Beruflich Dokumente

Kultur Dokumente

Petroleum Development Oman L.L.C.: Method Statement For Lifting Operation

Hochgeladen von

preventing becejOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Petroleum Development Oman L.L.C.: Method Statement For Lifting Operation

Hochgeladen von

preventing becejCopyright:

Verfügbare Formate

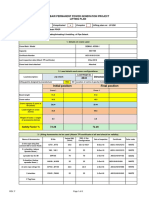

Petroleum Development Oman L.L.C.

METHOD STATEMENT FOR LIFTING OPERATION

PROJECT

ACTIVITY

Lifting Category Routine / Non routine Location / RIG No

PERMIT NO: Total weight

CONTARCTOR

To ensure the safety of the personnel/ equipment/ asset involved in lifting

OBJECTIVE

activities

Deploy individuals with valid certifications (Crane operator, lifting

supervisor & riggers)

MAN POWER

A designated lifting supervisor (person in charge PIC and banks man

who wear a colored vest)

Banks man / Signaler: Co-ordinate the lifting movements and maintains

radio- and/or visual communication with crane operator and persons close to

the load

Slinger /Rigger: Inspect the rigging, select rigging to suit the load, install

the equipment and connect/disconnect the load

RESPONSIBILITIES Lifting supervisor (PIC): Co-ordinate and control all aspects of lifting

operations on site. ( Banks man can be PIC if he is competent)

Crane Operator: Pre-use inspection of crane and rig up of the crane;

operating the crane and perform the lift in a safe manner taking the signals

from the Banksman / Signaler only, unless in an emergency situation.

Lifting Equipment with a valid third party certification only as per PR

EQUIPMENT

1708 / SP2275

Position the crane as close as possible to the load

Barricade the location

Verify the load chart and ensure that the distance between load and crane

are in the safe limit.

Fix the load to the crane hook using the correct method of rigging

PROCEDURE as per depending on the shape of the load

SP-2273 lift planning Gradually lift and hold for a while to ensure the stability of load and

and execution crane

If stable execute the lifting operation.

Ensure that a single banks man is communicating with the operator

Ensure that the hook is disengaged only after the load is positioned and

secured properly.

10 QUESTIONS FOR A SAFE LIFT

NO DESCRIPTION Yes No

Is everyone aware of and do they fully understand the lifting and hoisting

01

procedures applicable to the lift?

02 Has everyone attended the toolbox talk?

Has a pre-use inspection of the Lifting Equipment been carried out and are

the Lifting Accessories tagged or marked with:

03 - Safe Working Load

- A unique identification number

- A valid certification date

04 Are all safety devices working?

05 Does everyone know the Person-in-Charge of the lift?

06 Is everyone competent and aware of his or her tasks?

Is there a current Lift Plan and JHA and does everybody understand the

07

job and precautions?

Does everyone know the environmental limits (e.g. maximum permissible

08

wind speed) for the lift?

09 Is the lift area controlled and is everyone clear if the load falls or swings?

10 Are signaling methods and communication agreed and clear to you?

Sketch/calculation of lifting plan mentioning load, radius, boom length

and capacity of crane.

Load chart

Risk assessment*.

Attachment Lifting crew permits

Lifting equipment certificates i.e. cranes and lifting gears.

*For NON routine operation step-by-step instruction with a specific TRA

shall be attached.

Note: Never start any lifting operation until all concerned have been briefed in a Pre-Start Meeting, ensuring that they

understand their role and responsibilities and that they have signed onto the Permit-to-Work or record of attendance at the

Pre-Start Meeting.

Acknowledgment:

We acknowledge that have verified this method statement against the activities stated in this statement without any

deviation. This method statement will be discussed during the (TBT) discussion.

