Beruflich Dokumente

Kultur Dokumente

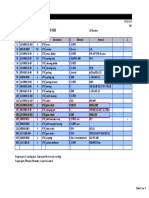

Subject Code Subject Name CO RTU (80%) MTT (80%) Indirect (20%) TOTAL (100%) X y Z .8x+.2 (.8y+.2z)

Hochgeladen von

rishipareekOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Subject Code Subject Name CO RTU (80%) MTT (80%) Indirect (20%) TOTAL (100%) X y Z .8x+.2 (.8y+.2z)

Hochgeladen von

rishipareekCopyright:

Verfügbare Formate

CO ATTAINMENT FOR YEAR 2018-19

MTT Indirect

SUBJECT RTU(80%) TOTAL(100%)

subject name CO (80%) (20%)

CODE

x y z .8x+.2(.8y+.2z)

Computer Integrated CO-1 To identify the main elements in Computer Integrated Manufacturing Systems. 51.89 43.87 86 55.3616

Manufacturing Systems

CO-2 To apply the knowledge of Computer Aided Process Planning (CAPP), features, Group Technology and data exchange in Manufacturing 51.89

Processes. 66.77 88 54.536

8ME1A CO-3 To analyze the process product models with CAM tools and CNC machines with Collaborative Engineering. 51.89 55.74 84 55.3616

CO-1 To recognise of their rights and also aware that to settle disputes in industry with leads to better human relation. 58.69 45.76 82

To identify various acts set by GOI, this will make them aware and conscious regarding the consequences in case of laws violation

8ME2A Laws for Engineers

CO-2 and punishment to be mattered. 58.69 56.69 86

CO-3 To discuss about the election provision in India. 58.69 62.94 84

Power Generation CO-1 To explain the fundamental concepts of electricity generation 52.17 64.66 82 55.3616

CO-2 To analyse the steam power plant with different conditions. 52.17 59 84 54.536

CO-3 To compare the function of hydroelectric ,diesel and gas power plant 52.17 63.66 86 55.3616

To identify the basic renewableenergy resources and implement

8ME3A CO-4 them in electricity generation 52.17 63.66 88 55.4416

Product Development CO-1 To apply techniques to generate new product ideas and translate them into clear sketches. 0.5185185185 0.6666666667

and Launching

CO-2 To design the product by identifying the subsystems and set engineering specifications. 0.5185185185 0.4074074074

CO-3 To develop a methodical approach to the management of product development to satisfy customer needs. 0.5185185185 0.2407407407

8ME4.1A CO-4 To recognize the importance of management, organization and challenges during new product development. 0.5185185185 0.4444444444

CAM Lab CO-1 To prepare program and execute it on Computer Numerical Control (CNC) Lathe Machine. 94.59459459 91 94 93.99567568

8ME5A CO-2 To prepare program and execute it on Computer Numerical Control (CNC) Milling Machine. 94.59459459 93 93 94.27567568

CAD Lab CO-1 To design different parts of mechanical components.

8ME6A CO-2 To prepare models of various designing and Manufacturing Industries.

Industrial Engineering To prepare flow chart , man machine chart , operation chart for improvement

Lab - II CO-1 of industrial setup. 98.91 98.91 94 98.7136

8ME7A CO-2 To apply tools of industrial engineering on shop floor. 98.91 98.91 96 98.7936

Project-2 CO-1 To generate the solution of given problem and acquire the system integration skills. 61.41 52.56 92

CO-2 To prepare project with overall safety concern. 61.41 56.59 96

CO-3 To relate the documentation and communication skills. 61.41 53.98 86

8MEPR CO-4 To develop, formulate and integrate the project with managerial skills. 61.41 54.54 88

Seminar CO-1 To analyse the real technical problems. 99.45 99.45 98 99.392

CO-2 To develop advance knowledge and leadership skills. 99.45 99.45 99 99.432

8MESM CO-3 To manage communication skills and presentation skills. 99.45 99.45 98 99.392

Finite Element Methods CO-1 To interpret the philosophy behind principles, design and modeling considerations in using finite element analysis 43.08510638 85.29 73.25 51.04448511

CO-2 To apply the concept of direct equilibrium method and potential energy method for structural mechanics problems 43.08510638 83.23 88.26 51.31528511

