Beruflich Dokumente

Kultur Dokumente

Ultramid B3WG6 NYLON PDF

Hochgeladen von

renebbOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultramid B3WG6 NYLON PDF

Hochgeladen von

renebbCopyright:

Verfügbare Formate

Product Information

Jan 2015

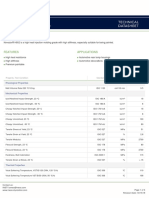

Ultramid® B3WG6

Polyamide 6

Product Description

Ultramid B3WG6 is a 30% glass fiber reinforced, heat stabilized injection molding PA6 grade.

Applications

Typical applications include automotive manifolds and pedals.

PHYSICAL ISO Test Method Property Value

Density, g/cm 1183 1.36

Moisture, % 62

(50% RH) 2.1

(Saturation) 6.6

RHEOLOGICAL ISO Test Method Dry Conditioned

Melt Volume Rate (275 C/5 Kg), cc/10min. 1133 50 -

MECHANICAL ISO Test Method Dry Conditioned

Tensile Modulus, MPa 527

23C 9,500 6,200

Tensile stress at break, MPa 527

23C 185 115

Tensile strain at break, % 527

23C 3.5 8

Flexural Strength, MPa 178

23C 270 180

Flexural Modulus, MPa 178

23C 8,600 5,000

IMPACT ISO Test Method Dry Conditioned

Izod Notched Impact, kJ/m2 180

23C 15 20

Charpy Notched, kJ/m2 179

23C 15 30

-30C 11 -

Charpy Unnotched, kJ/m2 179

23C 95 110

-30C 80 -

THERMAL ISO Test Method Dry Conditioned

Melting Point, C 3146 220 -

HDT A, C 75 210 -

HDT B, C 75 220 -

Coef. of Linear Thermal Expansion, Parallel, 0.23 X10-4 -

mm/mm C

Coef. of Linear Thermal Expansion, Normal, 0.65 X10-4 -

mm/mm C

ELECTRICAL ISO Test Method Dry Conditioned

Volume Resistivity IEC 60093 1E13 1E10

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 1 of 3

Ultramid® B3WG6

Dielectric Constant (1 MHz) IEC 60250 3.8 6.8

Dissipation Factor (1 MHz) IEC 60250 230 2,200

UL RATINGS UL Test Method Property Value

Relative Temperature Index, 0.75mm UL746B

Electrical, C 130

Flammability Rating, 1.5mm UL94 HB

Relative Temperature Index, 1.5mm UL746B

Mechanical w/o Impact, C 130

Mechanical w/ Impact, C 90

Electrical, C 130

Flammability Rating, 3.0mm UL94 HB

Relative Temperature Index, 3.0mm UL746B

Mechanical w/o Impact, C 130

Mechanical w/ Impact, C 95

Electrical, C 130

Processing Guidelines

Material Handling

Max. Water content: 0.15%

Material is supplied in sealed containers and drying prior to molding in a dehumidifying or desiccant

dryer is recommended. Drying parameters are dependent upon the actual percentage of moisture in

the pellets and typical pre-drying conditions are 2-4 hours at 180F (83C). Recommended moisture

levels for achieving optimum surface qualities and mechanical properties is 0.05% - 0.12%. Further

information concerning safe handling procedures can be obtained from the Safety Data Sheet

(MSDS), or by contacting your BASF representative.

Typical Profile

Melt Temperature 270-295 degC (518-563 degF)

Mold Temperature 80-95 degC (176-203 degF)

Injection and Packing Pressure 35-125 bar (500-1500 psi)

Mold Temperatures

This product can be processed over a wide range of mold temperatures; however, for applications

where aesthetics are critical, a mold surface temperature of 80-95 degC (176-203 degF) is

recommended.

Pressures

Injection pressure controls the filling of the part and should be applied for 90% of ram travel.

Packing pressure affects the final part and can be used effectively in controlling sink marks and

shrinkage. It should be applied and maintained until the gate area is completely frozen off.

Back pressure can be utilized to provide uniform melt consistency and reduce trapped air and gas.

Minimal back pressure should be utilized to prevent glass breakage.

