Beruflich Dokumente

Kultur Dokumente

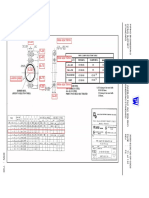

ASME B31.3-2016 Postweld Heat Treatment Table

Hochgeladen von

Sumner TingOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ASME B31.3-2016 Postweld Heat Treatment Table

Hochgeladen von

Sumner TingCopyright:

Verfügbare Formate

ASME B31.

3-2016

Table 331.1.1 Postweld Heat Treatment (16)

Minimum Holding Time at Temperature for

P-No. and Group No. Holding Temperature Range, Control Thickness [Note (2)]

(BPV Code Section IX, QW/QB-420) °C (°F) [Note (1)] Up to 50 mm (2 in.) Over 50 mm (2 in.)

P-No. 1, Group Nos. 1–3 595 to 650 (1,100 to 1,200) 1 h/25 mm (1 hr/in.); 2 hr plus 15 min for each

P-No. 3, Group Nos. 1 and 2 595 to 650 (1,100 to 1,200) 15 min min. additional 25 mm (in.)

P-No. 4, Group Nos. 1 and 2 650 to 705 (1,200 to 1,300) over 50 mm (2 in.)

P-No. 5A, Group No. 1 675 to 760 (1,250 to 1,400)

P-No. 5B, Group No. 1 675 to 760 (1,250 to 1,400)

P-No. 6, Group Nos. 1–3 760 to 800 (1,400 to 1,475)

P-No. 7, Group Nos. 1 and 2 [Note (3)] 730 to 775 (1,350 to 1,425)

P-No. 8, Group Nos. 1–4 PWHT not required unless required by WPS

P-No. 9A, Group No. 1 595 to 650 (1,100 to 1,200)

P-No. 9B, Group No. 1 595 to 650 (1,100 to 1,200)

P-No. 10H, Group No. 1 PWHT not required unless required by

WPS. If done, see Note (4).

P-No. 10I, Group No. 1 [Note (3)] 730 to 815 (1,350 to 1,500)

P-No. 11A 550 to 585 (1,025 to 1,085) [Note (5)]

P-No. 15E, Group No. 1 705 to 775 (1,300 to 1,425) 1 h/25 mm (1 hr/in.); 1 h/25 mm (1 hr/in.) up

[Notes (6) and (7)] 30 min min. to 125 mm (5 in.) plus

15 min for each addi-

tional 25 mm (in.) over

125 mm (5 in.)

P-No. 62 540 to 595 (1,000 to 1,100) ... See Note (8)

All other materials PWHT as required by WPS In accordance with WPS In accordance with WPS

GENERAL NOTE: The exemptions for mandatory PWHT are defined in Table 331.1.3.

NOTES:

(1) The holding temperature range is further defined in para. 331.1.6(c) and Table 331.1.2.

(2) The control thickness is defined in para. 331.1.3.

(3) Cooling rate shall not be greater than 55°C (100°F) per hour in the range above 650°C (1,200°F), after which the cooling rate shall be

sufficiently rapid to prevent embrittlement.

(4) If PWHT is performed after welding, it shall be within the following temperature ranges for the specific alloy, followed by rapid cooling:

Alloys S31803 and S32205 — 1 020°C to 1 100°C (1,870°F to 2,010°F)

Alloy S32550 — 1 040°C to 1 120°C (1,900°F to 2,050°F)

Alloy S32750 — 1 025°C to 1 125°C (1,880°F to 2,060°F)

All others — 980°C to 1 040°C (1,800°F to 1,900°F).

(5) Cooling rate shall be >165°C (300°F)/h to 315°C (600°F)/h.

(6) The minimum PWHT holding temperature may be 675°C (1,250°F) for nominal material thicknesses [see para. 331.1.3(c)]

≤13 mm (1⁄2 in.).

(7) The Ni + Mn content of the filler metal shall not exceed 1.2% unless specified by the designer, in which case the maximum tempera-

ture to be reached during PWHT shall be the A1 (lower transformation or lower critical temperature) of the filler metal, as determined by

analysis and calculation or by test, but not exceeding 800°C (1,470°F). If the 800°C (1,470°F) limit was not exceeded but the A1 of the

filler metal was exceeded or if the composition of the filler metal is unknown, the weld must be removed and replaced. It shall then be

rewelded with compliant filler metal and subjected to a compliant PWHT. If the 800°C (1,470°F) limit was exceeded, the weld and the

entire area affected by the PWHT will be removed and, if reused, shall be renormalized and tempered prior to reinstallation.

