 SeitenAir Cannonkarthikraja21100% (1)

- Road Design AspectDokument30 SeitenRoad Design AspectNiken RaharinaNoch keine Bewertungen

- Air Receiver Sizing PDFDokument3 SeitenAir Receiver Sizing PDFTifano KhristiyantoNoch keine Bewertungen

- Dense Medium Cyclone Operations TipsDokument15 SeitenDense Medium Cyclone Operations Tipsdavylee3100% (1)

- Signet 8550 Flow TransmittersDokument4 SeitenSignet 8550 Flow Transmitters129935Noch keine Bewertungen

- Belt ChainDokument95 SeitenBelt ChainLuis BalducciNoch keine Bewertungen

- Misc Equipment ItemsDokument18 SeitenMisc Equipment Itemshk168Noch keine Bewertungen

- PomeDokument17 SeitenPomeAnirudh KaushikNoch keine Bewertungen

- Medical Oxygen Generator FlyerDokument2 SeitenMedical Oxygen Generator FlyertahatekriNoch keine Bewertungen

- Piping Colour CodeDokument6 SeitenPiping Colour Codepramod_kbNoch keine Bewertungen

- 9.1 Lecture Material - Pneumatic Transport and Slurry TransportDokument51 Seiten9.1 Lecture Material - Pneumatic Transport and Slurry TransportDondon Irig100% (1)

- Complete Infinitynest Starter GuideDokument9 SeitenComplete Infinitynest Starter GuideSeptian Citra KusumaNoch keine Bewertungen

- LQ Unit 11 Mensuration SolDokument12 SeitenLQ Unit 11 Mensuration SolSamson YauNoch keine Bewertungen

- Gas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedDokument36 SeitenGas-Solid Flows: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Ball MillDokument3 SeitenBall MillHeeshanGunathilakaNoch keine Bewertungen

- ED3300Dokument4 SeitenED3300Mohamed Tahoun100% (1)

- Brosur Harga Bio Septic Tank Fiberglass BandungDokument1 SeiteBrosur Harga Bio Septic Tank Fiberglass BandungFiberglass BandungNoch keine Bewertungen

- CH 7. Pneumatic and HydroulicDokument20 SeitenCH 7. Pneumatic and HydroulicAbenezer Tasew100% (1)

- Air Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedDokument36 SeitenAir Requirements: 2004 by Marcel Dekker, Inc. All Rights ReservedGustavo Hernandez100% (1)

- Chain Drives: Back To Contents PagesDokument104 SeitenChain Drives: Back To Contents PagesArul KumarNoch keine Bewertungen

- Introduction To Mechanical Size ReductionDokument35 SeitenIntroduction To Mechanical Size ReductionFikrie MuhdNoch keine Bewertungen

- MixerDokument10 SeitenMixerKRYSTEL WENDY LAHOMNoch keine Bewertungen

- Destruction of Cyanide Waste Solutions Using Chlor-1Dokument10 SeitenDestruction of Cyanide Waste Solutions Using Chlor-1Brent WoottonNoch keine Bewertungen

- Text Dense PhaseDokument4 SeitenText Dense PhaseZakir Hossain BiplobNoch keine Bewertungen

- High Angle Conveyor Offers Mine Haulage SavingsDokument20 SeitenHigh Angle Conveyor Offers Mine Haulage SavingsZiggy Gregory100% (1)

- WWW Mechanicalengineeringblog Com 2Dokument6 SeitenWWW Mechanicalengineeringblog Com 2Mashudi FikriNoch keine Bewertungen

- Palm Kernel ShellsDokument13 SeitenPalm Kernel ShellsRiksan RiksanNoch keine Bewertungen

- Sprocket SelectionDokument4 SeitenSprocket SelectionallovidNoch keine Bewertungen

- Eriez CrossFlowTeeterBedSeparators BrochureDokument2 SeitenEriez CrossFlowTeeterBedSeparators BrochureChalsNoch keine Bewertungen

- Automatic Samplers: Proven & DependableDokument6 SeitenAutomatic Samplers: Proven & DependableHarish KumarNoch keine Bewertungen

- BOF Plant Write UpDokument20 SeitenBOF Plant Write UpKalyan HalderNoch keine Bewertungen

- CH 7 CoveyorsDokument37 SeitenCH 7 CoveyorsEbrahim Ali100% (1)

- Pneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsDokument11 SeitenPneumatic Conveyor: I. Introduction of Pneumatics and Its ApplicationsAbas S. AcmadNoch keine Bewertungen

- Conveyor For Quality ControlDokument6 SeitenConveyor For Quality ControlGajanan100% (2)

