Beruflich Dokumente

Kultur Dokumente

2 15a1 PDF

Hochgeladen von

Mike2322Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2 15a1 PDF

Hochgeladen von

Mike2322Copyright:

Verfügbare Formate

30

Appendix 1 - Rivets (Legacy)

— 2017 —

FOREWORD

This Appendix contains legacy information about rivets from the 2016 Manual. Articles in this Appendix are numbered with

A1 preceding the number of related material in Parts 1 through 9 of this Chapter. Use of “fastener” in Parts 1 through 9

includes rivets. Use of “A307 bolts” or “non-pretensioned high-strength bolts” in Parts 1 through 9 also applies to rivets. For

rating of riveted structures, see Part 7. The material in this Appendix is not updated. Care needs to be exercised as the material

and associated allowable stress levels for which these designs were originally written may no longer be applicable.

TABLE OF CONTENTS

Section/Para Description Page 1

Part A1.1. Design

A1.1.2 General Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-3

A1.1.2.1 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-3

3

A1.1.4 Basic Allowable Stresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-3

A1.1.4.1 Structural Steel, Fasteners and Pins. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-3

A1.1.5 General Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-4

A1.1.5.9 Connections and Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-4

A1.1.5.11 Development of Fillers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-4

A1.1.5.12 Combinations of Dissimilar Types of Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-5

A1.1.5.13 Sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-5

A1.1.9 Construction with Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-5

A1.1.9.2 Grip of Rivets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-5

A1.1.9.5 Fasteners with Indirect Splices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-5

Part A1.3. Fabrication

A1.3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.1.11 Flexural Member Web Plates, Riveted Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.2 Riveted Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.2.1 Rivets and Riveting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.2.3 Quantity of Field Fasteners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.2.4 Size and Workmanship of Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

© 2017, American Railway Engineering and Maintenance-of-Way Association 15-A1-1

Appendix 1 - Rivets (Legacy)

TABLE OF CONTENTS (CONT)

Section/Para Description Page

A1.3.2.9 Reaming and Drilling in Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-6

A1.3.2.11 Alignment of Finished Holes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-7

A1.3.2.12 Fitting for Shop Riveting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-7

Part A1.4. Erection

A1.4.18 Riveted Field Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-8

Part A1.5. Bearing Design and Construction

A1.5.3 Steel Bearing Component Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-9

A1.5.3.2 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-9

Part A1.9. Commentary

A1.9.1.9 Construction Using Fasteners. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-A1-10

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-2 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

PART A1.1. DESIGN

A1.1.2 GENERAL REQUIREMENTS

A1.1.2.1 MATERIALS1

This Appendix contains information useful in the design of Recommended Contemporary Structures.

a. The design requirements of these recommended practices, contained in this part are based on the use of materials

conforming to the requirements of the following ASTM specifications:

Rivet steel . . . . . . . . . . . . . . . . . . . . . . . . A502, Grade 1, 2, or Grade 3

(current in 2016)

A1.1.4 BASIC ALLOWABLE STRESSES

A1.1.4.1 STRUCTURAL STEEL, FASTENERS AND PINS2

Allowable stresses are as shown in Table 15-1-12 and Table 15-7-1 supplemented by the following:

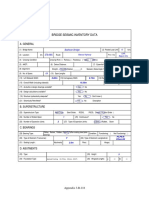

Stress Area Pounds per square inch 1

Axial compression, gross section:

For stiffeners of beams and girders See Article 1.7.7c

For splice material 0.55Fy

For compression members centrally loaded,

where:

kl is the effective length of the compression member, 4

inches, under usual conditions

k = 3/4 for members with riveted end connections,

k to be evaluated for each gusset plate on the effective

width, Lw,

(See Commentary Figure 15-9-4),

and

r is the applicable radius of gyration of the compression

member, inches.

Compression in extreme fibers of riveted built-up flexural

members symmetrical about the principal axis in the plane of

the web (other than box-type flexural members)

1

See Part 9 Commentary

2

See Part 9 Commentary

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 15-A1-3

Appendix 1 - Rivets (Legacy)

Stress Area Pounds per square inch

Compression in extreme fibers of box type welded, riveted

flexural members symmetrical about the principal axis

midway between the webs and whose proportions meet the

provisions of Article 1.6.1 and Article 1.6.2

A1.1.5 GENERAL RULES

A1.1.5.9 CONNECTIONS AND SPLICES

d. Members subject to compression only, if faced for bearing, shall be spliced on 4 sides sufficiently to hold the abutting

parts accurately and securely in place. The splice shall be as near a panel point as practicable and shall be designed to

transmit at least one-half of the force through the splice material. Where such members are in full milled bearing on

base plates, there shall be sufficient riveted connecting material, or welding, to hold all parts securely in place.