(8) Heat treat within 14 days after welding. Hold time shall be increased by 1.2 h for each 25 mm (1 in.) over 25 mm (1 in.) thickness.

Cool to 425°C (800°F) at a rate ≤280°C (500°F).

Das könnte Ihnen auch gefallen

- QAPDokument31 SeitenQAPlohitha100% (1)

- QC - 08 PTCDokument5 SeitenQC - 08 PTCmahendraNoch keine Bewertungen

- Hot Dip Coating, CladdingDokument18 SeitenHot Dip Coating, Claddingazim turanNoch keine Bewertungen

- Curriculum Vitae QA Engineer Joseph FisherDokument8 SeitenCurriculum Vitae QA Engineer Joseph FisherAbdulNoch keine Bewertungen

- Section13 Spark TestingDokument3 SeitenSection13 Spark TestingGustavoNoch keine Bewertungen

- Cryogenic Processes and Their ApplicationsDokument12 SeitenCryogenic Processes and Their ApplicationsRaghavendra Raghav100% (2)

- ASME P-Numbers 1Dokument2 SeitenASME P-Numbers 1SH1961Noch keine Bewertungen

- Exam Narative Cswip 3.2Dokument5 SeitenExam Narative Cswip 3.2yuwantoniNoch keine Bewertungen

- Modul Tambahan Kualifikasi Las (KL)Dokument27 SeitenModul Tambahan Kualifikasi Las (KL)Nurhamsyah Susianto0% (1)

- A Brief Synopsis ofDokument54 SeitenA Brief Synopsis ofNO ONENoch keine Bewertungen

- PWHTDokument3 SeitenPWHTharishcsharmaNoch keine Bewertungen

- Sbtis Model Question Part 1Dokument48 SeitenSbtis Model Question Part 1ganeshNoch keine Bewertungen

- PFIDokument2 SeitenPFIYulianus SReaNoch keine Bewertungen

- Drawing B BS 499 Part. 2Dokument10 SeitenDrawing B BS 499 Part. 2محمد اظهرNoch keine Bewertungen

- Highlight HDG Inspection CoursaaaaaaaaaaaaaaaaaDokument44 SeitenHighlight HDG Inspection CoursaaaaaaaaaaaaaaaaaAyman Hamed MalahNoch keine Bewertungen

- Production Test CouponDokument4 SeitenProduction Test CouponAbhijeet SahuNoch keine Bewertungen

- 2005 Stainless SteelsDokument76 Seiten2005 Stainless SteelsAnonymous 98vSKYTaDgNoch keine Bewertungen

- JG SUMMIT NAPHTHA CRACKER PROJECT PIPING MATERIAL SPECIFICATIONDokument6 SeitenJG SUMMIT NAPHTHA CRACKER PROJECT PIPING MATERIAL SPECIFICATIONOliver SanvictoresNoch keine Bewertungen

- Fdocuments - in Introduction To Static Equipment in Oil and Gas Industry Engineer in OperatingDokument95 SeitenFdocuments - in Introduction To Static Equipment in Oil and Gas Industry Engineer in OperatingRajaramNoch keine Bewertungen

- Heat treatment SS clad CS to prevent sensitisationDokument3 SeitenHeat treatment SS clad CS to prevent sensitisationarifhonNoch keine Bewertungen

- API 570 Piping Inspection: © Matthews Engineering Training LTDDokument35 SeitenAPI 570 Piping Inspection: © Matthews Engineering Training LTDFernando Santos0% (1)

- WM PWHTDokument18 SeitenWM PWHTFaiz IshakNoch keine Bewertungen

- ISO 9692 joint preparation guideDokument46 SeitenISO 9692 joint preparation guidebiancogallazziNoch keine Bewertungen

- Pump SpecificationDokument6 SeitenPump SpecificationPrabha KaranNoch keine Bewertungen

- Section 5 Welding Procedures & Welder ApprovalsDokument10 SeitenSection 5 Welding Procedures & Welder ApprovalsS GoudaNoch keine Bewertungen

- Submerged Arc Welding (Saw)Dokument5 SeitenSubmerged Arc Welding (Saw)Nnaji Chukwuma SlamNoch keine Bewertungen

- Table 330.1.1 Preheat TemperaturesDokument1 SeiteTable 330.1.1 Preheat TemperaturesMohdBadruddinKarimNoch keine Bewertungen