7ME1A CO-3 To Analyze1-D Heat transfer, Solid mechanics, fluid Mechanics problems using different integration and vibrational formulation

43.08510638 81.12 80.55 50.66928511

Refrigeration & Air- To apply the fundamentals of sciences and engineering for understanding the working of different types of

conditioning CO-1 refrigeration systems. 39.9 66.65 82 45.84

CO-2 To analyze the effect of different refrigeration conditions on the performance of refrigerator and environment. 39.9 58.36 74 44.21

CO-3 To identify best refrigeration system and component of refrigeration system according to need of customers 39.9 73.24 88 47.22

7ME2A CO-4 To design air condition unit according to the specific need of customers 39.9 67.58 84 46.09

Operations Research CO-1

CO-2

CO-3

7ME3A CO-4

Turbomachines To explain the working principles of turbomachines and apply it to various types of

CO-1 machine. 52.29 46.87 86 51.9712

To calculate work done and efficiency of turbomachines operating at design and

CO-2 off design conditions 52.29 64.77 88 55.7152

To apply working principle of various type of gas turbine and know their

CO-3 application range. 52.29 52.74 86 55.7152

7ME4A CO-4 To identify different type of turbines. 52.29 52.16 85 55.7152

Operations Management CO-1 Describe the basic concepts of operations management and production systems 59.57 89 77.94

CO-2 Analyse and solve the problems of production planning, scheduling & control 59.57 90 41.17

CO-3 Understand the concepts of MRP, JIT and SCM 59.57 88 22.02

7ME5A CO-4 Solve the problems using project management & reliability. 59.57 87 20

Micro and Nano CO-1 The students will acquire the knowledge of different techniques used in micro and nano manufacturing. 54.63 43.87 86 55.3616

Manufacturing

CO-2 The students will become aware about non‐conventional micro‐nano manufacturing and finishing approaches. 54.63 66.77 88 55.4416

CO-3 The students will understand techniques and other processing routes in micro and nano manufacturing. 54.63 55.74 84 55.4416

7ME6.1A CO-4 The students will be able to evaluate techniques used in micro joining and the metrology tools in micro and nano manufacturing. 54.63 52.15 85 55.4416

Thermal Engineering CO-1 Students will make some modification on thermal systems. 98.93617021 96 94 98.26893617

Lab-II

7ME7A CO-2 Students will work on turbomachines. 98.93617021 95 97 98.22893617

FEM Lab CO-1 To Implement and conduct the finite element analysis on different types of engineering problem i.e. structural, Thermal, Buckling and frequency analysis using FEA packages

7ME8A CO-2 To propose the safe design limits for engineering problems through the analysis of real-world problems

Practical Training & CO-1 To Co-relate the concepts learnt in classrooms to industrial application. 85.25 78.46 85 94.27567568

Industrial visit

CO-2 To identify sources of hazards, and assess/identify appropriate health & safety measures. 85.25 72.29 88 94.27567568

7METR CO-3 To attain thoughts and views into technical presentation form. 85.25 77.56 83 94.27567568

Project-1 CO-1 To identify the given problem and acquire the system integration skills. 48.4 48.4 84

CO-2 To prepare handle project with overall safety concern. 48.4 48.4 86

CO-3 To relate the documentation and communication skills. 48.4 48.4 88

7MEPR CO-4 To analyse and integrate the project with managerial skills. 48.4 48.4 86

Design of Machine CO-1

Elements - II

CO-2

CO-3

6ME1A CO-4

Newer Machining CO-1 To identify the best machining process for machining of particular material among the conventional and unconventional machining process.

0.1621621622 84.1456 83 16.91302573

Methods

CO-2 To describe the mechanism of metal removal of various unconventional machining processes. 0.1621621622 81.4562 86 16.60272173

CO-3 To explain the effect of unconventional machining condition on MRR and surface roughness. 0.1621621622 83.9475 81 16.80132973

6ME2A CO-4 To categorise nano and micromachining processes and their industrial applications. 0.1621621622 84.1631 85 16.99582573

Mechatronics CO-1

CO-2

CO-3

6ME3A CO-4

Vibration Engineering CO-1 To explain the propagation of sound, noise sources and need of vibration analysis in machine parts. 40.53 42.64 88 47.994