A1.1.5.11 DEVELOPMENT OF FILLERS1

b. For riveted construction, when rivets subject to force pass through fillers, the fillers shall be extended beyond the

connected member and the extension secured by enough rivets to distribute the total force to the member uniformly

over the combined sections of the member and the fillers, except that fillers less than 1/4 inch thick shall not be

extended beyond the splicing material, and additional rivets are not required.

c. For riveted construction, eccentricity must be considered on short, thick fillers.

1

See Part 9 Commentary.

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-4 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

A1.1.5.12 COMBINATIONS OF DISSIMILAR TYPES OF CONNECTIONS1

a. Rivets and high-strength bolts in the same connection plane may be considered as sharing the force. When such a

connection plane is subjected to fatigue conditions, the requirements of Article 1.3.13 applicable to rivets shall be

satisfied for both types of fasteners.

b. Welds acting in the same connection with fasteners shall be proportioned to carry the entire force. (See Article

9.1.5.12b)

A1.1.5.13 SEALING2

a. For riveted members, sealing shall be accomplished by limiting the spacing of the fasteners connecting component

parts. The pitch on a single line adjacent to a free edge of an outside plate or shape shall not exceed 4 + 4t, where t is

the thickness of the thinnest outside plate or shape in inches, nor 7 inches. Where there is a second line of fasteners

uniformly staggered with those in the line adjacent to the free edge, at a gage, g, less than 1-1/2 + 4t inches, therefrom,

the staggered pitch of the fasteners in the two lines shall not exceed 4 + 4t – 3/4 g inches, nor 7– 3/4 g inches, but need

not be less than one-half the requirement for a single line.

A1.1.9 CONSTRUCTION WITH FASTENERS

A1.1.9.2 GRIP OF RIVETS

Where the grip of rivets carrying calculated stress exceeds 4.5 times the diameter, the number of rivets shall be increased at

least 1% for each additional 1/16 inch of grip. Where the grip equals or exceeds 6 times the nominal diameter, the body shall 1

be tapered from the head for a distance not less than 3.42 times the nominal diameter, but not more than 4-3/4 inches. The

body diameter at the head shall be 1/32 inch greater and where not tapered, 1/64 inch less than the nominal diameter. (This

Article preceded current Article 1.9.2)

A1.1.9.5 FASTENERS WITH INDIRECT SPLICES3

For riveted construction only, where splice plates are not in direct contact with the parts which they connect, there shall be 3

rivets on each side of the joint in excess of the number required in the case of direct contact, to the extent of two extra lines at

each end of each intervening plate.

1

See Part 9 Commentary.

2

See Part 9 Commentary.

3 See Part 9 Commentary and Part A1.9 Commentary.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 15-A1-5

Appendix 1 - Rivets (Legacy)

PART A1.3. FABRICATION

A1.3.1 GENERAL

A1.3.1.11 FLEXURAL MEMBER WEB PLATES, RIVETED CONSTRUCTION

a. The edges of web plates of riveted flexural members that have no cover plates shall not be more than 1/8 inch above or

below the backs of the top flange angles. Web plates of such members with cover plates may be 1/2 inch less in depth

than the distance back to back of flange angles.

b. In riveted splices of web plates there shall not be more than 1/2 inch gap between the web plates.