- Inspection Guideline For Soil To Air Interface PipingDokument14 SeitenInspection Guideline For Soil To Air Interface PipingBenjapon bt750% (2)

- SMEA1301Dokument137 SeitenSMEA1301Nandha Gopal SenthilnathanNoch keine Bewertungen

- Lesson 14 WelderQuals - New2Dokument80 SeitenLesson 14 WelderQuals - New2Mohd Syafiq100% (1)

- Ultrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY JointsDokument14 SeitenUltrasonic Inspection of Welds in Nozzles, Nodes, Curved Surfaces & TKY Jointsleonciomavarez100% (1)

- WPSPQRDokument11 SeitenWPSPQR0502raviNoch keine Bewertungen

- WeldingDokument21 SeitenWeldingprabhatkumar_6657012Noch keine Bewertungen

- FAQ To NORSOK M650 Rev4Dokument19 SeitenFAQ To NORSOK M650 Rev4punitdubeyNoch keine Bewertungen

- CBT QuestionsDokument17 SeitenCBT QuestionsNaseer Ahmed SokhalNoch keine Bewertungen

- Job Knowledge 13Dokument3 SeitenJob Knowledge 13Mehmet SoysalNoch keine Bewertungen

- 254smo (Uns 31254)Dokument8 Seiten254smo (Uns 31254)Yang Gul LeeNoch keine Bewertungen

- Fissures in Austenitic Stainless Steel Weld MetalsDokument12 SeitenFissures in Austenitic Stainless Steel Weld MetalsthanhNoch keine Bewertungen

- Codes and Standards: ASME B31 Piping CodesDokument44 SeitenCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNoch keine Bewertungen

- Asme Boiler & Pressure Section ViiiDokument22 SeitenAsme Boiler & Pressure Section ViiiHesham ismail SeddikNoch keine Bewertungen

- Imp-Comparison of SpecificationsDokument7 SeitenImp-Comparison of SpecificationsKetan PatelNoch keine Bewertungen

- DSS PQR Requirements for Ferrite, Charpy, HI, PREN, MicrostructureDokument2 SeitenDSS PQR Requirements for Ferrite, Charpy, HI, PREN, MicrostructureANIL PLAMOOTTILNoch keine Bewertungen

- PRES TIG Hot Wire Narrow Gap Welding enDokument25 SeitenPRES TIG Hot Wire Narrow Gap Welding enRavishankarNoch keine Bewertungen

- Heat Treatment of Pressure Vessels GuideDokument103 SeitenHeat Treatment of Pressure Vessels GuidesheikbbaNoch keine Bewertungen

- Auditing Oof Welding Under ASME Section IXDokument21 SeitenAuditing Oof Welding Under ASME Section IXsabahiraqNoch keine Bewertungen

- WeldingDokument9 SeitenWeldingkiraneluruNoch keine Bewertungen

- GFT (General Fitter) - QUESTIONS & ANSWERS: Questions Related To SafetyDokument37 SeitenGFT (General Fitter) - QUESTIONS & ANSWERS: Questions Related To SafetyRajan PVNoch keine Bewertungen

- P1 A C LHDokument2 SeitenP1 A C LHMohamed Reda HusseinNoch keine Bewertungen

- Candidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Dokument4 SeitenCandidate's Name: - Nationality/Location: - Interview Date: - Interviewer(s)Ahmed Hassan100% (1)

- Introduction To API 571Dokument13 SeitenIntroduction To API 571M. Nasikhun WahidinNoch keine Bewertungen

- Mechanical Engineering Questions on Welding Standards and ProcessesDokument5 SeitenMechanical Engineering Questions on Welding Standards and ProcessesEhab Harb100% (1)

- Wps PQRDokument7 SeitenWps PQRsobariNoch keine Bewertungen

- Hydro Aluminium - AlSi7Mg0.6Dokument2 SeitenHydro Aluminium - AlSi7Mg0.6Raj PrasanthNoch keine Bewertungen

- Bend Testing: Job Knowledge 73Dokument3 SeitenBend Testing: Job Knowledge 73kevin herryNoch keine Bewertungen

- Answers Drawing B: BS 499 Part 2. Course Reference WIS 10Dokument10 SeitenAnswers Drawing B: BS 499 Part 2. Course Reference WIS 10Harkynollar Harkyntehye100% (1)

- API 570 Piping Inspector Certification PrepDokument4 SeitenAPI 570 Piping Inspector Certification Prepahmedm2020Noch keine Bewertungen