CO-2 To formulate mathematical models of problems in vibrations 40.53 37.84 88 47.994

CO-3 To determine vibratory responses of single and multi degree of freedom system 40.53 53.24 88 47.994

6ME4A CO-4 To analyse the parameters of vibration isolation system 40.53 35.27 88 47.994

Steam Engineering To identify components of boilers and their role in the efficiency and safely

CO-1 operation of the boilers. 26.48648649 78.4 82 37.01318919

To analyse the performance of nozzles and turbines by applying concepts

CO-2 and laws of thermodynamics and fluid mechanics. 26.48648649 79.43 81 37.13798919

To explain the working of rankine cycle and its efficiency improvement

6ME5A CO-3 methods. 26.48648649 84.62 85 38.12838919

CO-1 24.86 85.94 81 36.8784

CO-2 24.86 85.94 83 36.9584

Maintenance CO-3 24.86 85.94 82 36.9184

6ME6.3A Management CO-4 24.86 85.94 81 36.8784

Machine Design CO-1

Sessional -II

6ME7A CO-2

Industrial Engineering CO-1 to implement various concepts involved in statistical process controlas an Industrial Engineer in industry 55.45 92.6 92

Lab-I

6ME8A CO-2 to understand and verify probability distributions and solve the problems using statistical process control software in lab. 55.45 93.4 94

Mechatronics Lab CO-1

CO-2

6ME9A CO-3

Vibration Engineering CO-1 To determine the natural frequency of vibration problems that contain single and multi-degree of freedom systems. 48.2 68.5 82

Lab

6ME10A CO-2 To calculate the damping coefficient of single and multi-degree of freedom systems. 48.2 69.8 84

Heat Transfer CO-1 To calculate conductive heat transfer rate 36.21 67.85 85

CO-2 To analyze the basic conceptofconvection andvaporization phenomena 36.21 68.25 88

CO-3 To chose appropriate heat exchanger according to application 36.21 66 86

5ME1A CO-4 To discuss the concept of radiation and impact of energy systems on the global environment. 36.21 69.28 87

Dynamics of Machines CO-1 To analyze the governing mechanism and design the governor for given r.p.m. range. 0.347826087 74.73 91 15.87506087

CO-2 To explore the working of gyroscope in the turning of airplane/ships/automobiles. 0.347826087 76.52 93 16.24146087

CO-3 To design automobile gear box. 0.347826087 73.49 89 15.59666087

5ME2A CO-4 To balance the effect of disturbing mass on higher speed of automobiles. 0.347826087 72.82 96 15.76946087

Measurement & CO-1

Metrology

CO-2

CO-3

CO-4

5ME3A CO-5

Quality Assurance & CO-1 To discuss the various aspect of quality 30.48 62.029 68 37.03

Reliability

CO-2 To memorize the basic concept of applied statics 30.48 51.976 74 35.66

CO-3 To practice of statistical quality control tools 30.48 68.085 77 38.36

CO-4 To illustrate the quality assurances concept 30.48 68 69 38.02

5ME4A CO-5 To explain the concept of reliability and quality loss function. 30.48 66.091 76 38

Sociology and CO-1 To identify various sociological concepts and apply them for different social issues. 62.49 65.76 85 63.9136

Economics for Engineers

CO-2 To explain Monetary and Financial/Fiscal Policy and system. 62.49 72.67 83 64.9392

5ME5A CO-3 To recognize and comprehend contemporary socio-economic issues in India. 62.49 62.94 82 63.3424

Automobile Engg. CO-1 CO1-To interpret the function, constructional features of chassis and working of clutches and brakes. 31.51 48.26 78 36.0496

CO-2 CO2-To describe the working of transmission system with their necessity and application 31.51 51.36 80 36.6256

CO-3 CO3-To analyze tyre,steering system and geometry with utility of suspension system. 31.51 50.84 76 36.3824

5ME6.2A CO-4 CO4-To identify automotive electrical system,ignition system and requirement of aotomotive lighting , air conditioning and safety 31.51 52.76 82 36.9296

Heat Transfer Lab CO-1 To analyze the conduction and convection processes that occurs in multiple aspects of daily life. 78.2 77 95

5ME7A CO-2 To examine the process of radiation and relate its properties to design of thermal systems. 76 81 93