Fill Rate

Fast fill rates are recommended to ensure uniform melt delivery to the cavity and prevent premature

freezing. Surface appearance is directly affected by injection rate.

Note

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 2 of 3

Ultramid® B3WG6

Note

Although all statements and information in this publication are believed to be accurate and reliable,

they are presented gratis and for guidance only, and risks and liability for results obtained by use of

the products or application of the suggestions described are assumed by the user. NO

WARRANTIES OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE MADE REGARDING

PRODUCTS DESCRIBED OR DESIGNS, DATA OR INFORMATION SET FORTH. Statements or

suggestions concerning possible use of the products are made without representation or warranty

that any such use is free of patent infringement and are not recommendations to infringe any

patent. The user should not assume that toxicity data and safety measures are indicated or that

other measures may not be required.

BASF Corporation General Information: 800-BC-RESIN

Engineering Plastics Technical Assistance: 800-527-TECH (734-324-5150)

1609 Biddle Avenue Web address: http://www.plasticsportal.com/usa

Wyandotte, MI 48192 Page 3 of 3

Das könnte Ihnen auch gefallen

- Ultramid A3WG7 IsoDokument3 SeitenUltramid A3WG7 IsoRiccardoNoch keine Bewertungen

- Ultrason E 3010: Polyethersulfone (PESU)Dokument2 SeitenUltrason E 3010: Polyethersulfone (PESU)AmirNoch keine Bewertungen

- ULTRADUR B4300G6 (03p023)Dokument3 SeitenULTRADUR B4300G6 (03p023)ayala castroNoch keine Bewertungen

- UltrasonS6010 IsoDokument2 SeitenUltrasonS6010 IsoKablayialijanNoch keine Bewertungen

- Abs - Terluran GP22Dokument2 SeitenAbs - Terluran GP22armandoNoch keine Bewertungen

- ABS Terluran GP35Dokument2 SeitenABS Terluran GP35Alan MoraisNoch keine Bewertungen

- Ultraform N2320 003 BK120 Q600Dokument2 SeitenUltraform N2320 003 BK120 Q600JoelNoch keine Bewertungen

- Abs - Terluran GP35Dokument2 SeitenAbs - Terluran GP35armandoNoch keine Bewertungen

- Sabic® PP 575P: PP Homopolymer For Injection MouldingDokument1 SeiteSabic® PP 575P: PP Homopolymer For Injection MouldingPrinchipi YounesNoch keine Bewertungen

- Ultradur B 4300 G4: ® PBT (Polybutylene Terephthalate)Dokument2 SeitenUltradur B 4300 G4: ® PBT (Polybutylene Terephthalate)irisNoch keine Bewertungen

- Styrolution TDS401600170785Dokument3 SeitenStyrolution TDS401600170785shahin_723Noch keine Bewertungen

- Novodur P2MC: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenNovodur P2MC: Acrylonitrile Butadiene Styrene (ABS)heliocoelhojrNoch keine Bewertungen

- Basf - C 218 v30 BlackDokument7 SeitenBasf - C 218 v30 BlackfernandoincesaNoch keine Bewertungen

- Styrolution TDS401000260275Dokument3 SeitenStyrolution TDS401000260275vicenteNoch keine Bewertungen

- Petra 130 SpecsDokument2 SeitenPetra 130 SpecssdecarlogaNoch keine Bewertungen

- Novodur H802: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenNovodur H802: Acrylonitrile Butadiene Styrene (ABS)Maribel GutierrezNoch keine Bewertungen

- TDS - Terluran GP-22 PDFDokument3 SeitenTDS - Terluran GP-22 PDFebercueNoch keine Bewertungen

- Terluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenTerluran GP-22: Acrylonitrile Butadiene Styrene (ABS)Mahdi VolgarNoch keine Bewertungen

- LUPOX TE5100: Description ApplicationDokument2 SeitenLUPOX TE5100: Description Applicationhugo santiago chavez godoyNoch keine Bewertungen

- Abs-Er460 EngDokument2 SeitenAbs-Er460 Engjdstore99Noch keine Bewertungen

- Styro Lution Tds 400900240714Dokument3 SeitenStyro Lution Tds 400900240714vrjrNoch keine Bewertungen

