Beruflich Dokumente

Kultur Dokumente

Ytttgyy

Hochgeladen von

emmyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ytttgyy

Hochgeladen von

emmyCopyright:

Verfügbare Formate

COMPANY NAME

TOOLBOX TALK

Workplace / Activity / Equipment: Working At Height - Scaffolds

Script

Fortunately, falls from scaffolds or scaffold collapses are fairly rare, but when they occur they tend to be

spectacular and also sometimes catastrophic.

Remember a scaffold is only as safe as the last time it was inspected by a competent person. Before you

use any scaffold check with the person in charge that it is safe to do so, check for Scafftags ® or other

safety signs giving information on scaffold safety.

Key points to consider are:

Scaffolds must be provided where work cannot be safely done from the ground. As a fixed

structure it will provide a safe place of work, assuming it is constructed and maintained safely.

Remember, before you use a scaffold, visually inspect it. Does it look safe, is it tied to the main

structure or self- supporting, are all the load bearing standards footed at ground level. If you have

any doubts bring it to the attention of a competent person.

Erection, dismantling, and alteration of scaffolds must only be done by competent persons. You

must not do it. If alteration is required to do the job, inform the Site Manager, your own Manager

or Supervisor.

A completion certificate must be signed by a competent person before a scaffold is put to use.

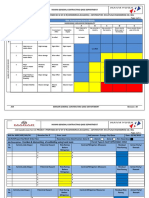

A scaffold must be inspected by a competent person at least every seven days (more often in bad

weather or a change in the structure) and a record book signed to that effect.

Sub-contractors using a main contractor’s scaffold must satisfy themselves that it is safe

(inspection of the record book mentioned above).

Unsafe or un-inspected scaffold must be barred off and notices erected to prevent use.

Toe boards 150mm high, and handrails between 914mm and 1.10m high, must be in place at

every working platform. No gaps should be left in the structure greater than 470mm.

No plank may extend more than 150mm beyond its point of support unless it is secured against

tipping.

Never walk along a single plank. The minimum width for a walk-way is 440mm (rule of thumb 2 x

9” planks). For access and working 640mm (3 planks). For access, working and materials (4 planks

or more).

Check that loading gantries are provided with roll-over pallet gates ensuring that the access point

is gated at all times.

Use the ladders or stairways provided. Never climb up scaffold poles.

Don’t use steps or ladders on a scaffold platform. This puts you above the safety rails and puts

you at risk.

Check that a correctly constructed loading bay is available before placing any load on the

structure.

Don’t throw things off scaffolds. Use a waste chute or a lifting wheel and bucket.

If the scaffold planks are damaged the scaffold is damaged. Tell the Site Manager.

Remember to use it safely and leave it safe, if you are the last person that day to use the scaffold.

Check and ensure it is secure and the ladders have been removed.

NatWest Mentor Issue 3: 20170315

COMPANY NAME

TOOLBOX TALK

Any Questions?

Toolbox Talk - Working at Height – Scaffolds

Location Date Presented By

Attendees

Name Signature

NatWest Mentor Issue 3: 20170315

Das könnte Ihnen auch gefallen

- SampleDokument11 SeitenSampleGia Minh Tieu TuNoch keine Bewertungen

- Scaffolding PresentationDokument57 SeitenScaffolding PresentationRmr ReyesNoch keine Bewertungen

- TBT - 037 Scissor LiftsDokument4 SeitenTBT - 037 Scissor LiftsRich PellettNoch keine Bewertungen

- Learning Activity Sheet Grade 11 Carpentry NC Ii I.: Week 3/480 MinutesDokument7 SeitenLearning Activity Sheet Grade 11 Carpentry NC Ii I.: Week 3/480 MinutesArnold Asio100% (2)

- 18 TBT - TopicsDokument41 Seiten18 TBT - TopicsGyanendra Narayan NayakNoch keine Bewertungen

- Scaffolding Safety TrainingDokument25 SeitenScaffolding Safety Trainingmt_powers100% (1)

- Scaffolding SafetyDokument20 SeitenScaffolding SafetyKate Ann Baja IINoch keine Bewertungen