Dynamics of Machines CO-1 To analyse the principles of mechanisms and machines, and their practical applications in Mechanical Engineering. 84.78 80 94 84.384

Lab

5ME8A CO-2 To determine the functions different mechanisms of an automobiles. 84.78 77 92 83.824

Production Engineering CO-1 To analyse the basic measurement units and able to calibrate various measuring devices. 92.4 82.67 86 90.5872

Lab

5ME9A CO-2 To determine error and correction factors of various measuring devices. 92.4 89.94 84 91.6704

Professional Ethics and CO-1 To implement professional ethics and human values in practical scenario. 99.45652174 94 97 98.48521739

Disaster Management

5ME10A CO-2 To integrate the situation of natural and manmade disaster and to identify how to manage disaster. 99.45652174 98 95 99.04521739

CO-1

CO-2

CO-3

4ME2-01 Data analytics CO-4

CO-1

CO-2

CO-3

4ME1-03/02 TC/MEFA CO-4

CO-1

CO-2

CO-3

4ME3-04 Digital Electronics CO-4

CO-1

CO-2

Fluid Mechanics and CO-3

4ME4-05 Fluid Machines CO-4

CO-1 To describe various type of casting processes. 32.12 64.24 64 38.53

CO-2 To memorize different forming & joining processes in manufacturing. 32.12 67.64 69 39.27

CO-3 To explain additive manufacturing process. 32.12 67.42 71 39.32

To classify plastic & nano technologies in manufacturing and their

4ME4-06 Manufacturing Processes CO-4 relevance to industry. 32.12 57.5 68 37.61

CO-1 Determine velocity and acceleration of various planar mechanisms using the concept of link, pair, and mechanism. 0.09392265193 52.87 90 12.13433812

CO-2 Demonstrate the working of clutches and brakes. 0.09392265193 50.1 89 11.65113812

4ME4-07 Theory of machines CO-3 Identify different type of gears and gear trains. 0.09392265193 49.93 95 11.86393812

CO-4 Apply the concept of gyroscope, cams, and cam followers in machines. 0.09392265193 53.76 91 12.31673812

CO-5 Explain the effect of disturbing mass on higher speed of automobiles. 0.09392265193 51.35 91 11.93113812

CO-1

4ME3-21 Digital Electronics lab CO-2

CO-1

4ME4-22 Fluid Mechanics lab CO-2

CO-1 To recognise about various machining processes and effect of machining parameters on quality of work piece.

4ME4-23 Production practice lab CO-2 To prepare tools and jobs by developing a manufacturing-centric knowledge.

CO-1 Express a good understanding of the principles of mechanisms and machines, and their practical applications in Mechanical Engineering. 72 78 92 73.76

4ME4-24 Theory of machines Lab CO-2 Apply the concepts of power transmission by the application of friction. 75 73 90 75.28

CO-3 Balance the wheel of automobiles. 74 76 90 74.96

CO1

Advance Engineering CO-2

3ME2-01 Mathematics-I CO-3

CO-1

CO-2

CO-3

CO-4

3ME1-02/ 3ME1-03

TC/MEFA CO-5

CO-1 Students will be able to describe fundamental laws of forces, FBD, Trusses and virtual work. 57.95 51.69 79

CO-2 Students will be able to identify problem associated with Centre of gravity and Moment of Inertia and lifting machines. 57.95 59.64 82

CO-3 Students will be able to understand the basic concept of Friction with belt and rope drive. 57.95 53.59 84

3ME3-04 ENG. MECH. CO-4 Students will be able to Understand the Kinematics, Dynamics and Vibration. 57.95 56.17 81

CO-1

CO-2

Engineering CO-3

3ME4-05 Thermodynamics CO-4

CO-1 To enumerate the basic understanding of atomic structure, bonding and crystal structure 58.62 62.89 85

CO-2 To classify the different type of materials with their mechanical properties and strengthening mechanism 58.62 53.59 79

To explain the concept of phase diagram, phase transformation and thermal processing of

Materials Science and CO-3 metal alloys. 58.62 30.8 84

3ME4-06 Engineering CO-4 To Impart the knowledge of various nonmetal martials such as polymers, composites their application and processing. 58.62 40.81 82

CO-1

CO-2

CO-3

3ME4-07 Mechanics of Solids CO-4

CO-1 Recall basics of engineering drawing and apply the concepts on various connections of machine parts and assembly. 95.4 85 92

