Beruflich Dokumente

Kultur Dokumente

Abrasion Resistance C944

Hochgeladen von

SAPTIONOCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Abrasion Resistance C944

Hochgeladen von

SAPTIONOCopyright:

Verfügbare Formate

Designation: C 944 – 99 (Reapproved 2005)

Standard Test Method for

Abrasion Resistance of Concrete or Mortar Surfaces by the

Rotating-Cutter Method1

This standard is issued under the fixed designation C 944; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope other samples of concrete of insufficient test area to permit the

1.1 This test method covers a procedure for determining the conduct of tests by Test Method C 418 or C 779/C 779M, this

resistance of either concrete or mortar to abrasion. This test test method is also applicable on concrete surfaces in place by

method is similar to Procedure B of Test Method C 779/ measuring the abrasion loss as described in Section 9, Proce-

C 779M. dure B, of Test Method C 779/C 779M.

1.2 The values stated in SI units or inch–pound units are to

4. Apparatus

be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system 4.1 Abrasion Device—A drill press or similar device with a

shall be used independently of the other. Combining values chuck capable of holding and rotating the abrading cutter at a

from the two systems may result in non–conformance with the speed of 200 r/min and exerting a force of either a normal load

standard. of 98 6 1 N [22 6 0.2 lbf] or a double load of 197 6 2 N [44

1.3 This standard does not purport to address all of the 6 0.4 lbf] on the test specimen surface. Fig. 1 shows a

safety concerns, if any, associated with its use. It is the commercial drill press and Fig. 2 illustrates details of the

responsibility of the user of this standard to establish appro- rotating cutter. The difficulty in maintaining a constant load on

priate safety and health practices and determine the applica- the abrading cutter when using the lever, gear, and spring

bility of regulatory limitations prior to use. system of a drill press has been eliminated by placing the

desired load directly upon the spindle that turns the cutter. The

2. Referenced Documents machine consists essentially of a frame that supports the drive

2.1 ASTM Standards: 2 motor, stepped pulley, and spindle. A clamping device to hold

C 42 Test Method for Obtaining and Testing Drilled Cores the specimen is built into the base.

and Sawed Beams of Concrete 4.2 Rotating Cutter—A rotating cutter similar to that shown

C 418 Test Method for Abrasion Resistance of Concrete by in Fig. 2 and Fig. 3 shall be used in which 22 37.5 mm [1.5 in.]

Sandblasting diameter dressing wheels and 24 25.4 to 31.75 mm [1 to 1.25

C 779/C 779M Test Method for Abrasion Resistance of in.] diameter washers are mounted. The washers as received

Horizontal Concrete Surfaces shall be stacked and locked on a bolt for the purpose of

reducing their diameter to the specified range to avoid restrict-

3. Significance and Use ing abrasion of the concrete by the washers. Cutter assembly,

3.1 This test method gives an indication of the relative wear including washers, shall be locked onto horizontal rods such

resistance of mortar and concrete based on testing of cored or that individual dressing wheels are free to turn independently.

fabricated specimens. This test method has been successfully The overall diameter of the cutter or the diameter of the

used in the quality control of highway and bridge concrete circular area abraded is 82.5 mm [31⁄4 in.]. Care shall be taken

subject to traffic. Primarily intended for use on the top ends of to achieve constant contact between the rotating cutter and the

152-mm [6-in.] diameter concrete cores, mortar specimens, or entire test surface of the sample. This can be better accom-

plished if the cutters have a swivel connection allowing some

vertical movement. If the dressing wheels have one rounded

1

This test method is under the jurisdiction of ASTM Committee C09 on edge, they shall be mounted with the rounded edge toward the

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee vertical shaft. The individual grinding wheel dressers on the

C09.62 on Abrasion Testing of Concrete.

Current edition approved July 10, 1999. Published September 1999. Originally horizontal shaft of the cutter shall be repositioned whenever a

approved in 1980. Last previous edition approved in 1990 as C 944 – 90a. change in the diameter of the outer cutters becomes apparent.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or This is accomplished by reversing each set of dressing wheels

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

to bring the smaller diameter cutters toward the vertical shaft.