- Vertical In-Line Pump: Technical FeaturesDokument22 SeitenVertical In-Line Pump: Technical FeaturesHicham HrslNoch keine Bewertungen

- Chain ConveyorrabDokument36 SeitenChain ConveyorrabPrayogo Hadi SNoch keine Bewertungen

- Pipe Conveyor: Sheet 1 of 3Dokument3 SeitenPipe Conveyor: Sheet 1 of 3Ravi KumarNoch keine Bewertungen

- Shaft Reclaim FeederDokument7 SeitenShaft Reclaim FeederWaris La Joi WakatobiNoch keine Bewertungen

- Fenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesDokument22 SeitenFenner Wedge Belt Drive Selection 299 - Friction - WedgebeltdrivesSubramanian ChidambaramNoch keine Bewertungen

- The Chilling of CarcassesDokument14 SeitenThe Chilling of CarcassesMamtaNoch keine Bewertungen

- Brochure - Slide Gate Valve - Pubc-0502-SvDokument2 SeitenBrochure - Slide Gate Valve - Pubc-0502-SvedgarspalaciosNoch keine Bewertungen

- Counter Current LeachingDokument4 SeitenCounter Current Leachingbelter99100% (1)

- StanexDokument2 SeitenStanexSamehibrahemNoch keine Bewertungen

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Dokument19 SeitenKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNoch keine Bewertungen

- Ven Ilat On Design General Ventilation Des GN: Gener 1Dokument1 SeiteVen Ilat On Design General Ventilation Des GN: Gener 1Anonymous PCsoNCt0mFNoch keine Bewertungen

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDokument5 SeitenHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiNoch keine Bewertungen

- Week # 10 MR Chapter 8: - Tutorial #10Dokument31 SeitenWeek # 10 MR Chapter 8: - Tutorial #10Farras HanifNoch keine Bewertungen

- Basic Introduction of Coal Handling SystemDokument7 SeitenBasic Introduction of Coal Handling SystemHerman AbdullahNoch keine Bewertungen

- Belt Drive SystemDokument15 SeitenBelt Drive Systemafsana_rajNoch keine Bewertungen

- Mechanical Grain ConveyingDokument64 SeitenMechanical Grain ConveyingDaniel CookNoch keine Bewertungen

- Chapter 1Dokument56 SeitenChapter 1Surbhi JainNoch keine Bewertungen

- Makron Fibretec 1000-2000 EngDokument10 SeitenMakron Fibretec 1000-2000 EngMAKRONNoch keine Bewertungen

- Coal Handling System: (Black & Veatch, 1996)Dokument36 SeitenCoal Handling System: (Black & Veatch, 1996)Mel Ann B. BayorNoch keine Bewertungen

- 1 X 600 MW JPL Seoni Project Madhya Pradesh: Stockpile Capacity CalculationDokument8 Seiten1 X 600 MW JPL Seoni Project Madhya Pradesh: Stockpile Capacity Calculationdnyanesh_accNoch keine Bewertungen

- Centrifuge PDFDokument11 SeitenCentrifuge PDFسراء حيدر كاظمNoch keine Bewertungen

- Biomass Storage Capacity - Rev.01Dokument5 SeitenBiomass Storage Capacity - Rev.01vidyaNoch keine Bewertungen

- Boogie Stacker: Concret e WheelDokument4 SeitenBoogie Stacker: Concret e WheelWaris La Joi WakatobiNoch keine Bewertungen

- Chlorine: International Thermodynamic Tables of the Fluid StateVon EverandChlorine: International Thermodynamic Tables of the Fluid StateNoch keine Bewertungen

- Ash HandlingDokument30 SeitenAsh Handlingrmm99rmm99100% (2)

- Title: System and Apparatus For Climbing Up A Tree To Perform Various TasksDokument3 SeitenTitle: System and Apparatus For Climbing Up A Tree To Perform Various TasksGirish HegdeNoch keine Bewertungen

- Coal HandlingDokument33 SeitenCoal HandlingGirish Hegde100% (2)

- ABVPDokument1 SeiteABVPGirish HegdeNoch keine Bewertungen

- I G Mulani: 4th May 2008, 15:08#3Dokument1 SeiteI G Mulani: 4th May 2008, 15:08#3Girish HegdeNoch keine Bewertungen

- Coal Handling Plant Design ReviewDokument125 SeitenCoal Handling Plant Design ReviewDC ProyectosNoch keine Bewertungen

- Aerial RoboticsDokument15 SeitenAerial RoboticsSri SaiNoch keine Bewertungen

- Apb Calculation (Natural Gas)Dokument8 SeitenApb Calculation (Natural Gas)Nasrul HazimNoch keine Bewertungen