- 4lex® 10F10000Dokument3 Seiten4lex® 10F10000srinivasaNoch keine Bewertungen

- Styrolution Basf Terluran GP-22Dokument3 SeitenStyrolution Basf Terluran GP-22medo.k016Noch keine Bewertungen

- Astm Lupol gp3156f - EngDokument2 SeitenAstm Lupol gp3156f - EngYo ANoch keine Bewertungen

- Novodur P2H-ATDokument3 SeitenNovodur P2H-ATavinashchauhan2695Noch keine Bewertungen

- Ultraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Dokument2 SeitenUltraform N 2320 003 UNC Q600: Polyoxymethylene (POM)Phuoc Thinh TruongNoch keine Bewertungen

- StyrolutionTDS400700190196 PDFDokument3 SeitenStyrolutionTDS400700190196 PDFMirella FaresNoch keine Bewertungen

- Grivory GVX 5h Nat - Mds - enDokument5 SeitenGrivory GVX 5h Nat - Mds - enJohn KingNoch keine Bewertungen

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Dokument3 SeitenStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNoch keine Bewertungen

- Styro Lution Tds 401200140448Dokument3 SeitenStyro Lution Tds 401200140448scribdNoch keine Bewertungen

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Dokument3 SeitenStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNoch keine Bewertungen

- ABS LG HI21H. Rev.01Dokument2 SeitenABS LG HI21H. Rev.01Ivan TimarevNoch keine Bewertungen

- LEXAN™ FR Resin 916R - EuropeDokument3 SeitenLEXAN™ FR Resin 916R - EuropesrinivasaNoch keine Bewertungen

- Kapton HN Data SheetDokument5 SeitenKapton HN Data Sheet谢朋亨Noch keine Bewertungen

- POLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetDokument2 SeitenPOLICARBONATO LEXAN™ Resin - 123R - Europe - Technical - Data - SheetscribdNoch keine Bewertungen

- PC Makrolon 2458 - 2006Dokument4 SeitenPC Makrolon 2458 - 2006countzeroaslNoch keine Bewertungen

- Luran 368R: Technical DatasheetDokument3 SeitenLuran 368R: Technical DatasheetVictor PuertoNoch keine Bewertungen

- B70 S Natural S1: Badamid®Dokument2 SeitenB70 S Natural S1: Badamid®hocineNoch keine Bewertungen

- Victrex PEEK 450FE20: Conditions Test Method Units Typical ValueDokument2 SeitenVictrex PEEK 450FE20: Conditions Test Method Units Typical ValueRohan KulkarniNoch keine Bewertungen

- 2.2.Tds Astm-Abs Lgchem Hi121Dokument2 Seiten2.2.Tds Astm-Abs Lgchem Hi121Wilda Sania MtNoch keine Bewertungen

- POM Delrin 500Dokument2 SeitenPOM Delrin 500countzeroaslNoch keine Bewertungen

- Terluran HI-10: Acrylonitrile Butadiene Styrene (ABS)Dokument3 SeitenTerluran HI-10: Acrylonitrile Butadiene Styrene (ABS)bobNoch keine Bewertungen

- Hoja Tecnica ASADokument2 SeitenHoja Tecnica ASAFernando AngioliniNoch keine Bewertungen

- PP Compound - PP15T1020Dokument2 SeitenPP Compound - PP15T1020Chaimae HanynyNoch keine Bewertungen

- LEXAN™ Resin - 141R - Europe - Technical - Data - SheetDokument2 SeitenLEXAN™ Resin - 141R - Europe - Technical - Data - SheetMinh Quãng PhạmNoch keine Bewertungen

- Styrolution PS 476L: Technical DatasheetDokument3 SeitenStyrolution PS 476L: Technical DatasheetTRUONGNoch keine Bewertungen

- Luran S 778T: Acrylonitrile Styrene Acrylate (ASA)Dokument3 SeitenLuran S 778T: Acrylonitrile Styrene Acrylate (ASA)jineshdmehtaNoch keine Bewertungen