--`,,``,,,,`,```,`,`,`,,````,,-`-`,,`,,`,`,,`---

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 09/10/2007 13:49:12 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Jun 13 12:05:34 EDT 2005

C 944 – 99 (2005)

FIG. 1 Rotating-Cutter Drill Press

4.2.1 In making a test, the rotating cutter is held in a raised 5. Sampling

position by means of the rod provided, the specimen clamped 5.1 Cores shall be taken in accordance with Test Method

securely in position, and motor started. The rotating cutter is C 42.

then lowered into contact with the specimen for a specified

time, after which the cutter is raised. 6. Specimens

4.2.2 A set of dressing wheels shall be replaced periodically, 6.1 The specimens used in this test shall be of any size and

preferably after each 90 min of use. The washers may be shape that can be accommodated by the abrasion device and

ground or replaced to maintain the proper diameter. the balance provided. The surface to be tested shall be either

4.3 Balance—A balance having a capacity of at least 4 kg, formed or finished and shall be positioned in the plane of

and accurate to at least 0.1 g. contact of the cutter.

4.4 Leveling Plate—The base plate upon which the speci-

men rests shall be capable of rotating in the horizontal plane so 7. Procedure

that the specimens when placed thereon can be positioned to 7.1 Determine the mass of the specimen to the nearest 0.1 g.

secure maximum contact with the rotating cutter throughout 7.2 Fasten the specimens securely in the abrasion device so

the full test area. that the surface to be tested is normal to the shaft.

--`,,``,,,,`,```,`,`,`,,````,,-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 09/10/2007 13:49:12 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Jun 13 12:05:34 EDT 2005

C 944 – 99 (2005)

--`,,``,,,,`,```,`,`,`,,````,,-`-`,,`,,`,`,,`---

FIG. 2 Typical Rotating Cutters

7.3 Mount the rotating cutter device in the abrasion device. 8.1.2 Size of specimen,

7.4 Start the motor and lower the cutter slowly until just in 8.1.3 Type of finish,

contact with the surface of the specimen. 8.1.4 Concrete compaction, age, and strength,

7.5 Continue abrasion with a normal or a double load on the 8.1.5 Applied surface treatment,

specimen for 2 min after contact between the cutter and the 8.1.6 Time of abrasion and load used (normal or double),

surface. At the end of each 2-min abrasion period, remove the 8.1.7 Average loss in grams or depth of wear in millimetres

test specimen from the device and clean surfaces to remove and,

debris using a soft brush or blow the surface with air. 8.1.8 Loss in mass and time abraded.

Determine the specimen mass to the nearest 0.1 g. The

minimum test schedule shall involve three 2-min periods 9. Precision and Bias

conducted on three separate areas of representative surfaces of 9.1 Precision—Criteria for judging the acceptability of

the concrete or mortar. abrasion resistance test results obtained by this test method are

7.6 For concrete that is highly resistant to abrasion addi- as follows:

tional testing may be required. Doubling the applied load, or 9.1.1 Normal Load Condition—The single-operator coeffi-

the time, or both, as shown in the following chart, should cient of variation has been found to be 21 %. Therefore, the

provide more comprehensive information on such concrete. results of two properly conducted tests by the same operator on

Abrasion Cycle Load, N (lbf) Test Frequency/Period similar samples should not differ from each other by more than

59 % of the average.

A Normal 98 (22) 3 3 2 min 9.1.2 Double Load Condition—The single-operator coeffi-

B Double load 197 (44) 3 3 2 min

cient of variation has been found to be 12.6 %. Therefore, the

7.7 When testing surfaces in place, or when the depth of results of two properly conducted tests by the same operator on

wear is to be determined due to significant differences in similar samples should not differ from each other by more than

surface density, refer to Test Method C 779/C 779M Procedure 36 % of their average.

B, to determine abraded depth using the apparatus in this test 9.2 Bias—The procedure in this test method has no bias

method. because the value of abrasion resistance of concrete surfaces

can be only defined in terms of a test method.

8. Report

8.1 Report the following information on: 10. Keywords

8.1.1 Description of surface, 10.1 abrasion; concrete; impact; mortar; wear

Copyright ASTM International 3

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 09/10/2007 13:49:12 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Jun 13 12:05:34 EDT 2005

C 944 – 99 (2005)

FIG. 3 Design Details of Rotating-Cutter Drill Press

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--`,,``,,,,`,```,`,`,`,,````,,-`-`,,`,,`,`,,`---

Copyright ASTM International 4

Copyright by ASTM Int'l (all rights reserved);

Provided by IHS under license with ASTM Licensee=Purdue University/5923082001

No reproduction or networking permitted without license from IHS Not for Resale, 09/10/2007 13:49:12 MDT

Reproduction authorized per License Agreement with Kathe Hooper (ASTMIHS Account); Mon Jun 13 12:05:34 EDT 2005

Das könnte Ihnen auch gefallen

- Role of QA&QC in Manufacturing - PresentationDokument32 SeitenRole of QA&QC in Manufacturing - Presentationimran jamilNoch keine Bewertungen