- Work at Height - ScaffoldingDokument46 SeitenWork at Height - ScaffoldingajayjanardhankasleNoch keine Bewertungen

- Ladder SafetyDokument3 SeitenLadder SafetyJomy JohnyNoch keine Bewertungen

- Scaffold OverviewDokument33 SeitenScaffold OverviewMohamedSaidNoch keine Bewertungen

- Technical Presentation On: Freddie J. AmicanDokument48 SeitenTechnical Presentation On: Freddie J. Amicanjing aytona100% (2)

- Scaffolds 3slidesDokument13 SeitenScaffolds 3slidesCharles MitchellNoch keine Bewertungen

- Safety With Scaffolds RevDokument41 SeitenSafety With Scaffolds Revkarthika18maniNoch keine Bewertungen

- Ladder and StepladderDokument4 SeitenLadder and Stepladderaymen145771552Noch keine Bewertungen

- Scaffolding Written ReportDokument21 SeitenScaffolding Written ReportJenie Marie Nitoral100% (1)

- Scaffold User Safety: FN000681/CR/01Dokument51 SeitenScaffold User Safety: FN000681/CR/01Ryan Au YongNoch keine Bewertungen

- WAH Final PresentationDokument72 SeitenWAH Final PresentationS RNoch keine Bewertungen

- Scaffold Tampering Toolbox TalkDokument2 SeitenScaffold Tampering Toolbox TalkJohn GeddesNoch keine Bewertungen

- Ladder Safety FinalDokument6 SeitenLadder Safety Finalkanakarao1Noch keine Bewertungen

- Scaffold SafetyDokument4 SeitenScaffold SafetyMahadevan Somasundaram100% (1)

- Safety While Working at HeightsDokument57 SeitenSafety While Working at HeightsRísês Ãfröz100% (1)

- Ladder Safety PDFDokument12 SeitenLadder Safety PDFWaqar DarNoch keine Bewertungen

- Ladder Safety TBTDokument1 SeiteLadder Safety TBTkowshickNoch keine Bewertungen

- ScaffoldingDokument4 SeitenScaffoldingolvernejacobs9741Noch keine Bewertungen

- Toolbox Talk - Ladders: Planning and Assessment of RisksDokument3 SeitenToolbox Talk - Ladders: Planning and Assessment of RisksRedouan Lerhrissi100% (1)

- DownloadDokument9 SeitenDownloadAhmed FoudaNoch keine Bewertungen

- Bekerja DiketinggianDokument13 SeitenBekerja DiketinggianKarin KurniaNoch keine Bewertungen

- Scaffolding: Shahzad AhmedDokument74 SeitenScaffolding: Shahzad AhmedmohammedNoch keine Bewertungen

- Scaffold SafetyDokument33 SeitenScaffold SafetyB3rnard Ma1na100% (1)

- Scaffold SWMS & JSA GuideDokument10 SeitenScaffold SWMS & JSA Guidelabaimathuatqn2000Noch keine Bewertungen

- Scaffolding 1Dokument2 SeitenScaffolding 1Anica Pollyn Bumanglag VillanuevaNoch keine Bewertungen

- SOP ScaffoldingDokument7 SeitenSOP ScaffoldingNakkolop100% (1)

- Icorr BookDokument984 SeitenIcorr BookSuraj M SethuNoch keine Bewertungen

- Working at Height On 25.03.2021Dokument80 SeitenWorking at Height On 25.03.2021AMAN GUPTANoch keine Bewertungen

- Scaffolding Safety GuidelinesDokument6 SeitenScaffolding Safety GuidelinesCaron KarlosNoch keine Bewertungen

- Safety Guide to Scaffolds and LaddersDokument21 SeitenSafety Guide to Scaffolds and LaddersShreyas MNoch keine Bewertungen

- Scaffold Safety TrainingDokument72 SeitenScaffold Safety TrainingEngr Faheem AkhtarNoch keine Bewertungen

- 4 Ladder SafetyDokument11 Seiten4 Ladder SafetyBruce RamosNoch keine Bewertungen