A1.3.2 RIVETED CONSTRUCTION

A1.3.2.1 RIVETS AND RIVETING

This Article preceded current Article 3.2.1.

a. Rivet dimensions shall conform to the current requirements of the American National Standards Institute for large

rivets, 1/2 inch in nominal diameter and larger, ANSI Standard B 18.4 (current in 2016).

b. Rivets shall be heated uniformly to a light cherry red and driven while hot to fill the holes completely. They shall be

free from slag, scale and carbon deposit. Loose, burned, or otherwise defective rivets shall be replaced. In removing

rivets, care shall be taken not to injure the adjacent metal and, if necessary, the rivets shall be drilled out. Caulking or

recupping shall not be done.

c. Rivets shall be driven by direct-acting riveters where practicable. The pressure shall be continued after the upsetting

has been completed.

d. Where rivets are driven with a pneumatic riveting hammer, a pneumatic bucker shall be used where practicable.

e. Driven rivet heads shall be fully formed, neatly made, concentric with the rivet holes, and in full contact with the

member.

f. Rivets of ASTM A502, Grade 2, shall not be driven by hand.

A1.3.2.3 QUANTITY OF FIELD FASTENERS

The number of field rivets of each size and length furnished in excess of the nominal number required shall be 10% plus 10.

(Current Article 3.2.3 was originally 3.2.3b following this Article.)

A1.3.2.4 SIZE AND WORKMANSHIP OF HOLES

b. For riveted construction where the grip exceeds 4-1/2 inches the holes shall be chamfered 1/32 inch.

A1.3.2.9 REAMING AND DRILLING IN ASSEMBLY

Reaming, or drilling full size, of assembled parts shall be done only after the parts are firmly clamped together with the

surfaces in close contact. If necessary, parts shall be separated before riveting for removal of shavings.

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-6 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

A1.3.2.11 ALIGNMENT OF FINISHED HOLES

a. The offset in any hole reamed 1/4 inch in any ply of material measured from an outer ply after the hole has been

finished for riveting, shall not exceed 1/16 inch. Not more than 10% of the holes shall be offset as much as 1/16 inch

and not more than 20% shall be offset as much as 1/32 inch.

b. The offset in any hole reamed 1/8 inch or punched full size, in any ply of material, measured from an outer ply after the

hole has been finished for riveting, shall not exceed 1/8 inch. Not more than 10% of the holes shall be offset as much as

1/8 inch, and not more than 20% shall be offset as much as 1/16 inch.

A1.3.2.12 FITTING FOR SHOP RIVETING

The parts of riveted members shall be adequately pinned and firmly drawn together in close contact with bolts before riveting

is begun. Tack welding shall not be used. The drifting done during assembly shall be only such as to bring the parts into

position and shall not enlarge the holes or distort the metal.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 15-A1-7

Appendix 1 - Rivets (Legacy)

PART A1.4. ERECTION

A1.4.18 RIVETED FIELD CONNECTIONS

This Section preceded current Section 4.18.

a. Where rivets are used in field connections, they shall be driven with pneumatic riveting hammers, and when practical,

shall be bucked with pneumatic buckers.

b. The requirements for the rivets, and for the general procedure of heating and driving, shall be as specified in Article

A1.3.2.1.

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-8 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

PART A1.5.BEARING DESIGN AND CONSTRUCTION

A1.5.3 STEEL BEARING COMPONENT DESIGN

A1.5.3.2 MATERIALS

A1.5.3.2.3 Fasteners

Fasteners may be power-driven rivets, ASTM A502 Grades 1 or 2, in accordance with Part 1, Design, and Part 3, Fabrication.

© 2017, American Railway Engineering and Maintenance-of-Way Association

AREMA Manual for Railway Engineering 15-A1-9

Appendix 1 - Rivets (Legacy)

PART A1.9. COMMENTARY

A1.9.1.9 CONSTRUCTION USING FASTENERS

A1.9.1.9.5 Fasteners in Indirect Splices

For splices with fill plates, additional rivet rows are required at the ends of the plates to ensure an adequate connection.

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-10 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

THIS PAGE INTENTIONALLY LEFT BLANK.

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-11 AREMA Manual for Railway Engineering

Appendix 1 - Rivets (Legacy)

© 2017, American Railway Engineering and Maintenance-of-Way Association

15-A1-12 AREMA Manual for Railway Engineering

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1091)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Seismic Design of Bridges in PhilippinesDokument80 SeitenSeismic Design of Bridges in PhilippinesMike2322Noch keine Bewertungen

- Seismic Design of Bridges Example 7Dokument62 SeitenSeismic Design of Bridges Example 7Mike2322Noch keine Bewertungen