- C78 PDFDokument4 SeitenC78 PDFgrats_singcoNoch keine Bewertungen

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDokument7 SeitenAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method FormickyfelixNoch keine Bewertungen

- Astm C78 C78M 22Dokument3 SeitenAstm C78 C78M 22Ajit P. SinghNoch keine Bewertungen

- Astm C-496Dokument5 SeitenAstm C-496Carlos R Martinez100% (2)

- Standard Test Method For Comparing Concretes On The Basis of The Bond Developed With Reinforcing Steel (Withdrawn 2000) - 1Dokument5 SeitenStandard Test Method For Comparing Concretes On The Basis of The Bond Developed With Reinforcing Steel (Withdrawn 2000) - 1Nushrat Zahan MimNoch keine Bewertungen

- Bmsa Book With CoverDokument251 SeitenBmsa Book With CoverHurol Samuel100% (7)

- 100 Project Manager Interview QuestionsDokument4 Seiten100 Project Manager Interview Questionsadon970% (1)

- Abrasion Resistance of Concrete or Mortar Surfaces by The Rotating-Cutter MethodDokument4 SeitenAbrasion Resistance of Concrete or Mortar Surfaces by The Rotating-Cutter Methodايات علي احمدNoch keine Bewertungen

- BO3 B NIJBFNWm QDokument4 SeitenBO3 B NIJBFNWm QFatah FatahNoch keine Bewertungen

- C944 - C944M-12 Standard Test Method For Abrasion Resistance of Concrete or Mortar Surfaces by The Rotating-Cutter MethodDokument5 SeitenC944 - C944M-12 Standard Test Method For Abrasion Resistance of Concrete or Mortar Surfaces by The Rotating-Cutter MethodFahad RedaNoch keine Bewertungen

- Abrasion Resistance C944Dokument4 SeitenAbrasion Resistance C944takiasNoch keine Bewertungen

- Astm c78Dokument4 SeitenAstm c78Elkin GonzalezNoch keine Bewertungen

- Astm c78Dokument4 SeitenAstm c78Budi PrakosoNoch keine Bewertungen

- C78 PDFDokument3 SeitenC78 PDFNgayxuan NguyenNoch keine Bewertungen

- Flexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Dokument3 SeitenFlexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Jhon Paul EstopinNoch keine Bewertungen

- Abrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method ForDokument5 SeitenAbrasion Resistance of Horizontal Concrete Surfaces: Standard Test Method Forrajeshji_000Noch keine Bewertungen

- C78C78M 15aDokument4 SeitenC78C78M 15adiego rodriguezNoch keine Bewertungen

- Flexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Dokument4 SeitenFlexural Strength of Concrete (Using Simple Beam With Third-Point Loading)Chuwaka OlanNoch keine Bewertungen

- C779C779MDokument6 SeitenC779C779MJorge Luis ArévaloNoch keine Bewertungen

- Flexion de VigasDokument4 SeitenFlexion de VigasAdán Cogley CantoNoch keine Bewertungen

- SNI EngDokument5 SeitenSNI EngSAANO SOLOMENoch keine Bewertungen

- Abrasion Resistance of Mortar Surfaces Using A Rotary Platform AbraserDokument5 SeitenAbrasion Resistance of Mortar Surfaces Using A Rotary Platform AbraserPedro SánchezNoch keine Bewertungen

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Dokument3 SeitenFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Edmundo Jaita CuellarNoch keine Bewertungen

- C293 Flexural Sterength of ConcreyteDokument3 SeitenC293 Flexural Sterength of Concreyteronnie_syncinNoch keine Bewertungen

- BO1 at 6 HSD UMFQDokument4 SeitenBO1 at 6 HSD UMFQFatah FatahNoch keine Bewertungen

- C 1245 - 93 - QzeyndutotmDokument7 SeitenC 1245 - 93 - QzeyndutotmgadNoch keine Bewertungen

- C29 Standard Test Method For Flexural Strength of ConcreteDokument3 SeitenC29 Standard Test Method For Flexural Strength of ConcreteLupita RamirezNoch keine Bewertungen

- C469Static Modulus of ElasticityDokument4 SeitenC469Static Modulus of Elasticityronnie_syncinNoch keine Bewertungen

- C 469 PDFDokument5 SeitenC 469 PDFTommy Cr100% (3)

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDokument5 SeitenSplitting Tensile Strength of Cylindrical Concrete SpecimensmickyfelixNoch keine Bewertungen