- Walking Work SurfacesDokument8 SeitenWalking Work SurfacesSb TeoNoch keine Bewertungen

- Scaffolding SafetyDokument2 SeitenScaffolding SafetyJaymar O. BuenaventeNoch keine Bewertungen

- What Should You Check Before Using Scaffold?Dokument2 SeitenWhat Should You Check Before Using Scaffold?Ange JuanNoch keine Bewertungen

- CHECKLIST FOR SCAFFOLDING SAFETYDokument2 SeitenCHECKLIST FOR SCAFFOLDING SAFETYHarihar PandaNoch keine Bewertungen

- Fallhaz Handouts PDFDokument10 SeitenFallhaz Handouts PDFAndres Cedeno TutivenNoch keine Bewertungen

- Scaffold and Ladder SafetyDokument1 SeiteScaffold and Ladder SafetyshijinrajagopalNoch keine Bewertungen

- Ladder SafetyDokument27 SeitenLadder SafetySantanu Kumar Sahu100% (1)

- Osha FS-3759 PDFDokument3 SeitenOsha FS-3759 PDFabdul khaderNoch keine Bewertungen

- ScaffoldingDokument120 SeitenScaffoldingMohamed Hadjkacem100% (4)

- Scaffolding Safety ReportDokument6 SeitenScaffolding Safety ReportRam RamirezNoch keine Bewertungen

- Toolbox Scaffolding Final 9.2019Dokument3 SeitenToolbox Scaffolding Final 9.2019Jegan Suresh100% (1)

- Working at Height FINALDokument57 SeitenWorking at Height FINALInnocent BhaikwaNoch keine Bewertungen

- Working at Height ISO CertificateDokument7 SeitenWorking at Height ISO Certificatesufyan shahidNoch keine Bewertungen

- Healt and SafetyDokument14 SeitenHealt and SafetyJefry SandyNoch keine Bewertungen

- COSH 413 2022 - Module 5 – Scaffolding Safety, DO 128- 13 as Amended Rule 1414Dokument12 SeitenCOSH 413 2022 - Module 5 – Scaffolding Safety, DO 128- 13 as Amended Rule 1414Xandra Patricia BarreraNoch keine Bewertungen

- Method Statement Column SystemDokument6 SeitenMethod Statement Column SystemShakila NishaniNoch keine Bewertungen

- Scaffolding Safety (Erecting and Dismantling)Dokument55 SeitenScaffolding Safety (Erecting and Dismantling)Tehman AlamNoch keine Bewertungen

- Osha3722 PDFDokument2 SeitenOsha3722 PDFTharaka Perera100% (1)

- Ultimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildVon EverandUltimate Guide: Decks, 5th Edition: 30 Projects to Plan, Design, and BuildNoch keine Bewertungen

- Ultimate Guide to Basements, Attics & Garages, 3rd Revised Edition: Step-by-Step Projects for Adding Space without Adding onVon EverandUltimate Guide to Basements, Attics & Garages, 3rd Revised Edition: Step-by-Step Projects for Adding Space without Adding onNoch keine Bewertungen

- SCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGEVon EverandSCAFFOLDING - THE HANDBOOK FOR ESTIMATING and PRODUCT KNOWLEDGENoch keine Bewertungen

- Interested Parties and Thier RequirementsDokument2 SeitenInterested Parties and Thier RequirementsemmyNoch keine Bewertungen

- Internal and External IssuesDokument2 SeitenInternal and External IssuesemmyNoch keine Bewertungen

- JHA - Erection of Scaffolding Using Hand ToolsDokument3 SeitenJHA - Erection of Scaffolding Using Hand ToolsemmyNoch keine Bewertungen

- Cuplok Scaffold System PDFDokument24 SeitenCuplok Scaffold System PDFNestor Adolfo Freites PuelloNoch keine Bewertungen

- Tower Scaffold Risk Assessment (40Dokument8 SeitenTower Scaffold Risk Assessment (40emmyNoch keine Bewertungen

