Beruflich Dokumente

Kultur Dokumente

CBEN409 02 Summary Correlations

Hochgeladen von

die_1Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

CBEN409 02 Summary Correlations

Hochgeladen von

die_1Copyright:

Verfügbare Formate

Summary Correlations from “Feedstocks & Products”

1. API gravity (G) & specific gravity ( o ). Higher density lower °API

141.5 141.5

G 131.5 o

o 131.5 G

2. Watson characterization factor. Tendencies: 12 – 13 (paraffinic) to 10 (aromatic)

3 Tb

KW Tb in units of °R

o

3. Blending rules

Volume blending Mass blending

V X mi X i vi oi X i

X mix vi X i i i

X mix wi X i

V i mi vi oi

4. Blend specific gravities – directly by volume

Volume blending Alternate blending

Vi o ,i Vi o,i v 1 w

i

M xM

i i

o ,mix i o ,i

Vi V o ,mix o ,i o ,mix o ,i

5. Blend API gravities – blend specific gravities & calculate from blended value

6. O’Donnell method to correct liquid specific gravity for temperature

T2 2o 0.000601 T 60 with T in °F

Multiply T by the 60°F water density to get the density at the temperature T .

Original equation in terms of liquid density:

T2 o2 0.00108 T T0 with T in °C, in kg/L, & T0 near 15°C

7. Method in Chapter 12.3 of API Measurement Manual to estimate volumetric shrinkage

VL

S 4.86 108 C 100 C GL GH

0.819 2.28

where C 100

VH VL

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -1- July 12, 2018

8. Maxwell-Bonnell equations to correct boiling point for pressure (T in °R & P in mmHg)

3000.538 X 6.761560 X 0.002184346

43X 0.987672 P vap 1.7 mmHg

2663.129 X 5.994296 0.001201343 X 0.002184346

log 10 P

vap

95.76 X 0.972546

1817 mmHg P vap 1.7 mmHg

0.001201343 X

2770.085X 6.412631

36 X 0.989679

1817 mmHg P vap

1

0.0002867 P vap

X T & TB TB 2.5 f K W 12 log10

1 760

748.1 0.0002867

TB

1 P vap 760 mmHg

f TB 659.67

Min 1,Max ,0 P vap 760 mmHg

200

9. Interconvert D86 & TBP Temperatures – 1994 API Technical Data Book method

TTBP,50% 0.87180 TD86,50%

1.0258

(TTBP,50% & TD86,50% in °F)

TTBP A TD86

B

( TTBP & TD86 in °F)

Vol% A B Max T [°F]

100% to 90%* 0.11798 1.6606

90% to 70% 3.0419 0.75497 100

70% to 50% 2.5282 0.82002 150

50% to 30% 3.0305 0.80076 250

30% to 10% 4.9004 0.71644 250

10% to 0%* 7.4012 0.60244 100

10. Interconvert D1160 & TBP Temperatures – temperatures evaluated at 10 mmHg

TTBP a TD1160 b TD1160 c TD1160 d TD1160

2 3 4

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -2- July 12, 2018

Vol%

Distilled a b c d

Range

0% - 10% 2.23652561 -1.39334703×10-2 3.6358409×10-5 1.433117×10-8

10%-30%

1.35673984 -5.4126509×10-3 2.9883895×10-5 -6.007274×10-8

30%-50%

11. Riazi equation to smooth distillation data

1

T T0 AT 1 BT B T T BT

ln

Y 1 exp T 0

T0 BT 1 Y AT T0

12. Excel functions to interpolate/extrapolate distillation data

Transformed Yield: =NORMSINV( Pct_Yield/100 )

From interpolated value: =NORMSDIST( Value ) * 100

Functions return errors for the extreme values of 0% & 100%. Typical practice is to use 0.1% &

99.9% instead.

13. Estimate molecular weight of narrow petroleum fraction

M 20.486TB1.26007 o4.98308 exp 0.0001165TB 7.78712 o 0.0011582TB o

14. Estimate heat of combustion of petroleum fraction (Btu/lb, liquid state @ 60°F)

Hˆ LHV 16792 54.5G 0.217G 2 0.0019G3

Hˆ HHV 17672 66.6G 0.316G 2 0.0014G 3

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -3- July 12, 2018

Heating values for the vapor state must take into account the heat of vaporization at the reference

temperature.