- The Complete Guide to Telephone Interview Questions and AnswersVon EverandThe Complete Guide to Telephone Interview Questions and AnswersNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsVon EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNoch keine Bewertungen

- Pengerang Integrated Petroleum Complex (PIPC) : Malaysia ThematicDokument44 SeitenPengerang Integrated Petroleum Complex (PIPC) : Malaysia ThematicSumner TingNoch keine Bewertungen

- Malaysia-Tapis CPP Topside PDFDokument2 SeitenMalaysia-Tapis CPP Topside PDFSumner TingNoch keine Bewertungen

- Pressure Seal Bolted Bonnet Valves (Velan) PDFDokument56 SeitenPressure Seal Bolted Bonnet Valves (Velan) PDFUtku KepcenNoch keine Bewertungen

- SteamDokument1 SeiteSteamSumner TingNoch keine Bewertungen

- Pressure Test Procedure Rev.cDokument8 SeitenPressure Test Procedure Rev.cSumner TingNoch keine Bewertungen

- Shale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaDokument15 SeitenShale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaSumner TingNoch keine Bewertungen

- Shale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaDokument15 SeitenShale Oil & Gas: Overview of Shale HC Potential in Onshore East MalaysiaSumner TingNoch keine Bewertungen

- Petronas Vendor Approved List Jan 2018Dokument50 SeitenPetronas Vendor Approved List Jan 2018Sumner Ting60% (5)

- 6" to 3Dokument1 Seite6" to 3Sumner TingNoch keine Bewertungen

- Spring HangerDokument1 SeiteSpring HangerSumner TingNoch keine Bewertungen

- Fgru RFC PDFDokument1 SeiteFgru RFC PDFSumner TingNoch keine Bewertungen

- Structural Gratings Standard Drawing Type 1Dokument1 SeiteStructural Gratings Standard Drawing Type 1Sumner TingNoch keine Bewertungen

- Mesh CalculationDokument1 SeiteMesh CalculationSumner TingNoch keine Bewertungen

- P9 ClampDokument1 SeiteP9 ClampSumner TingNoch keine Bewertungen

- P9 ClampDokument1 SeiteP9 ClampSumner TingNoch keine Bewertungen

- Pipe Sizes ThreadsDokument2 SeitenPipe Sizes ThreadsSumner TingNoch keine Bewertungen

- Pig Weight Vs TimeDokument4 SeitenPig Weight Vs TimeSumner TingNoch keine Bewertungen

- Off-Campus Programmes Offered Semester I 2012/2013Dokument2 SeitenOff-Campus Programmes Offered Semester I 2012/2013Sumner TingNoch keine Bewertungen

- B3200 2017-Catalogue LRDokument508 SeitenB3200 2017-Catalogue LRSumner TingNoch keine Bewertungen

- Baumann Actuator Type32 Instr D1099Dokument8 SeitenBaumann Actuator Type32 Instr D1099Sumner TingNoch keine Bewertungen

- CorrosionDokument3 SeitenCorrosionSumner TingNoch keine Bewertungen

- Crosby 2130 2150Dokument1 SeiteCrosby 2130 2150Sumner TingNoch keine Bewertungen

- CY Comment Response Sheet - TH LT1 XX GENP INT PRC 1203 Rev C1Dokument3 SeitenCY Comment Response Sheet - TH LT1 XX GENP INT PRC 1203 Rev C1Sumner TingNoch keine Bewertungen

- Stencil WP03Dokument18 SeitenStencil WP03Sumner TingNoch keine Bewertungen

- DNV RP D101 October 2008Dokument42 SeitenDNV RP D101 October 2008aop10468100% (1)

- Control ValveDokument10 SeitenControl ValveSumner TingNoch keine Bewertungen

- Convo HotelDokument1 SeiteConvo HotelSumner TingNoch keine Bewertungen

- Convo HotelDokument1 SeiteConvo HotelSumner TingNoch keine Bewertungen

- Quickly analyze risks in Excel with @RISK in under 20 minutesDokument3 SeitenQuickly analyze risks in Excel with @RISK in under 20 minutesSumner TingNoch keine Bewertungen

- Utek PYJ9114 SMC SHEETDokument2 SeitenUtek PYJ9114 SMC SHEETFrederik TjonnelandNoch keine Bewertungen

- Passive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsDokument12 SeitenPassive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsmarkicivanNoch keine Bewertungen