- FMD Control of Documents and Records With Authority Matrix: Facilities Maintenance Department FilesDokument1 SeiteFMD Control of Documents and Records With Authority Matrix: Facilities Maintenance Department FilesemmyNoch keine Bewertungen

- Pit Preventing Workshop Pit FallsDokument4 SeitenPit Preventing Workshop Pit FallsemmyNoch keine Bewertungen

- Main Progress for Lusail Stadium WorksDokument4 SeitenMain Progress for Lusail Stadium Worksemmy100% (1)

- Lusail Stadium Steel Structure Works Preliminary Schedule: Mobilization DemobilizationDokument4 SeitenLusail Stadium Steel Structure Works Preliminary Schedule: Mobilization DemobilizationemmyNoch keine Bewertungen

- Health Assessment Statistics-As of 31 March-2018Dokument1 SeiteHealth Assessment Statistics-As of 31 March-2018emmyNoch keine Bewertungen

- Safety Violation Report and Corrective Action: Location: Description of DeficiencyDokument1 SeiteSafety Violation Report and Corrective Action: Location: Description of DeficiencyemmyNoch keine Bewertungen

- READ ME (15 Page Walkthrough)Dokument15 SeitenREAD ME (15 Page Walkthrough)emmyNoch keine Bewertungen

- Flashing Light Bulbs PowerPoint Diagram TemplateDokument1 SeiteFlashing Light Bulbs PowerPoint Diagram TemplatemayaNoch keine Bewertungen

- SOP For Preventive Maintenance (Electric) PDFDokument3 SeitenSOP For Preventive Maintenance (Electric) PDFemmy100% (2)

- READ ME (Unison MIDI Chord Pack Setup Instructions)Dokument1 SeiteREAD ME (Unison MIDI Chord Pack Setup Instructions)emmyNoch keine Bewertungen

- 16 Participant Training FeedbackDokument1 Seite16 Participant Training FeedbackemmyNoch keine Bewertungen

- Ra-27 Covid-19 01 PDFDokument4 SeitenRa-27 Covid-19 01 PDFemmyNoch keine Bewertungen

- ElectricalSafety SOP PDFDokument5 SeitenElectricalSafety SOP PDFemmyNoch keine Bewertungen

- Cover PageDokument1 SeiteCover PageemmyNoch keine Bewertungen

- Wheel Cycle PowerPoint Diagram TemplateDokument1 SeiteWheel Cycle PowerPoint Diagram TemplateLakhsmie Herawati YuwantinaNoch keine Bewertungen

- ISO 9001 LATC Course AgendaDokument2 SeitenISO 9001 LATC Course AgendaemmyNoch keine Bewertungen

- Permanent Fence Method Statement Rev 1 2Dokument18 SeitenPermanent Fence Method Statement Rev 1 2Bishop Ojonuguwa AmehNoch keine Bewertungen

- Irca 106 Audit Log 1Dokument9 SeitenIrca 106 Audit Log 1Huascaran Asesores SacNoch keine Bewertungen

- Build List For ParticipantDokument1 SeiteBuild List For ParticipantemmyNoch keine Bewertungen

- Build List For ParticipantDokument1 SeiteBuild List For ParticipantemmyNoch keine Bewertungen

- 12 Irca 190-2Dokument1 Seite12 Irca 190-2emmyNoch keine Bewertungen

- Cover PageDokument2 SeitenCover PageemmyNoch keine Bewertungen

- Al Nokhba Cont (BLDG G+M+2-1st FLR SLB)Dokument2 SeitenAl Nokhba Cont (BLDG G+M+2-1st FLR SLB)emmyNoch keine Bewertungen

- 5 IRCA Code of ConductDokument1 Seite5 IRCA Code of ConductemmyNoch keine Bewertungen

- Collection Sheet Aldwalia DXB BranchDokument15 SeitenCollection Sheet Aldwalia DXB BranchemmyNoch keine Bewertungen

- Reference UMDNS Codes PDFDokument69 SeitenReference UMDNS Codes PDFPumps RnDNoch keine Bewertungen

