Beruflich Dokumente

Kultur Dokumente

Wps 2-8

Hochgeladen von

Anonymous XYt4Y9q0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten1 Seitewps

Originaltitel

wps 2-8

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenwps

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

71 Ansichten1 SeiteWps 2-8

Hochgeladen von

Anonymous XYt4Y9qwps

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

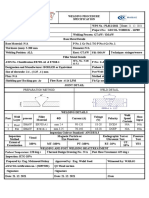

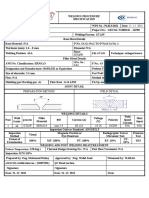

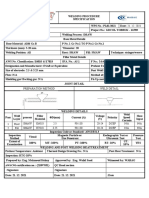

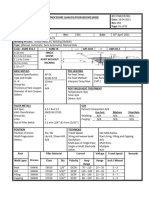

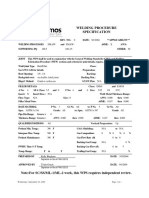

No: 2-8/19

WELDING PROCEDURE Date: jun, 2019

SPECIFICATION Issue: 01 Revision: 00

Location: RN Pančevo :Pipeline S-16800 Inspector and ispection location:

PQR: K-3.2.094 Prep. and cleaning method: Grinding

Made by: Feromont Inženjering doo Base material specification: TP304L

Welders name & identification No.: /

Welding process: 141 Thickness "s"(mm): 2,77; 3.05; 3,76

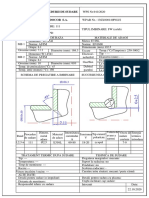

Type of welded joint: FW Inner diameter (mm): 2’’ ;4’’; 8’’

Detail of groove design: Supports Welding position: PD

Joint design Welding sequence

Welding parameters

Run Process Filler Current (A) Voltage Type of Wire feed Feed velocity Heat input

material (V) current

(mm) /polarity

1-2 141 2.4 90-120 12-13 DC/- / 5-8 0,65-0,8

Filler material (class and designation): Preheat temperature: /

BÖHLER SAS 2-IG; EN ISO 14343-A:2007: W 19 9 Nb Interpass temperature: Max 150˚C

o

Prescribed drying method: 2 h na 250-350 C Heat treatment or annealing: /

Shielding gas / flux - face: I1(Ar) ISO 14175 Duration of heat treatment: /

- root: / Heating and cooling speed: /

Gas flow l/min - face: 10-12 l/min Other data: /

- root: / e.g. Weaving (max. bead width):

Type of tungsten electrode/diameter: /

/ Oscillation: amplitude, frequency, holding time:

Gouging detail: Max 3d

Orifice or gas cup size:

Details of plasma weld.:

Torch adjustment angle:

Written by: Jelena Rakić,Mast. Mech. Eng.IWE

________________________ ________________________________

Das könnte Ihnen auch gefallen

- WPQR Welding Procedure Qualification RecordsDokument3 SeitenWPQR Welding Procedure Qualification Recordsramesh rajaNoch keine Bewertungen

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDokument1 SeitePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNoch keine Bewertungen

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDokument1 SeitePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNoch keine Bewertungen

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CDokument1 SeitePessing Libya INC: Fill: SMAW Sfa. No: 5.28 & 5.1 Post Weld Heat Treatment: 655 Deg CMahmoud HaggagNoch keine Bewertungen

- Wps 141 PA #5Dokument2 SeitenWps 141 PA #5cosmo5555Noch keine Bewertungen

- Pessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/ADokument1 SeitePessing Libya INC: Fill: GTAW Sfa. No: 5.14 Post Weld Heat Treatment: N/AMahmoud HaggagNoch keine Bewertungen

- Pessing Libya INC: Weld Detail Preparation MethodDokument1 SeitePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNoch keine Bewertungen

- Pessing Libya INC: As Per P No.3,4 To As Per P No.3,4Dokument1 SeitePessing Libya INC: As Per P No.3,4 To As Per P No.3,4Mahmoud HaggagNoch keine Bewertungen