- Static Modulus of Elasticity and Poisson's Ratio of Concrete in CompressionDokument5 SeitenStatic Modulus of Elasticity and Poisson's Ratio of Concrete in Compressionjorgesilva84Noch keine Bewertungen

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Dokument4 SeitenFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Oscar RincónNoch keine Bewertungen

- Astm C418 PDFDokument3 SeitenAstm C418 PDFmjgutierrezperalta100% (1)

- Flexural Strength of Hydraulic-Cement Mortars: Standard Test Method ForDokument6 SeitenFlexural Strength of Hydraulic-Cement Mortars: Standard Test Method ForVikas SharmaNoch keine Bewertungen

- Retraccion Del Hormigon EnsayoDokument5 SeitenRetraccion Del Hormigon Ensayorodrigoagro1Noch keine Bewertungen

- C293 PDFDokument3 SeitenC293 PDFHassan MokhtarNoch keine Bewertungen

- Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure)Dokument4 SeitenCompressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure)Ayoseth Chulines DominguezNoch keine Bewertungen

- Astm C496C496M.18825Dokument5 SeitenAstm C496C496M.18825Helena Leon100% (1)

- C78C78M.38385 Flexión de Vigas de HormigónDokument5 SeitenC78C78M.38385 Flexión de Vigas de HormigónMary PalaciosNoch keine Bewertungen

- Design of Journal Bearing Supports To Be Used in Fiber Reinforced Concrete Beam TestsDokument7 SeitenDesign of Journal Bearing Supports To Be Used in Fiber Reinforced Concrete Beam TestsConnieNoch keine Bewertungen

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersDokument5 SeitenUse of Unbonded Caps in Determination of Compressive Strength of Hardened Concrete CylindersqsegaqgNoch keine Bewertungen

- ASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFDokument7 SeitenASTM D4648-D4648M - 13, Laboratory Miniature Vane Shear Test For Saturated Fine-Grained Clayey Soil PDFMarcosNoch keine Bewertungen

- Restrained Expansion of Shrinkage-Compensating Concrete: Standard Test Method ForDokument5 SeitenRestrained Expansion of Shrinkage-Compensating Concrete: Standard Test Method ForJosé Manuel FigueroaNoch keine Bewertungen

- ASTM C78 - Flexural Strength of ConcreteDokument5 SeitenASTM C78 - Flexural Strength of Concretejhon jairo portillaNoch keine Bewertungen

- ASTM C1006 (FT CCA) (2020)Dokument4 SeitenASTM C1006 (FT CCA) (2020)anglejalgoNoch keine Bewertungen

- C 512 - 02 Creep Test For ConcreteDokument4 SeitenC 512 - 02 Creep Test For ConcreteWin Than100% (1)

- Splitting Tensile Strength of Cylindrical Concrete SpecimensDokument5 SeitenSplitting Tensile Strength of Cylindrical Concrete Specimenssayra chavezNoch keine Bewertungen

- Resistance To Degradation of Large-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachineDokument3 SeitenResistance To Degradation of Large-Size Coarse Aggregate by Abrasion and Impact in The Los Angeles MachinehhhhNoch keine Bewertungen

- Flexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Dokument4 SeitenFlexural Strength of Concrete (Using Simple Beam With Center-Point Loading)Raul MenachoNoch keine Bewertungen

- C97 C97M 15 1Dokument4 SeitenC97 C97M 15 1Marcelo Alejandro GonzalezNoch keine Bewertungen

- ASTM C 617 Cabeceo Con AzufreDokument4 SeitenASTM C 617 Cabeceo Con AzufreAlejandro Garcia LopezNoch keine Bewertungen

- Use of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete SpecimensDokument5 SeitenUse of Unbonded Caps in Determination of Compressive Strength of Hardened Cylindrical Concrete SpecimenswarsitoNoch keine Bewertungen

- Hard Concrete Tests - ASTM PDFDokument21 SeitenHard Concrete Tests - ASTM PDFeyasNoch keine Bewertungen

- Flexural C 78 C 78M 16Dokument4 SeitenFlexural C 78 C 78M 16Pamela Polo100% (1)

- C 293 - 00 Qzi5my0wma - PDFDokument3 SeitenC 293 - 00 Qzi5my0wma - PDFMarceloNoch keine Bewertungen

- C341C341M 18Dokument4 SeitenC341C341M 18Jamman Shahid ShiblyNoch keine Bewertungen

- ASTM D3167 Method-for-Floating-Roller-Peel-Resistance-of-Adhesives PDFDokument4 SeitenASTM D3167 Method-for-Floating-Roller-Peel-Resistance-of-Adhesives PDFJesse KrebsNoch keine Bewertungen