- As 1397-2001 Steel Sheet and Strip - Hot-Dipped Zinc-Coated or Aluminium Zinc-CoatedDokument7 SeitenAs 1397-2001 Steel Sheet and Strip - Hot-Dipped Zinc-Coated or Aluminium Zinc-CoatedSAI Global - APAC0% (2)

- Chap 07 PDFDokument26 SeitenChap 07 PDFdada jamdarNoch keine Bewertungen

- QR 0109 Fire Pumps Sensing LinesDokument1 SeiteQR 0109 Fire Pumps Sensing LinesStory LoveNoch keine Bewertungen

- Engineering Materials Geoffrey W Meetham M B E Prof DR Ir Marcel H Van de Voorde Auth Materials For High Temperature Engineering Applicati PDFDokument173 SeitenEngineering Materials Geoffrey W Meetham M B E Prof DR Ir Marcel H Van de Voorde Auth Materials For High Temperature Engineering Applicati PDFIlham HakikiNoch keine Bewertungen

- Kolkata 2Dokument2 SeitenKolkata 2raj.kajaniya100% (1)

- Steel Bars, Alloys, For NitridingDokument2 SeitenSteel Bars, Alloys, For Nitridingruben carcamoNoch keine Bewertungen

- Microstructural Changes in The Forge Weld Area During HF-ERWDokument4 SeitenMicrostructural Changes in The Forge Weld Area During HF-ERWilze86Noch keine Bewertungen

- Sulphamic AcidDokument3 SeitenSulphamic AcidmelvinkuriNoch keine Bewertungen

- ASME IX Interpretation-Part1Dokument51 SeitenASME IX Interpretation-Part1kevin herry100% (5)

- Amm 3cm Mk108 Komet CannonDokument9 SeitenAmm 3cm Mk108 Komet CannonenricoNoch keine Bewertungen

- 2021-11-16 - ABCD NEOH - Cross-Frames - ChavelDokument36 Seiten2021-11-16 - ABCD NEOH - Cross-Frames - ChavelMike2322Noch keine Bewertungen

- Guard Rail Special Details MASHDokument11 SeitenGuard Rail Special Details MASHMike2322Noch keine Bewertungen

- LARSA WJE Solving-For-StabilityDokument39 SeitenLARSA WJE Solving-For-StabilityMike2322Noch keine Bewertungen

- AASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Dokument8 SeitenAASHTO NSBA POST TENSIONED CAP Steel - Bridge - News - v6 - n3Mike2322Noch keine Bewertungen

- Guard Rail On-System Bridge (MASH) Set (4-13-23)Dokument11 SeitenGuard Rail On-System Bridge (MASH) Set (4-13-23)Mike2322Noch keine Bewertungen

- Camber Haunch Girder WSDOT A-Dimension RevisionsDokument8 SeitenCamber Haunch Girder WSDOT A-Dimension RevisionsMike2322Noch keine Bewertungen

- Seismic Design Bridges For Rural Areas South East AsiaDokument85 SeitenSeismic Design Bridges For Rural Areas South East AsiaMike2322Noch keine Bewertungen

- Seismic Bridge Design Mitigation Outline Part 4Dokument170 SeitenSeismic Bridge Design Mitigation Outline Part 4Mike2322Noch keine Bewertungen

- Design Spectra Philippines Seismic Part 4Dokument144 SeitenDesign Spectra Philippines Seismic Part 4Mike2322Noch keine Bewertungen

- Public Roads Vol 23 Issue 7Dokument32 SeitenPublic Roads Vol 23 Issue 7Mike2322Noch keine Bewertungen

- Seismic Bridge Design Mitigation Outline Part 5Dokument398 SeitenSeismic Bridge Design Mitigation Outline Part 5Mike2322Noch keine Bewertungen

- Mitigation of Seismic Disasters in Bridges Part 1Dokument291 SeitenMitigation of Seismic Disasters in Bridges Part 1Mike2322Noch keine Bewertungen

- Seismic Bridge Design Mitigation Outline Part 3Dokument156 SeitenSeismic Bridge Design Mitigation Outline Part 3Mike2322Noch keine Bewertungen

- CompositeFloorSystems - ChienRitchie1984 Canada CISCDokument171 SeitenCompositeFloorSystems - ChienRitchie1984 Canada CISCMike2322Noch keine Bewertungen

- Xu - Jian Gong - DissertationDokument341 SeitenXu - Jian Gong - DissertationMike2322Noch keine Bewertungen