Name Signature Date

Lift plan preparer

Lift plan reviewer

Approved by

Das könnte Ihnen auch gefallen

- African Traditional Medicine A PrimerDokument5 SeitenAfrican Traditional Medicine A PrimerEditor IJTSRDNoch keine Bewertungen

- Lifting 50 RedaDokument1 SeiteLifting 50 Redausman khalid0% (1)

- Mobile Crane Lifting Plan - Routine Operation1Dokument2 SeitenMobile Crane Lifting Plan - Routine Operation1Becha MouradNoch keine Bewertungen

- Lifting Procedure Rev.4Dokument49 SeitenLifting Procedure Rev.4wendypost73100% (5)

- Critical Lift Plan For Pile Load Test-2Dokument14 SeitenCritical Lift Plan For Pile Load Test-2sivakumarNoch keine Bewertungen

- Science Grade 7: Active Reading Note-Taking GuideDokument140 SeitenScience Grade 7: Active Reading Note-Taking Guideurker100% (1)

- AppointedPerson CalculationTemplateDokument5 SeitenAppointedPerson CalculationTemplateviniciusgdelimaNoch keine Bewertungen

- A Lifting Plan Using ExcavatorDokument1 SeiteA Lifting Plan Using ExcavatorSyed Fawad ShahNoch keine Bewertungen

- GBP Calculation Kobelco 7300Dokument2 SeitenGBP Calculation Kobelco 7300Gorga Simamora0% (1)

- Crane Work Method Statement - Compressed NewDokument15 SeitenCrane Work Method Statement - Compressed NewAvinashNoch keine Bewertungen

- Lifting Plan: General Information: LP - 01 / Rev 00Dokument8 SeitenLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNoch keine Bewertungen

- Complex Lift Plan and ChecklistDokument3 SeitenComplex Lift Plan and Checklistsudeesh kumar100% (1)

- SWP 04 Lifting OperationDokument4 SeitenSWP 04 Lifting Operationমমিন মানবNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument5 SeitenSafe Work Method Statement Worksheetgoodspeed_phNoch keine Bewertungen

- TBA NA: Lifting and Hoisting PlanDokument4 SeitenTBA NA: Lifting and Hoisting Planikponmwonsa67% (3)

- Lifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaDokument100 SeitenLifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaPhilip AdewunmiNoch keine Bewertungen

- Hoisting and Rigging - Lift Planning and Control For Ordinary LiftsDokument5 SeitenHoisting and Rigging - Lift Planning and Control For Ordinary Liftscyno21Noch keine Bewertungen

- Petroleum Development Oman: Lift Plan For Lifting OperationDokument7 SeitenPetroleum Development Oman: Lift Plan For Lifting OperationVuthpalachaitanya KrishnaNoch keine Bewertungen

- Sample Lifting Plan 300909Dokument5 SeitenSample Lifting Plan 300909sugiyantoNoch keine Bewertungen

- Rigging Plan Cement Silo+Crane 45Dokument96 SeitenRigging Plan Cement Silo+Crane 45rtyuibnm86% (21)

- Method Statement For BR445 Lifting PlanDokument28 SeitenMethod Statement For BR445 Lifting PlanJuan Dela Cruz100% (3)

- Method Statement For Installation of Access ScafoldingDokument9 SeitenMethod Statement For Installation of Access Scafoldingbureau servicesNoch keine Bewertungen

- Lifting Plan of Generator Set at C.B SPL MahakamDokument10 SeitenLifting Plan of Generator Set at C.B SPL MahakamAditya Permana PutraNoch keine Bewertungen

- Lifting Plan Blank (PDF Library)Dokument4 SeitenLifting Plan Blank (PDF Library)Alina UribeNoch keine Bewertungen

- Lifting Plan FormDokument2 SeitenLifting Plan FormezuanNoch keine Bewertungen

- Lifting PlanDokument2 SeitenLifting PlansivaavissriNoch keine Bewertungen

- Upper Mast Section Lifting PlanDokument7 SeitenUpper Mast Section Lifting PlanDurgham Adel EscanderNoch keine Bewertungen