3ME4-21 Machine drawing practice CO-2 Make 2D/3D model of different mechanical parts using different CADD software 94.5 80 94

CO-1

3ME4-22 Materials Testing Lab CO-2

CO-1 To analyse the mechanism of bicycle, sewing machine 93.25 97.75 90 93.84

Basic Mechanical

3ME4-23 Engineering Lab CO-2 To compare the working of pump, engine and air conditioners 93.25 97.75 94 94

Programming using CO-1 To become familiar with fundamental operations in Matlab 68.2 82.2 88

3ME4-24 MATLAB CO-2 To perform statistical data analysis, data interpolation by Matlab, solve differentiation equation with Matlab 68.2 84.4 86

CO-1

3ME7-30 Industrial Training CO-2

Das könnte Ihnen auch gefallen

- Computer Aided Process Planning (CAPP): 2nd EditionVon EverandComputer Aided Process Planning (CAPP): 2nd EditionNoch keine Bewertungen

- An Industry 4 0 Framework For Tooling Production Using Metal Add - 2020 - ProcedDokument6 SeitenAn Industry 4 0 Framework For Tooling Production Using Metal Add - 2020 - ProcedajayvgNoch keine Bewertungen

- Design of A Microprocessor-Based Control System of A Compression Molding Process George K. AdamDokument7 SeitenDesign of A Microprocessor-Based Control System of A Compression Molding Process George K. AdamLutaaya Geoff UGNoch keine Bewertungen

- Modeling and Problem Solving Techniques for EngineersVon EverandModeling and Problem Solving Techniques for EngineersNoch keine Bewertungen

- Cad 20 (S3) 2023 72-83Dokument12 SeitenCad 20 (S3) 2023 72-83vipinNoch keine Bewertungen

- Embedded Microcontroller Interfacing for M-COR ® SystemsVon EverandEmbedded Microcontroller Interfacing for M-COR ® SystemsNoch keine Bewertungen

- Cad 20S3 2023 72-83Dokument13 SeitenCad 20S3 2023 72-83vipinNoch keine Bewertungen

- Advanced MaterialsDokument2 SeitenAdvanced MaterialsJohn SantoshNoch keine Bewertungen

- Capp PDFDokument201 SeitenCapp PDFEdgardo Ed RamirezNoch keine Bewertungen

- Talon Garikayi c056634k - Final Automated Lubrication System Project For Simbi Plant With Cover Page PageDokument88 SeitenTalon Garikayi c056634k - Final Automated Lubrication System Project For Simbi Plant With Cover Page Pagetalon0% (1)

- 1637146138aa21 Energy Optimization Through A Metso Outotec Process Control Optimizer in Fluid Bed Alumina Calciner at Cba pdf1637146138Dokument11 Seiten1637146138aa21 Energy Optimization Through A Metso Outotec Process Control Optimizer in Fluid Bed Alumina Calciner at Cba pdf1637146138Senthilkumar PragasamNoch keine Bewertungen

- CADCAM MinDokument91 SeitenCADCAM MinBandi KumarreddyNoch keine Bewertungen

- Department of Mechanical Engineering: Mec18R448: Automation in Manufacturing L T P C 3 0 0 3Dokument1 SeiteDepartment of Mechanical Engineering: Mec18R448: Automation in Manufacturing L T P C 3 0 0 3Raj KumarNoch keine Bewertungen

- ME8791 Mechatronics - UNIT IIDokument52 SeitenME8791 Mechatronics - UNIT IIUdamanNoch keine Bewertungen

- 12 (Report)Dokument84 Seiten12 (Report)Nishant MishraNoch keine Bewertungen

- Integrated Geometry AND Grid Generation System FOR: Pi: - Ceding Bla, NK Not FilmedDokument12 SeitenIntegrated Geometry AND Grid Generation System FOR: Pi: - Ceding Bla, NK Not FilmeddibekayaNoch keine Bewertungen

- DR - 50 - Cloud-Based Control Strategy - Downstream Defect Reduction in The Production of Electric MotorsDokument6 SeitenDR - 50 - Cloud-Based Control Strategy - Downstream Defect Reduction in The Production of Electric MotorsMukti Ali SadikinNoch keine Bewertungen