- Mitigation of Seismic Disasters in Bridges Part 1Dokument466 SeitenMitigation of Seismic Disasters in Bridges Part 1Mike2322Noch keine Bewertungen

- Seismic Design of Bridges South East Asia Part 1Dokument173 SeitenSeismic Design of Bridges South East Asia Part 1Mike2322Noch keine Bewertungen

- ETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMDokument18 SeitenETL 1110-2-322 (1990) Retaining and Flood Walls (2 of 3) WMMike2322Noch keine Bewertungen

- Seismic Design of Bridges South East Asia Part 3Dokument192 SeitenSeismic Design of Bridges South East Asia Part 3Mike2322Noch keine Bewertungen

- MATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Dokument195 SeitenMATHCAD DESIGN OF PSC GIRDER NCHRP - RPT - 907Mike2322Noch keine Bewertungen

- AZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFDokument76 SeitenAZDOT EXAMPLE SUBSTRUCTURE Appendix - A - Example - 2 - 2 PDFMike2322Noch keine Bewertungen

- ETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMDokument18 SeitenETL 1110-2-322 (1990) Retaining and Flood Walls (1 of 3) WMMike2322Noch keine Bewertungen

- Magnetite Vs HematiteDokument2 SeitenMagnetite Vs HematiteKiran KNoch keine Bewertungen

- Astm - Mag. PropertiesDokument2 SeitenAstm - Mag. PropertiesPetr HavelNoch keine Bewertungen

- Vimal FireDokument4 SeitenVimal FireVisas SivaNoch keine Bewertungen

- MCQ Unit 5Dokument8 SeitenMCQ Unit 5radhakrishnanNoch keine Bewertungen

- Astm b86.5503 ZamakDokument7 SeitenAstm b86.5503 ZamakJosé SierraNoch keine Bewertungen

- UchwytyDokument42 SeitenUchwytyharlyganNoch keine Bewertungen

- Is 10080 - Vibrating TableDokument15 SeitenIs 10080 - Vibrating TableVivek GaurNoch keine Bewertungen

- 17 July - Shift 1Dokument29 Seiten17 July - Shift 1AbduNoch keine Bewertungen

- Metoda Mathara (Hole Drilling Method)Dokument6 SeitenMetoda Mathara (Hole Drilling Method)o_l_0Noch keine Bewertungen

- Trent Stainless Steel and Alloy Tubular Products HandbookDokument37 SeitenTrent Stainless Steel and Alloy Tubular Products HandbooksumomonoNoch keine Bewertungen

- Mould HPDC Alloys PDFDokument4 SeitenMould HPDC Alloys PDFMohd Nazri SalimNoch keine Bewertungen

- 07 Continuous HM IDokument102 Seiten07 Continuous HM IRacielMCNoch keine Bewertungen

- CURC 01bDokument8 SeitenCURC 01bmontsegranNoch keine Bewertungen

- SR 6898 1 Tevi de Otel PDFDokument1 SeiteSR 6898 1 Tevi de Otel PDFCRISTIAN SILVIU IANUCNoch keine Bewertungen

- Engineering Standards Manual ISD 341-2 Chapter 13, Welding & Joining GWS 1-07 - Consumable MaterialsDokument3 SeitenEngineering Standards Manual ISD 341-2 Chapter 13, Welding & Joining GWS 1-07 - Consumable MaterialsshijinrajagopalNoch keine Bewertungen

- ChirayuDokument15 SeitenChirayuDevashish JoshiNoch keine Bewertungen

- Rasa Shastra The Art of Vedic Alchemy Vol.4 This LatestDokument19 SeitenRasa Shastra The Art of Vedic Alchemy Vol.4 This Latesthk_scribdNoch keine Bewertungen

- Pinnacle Alloys E7018 E7018 1Dokument2 SeitenPinnacle Alloys E7018 E7018 1BerniIrleNoch keine Bewertungen

- 0671 DULUX PaintingDokument32 Seiten0671 DULUX PaintingSyed SyafiqNoch keine Bewertungen

- WA Hardlite™: Ultra-Thin Composite WearplatesDokument5 SeitenWA Hardlite™: Ultra-Thin Composite WearplatesFernando MilmanNoch keine Bewertungen