- Lift PlanningDokument23 SeitenLift PlanningFaiyazNoch keine Bewertungen

- Gas Turbine and Generator UnloadingDokument9 SeitenGas Turbine and Generator Unloadingamritrj444Noch keine Bewertungen

- Clinical Crown Lengthening in The Esthetic Zone2028Dokument12 SeitenClinical Crown Lengthening in The Esthetic Zone2028AchyutSinhaNoch keine Bewertungen

- Construction Lifting PlanDokument5 SeitenConstruction Lifting PlanJuma KavesuNoch keine Bewertungen

- Matter and Change 2008 Chapter 14Dokument40 SeitenMatter and Change 2008 Chapter 14cattmy100% (1)

- G18-2-LP-003 DG - Lifting PlanDokument25 SeitenG18-2-LP-003 DG - Lifting PlanMohammed JassimNoch keine Bewertungen

- Generic Method Statement For Routine LiftingDokument3 SeitenGeneric Method Statement For Routine Liftingmuhammad umarNoch keine Bewertungen

- User Manual: Samsung Medison Diagnostic Ultrasound SystemDokument686 SeitenUser Manual: Samsung Medison Diagnostic Ultrasound SystemHuế Trần100% (1)

- Mobile Crane Lifting Plan SheetDokument2 SeitenMobile Crane Lifting Plan SheetBagus Dwi0% (1)

- Lift Plan - Method Statement - Risk Assessment - SafetyCultureDokument21 SeitenLift Plan - Method Statement - Risk Assessment - SafetyCulturebalachander100% (1)

- Kristen Swanson's Theory of CaringDokument12 SeitenKristen Swanson's Theory of CaringAlexandria David50% (2)

- CLP 1 & CLP2 Critical Lift Plan (350T & 100T)Dokument2 SeitenCLP 1 & CLP2 Critical Lift Plan (350T & 100T)babjihanumanthu100% (2)

- Lifting Plan Registration PDFDokument1 SeiteLifting Plan Registration PDFScribdTranslationsNoch keine Bewertungen

- NLP 296 LoadingUnloading Positioning of Pipe Stack 500TDokument8 SeitenNLP 296 LoadingUnloading Positioning of Pipe Stack 500TAhmed AliNoch keine Bewertungen

- Lifting ProcedureDokument25 SeitenLifting ProcedureAkmal Yassin100% (1)

- Crane Load ChartDokument4 SeitenCrane Load ChartPT Bahtera AgungNoch keine Bewertungen

- 12 - Method Statement For Steel Structure ErectionDokument5 Seiten12 - Method Statement For Steel Structure ErectionidzwanNoch keine Bewertungen

- SPLASH Lifting Plan 175040419Dokument2 SeitenSPLASH Lifting Plan 175040419mohamed atef100% (1)

- SOP Installation of Lifeline Rev. 01Dokument30 SeitenSOP Installation of Lifeline Rev. 01Fahrizal NurNoch keine Bewertungen

- Crane Lifting PlanDokument20 SeitenCrane Lifting Plan101ar85% (13)

- Lifting Plan AgcDokument8 SeitenLifting Plan Agcragesh p rNoch keine Bewertungen

- Crane Stability and Ground PressureDokument14 SeitenCrane Stability and Ground PressureameerNoch keine Bewertungen

- 1a. Lifting Data Sheet (Cage 24m)Dokument4 Seiten1a. Lifting Data Sheet (Cage 24m)Mohd FadliNoch keine Bewertungen

- OHDC Lifting ProcedureDokument12 SeitenOHDC Lifting ProcedureHamid Ali100% (1)

- PR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationDokument113 SeitenPR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and Certificationmac1677Noch keine Bewertungen

- Souvenir Mushrooms 1986Dokument106 SeitenSouvenir Mushrooms 1986Ankit MishraNoch keine Bewertungen

- PMF 015 HSE 151 v1 Lifting PlanDokument8 SeitenPMF 015 HSE 151 v1 Lifting Plansikandar1234Noch keine Bewertungen