- Technyl Star® A 205F Natural SDokument3 SeitenTechnyl Star® A 205F Natural STiago GalloNoch keine Bewertungen

- YEE70G30HSLNCDokument2 SeitenYEE70G30HSLNCRanjan GnanaoliNoch keine Bewertungen

- PBT GF30 enDokument1 SeitePBT GF30 enSteven Rojas JerezNoch keine Bewertungen

- Abs Xr409H: Description ApplicationDokument2 SeitenAbs Xr409H: Description ApplicationPhuoc Thinh TruongNoch keine Bewertungen

- VictrexTDS150G 151GDokument2 SeitenVictrexTDS150G 151GKumaar RanjanNoch keine Bewertungen

- Victrex™ Peek 450G™: Product DescriptionDokument2 SeitenVictrex™ Peek 450G™: Product DescriptionBerkant CangalNoch keine Bewertungen

- LG Abs - Hi100hDokument2 SeitenLG Abs - Hi100hqshakimNoch keine Bewertungen

- Bayblend T85 XF ISO enDokument3 SeitenBayblend T85 XF ISO enryanNoch keine Bewertungen

- Bayblend T88 GF 20 - en - 56968672 00003567 20081863Dokument3 SeitenBayblend T88 GF 20 - en - 56968672 00003567 20081863Mattia Terri TerrandoNoch keine Bewertungen

- Abs XR 404 LGDokument2 SeitenAbs XR 404 LGLeandro LacerdaNoch keine Bewertungen

- Durethan BKV240 H20 XCP901510 ISOinternetDokument3 SeitenDurethan BKV240 H20 XCP901510 ISOinternetshahin_723Noch keine Bewertungen

- Luran HH-120: Please SelectDokument3 SeitenLuran HH-120: Please SelectDavid Costi da RosaNoch keine Bewertungen

- PVAR Catalog PDFDokument16 SeitenPVAR Catalog PDFrenebbNoch keine Bewertungen

- NGT Thread Series: Total Solution For Thread GaugingDokument2 SeitenNGT Thread Series: Total Solution For Thread Gaugingrenebb100% (1)

- Design and Testing of Unbalanced Mass Mechanical Vibration ExciterDokument7 SeitenDesign and Testing of Unbalanced Mass Mechanical Vibration ExciterrenebbNoch keine Bewertungen

- Chapter 16 Compressible Flow: 16.1 Speed of SoundDokument42 SeitenChapter 16 Compressible Flow: 16.1 Speed of SoundrenebbNoch keine Bewertungen

- ASME Section VIII Rules For Construction of Pressure Vessels Division 1Dokument820 SeitenASME Section VIII Rules For Construction of Pressure Vessels Division 1renebb100% (1)

- Screw 1942Dokument254 SeitenScrew 1942renebbNoch keine Bewertungen

- Ultramid B3WG6Dokument3 SeitenUltramid B3WG6renebbNoch keine Bewertungen

- N GT, SGT : TABLE IX.6. - Dtmensions of Plug (External Q P P H XDokument1 SeiteN GT, SGT : TABLE IX.6. - Dtmensions of Plug (External Q P P H XrenebbNoch keine Bewertungen

- Snap-Fit Design ManualDokument24 SeitenSnap-Fit Design ManualrenebbNoch keine Bewertungen

- Deflection of Symmetric Beams: Chapter SevenDokument49 SeitenDeflection of Symmetric Beams: Chapter SevenrenebbNoch keine Bewertungen

- Y77G33LKDokument1 SeiteY77G33LKrenebbNoch keine Bewertungen

- FastRite2012 FittingsCatalogDokument425 SeitenFastRite2012 FittingsCatalogrenebbNoch keine Bewertungen

- Donatelle Ch03Dokument25 SeitenDonatelle Ch03renebb100% (1)

- SBI Clerk Mains Bolt 2023 OliveboardDokument160 SeitenSBI Clerk Mains Bolt 2023 OliveboardMaahi ThakorNoch keine Bewertungen

- Mouse 200Dokument2 SeitenMouse 200Amjad AliNoch keine Bewertungen

- Camsco Breaker PDFDokument12 SeitenCamsco Breaker PDFMichael MaiquemaNoch keine Bewertungen