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsVon EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsBewertung: 5 von 5 Sternen5/5 (1)

- Pressuremeter Testing: Methods and InterpretationVon EverandPressuremeter Testing: Methods and InterpretationBewertung: 5 von 5 Sternen5/5 (2)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingVon EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNoch keine Bewertungen

- Natalie ResumeDokument1 SeiteNatalie Resumeapi-430414382Noch keine Bewertungen

- Create Storage LocationDokument6 SeitenCreate Storage LocationganeshNoch keine Bewertungen

- Books of PDokument13 SeitenBooks of PicadeliciafebNoch keine Bewertungen

- Production Planning and Inventory ManagementDokument31 SeitenProduction Planning and Inventory ManagementramakrishnaNoch keine Bewertungen

- Daclag Vs MacahiligDokument2 SeitenDaclag Vs MacahiligkimuchosNoch keine Bewertungen

- ITIL Test PaperDokument9 SeitenITIL Test PaperNitinNoch keine Bewertungen

- Payment Advice TUCKSHOP IBM-20230717-20230719Dokument3 SeitenPayment Advice TUCKSHOP IBM-20230717-20230719spraju1947Noch keine Bewertungen

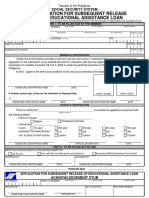

- Application For Subsequent Release of Educational Assistance LoanDokument2 SeitenApplication For Subsequent Release of Educational Assistance LoanNikkiQuiranteNoch keine Bewertungen

- RACI - Future To Be PDFDokument1 SeiteRACI - Future To Be PDFAndrianus LontengNoch keine Bewertungen

- Rent Receipt With Stamp - PDFDokument1 SeiteRent Receipt With Stamp - PDFSAI ANURAGNoch keine Bewertungen

- Testimonial YakultDokument3 SeitenTestimonial YakultRahmanTigerNoch keine Bewertungen

- Peoplesoft Campus Solutions Warehouse For Higher EducationDokument6 SeitenPeoplesoft Campus Solutions Warehouse For Higher EducationvladimirsaavedraNoch keine Bewertungen

- Bank Statement Apr2022 Jan2023 - WPW 14 26 - 004Dokument13 SeitenBank Statement Apr2022 Jan2023 - WPW 14 26 - 004Adarsh RavindraNoch keine Bewertungen

- HLS Process ImprovementDokument18 SeitenHLS Process ImprovementsivaNoch keine Bewertungen

- Social Media AssesmentDokument2 SeitenSocial Media Assesmentandrew imanuelNoch keine Bewertungen

- Lincoln Automatic Lubrication SystemsDokument8 SeitenLincoln Automatic Lubrication Systemsromaoj671Noch keine Bewertungen

- Chapter 2 - Statutory and Regulatory RequirementDokument7 SeitenChapter 2 - Statutory and Regulatory RequirementTeneswari RadhaNoch keine Bewertungen

- Apollo Tyres Limited: Rating RationaleDokument4 SeitenApollo Tyres Limited: Rating Rationaleragha_4544vNoch keine Bewertungen

- Ezulwini Reinsurance Company ProfileDokument17 SeitenEzulwini Reinsurance Company ProfileAnonymous fuLrGAqg100% (2)

- FEA V Poole - Complaint For Declaratory and Injunctive ReliefDokument14 SeitenFEA V Poole - Complaint For Declaratory and Injunctive Reliefamydaniels99Noch keine Bewertungen

- MCS in Service OrganizationDokument7 SeitenMCS in Service OrganizationNEON29100% (1)

- MILAOR+ +Province+of+Tarlac+vs.+AlcantaraDokument3 SeitenMILAOR+ +Province+of+Tarlac+vs.+AlcantaraAndrea MilaorNoch keine Bewertungen

- Special Consideration For The Sole Practitioner Operating As A Management ConsultantDokument3 SeitenSpecial Consideration For The Sole Practitioner Operating As A Management ConsultantJessyNoch keine Bewertungen

- Advanced Cost and Management Accounting ConceptsDokument17 SeitenAdvanced Cost and Management Accounting ConceptsharlloveNoch keine Bewertungen

- Francisco Vs Chemical Bulk CarriersDokument2 SeitenFrancisco Vs Chemical Bulk CarriersJerahmeel Cuevas0% (1)

- HOA - Monthly DuesDokument2 SeitenHOA - Monthly DuesTosca MansujetoNoch keine Bewertungen

- Assignment 3 Advertising and PromotionDokument4 SeitenAssignment 3 Advertising and Promotionapi-203304719Noch keine Bewertungen