15. Approximate method to blend individual Watson K factors (by weight)

K mix wi K i

v K

i oi i

v i oi

16. 5 definitions for different types of average boiling points:

n

Volume average boiling point (VABP) Tb v viTb ,i

i 1

n

Weight average boiling point (WABP) Tb w wiTb ,i

i 1

n

Molar average boiling point (MABP) Tb M xiTb ,i

i 1

3

n

Cubic average boiling point (CABP) Tb cubic vi 3 Tb ,i

i 1

Tb M Tb cubic

Mean average boiling point (MeABP) Tb mean

2

17. Estimate average boiling points from ASTM D 86 distillation values (in °F)

T10 T30 T50 T70 T90

VABP

5

T T

SL 90 10

90 10

WABP VABP 1

MABP VABP 2

CABP VABP 3

MeABP VABP 4

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -4- July 12, 2018

ln 1 3.062123 0.01829 VABP 32 4.45818 SL

0.6667 0.25

ln 2 0.563793 0.007981 VABP 32 3.04729 SL

0.6667 0.333

ln 3 0.23589 0.06906 VABP 32 1.8858 SL

0.45 0.45

ln 4 0.94402 0.00865 VABP 32 2.99791 SL

0.6667 0.333

18. Vapor pressure approximation using acentric factor definition

P vap 7 Tci

log10 i 1 i 1

Pci 3 T

19. Volumetric blending with “RVP Blending Indices”

1.25 1/1.25

RVP mix vi RVP i RVP mix vi RVP i

1.25 1.25

20. Non-linear octane blending equations – Ethyl Corporation models

A is %aromatics (0 to 100) & O is %olefins (0 to 100)

R R a1 RJ R J a2 O 2 O 2 a3 A2 A2

2

A2 A2

M M b1 MJ M J b2 O O b3

2

100

2

RM

"Road" Octane

2

Sensitivity J R M

Volume Average X

v X

i i

v i

75 Blends 135 Blends

a1 0.03224 0.03324

a2 0.00101 0.00085

a3 0 0

b1 0.04450 0.04285

b2 0.00081 0.00066

b3 -0.00645 -0.00632

21. Driveability Index

DI 1.5 T10 3 T50 T90 2.4°F EtOH vol%

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -5- July 12, 2018

22. Estimate Flash Point

For pure components or well‐defined pseudo‐components

Method of Lenoir

i

x i M i i Pivap 1.3

1

where i is the liquid activity coefficient

Method of Gmehling & Rasmussen

N

x i i Pivap T 25

Li

1 with Li Li 25C 0.182

H

i 1 c ,i

For petroleum fraction characterized by distillation

curve

API Procedure 2B7.1 (using ASTM D86 T10 value)

1999 Version (units of °F)

TF 0.69 T10 118.2

1987 Version (units of °R). Questionable accuracy

above T10 of 500°F.

1 2.84947

0.014568 0.001903 ln T10

TF T10

23. Estimate Cetane index by ASTM D 976 (using

ASTM D 86 T50 value in °R)

Index 420.34 0.016G 2 0.192G log T50 65.01 log T50 0.0001809T502

2

24. Relationship between octane & cetane numbers

CN 60.96 0.56 MON

CN 68.54 0.61 RON

25. Interrelate SUS viscosity with cSt viscosity (T in °F)

1.0 0.03264

SUS 1.0 0.000061 T 100 4.6324

3930.2 262.7 23.97 2 3 105

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -6- July 12, 2018

26. Adjust kinematic viscosity for temperature using Walther equation. Provides a framework to

regress viscosity data with respect to temperature.

log log 0.7 A B log T 1010

A BlogT

0.7

Can also use natural logarithms:

ln ln 0.7 A B ln T exp exp A B ln T 0.7 .

27. Adjust viscosity for temperature using ASTM D341 for viscosities above 0.21 cSt. An adjustment

to the “shift factor” of the Walther equation for applicability to viscosities lower than 0.3 cSt.

log log Z A B log T

Z 0.7 C D E F G H

C exp 1.14883 2.65868

D exp 0.0038138 12.5645

E exp 5.46491 37.6289

F exp 13.0458 74.6851

G exp 37.4619 192.643

H exp 80.4945 400.468

Z 0.7 exp 0.7487 3.295 Z 0.7 0.6119 Z 0.7 0.3193 Z 0.7

2 3

28. Blend viscosities

“log-log” method as volume blend

Wi log log mix 0.7

Wmix vi Wi

V W i i

mix 1010

Wmix

0.7

V i

Will also work with natural logs:

Wi ln ln mix 0.7

Wmix vi Wi

V W i i

mix exp exp Wmix 0.7

V i

ASTM D 7152 extends the validity of method to lower viscosities

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -7- July 12, 2018

Z i i 0.7 exp 1.47 1.84 i 0.512i

Wi log log Z i

WB vi Wi

WB

Z B 1010 0.7

B Z B exp 0.7487 3.295Z B 0.6119Z B2 0.3193Z B3

Chevron Method 2. Volume blend the viscosity indices:

ln i

Wi

ln 1000 i

Wmix vi Wi

V W i i

ln mix ln 1000

Wmix

V i 1 Wmix

29. Relationship of Ramsbottom to Conradson Carbon

RCR exp 0.236 0.883ln CCR 0.0657ln2 CCR

Additional Useful Correlations

30. Critical temperature & pressure for a narrow boiling fraction. Lee & Kesler method also

published as Procedures 4D3.1 & 4D4.1 (4th ed., 1987). Temperatures are in °R & pressure is in

psia.

Tc 10.6443 exp 5.1747 104 Tb 0.5444 o 3.5995 104 Tb o Tb0.81067 0.53091

o

..

31. Heat of Vaporization. Kistiakowsky equation (The Properties Of Gases And Liquids, 3rd ed., p

215):

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -8- July 12, 2018

Tb

Hvb

Tc

8.75 R log Tb

where temperatures are in units of K & the heat of vaporization are in units of J/g.mol. The effect of

temperature can be estimated using the Watson method (The Properties Of Gases And Liquids, 4th

ed., p 228):

0.38

1 Tr 2

Hv 2 Hv 1

1 Tr 1

32. Prediction of kinematic viscosities @ 100 & 210°F. Correlation by Abbott included in old

editions the API Technical Data Book:

log 100F 4.39371 1.9473 K W 0.12769 K W2

3.2629 104 G 2 1.18246 102 K W G

0.171617 K W2 10.9943G 9.50663 102 G 2 0.860218 K W G

G 50.3642 4.78231 K W

log 210F 0.463634 0.166532G 5.13447 104 G 2 8.48995 103 K W G

8.0325 102 K W 1.24899 G 0.19768 G 2

G 26.786 2.26296 K W

where the units on kinematic viscosity is cSt. However, this technique does not extrapolate well & is

only valid for boiling points 600‐ 700°F or so.

Once these values are known then the temperature dependency can be determined from:

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 -9- July 12, 2018

log log 0.7 cT A1 B1 log T

0.085 T 1.52 if T 1.5 cSt

cT

0 if T 1.5 cSt

The latest API Technical Data Book (10th ed.) has a better Procedure 11.A4.2:

log10 ref 1.35579 8.16059 104 Tb +8.38505 107 Tb2

log 10 cor A1 A2 K W

A1 34.9310 8.84387 102 Tb 6.73513 105 Tb2 1.01394 108 Tb3

A2 2.92649 6.98405 103 Tb 5.09947 106 Tb2 7.49378 1010 Tb2

100F ref cor

log 10 210F 1.92353 2.41071 104 Tb 0.511300 log10 Tb 100F

where the boiling point is in units of °R. The recommended equation to modify these viscosities

with respect to temperature is:

log10 T 0.86960 To

S

where S 0.28008 log10 0 1.8616 .

log10 0 0.86960 T

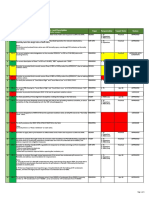

This procedure gives viscosity curves those shown below.

33. Freezing point, pour point, & cloud point. If kinematic viscosities are not known then

Procedures 2C5.1, 2C2, & 2C6.1, respectively (10th ed. API Technical Data Book) can be used:

TFPT ,R 2390.42 1826 o 122.49 K W 0.135 MeABP .

Tpour , R 3.85 108 MeABP

5.49

10

0.712 MeABP

0.315

0.133 o 1.4 .

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 - 10 - July 12, 2018

log 10 TCPT , R 7.41 5.49 log10 MeABP 0.712 MeABP

0.315

0.133 o .

If kinematic viscosity is known:

Tpour , R 753 136 1 e 0.15100 F 572 o 0.0512 100 F 0.139 MeABP .

If cloud point is known then (Procedure 2C8.2):

Tpour , R 0.9895 TCPT , R 1.4 .

The correlations using MeABP, specific gravity, and/or Watson K factor are depicted in the

following figures.