- How To Assign Cost To DCS Points - Automation & Control Engineering ForumDokument14 SeitenHow To Assign Cost To DCS Points - Automation & Control Engineering ForumPravivVivpraNoch keine Bewertungen

- 16mec324 Cad Cam Cim Question BankDokument8 Seiten16mec324 Cad Cam Cim Question BankAbdalmalek ShamsanNoch keine Bewertungen

- Ofsopc: With Citect SCADA 2016Dokument35 SeitenOfsopc: With Citect SCADA 2016Pedro GuardoneNoch keine Bewertungen

- Model Predictive Controllers: A Critical Synthesis of Theory and Industrial NeedsDokument50 SeitenModel Predictive Controllers: A Critical Synthesis of Theory and Industrial NeedsRenan RanelliNoch keine Bewertungen

- Implementation of An Intelligent Robotized GMAW Welding Cell, Part 1 - Design and SimulationDokument22 SeitenImplementation of An Intelligent Robotized GMAW Welding Cell, Part 1 - Design and SimulationLeonardo LoretiNoch keine Bewertungen

- Development of A Combustion Chamber Design Methodology and Automation of The Design ProcessDokument10 SeitenDevelopment of A Combustion Chamber Design Methodology and Automation of The Design ProcessDƯƠNG CẨM TOÀNNoch keine Bewertungen

- Modeling An SMT Line To Improve ThroughputDokument6 SeitenModeling An SMT Line To Improve Throughputgautham VNoch keine Bewertungen

- The Catia Design Process, Design and Manufacture in AviationDokument3 SeitenThe Catia Design Process, Design and Manufacture in AviationVigneshkumarNoch keine Bewertungen

- PDF 163423 89729Dokument13 SeitenPDF 163423 89729teddygg468Noch keine Bewertungen

- N217 DocumentationDokument108 SeitenN217 DocumentationSyed MohiuddinNoch keine Bewertungen

- Idea Submission Form: Institution's Innovation CouncilDokument4 SeitenIdea Submission Form: Institution's Innovation CouncilAnuj MathurNoch keine Bewertungen

- Application of PLC's For Automation of Processes in IndustriesDokument7 SeitenApplication of PLC's For Automation of Processes in IndustriesMHMDNoch keine Bewertungen

- Project Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Dokument2 SeitenProject Proposals For: Manufacturing Engineering Projects (IM-416) Batch: 2009-2010Timothy FieldsNoch keine Bewertungen

- CFD - Driving Engineering ProductivityDokument5 SeitenCFD - Driving Engineering ProductivityBramJanssen76Noch keine Bewertungen

- Combining Holistic Programming With Kinematic Parameter Opti-Misation For Robot MachiningDokument7 SeitenCombining Holistic Programming With Kinematic Parameter Opti-Misation For Robot MachiningJavier Baliñas SantosNoch keine Bewertungen

- Design Engineering-May June 2023Dokument32 SeitenDesign Engineering-May June 2023Dizzy_88Noch keine Bewertungen

- CO: The Chameleon 64-Bit Microprocessor Prototype: B. F. Sgs-ThomsonDokument6 SeitenCO: The Chameleon 64-Bit Microprocessor Prototype: B. F. Sgs-ThomsonLekhank NandakumarNoch keine Bewertungen

- Me8691 Computer Aided Design and Manufacturing SyllabusDokument2 SeitenMe8691 Computer Aided Design and Manufacturing SyllabusGanapathy TNoch keine Bewertungen

- DO Seminar ReportDokument18 SeitenDO Seminar ReportMithun N Gowda ME-MD-2019-21Noch keine Bewertungen

- Design and Analysis of Gantry Robot For Pick and Place Mechanism WithDokument8 SeitenDesign and Analysis of Gantry Robot For Pick and Place Mechanism WithHaider AliNoch keine Bewertungen

- L'Aquila, Italy L'Aquila, Italy L'Aquila, Italy: BstractDokument6 SeitenL'Aquila, Italy L'Aquila, Italy L'Aquila, Italy: Bstracts3ct0r 10Noch keine Bewertungen

- A Flexible Real-Time Motor Control System For Robot JointsDokument4 SeitenA Flexible Real-Time Motor Control System For Robot JointsmalleswarararaoNoch keine Bewertungen