- Module 3 Passive Heating 8.3.18Dokument63 SeitenModule 3 Passive Heating 8.3.18Aman KashyapNoch keine Bewertungen

- 200 State Council Members 2010Dokument21 Seiten200 State Council Members 2010madhu kanna100% (1)

- Statement For Routine Lifting: (XXX Room For Your Own Numbering System)Dokument3 SeitenStatement For Routine Lifting: (XXX Room For Your Own Numbering System)Mark Julius CabasanNoch keine Bewertungen

- Outrigger Pads Brochure Low ResDokument8 SeitenOutrigger Pads Brochure Low Resfcesar1986Noch keine Bewertungen

- Critical & General LiftingDokument9 SeitenCritical & General LiftingVikash Kumar RayNoch keine Bewertungen

- Loading-Unloading-Low-Loader Risk AssmntDokument10 SeitenLoading-Unloading-Low-Loader Risk AssmntStansilous Tatenda NyagomoNoch keine Bewertungen

- Slip Form (Our Report)Dokument16 SeitenSlip Form (Our Report)Simran DeepNoch keine Bewertungen

- Tools & Tackles Monthly InspectionDokument4 SeitenTools & Tackles Monthly InspectionDeepu ChandranNoch keine Bewertungen

- Crane Derating FactorsDokument1 SeiteCrane Derating FactorsvishnuNoch keine Bewertungen

- Contoh LIfting Plan #1Dokument5 SeitenContoh LIfting Plan #1KevinNoch keine Bewertungen

- Wire Rope Cutting ChartDokument8 SeitenWire Rope Cutting ChartAkash SharmaNoch keine Bewertungen

- Pilling Machine ChecklistDokument3 SeitenPilling Machine Checklisttanoycomet100% (1)

- Lifting Operations Toolbox TalkDokument2 SeitenLifting Operations Toolbox TalkMohammed Amer PashaNoch keine Bewertungen

- PlanDokument30 SeitenPlanMorad M SwidNoch keine Bewertungen

- Safe Lifting Paln - (Yuanju)Dokument4 SeitenSafe Lifting Paln - (Yuanju)কাজি আরিফNoch keine Bewertungen

- Policy: Short Service EmployeeDokument12 SeitenPolicy: Short Service Employeepreventing becejNoch keine Bewertungen

- Company Policy For Occupational Noise Exposure: E & B Oilfield Services IncDokument10 SeitenCompany Policy For Occupational Noise Exposure: E & B Oilfield Services Incpreventing becejNoch keine Bewertungen

- Doirc Lateral Learning: Crane Cabin Struck by LoadDokument1 SeiteDoirc Lateral Learning: Crane Cabin Struck by Loadpreventing becejNoch keine Bewertungen

- Control of Work (Cow)Dokument2 SeitenControl of Work (Cow)preventing becejNoch keine Bewertungen

- Policy: Noise ExposureDokument6 SeitenPolicy: Noise Exposurepreventing becejNoch keine Bewertungen

- Reader Registration Form PDFDokument2 SeitenReader Registration Form PDFpreventing becejNoch keine Bewertungen

- Preventative Maintenance ProceduresDokument2 SeitenPreventative Maintenance Procedurespreventing becejNoch keine Bewertungen

- Policy: Pre-Employment Testing ProceduresDokument4 SeitenPolicy: Pre-Employment Testing Procedurespreventing becejNoch keine Bewertungen

- Pigging ProceduresDokument3 SeitenPigging Procedurespreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument2 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument2 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument3 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- Policy Reference ResponsibilitiesDokument6 SeitenPolicy Reference Responsibilitiespreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument3 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument2 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- Policy: All EmployeesDokument22 SeitenPolicy: All Employeespreventing becejNoch keine Bewertungen