John Jechura, jjechura@mines.edu

CBEN 409, Rev 1.2 - 11 - July 12, 2018

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- IEDs; A Contemporary Viewpoint on Threats and PrecautionsDokument67 SeitenIEDs; A Contemporary Viewpoint on Threats and PrecautionsDeepak Mishra100% (2)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Kelloggs Edition 14 SummaryDokument2 SeitenKelloggs Edition 14 SummaryRitu JainNoch keine Bewertungen

- Lube BAse Oil (S-Oil)Dokument6 SeitenLube BAse Oil (S-Oil)die_1Noch keine Bewertungen

- Crude Distillation: Petroleum Refining Engineering 2012 - 2013Dokument22 SeitenCrude Distillation: Petroleum Refining Engineering 2012 - 2013die_1Noch keine Bewertungen

- Spe 131758 Ms - GL and EspDokument11 SeitenSpe 131758 Ms - GL and EspSamuel VmNoch keine Bewertungen

- PHYSICSDokument3 SeitenPHYSICSAndrew NibungcoNoch keine Bewertungen

- Oil Refining and ProductsDokument15 SeitenOil Refining and Productsdie_1Noch keine Bewertungen

- Advanced Fluid Characterization (Schlumberger)Dokument8 SeitenAdvanced Fluid Characterization (Schlumberger)Astrid Hardtke100% (1)

- Presentations Oil Refinery ProcessesDokument36 SeitenPresentations Oil Refinery ProcessesGururaj SreepatharaoNoch keine Bewertungen

- Presentations Oil Refinery ProcessesDokument36 SeitenPresentations Oil Refinery ProcessesGururaj SreepatharaoNoch keine Bewertungen

- Catalyst DeactivationDokument20 SeitenCatalyst Deactivationdie_1Noch keine Bewertungen

- Marine Lubricants Viscosity ClassificationsDokument4 SeitenMarine Lubricants Viscosity Classificationsdie_1Noch keine Bewertungen

- Future Perspectives in Catalyst PDFDokument84 SeitenFuture Perspectives in Catalyst PDFdie_1Noch keine Bewertungen

- CBEN409 02 Summary CorrelationsDokument11 SeitenCBEN409 02 Summary Correlationsdie_1Noch keine Bewertungen

- Research Highlights in New Catalytic Technologies: 1.theme DescriptionDokument13 SeitenResearch Highlights in New Catalytic Technologies: 1.theme Descriptiondie_1Noch keine Bewertungen

- Selecting Tema HXDokument4 SeitenSelecting Tema HXDavitxu1Noch keine Bewertungen

- HAZOP STUDY RECOMMENDATIONS FOR PATRA SK UTILITY SYSTEMSDokument4 SeitenHAZOP STUDY RECOMMENDATIONS FOR PATRA SK UTILITY SYSTEMSdie_1Noch keine Bewertungen

- Criterion Catalyst Increase YieldDokument2 SeitenCriterion Catalyst Increase Yielddie_1Noch keine Bewertungen

- Jan Trocki Pres EngDokument28 SeitenJan Trocki Pres Engdie_1Noch keine Bewertungen

- Base Oil Manufacturing Hydroprocessing (Amy Claxton, ICIS)Dokument36 SeitenBase Oil Manufacturing Hydroprocessing (Amy Claxton, ICIS)die_1Noch keine Bewertungen

- CEPSA Good Reference For ZeoliteDokument29 SeitenCEPSA Good Reference For Zeolitedie_1Noch keine Bewertungen

- Viscosity: A Lubricant Most Important CharacteristicDokument11 SeitenViscosity: A Lubricant Most Important Characteristicazhar_11094909Noch keine Bewertungen

- Hydrocracking CatalystsDokument8 SeitenHydrocracking Catalystsdie_1Noch keine Bewertungen

- Mar - 2013 - CEP Coriolis The Direct Approach To Mass Flow Measurement PDFDokument6 SeitenMar - 2013 - CEP Coriolis The Direct Approach To Mass Flow Measurement PDFJairo AltamiranoNoch keine Bewertungen

- Midw Technology As A Drop-In Catalyst SolutionDokument11 SeitenMidw Technology As A Drop-In Catalyst Solutiondie_1Noch keine Bewertungen

- ExxonMobil Basestocks Industry Pulse Report - FINALDokument28 SeitenExxonMobil Basestocks Industry Pulse Report - FINALdie_1Noch keine Bewertungen

- Optimise Hydrocracker Operations For Maximum DistillatesDokument8 SeitenOptimise Hydrocracker Operations For Maximum Distillatesdantorrelio89Noch keine Bewertungen