- Cocktail Automation Management SystemDokument58 SeitenCocktail Automation Management Systemapip055Noch keine Bewertungen

- Norma VDI 2206Dokument6 SeitenNorma VDI 2206Nelson Sanchez0% (1)

- SyllabusDokument17 SeitenSyllabusShanmuk ReddyNoch keine Bewertungen

- A Parametric Blade Design System - AndersDokument50 SeitenA Parametric Blade Design System - Andersaxeem1Noch keine Bewertungen

- Using Simulation Driven Design and Optimizations To Increase ProductivityDokument11 SeitenUsing Simulation Driven Design and Optimizations To Increase Productivitygshock65Noch keine Bewertungen

- BPM For Analysis of Industrial Lot Applications PapaerDokument8 SeitenBPM For Analysis of Industrial Lot Applications PapaerDaniela HernandezNoch keine Bewertungen

- Spe 192080 MsDokument14 SeitenSpe 192080 Ms9412ttjNoch keine Bewertungen

- 1998-On The Use of CFD in The Automotive Engine Cooling Fan System DesignDokument12 Seiten1998-On The Use of CFD in The Automotive Engine Cooling Fan System DesignJianbo JiangNoch keine Bewertungen

- Dom Equ and Sys Eng Sol v5r18 enDokument20 SeitenDom Equ and Sys Eng Sol v5r18 enbelal MahmoudNoch keine Bewertungen

- 3 Axis Milling Machine PDFDokument5 Seiten3 Axis Milling Machine PDFAnuj MathurNoch keine Bewertungen

- Report On InternshipDokument26 SeitenReport On Internship4AI20EC078 Safa AliNoch keine Bewertungen

- A Project Report OnDokument84 SeitenA Project Report OnyaminiNoch keine Bewertungen

- Courses of Content: Mc-091-3 Ndustrial Automation Engineering Systems AssemblyDokument4 SeitenCourses of Content: Mc-091-3 Ndustrial Automation Engineering Systems AssemblyIzz Hanzalah AhmadNoch keine Bewertungen

- Coker UnitDokument15 SeitenCoker UnitAhmed YousryNoch keine Bewertungen

- 00 - ArtículoDokument7 Seiten00 - Artículoheidy pintoNoch keine Bewertungen

- Automatic Welding and Soldering MachineDokument6 SeitenAutomatic Welding and Soldering Machine07 Bharath SNoch keine Bewertungen

- CIRED2017 - 0057 - Final RULES DRIVEN PROJECT SPECIFICATION IN THE CONTEXT OF IEC 61850 BASIC APPLICATION PROFILESDokument5 SeitenCIRED2017 - 0057 - Final RULES DRIVEN PROJECT SPECIFICATION IN THE CONTEXT OF IEC 61850 BASIC APPLICATION PROFILESChris ParkinsonNoch keine Bewertungen

- B. Sc. In: MechatronicsDokument8 SeitenB. Sc. In: MechatronicsyHtetAgNoch keine Bewertungen

- 17 MPC - Distillation - Column PDFDokument15 Seiten17 MPC - Distillation - Column PDFneiljain421Noch keine Bewertungen

- B TechDokument39 SeitenB TechrishipareekNoch keine Bewertungen

- A Technical Seminar ON Cryogenic CoolingDokument16 SeitenA Technical Seminar ON Cryogenic CoolingrishipareekNoch keine Bewertungen

- A Technical Seminar ON Cryogenic CoolingDokument15 SeitenA Technical Seminar ON Cryogenic CoolingrishipareekNoch keine Bewertungen

- A Technical Seminar ON Cryogenic CoolingDokument16 SeitenA Technical Seminar ON Cryogenic CoolingrishipareekNoch keine Bewertungen

- CryogeniDokument17 SeitenCryogenirishipareekNoch keine Bewertungen

- 300 ZX Twin Turbo Nitrous Oxide System: Installation InstructionsDokument3 Seiten300 ZX Twin Turbo Nitrous Oxide System: Installation InstructionsrishipareekNoch keine Bewertungen

- Cryogenic CoolingDokument17 SeitenCryogenic Coolingrishipareek0% (1)

- Mathematics 7 LAS Quarter 3Dokument97 SeitenMathematics 7 LAS Quarter 3Villamor Baculi82% (17)