- Kieselmann Butterfly Valves InstruktionDokument23 SeitenKieselmann Butterfly Valves InstruktionVLASTAR100% (2)

- Trimmer Ceramic CapDokument46 SeitenTrimmer Ceramic CapWickna PratabanNoch keine Bewertungen

- CV6312 S1 OverviewDokument6 SeitenCV6312 S1 Overviewlim kang haiNoch keine Bewertungen

- 0705 Oil ReportDokument12 Seiten0705 Oil ReportAnonymous oUJSCyZNoch keine Bewertungen

- Troubleshooting and Service Manual 120V-240VDokument48 SeitenTroubleshooting and Service Manual 120V-240Vkloberg123Noch keine Bewertungen

- P & I DiagramsDokument26 SeitenP & I Diagramsengrfarhansiddiqui100% (3)

- Alibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputDokument2 SeitenAlibration Escription: - F-1210 Dual Turbine - Insertion Flow Meter Analog OutputrameshNoch keine Bewertungen

- Final Report IOCL GuwahatiDokument17 SeitenFinal Report IOCL GuwahatiSonu KumarNoch keine Bewertungen

- DowsingDokument76 SeitenDowsingBacean Aurel IoanNoch keine Bewertungen

- Lesson 2 Commercial Refrigeration and Airconditioning TypesDokument41 SeitenLesson 2 Commercial Refrigeration and Airconditioning TypesEddie AbugNoch keine Bewertungen

- 06-431 Rev8 - Ecaro-25 Ivo ManualDokument108 Seiten06-431 Rev8 - Ecaro-25 Ivo ManualjonyNoch keine Bewertungen

- Technical Capabilities PDI 2019 09Dokument10 SeitenTechnical Capabilities PDI 2019 09carlosNoch keine Bewertungen

- Planetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)Dokument15 SeitenPlanetophysical Function of Vacuum Domains (Dmitriev, Dyatlov)THE NIKOLA TESLA INSTITUTE100% (1)

- ANSYS-Based Detailed Thermo-Mechanical Modeling of Complex Thermoelectric Power DesignsDokument3 SeitenANSYS-Based Detailed Thermo-Mechanical Modeling of Complex Thermoelectric Power DesignsablueleafNoch keine Bewertungen

- ATT III - 2. Use Internal Communication SystemsDokument9 SeitenATT III - 2. Use Internal Communication Systemsedwin90276Noch keine Bewertungen

- Thermal Science and Engineering Progress: Tayebeh Darbandi, Mikael Risberg, Lars WesterlundDokument9 SeitenThermal Science and Engineering Progress: Tayebeh Darbandi, Mikael Risberg, Lars WesterlundSaleel ChuriNoch keine Bewertungen

- Inert GasDokument3 SeitenInert Gasankitshr09Noch keine Bewertungen

- Pressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdDokument1 SeitePressure - Enthalpy Diagram For The Refrigerant R-22: Li Q U IdRifki AuliaNoch keine Bewertungen

- Soil Colloid AVIDokument5 SeitenSoil Colloid AVIMonika KshetriNoch keine Bewertungen

- Aerial Propeller - Aerial Navigation (Unedited Bloomfield-Moore On John Keely)Dokument27 SeitenAerial Propeller - Aerial Navigation (Unedited Bloomfield-Moore On John Keely)Gregg Martin100% (1)

- Two-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingDokument40 SeitenTwo-Stage Ball Milling of Recycled Machining Chips To Create An Alternative Feedstock Powder For Metal Additive ManufacturingJazmínARNoch keine Bewertungen

- BlakeDokument19 SeitenBlakeDeanneLaylayNoch keine Bewertungen

- G5 Low Profile Unit Cooler Ver 2.0Dokument10 SeitenG5 Low Profile Unit Cooler Ver 2.0Wawan NuryanaNoch keine Bewertungen

- Residential KitchenBathrooDokument7 SeitenResidential KitchenBathrooCarlos Daniel Ayala GonzalezNoch keine Bewertungen

- Manuel Manto 785C InglesDokument104 SeitenManuel Manto 785C Inglesciprian quispe challco100% (1)

- C13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationDokument3 SeitenC13, C15, and C18 Engines Alternator Problem - Charging Problem Andor Noisy OperationRaphael ThornerNoch keine Bewertungen

- Mid Term Exam Preparation SeatworkDokument1 SeiteMid Term Exam Preparation SeatworkFour AyesNoch keine Bewertungen

- Port Info Booklet 2013Dokument35 SeitenPort Info Booklet 2013Leonard Chan ChowNoch keine Bewertungen

- Engineering Guide Custom Battery PacksDokument16 SeitenEngineering Guide Custom Battery PacksAndrew PNoch keine Bewertungen