- Selecting Tema HXDokument4 SeitenSelecting Tema HXDavitxu1Noch keine Bewertungen

- Masoneilan TablesDokument6 SeitenMasoneilan TablesgajaremdNoch keine Bewertungen

- Masoneilan TablesDokument6 SeitenMasoneilan TablesgajaremdNoch keine Bewertungen

- SiteDokument1 SeiteSitedie_1Noch keine Bewertungen

- Msds of TccaDokument5 SeitenMsds of Tccadie_1Noch keine Bewertungen

- Pres Middle East Catalyst Marketapril 2016Dokument17 SeitenPres Middle East Catalyst Marketapril 2016die_1Noch keine Bewertungen

- Acd (Microproject Report)Dokument42 SeitenAcd (Microproject Report)Gaurav SapkalNoch keine Bewertungen

- 2 - Acid and Base TitrationDokument90 Seiten2 - Acid and Base TitrationEnin SofiyaNoch keine Bewertungen

- Costa Hosh - SP Final DraftDokument10 SeitenCosta Hosh - SP Final Draftapi-551407564Noch keine Bewertungen

- 01 V5 X Series Engineering Data BookDokument212 Seiten01 V5 X Series Engineering Data Bookcalvin.bloodaxe4478Noch keine Bewertungen

- Diagrama de Interconexion XL 200 PDFDokument9 SeitenDiagrama de Interconexion XL 200 PDFjoseNoch keine Bewertungen

- Clivet Carel PcoDokument80 SeitenClivet Carel PcoToni Dlabac100% (2)

- Electrochemistry NotesDokument16 SeitenElectrochemistry NotesRandomNoch keine Bewertungen

- Zone 22 Hazardous Locations Classification and RequirementsDokument3 SeitenZone 22 Hazardous Locations Classification and RequirementsVictor TenorioNoch keine Bewertungen

- Instructions for use and installation of a washing machineDokument16 SeitenInstructions for use and installation of a washing machineVale MocanuNoch keine Bewertungen

- Minerals Engineering: Paul W. Cleary, Matt D. SinnottDokument22 SeitenMinerals Engineering: Paul W. Cleary, Matt D. SinnottAlbertoNoch keine Bewertungen

- Learn Discrete ComponentsDokument2 SeitenLearn Discrete ComponentsamitcrathodNoch keine Bewertungen

- 7.5 01 02 01Dokument19 Seiten7.5 01 02 01Feri SaputraNoch keine Bewertungen

- High Voltage Engineering Ref ManualDokument147 SeitenHigh Voltage Engineering Ref Manualzeus009100% (1)

- 436 - 1 - 1 - Sampling of CoalDokument24 Seiten436 - 1 - 1 - Sampling of CoalSudhanshu DashNoch keine Bewertungen

- BIOCNGDokument23 SeitenBIOCNGDhruva DNoch keine Bewertungen

- Asco Avtron 2000 Series With Sigma LT User Manual PDFDokument43 SeitenAsco Avtron 2000 Series With Sigma LT User Manual PDFfernandoNoch keine Bewertungen

- LP2014Dokument56 SeitenLP2014Rodrigo Navarra JrNoch keine Bewertungen

- OCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Dokument12 SeitenOCR Advanced GCE Physics A - 2826/01 - Unifying Concepts in Physics - January 2007Soham PatwardhanNoch keine Bewertungen

- SERIES AC CIRCUIT PROBLEMSDokument4 SeitenSERIES AC CIRCUIT PROBLEMSHubert Semeniano100% (1)

- 1.ENERGY SCENARIO-merged PDFDokument188 Seiten1.ENERGY SCENARIO-merged PDFraj walkeNoch keine Bewertungen

- Induction Material MoPnGDokument60 SeitenInduction Material MoPnGRaghvendra UpadhyaNoch keine Bewertungen

- 0401544-Hydraulic StructuresDokument38 Seiten0401544-Hydraulic StructuresEfremWakjiraHodeNoch keine Bewertungen

- Bhagvender Singh XII-A Physics Project PDFDokument15 SeitenBhagvender Singh XII-A Physics Project PDFvoid50% (4)

- Lecture-3,4, 5-Weirs and BarragesDokument41 SeitenLecture-3,4, 5-Weirs and BarragesMuhammad Sakib0% (1)

- Wattstopper Sensor The Most Advanced Energy Saving TechnologyDokument7 SeitenWattstopper Sensor The Most Advanced Energy Saving TechnologyDemo Only100% (1)