- ESM-4810A1 Energy Storage Module User ManualDokument31 SeitenESM-4810A1 Energy Storage Module User ManualOscar SosaNoch keine Bewertungen

- Part 3-Chap 2 - Classification of Buildings Based On OccupanciesDokument60 SeitenPart 3-Chap 2 - Classification of Buildings Based On Occupanciesfaruque65Noch keine Bewertungen

- International Travel Insurance Policy: PreambleDokument20 SeitenInternational Travel Insurance Policy: Preamblethakurankit212Noch keine Bewertungen

- Plaquette - PRECASEM - CIMEC 2019 English VersionDokument18 SeitenPlaquette - PRECASEM - CIMEC 2019 English VersionFranck BertrandNoch keine Bewertungen

- Mechanism Design: A SeriesDokument3 SeitenMechanism Design: A Seriesamirmasood kholojiniNoch keine Bewertungen

- Circle Theorem 1Dokument3 SeitenCircle Theorem 1yaw197Noch keine Bewertungen

- Ayushi Environment FinalDokument21 SeitenAyushi Environment FinalRishabh SinghNoch keine Bewertungen

- Bahasa Inggris PATDokument10 SeitenBahasa Inggris PATNilla SumbuasihNoch keine Bewertungen

- South Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliDokument29 SeitenSouth Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliHari Dante Cry100% (1)

- The Royal Commonwealth Society of Malaysia: Function MenuDokument3 SeitenThe Royal Commonwealth Society of Malaysia: Function MenuMynak KrishnaNoch keine Bewertungen

- LINEAR INDUCTION MOTOR 6981660.ppsxDokument56 SeitenLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterNoch keine Bewertungen

- Etl 213-1208.10 enDokument1 SeiteEtl 213-1208.10 enhossamNoch keine Bewertungen

- Second Advent Herald (When God Stops Winking (Understanding God's Judgments) )Dokument32 SeitenSecond Advent Herald (When God Stops Winking (Understanding God's Judgments) )Adventist_TruthNoch keine Bewertungen

- SweetenersDokument23 SeitenSweetenersNur AfifahNoch keine Bewertungen

- 02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFDokument31 Seiten02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFswarupNoch keine Bewertungen

- Chapter 1 - Part 1 Introduction To Organic ChemistryDokument43 SeitenChapter 1 - Part 1 Introduction To Organic ChemistryqilahmazlanNoch keine Bewertungen

- Farmhouse Style Plans - Farm & CountryDokument6 SeitenFarmhouse Style Plans - Farm & Countryhanif azriNoch keine Bewertungen

- Thesis Brand BlanketDokument4 SeitenThesis Brand BlanketKayla Smith100% (2)

- Practical 3.1 Determining The Specific Heat CapacityDokument3 SeitenPractical 3.1 Determining The Specific Heat CapacityiAlex11Noch keine Bewertungen

- The Latent Phase of LaborDokument8 SeitenThe Latent Phase of LaborLoisana Meztli Figueroa PreciadoNoch keine Bewertungen

- Science7 q2 Mod6of8 Asexual Sexualrep v2Dokument26 SeitenScience7 q2 Mod6of8 Asexual Sexualrep v2Ishi OcheaNoch keine Bewertungen

- 1943 Dentures Consent FormDokument2 Seiten1943 Dentures Consent FormJitender ReddyNoch keine Bewertungen

- Titan GelDokument6 SeitenTitan GelVladi Salas100% (1)

- Need For Advanced Suspension SystemsDokument10 SeitenNeed For Advanced Suspension SystemsIQPC GmbHNoch keine Bewertungen

- Science: The Menstrual CycleDokument4 SeitenScience: The Menstrual CycleLena Beth Tapawan YapNoch keine Bewertungen

- Syllabus (402050B) Finite Element Analysis (Elective IV)Dokument3 SeitenSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavNoch keine Bewertungen

- 3TRIGODokument5 Seiten3TRIGOCielo Pabilan ObemioNoch keine Bewertungen

- Section Thru A-A at S-1: Footing ScheduleDokument1 SeiteSection Thru A-A at S-1: Footing ScheduleJan GarciaNoch keine Bewertungen

- The Earth's SubsystemsDokument17 SeitenThe Earth's SubsystemsAndevie Balili Iguana100% (1)