- Pessing Libya INC: Sfa. No: A5.9Dokument1 SeitePessing Libya INC: Sfa. No: A5.9Mahmoud HaggagNoch keine Bewertungen

- WPS Racord Intepat 2335Dokument1 SeiteWPS Racord Intepat 2335Andrei UrsacheNoch keine Bewertungen

- Welding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)Dokument3 SeitenWelding Procedure Qualification Record (WPQR) (ISO 15614-1-2017)ramesh rajaNoch keine Bewertungen

- P WPSDokument3 SeitenP WPSAnilkumar G NairNoch keine Bewertungen

- Pessing Libya INC: Weld Detail Preparation MethodDokument1 SeitePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNoch keine Bewertungen

- WPS PQR FormulirDokument2 SeitenWPS PQR FormulirAZaiNoch keine Bewertungen

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDokument3 SeitenWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- Welding Procedure For Plate - WPSDokument1 SeiteWelding Procedure For Plate - WPSCristian ZidarescuNoch keine Bewertungen

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDokument3 SeitenWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNoch keine Bewertungen

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Dokument1 SeiteWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNoch keine Bewertungen

- Pessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/ADokument1 SeitePessing Libya INC: Fill: FCAW Sfa. No: 5.18&5.20 Post Weld Heat treatment:N/AMahmoud HaggagNoch keine Bewertungen

- Welding Procedure Qualification Records (WPQR) GuideDokument3 SeitenWelding Procedure Qualification Records (WPQR) Guideramesh rajaNoch keine Bewertungen

- DraftDokument32 SeitenDraftAnilkumarNoch keine Bewertungen

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDokument3 SeitenWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENoch keine Bewertungen

- Welding Procedure Specification: ST NDDokument1 SeiteWelding Procedure Specification: ST NDMaung SleeperNoch keine Bewertungen

- Pessing Libya INC: SA 312 TP 316 TO SA 312 TPDokument1 SeitePessing Libya INC: SA 312 TP 316 TO SA 312 TPMahmoud HaggagNoch keine Bewertungen

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDokument1 SeiteWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNoch keine Bewertungen

- WPS 141-111 P460QH To SameDokument1 SeiteWPS 141-111 P460QH To SameakisdassasNoch keine Bewertungen

- Draft WPSDokument32 SeitenDraft WPSAnilkumar G NairNoch keine Bewertungen

- Calculation sheet for flow element FE-203Dokument4 SeitenCalculation sheet for flow element FE-203scploperation.2x50 CommonNoch keine Bewertungen

- WPS - Merd-01Dokument3 SeitenWPS - Merd-01Phuong NguyenNoch keine Bewertungen

- WPS 2014-002 002 - 1G & 2G S 275 JRDokument2 SeitenWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- PQR - Gmaw BCCDokument2 SeitenPQR - Gmaw BCCBasel MohammadNoch keine Bewertungen

- Procedure Qualification SpecificationDokument4 SeitenProcedure Qualification Specificationriyas.hvacworkNoch keine Bewertungen

- Sabari Engineering PQRDokument3 SeitenSabari Engineering PQRAdvanced Quality Centre AQC100% (1)

- PQR FLow LineDokument2 SeitenPQR FLow Linesar sarNoch keine Bewertungen

- WPS & PQRDokument13 SeitenWPS & PQRValentin RadulescuNoch keine Bewertungen

- DML welding procedureDokument1 SeiteDML welding procedureNuwan RanaweeraNoch keine Bewertungen

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Dokument2 SeitenPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya BaraniNoch keine Bewertungen

- PQR Procedure Qualification Record Krishna SteelDokument2 SeitenPQR Procedure Qualification Record Krishna SteelHarshit Adwani100% (2)

- Welding Procedure Specification (WPS)Dokument2 SeitenWelding Procedure Specification (WPS)Ramadhan AdityaNoch keine Bewertungen