- 01 Samss 010 PDFDokument11 Seiten01 Samss 010 PDFAnonymous hBBam1nNoch keine Bewertungen

- Welding Procedure Qualification: in According ASME IXDokument3 SeitenWelding Procedure Qualification: in According ASME IXRochy GbNoch keine Bewertungen

- Cien-01106 Civil Engineering Materials (Lab. Manual) : The Islamia University of Bahawalpur-PakistanDokument8 SeitenCien-01106 Civil Engineering Materials (Lab. Manual) : The Islamia University of Bahawalpur-PakistanYasir Ali Dharejo100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDokument1 SeiteUltratech Cement: Particulars Test Results Requirements ofjitendra100% (1)

- Procedures For Hot Insulation - 2Dokument8 SeitenProcedures For Hot Insulation - 2Quy RomNoch keine Bewertungen

- LATICRETE Medical, Educational and Hospitality Facilities Technical Design ManualDokument290 SeitenLATICRETE Medical, Educational and Hospitality Facilities Technical Design ManualLATICRETE® InternationalNoch keine Bewertungen

- Ac 04Dokument1 SeiteAc 04Ajit ShettyNoch keine Bewertungen

- AWWA D100-11 PreDokument6 SeitenAWWA D100-11 PremojeebmashalNoch keine Bewertungen

- ASTM - Aceptables Por ASME - 2019Dokument10 SeitenASTM - Aceptables Por ASME - 2019Javier CeladaNoch keine Bewertungen

- Diaphragm DesignDokument32 SeitenDiaphragm Designwestqueen100% (6)

- q24 - 115 Hydropave Permeable PavingDokument4 Seitenq24 - 115 Hydropave Permeable PavingadingkoanapintasNoch keine Bewertungen

- HOT-ROLLED STEEL PRODUCTSDokument8 SeitenHOT-ROLLED STEEL PRODUCTS25091972Noch keine Bewertungen

- Why Matters in Concrete: ChemistryDokument6 SeitenWhy Matters in Concrete: Chemistryjulianc08Noch keine Bewertungen

- Top Hat & Cladding SectionsDokument8 SeitenTop Hat & Cladding SectionsDavid ShutteNoch keine Bewertungen

- SPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMDokument74 SeitenSPARE PARTS MANUAL of AM7 SHC2 RH VERSION, Edition - Dec '16 TMMECHANICAL KOLLAMNoch keine Bewertungen

- Ceramic InstallationDokument49 SeitenCeramic InstallationKevin Tate100% (1)

- Cable Trench Installation Guide: 1.0 IndexDokument12 SeitenCable Trench Installation Guide: 1.0 IndexThangarajan NagarajanNoch keine Bewertungen

- Alsun Aluminium Catalogue PDFDokument104 SeitenAlsun Aluminium Catalogue PDFStephen100% (2)

- D2092-95 (01) Preparation of Zinc-Coated (Galvanized) Steel Surfaces For Painting PDFDokument3 SeitenD2092-95 (01) Preparation of Zinc-Coated (Galvanized) Steel Surfaces For Painting PDFkyeong cheol leeNoch keine Bewertungen

- S04 BoomDokument60 SeitenS04 BoomJorsh GonzalesNoch keine Bewertungen

- Project 15: Ultratech Building Products DivisionDokument11 SeitenProject 15: Ultratech Building Products DivisionBibhuti NaikNoch keine Bewertungen

- 0 - Mains Water Pipe SizingDokument4 Seiten0 - Mains Water Pipe SizingstarykltNoch keine Bewertungen

- Selection of NodularizersDokument2 SeitenSelection of Nodularizersarnaldorcr8646100% (2)

- Plastering Techniques and MethodsDokument6 SeitenPlastering Techniques and MethodsYazhisai SelviNoch keine Bewertungen

- Ari Armaturen 1Dokument26 SeitenAri Armaturen 1Ardi 4791Noch keine Bewertungen

- Upgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsDokument39 SeitenUpgraded Thermal Insulation for Minimizing Heat Losses in Cement PlantsBalson VijaishNoch keine Bewertungen

- Controlling Heat Treatment of Welded P91 with Hardness TestingDokument3 SeitenControlling Heat Treatment of Welded P91 with Hardness TestingyesimeonNoch keine Bewertungen

- Product Data Sheet: Astm Grade 2 Babbitt MetalDokument1 SeiteProduct Data Sheet: Astm Grade 2 Babbitt MetalAshutosh PandeyNoch keine Bewertungen