- Turbofarmer P 34.7: AustraliaDokument2 SeitenTurbofarmer P 34.7: AustraliaDenis OhmakNoch keine Bewertungen

- 6013 GCS-CONTROLS enDokument5 Seiten6013 GCS-CONTROLS enMuhammad SyaqirinNoch keine Bewertungen

- 3 1Dokument4 Seiten3 1HakanNoch keine Bewertungen

- Wattgate 381 Audio Grade Duplex Socket - y CableDokument20 SeitenWattgate 381 Audio Grade Duplex Socket - y Cableapi-11530725100% (1)

- PLOTINUS: On Beauty (Essay On The Beautiful)Dokument12 SeitenPLOTINUS: On Beauty (Essay On The Beautiful)Frederic LecutNoch keine Bewertungen

- D5293Dokument8 SeitenD5293Carlos Olivares ZegarraNoch keine Bewertungen

- Ajhgaa English O6Dokument28 SeitenAjhgaa English O6dhirumeshkumarNoch keine Bewertungen

- Axminster CarpetDokument19 SeitenAxminster Carpetrohit sinhaNoch keine Bewertungen

- GadDokument1 SeiteGadFakhruddin DhilawalaNoch keine Bewertungen

- Data Sheet 2.07 Issue A: Water Flow Detector Model: WFDENDokument2 SeitenData Sheet 2.07 Issue A: Water Flow Detector Model: WFDENOvidiu GavrilasNoch keine Bewertungen

- AbstractsDokument224 SeitenAbstractsFrankmerced Emerzon Farfan HuancaNoch keine Bewertungen

- GRT9165 Product GuideDokument23 SeitenGRT9165 Product GuideEslamAldenAbdoNoch keine Bewertungen

- D-Glucitol (420i) Dextrose MonohydrateDokument3 SeitenD-Glucitol (420i) Dextrose MonohydrateSilvia Melendez HNoch keine Bewertungen

- Tabel Benkelman Beam Baru - AsisDokument21 SeitenTabel Benkelman Beam Baru - AsisAsisNoch keine Bewertungen

- University of Toronto Astronomy 101 Midterm Test QuestionsDokument6 SeitenUniversity of Toronto Astronomy 101 Midterm Test QuestionsTrash RowzanNoch keine Bewertungen

- Water Demand Fire Flow Calculation Hydraulic ModelingDokument110 SeitenWater Demand Fire Flow Calculation Hydraulic ModelingArthur DeiparineNoch keine Bewertungen

- Interaction of Radiation With Matter: Dhruba GuptaDokument36 SeitenInteraction of Radiation With Matter: Dhruba GuptaHala SweetNoch keine Bewertungen

- Eko 75 Spare Part ListDokument23 SeitenEko 75 Spare Part ListРустам Хайретдинов100% (1)

- Sea Cucumber PDFDokument171 SeitenSea Cucumber PDFRebeccaSulivanNoch keine Bewertungen

- Hanoi 2023 Peoples Picks AwardsDokument113 SeitenHanoi 2023 Peoples Picks AwardsNguyen Anh VuNoch keine Bewertungen

- Energy Monitoring With Ultrasonic Flow MetersDokument35 SeitenEnergy Monitoring With Ultrasonic Flow MetersViswa NathanNoch keine Bewertungen

- Adept Conveyor Technologies Product ManualDokument32 SeitenAdept Conveyor Technologies Product ManualBagus Eko BudiyudhantoNoch keine Bewertungen

- Final StereogramDokument16 SeitenFinal StereogramsimNoch keine Bewertungen

- PHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionDokument2 SeitenPHD Call - TCD - Micha Ruhl - PHD Project Short DescriptionabuzarNoch keine Bewertungen

- Intelligence, Reasoning, Creativity, and WisdomDokument3 SeitenIntelligence, Reasoning, Creativity, and WisdomSammy DeeNoch keine Bewertungen

- Tivax STB-T12 Owners ManualDokument32 SeitenTivax STB-T12 Owners ManualJesseNoch keine Bewertungen

- CH 01Dokument24 SeitenCH 01Gabriel FlorêncioNoch keine Bewertungen