- WPS 3-A36 Rudder Shaft To Rudder BladeDokument1 SeiteWPS 3-A36 Rudder Shaft To Rudder BladeNuwan RanaweeraNoch keine Bewertungen

- WPS 2-A36 Rudder Shaft To FlangeDokument2 SeitenWPS 2-A36 Rudder Shaft To FlangeNuwan RanaweeraNoch keine Bewertungen

- Template Pipe PlateDokument1 SeiteTemplate Pipe PlateFarhan AmzarNoch keine Bewertungen

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Dokument1 SeiteAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetNoch keine Bewertungen

- WPQR No. 2016 02Dokument14 SeitenWPQR No. 2016 02GANESH ANoch keine Bewertungen

- Document Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Dokument1 SeiteDocument Title: Welding Procedure Specification: Champion West Phase Iii Dev. Project C030005/ESP MSE BSP (ESP/2)Ed FangNoch keine Bewertungen

- WPS - 600 MW ChampaDokument7 SeitenWPS - 600 MW ChampaAmjad PathanNoch keine Bewertungen

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Dokument4 SeitenPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNoch keine Bewertungen

- WPS - 0601 00112 01 PDFDokument1 SeiteWPS - 0601 00112 01 PDFAnonymous zzMwR2aNNoch keine Bewertungen

- Welding Procedure Specification (WPS)Dokument2 SeitenWelding Procedure Specification (WPS)Ramadhan AdityaNoch keine Bewertungen

- Welding Procedure SpecificationDokument2 SeitenWelding Procedure SpecificationWaranya Musika100% (1)

- WPS 1-SS 316 Rudder Stock With Letter HeadDokument2 SeitenWPS 1-SS 316 Rudder Stock With Letter HeadNuwan RanaweeraNoch keine Bewertungen

- Draft WPS For Carbon Steel PipeDokument2 SeitenDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Dokument2 SeitenWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNoch keine Bewertungen

- WPS For SSDokument1 SeiteWPS For SSdeepakNoch keine Bewertungen

- Welding Procedure Specifications (Wps - 6G) : 2mm (Max)Dokument2 SeitenWelding Procedure Specifications (Wps - 6G) : 2mm (Max)Gbenga Mobolade100% (1)

- Welding Procedure SpecificationDokument2 SeitenWelding Procedure SpecificationFrancisco HoyosNoch keine Bewertungen

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDokument5 SeitenBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNoch keine Bewertungen

- Preliminary Welding Procedure Specification (PWPS)Dokument2 SeitenPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- PIF Energy REVISION NEW - Decembar2013Dokument6 SeitenPIF Energy REVISION NEW - Decembar2013Anonymous XYt4Y9qNoch keine Bewertungen

- Inspection HandbookDokument126 SeitenInspection Handbooksteffy18295% (21)

- Linde NormDokument68 SeitenLinde NormAnonymous XYt4Y9q100% (3)

- Bs en 13927-Visual Testing EquipmentDokument17 SeitenBs en 13927-Visual Testing EquipmentAnonymous XYt4Y9q100% (1)

- Danfoss Razmenjivac 1400kWDokument1 SeiteDanfoss Razmenjivac 1400kWAnonymous XYt4Y9qNoch keine Bewertungen

- Datasheet For Metals GX 6 Crnimo 24-8-2Dokument2 SeitenDatasheet For Metals GX 6 Crnimo 24-8-2andreNoch keine Bewertungen

- Danh Muc Tieu Chuan JIS 2007Dokument3 SeitenDanh Muc Tieu Chuan JIS 2007Nguyeentt TntNoch keine Bewertungen

- Power Skiving Machining for Complete Gear ProductionDokument9 SeitenPower Skiving Machining for Complete Gear Productionnovkovic1984Noch keine Bewertungen

- ME8392 Manufacturing TechnologyDokument41 SeitenME8392 Manufacturing Technology26 MaheshkannanNoch keine Bewertungen