- Average - Aptitude MCQ Questions and Solutions Wit - 1597107113795Dokument6 SeitenAverage - Aptitude MCQ Questions and Solutions Wit - 1597107113795Manish ChavannavarNoch keine Bewertungen

- 中国铁路客运枢纽发展回顾与展望 王昊Dokument9 Seiten中国铁路客运枢纽发展回顾与展望 王昊qiqiaorongNoch keine Bewertungen

- Seismic Data AcquisitionDokument14 SeitenSeismic Data Acquisitionjoao kiala100% (1)

- 2537 - York YCAS 690Dokument11 Seiten2537 - York YCAS 690Md JamilNoch keine Bewertungen

- DH Xvr4b16Dokument3 SeitenDH Xvr4b16Jumar JumadiaoNoch keine Bewertungen

- Handheld YokogawaDokument38 SeitenHandheld YokogawaArturo Gasperin BarrigaNoch keine Bewertungen

- Mix Design PosterDokument1 SeiteMix Design PosterAbhilash KumarNoch keine Bewertungen

- Brochure A35g A40g t4f en 22 20050840 DDokument20 SeitenBrochure A35g A40g t4f en 22 20050840 DRengga PratamaNoch keine Bewertungen

- ASSA ABLOY - Digital Cam LocksDokument12 SeitenASSA ABLOY - Digital Cam LocksSales Project 2 VCPNoch keine Bewertungen

- White BoxDokument9 SeitenWhite BoxAmitsonu222Noch keine Bewertungen

- d350 Taper Lock End Anchor Tech Data SheetDokument2 Seitend350 Taper Lock End Anchor Tech Data SheetEdsantadNoch keine Bewertungen

- LIVING IN THE IT ERA (Introduction)Dokument9 SeitenLIVING IN THE IT ERA (Introduction)johnnyboy.galvanNoch keine Bewertungen

- 9500MPR - MEF8 Circuit Emulation ServicesDokument5 Seiten9500MPR - MEF8 Circuit Emulation ServicesedderjpNoch keine Bewertungen

- Chapter 7 Series Parallel CircuitsDokument70 SeitenChapter 7 Series Parallel CircuitsAbdullrahman Al-ShammaaNoch keine Bewertungen

- Zeal High Precision Wet Test Gas Flow Meters 2022Dokument5 SeitenZeal High Precision Wet Test Gas Flow Meters 2022Hiran ChathurangaNoch keine Bewertungen

- HL780 9SDokument583 SeitenHL780 9SAnonymous yjK3peI7100% (3)

- HGU User ManualDokument72 SeitenHGU User Manuallomayani100% (1)

- The Impact of Internet Use For StudentsDokument8 SeitenThe Impact of Internet Use For StudentsCharlesNoch keine Bewertungen

- Infile StatementDokument21 SeitenInfile StatementNagarjuna Parvatala100% (1)

- Transition SignalsDokument10 SeitenTransition Signalshana nixmaNoch keine Bewertungen

- Rotation Gearbox Component Fig 1Dokument2 SeitenRotation Gearbox Component Fig 1Mohamed RashedNoch keine Bewertungen

- A Modified Vince Gingery PlasticDokument13 SeitenA Modified Vince Gingery PlasticgeppaNoch keine Bewertungen

- Pest Analysis of Telecom IndustryDokument6 SeitenPest Analysis of Telecom IndustryAymanCheema70% (10)

- Johannes Gensfleisch Zur Laden Zum GutenbergDokument2 SeitenJohannes Gensfleisch Zur Laden Zum GutenbergNathan SidabutarNoch keine Bewertungen

- Ne40 Ne80 PDFDokument192 SeitenNe40 Ne80 PDFณัชชา ธนปัญจาภรณ์Noch keine Bewertungen

- RAC D Expansion DevicesDokument21 SeitenRAC D Expansion DevicesSohaib IrfanNoch keine Bewertungen

- Database Upgrade 10g To 11gDokument28 SeitenDatabase Upgrade 10g To 11gSubhasis1928Noch keine Bewertungen