- 2 PDFDokument3 Seiten2 PDFpreventing becejNoch keine Bewertungen

- Hazard Identification and Assessment: PurposeDokument4 SeitenHazard Identification and Assessment: Purposepreventing becejNoch keine Bewertungen

- E & B Oilfield Services Inc. PHMSA/DOT Substance Abuse Prevention PlanDokument6 SeitenE & B Oilfield Services Inc. PHMSA/DOT Substance Abuse Prevention Planpreventing becejNoch keine Bewertungen

- BS Pharmacy - ProspectusDokument9 SeitenBS Pharmacy - ProspectusDomz BucadNoch keine Bewertungen

- Prednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialDokument11 SeitenPrednisolone Versus Dexamethasone For Croup: A Randomized Controlled TrialA Joel ZjNoch keine Bewertungen

- Monthly Hse Report Nhai Org inDokument12 SeitenMonthly Hse Report Nhai Org inPhilip S. GongarNoch keine Bewertungen

- Textile Chemical Brochure 8.6.22 - 031Dokument1 SeiteTextile Chemical Brochure 8.6.22 - 031NIKESH PRAKASHNoch keine Bewertungen

- CHN REVIEWER LESSON 1 and 2Dokument9 SeitenCHN REVIEWER LESSON 1 and 2Imogen MasumiNoch keine Bewertungen

- Micromechanical Testing of Thin Die: (Nordson DAGE UK)Dokument2 SeitenMicromechanical Testing of Thin Die: (Nordson DAGE UK)Thanalachmy GopiNoch keine Bewertungen

- (R#1) XQ-450 - 600-800VDokument121 Seiten(R#1) XQ-450 - 600-800VFrancisco PestañoNoch keine Bewertungen

- Hygold 5000Bs: Base Oil Marketing SpecificationDokument1 SeiteHygold 5000Bs: Base Oil Marketing Specificationsamsoon80100% (1)

- Multiscale Modeling of Bone Tissue MechanobiologyDokument12 SeitenMultiscale Modeling of Bone Tissue MechanobiologyLina AvilaNoch keine Bewertungen

- Data Sheet HFE-7000 Prod SpecDokument6 SeitenData Sheet HFE-7000 Prod Specsshaffer_9Noch keine Bewertungen

- TRAFFIC RULES PDF Project ReportDokument18 SeitenTRAFFIC RULES PDF Project ReportShweta SharmaNoch keine Bewertungen

- Filipino Concept of Health and IllnessDokument43 SeitenFilipino Concept of Health and IllnessFelisa Lacsamana Gregorio50% (2)

- A Research Presented ToDokument28 SeitenA Research Presented ToAngeliePanerioGonzagaNoch keine Bewertungen

- Victron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedDokument19 SeitenVictron Orion-Tr - Smart - DC-DC - Charger-Manual Non IsolatedThomist AquinasNoch keine Bewertungen

- 04 TitrimetryDokument7 Seiten04 TitrimetryDarwin Fetalbero ReyesNoch keine Bewertungen

- Measurement LabDokument4 SeitenMeasurement LabHenessa GumiranNoch keine Bewertungen

- Construction Regulations, 2014 PDFDokument58 SeitenConstruction Regulations, 2014 PDFbubele pamlaNoch keine Bewertungen

- Achai, Sydney Jill S. GE 15 - SIM - ULOcDokument13 SeitenAchai, Sydney Jill S. GE 15 - SIM - ULOcSydney AchaiNoch keine Bewertungen

- Pathology SEQ Answers - Adaptive Responses & Cell InjuryDokument7 SeitenPathology SEQ Answers - Adaptive Responses & Cell InjurysugandiNoch keine Bewertungen

- Osmotic Power Generation: Prepared byDokument16 SeitenOsmotic Power Generation: Prepared byPritam MishraNoch keine Bewertungen

- Peritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionDokument10 SeitenPeritoneal Dialysis Unit Renal Department SGH PD WPI 097 Workplace InstructionAjeng SuparwiNoch keine Bewertungen