- Kasier Aluminum 2024-T4 T-FORM PDFDokument2 SeitenKasier Aluminum 2024-T4 T-FORM PDFRizkiyan ArdiNoch keine Bewertungen

- Workshop Theory and PracticeDokument35 SeitenWorkshop Theory and PracticeWilliam SalazarNoch keine Bewertungen

- Lathe ManualDokument14 SeitenLathe ManualRC Villeda100% (1)

- Roland JWX-30 Set UpDokument62 SeitenRoland JWX-30 Set UpDragos Manzateanu0% (1)

- ME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsDokument19 SeitenME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsAniket SankpalNoch keine Bewertungen

- Forging SDokument14 SeitenForging SGowrisanthosh PalikaNoch keine Bewertungen

- Wood Machining Tech in JapanDokument20 SeitenWood Machining Tech in JapanMayur12345dtNoch keine Bewertungen

- OX CNC Mechanical Assembly InstructionsDokument49 SeitenOX CNC Mechanical Assembly InstructionsISABEL RINCONNoch keine Bewertungen

- Ficha Tecnica Pija Punta BrocaDokument1 SeiteFicha Tecnica Pija Punta BrocajulioNoch keine Bewertungen

- Welding Metallurgy and Heat Affected Zone PropertiesDokument198 SeitenWelding Metallurgy and Heat Affected Zone PropertiesAgil SetyawanNoch keine Bewertungen

- AWS - CWI Model Question Foundamental - Part 1Dokument16 SeitenAWS - CWI Model Question Foundamental - Part 1dhasdj75% (4)

- English FP4MEDokument2 SeitenEnglish FP4MEHossein TomariNoch keine Bewertungen

- Limpieza Superficial en Recocido BatchDokument10 SeitenLimpieza Superficial en Recocido BatchDebora ChavezNoch keine Bewertungen

- SONNAX 45rfeDokument2 SeitenSONNAX 45rfefulltransmissionNoch keine Bewertungen

- Casting ToleranceDokument1 SeiteCasting ToleranceTrushant NakumNoch keine Bewertungen

- Sagar Institute of Research & Technology - Excellence: "Design & Fabrication of Mini Lathe Machine"Dokument9 SeitenSagar Institute of Research & Technology - Excellence: "Design & Fabrication of Mini Lathe Machine"Lu CkyNoch keine Bewertungen

- 金属车床说明书1835A (3) (1) (2) 1687946779071Dokument56 Seiten金属车床说明书1835A (3) (1) (2) 1687946779071philip coquelinNoch keine Bewertungen

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDokument1 SeiteWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNoch keine Bewertungen

- KORLOYTESTDEHAYEDokument36 SeitenKORLOYTESTDEHAYEnicodehayeNoch keine Bewertungen

- Shim SpacerDokument24 SeitenShim Spacerrasalkeshav4563Noch keine Bewertungen

- 4.4 Process Parameters On Tool Life - Class NotesDokument35 Seiten4.4 Process Parameters On Tool Life - Class NotesTAMILARASAN MNoch keine Bewertungen

- Tricking Out Asian 9x20 LatheDokument48 SeitenTricking Out Asian 9x20 Lathearanicki8587Noch keine Bewertungen

- International Journal of Research Publication and ReviewsDokument7 SeitenInternational Journal of Research Publication and ReviewsBasavaraj G LNoch keine Bewertungen

- Pueblo Viejo Project Barrick Gold - Dominican Republic CM 001Dokument6 SeitenPueblo Viejo Project Barrick Gold - Dominican Republic CM 001Silvia Quispe CerinNoch keine Bewertungen

- Material data sheet for steel grades SB-C45, 047 and Imatra 4MDokument2 SeitenMaterial data sheet for steel grades SB-C45, 047 and Imatra 4Mabu asiyahNoch keine Bewertungen

- Lathe Spindle Nose Mounting Identification ChartDokument1 SeiteLathe Spindle Nose Mounting Identification ChartYahia Mustafa Alfazazi100% (1)