Beruflich Dokumente

Kultur Dokumente

Xomox 070 WaferSwingCheckValvesInstall 335696 NorthAmerica PDF

Hochgeladen von

sennimalaiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Xomox 070 WaferSwingCheckValvesInstall 335696 NorthAmerica PDF

Hochgeladen von

sennimalaiCopyright:

Verfügbare Formate

brands you trust.

Installation Instructions

CRANE ChemPharma, Tufline®

070 Wafer Swing Check Valve

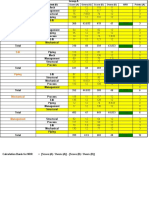

Installation Instructions Flange Bolt Selection Guide

070

The flange bolt dimensions provided here are based on

nominal dimensions and are intended only as a guide.

Bolt length in any given installation may vary due to

manufacturing tolerances of valves, flanges, flange bolts,

Wafer Swing Check Valve gaskets, and any additional auxiliary equipment.

Sizes 3 through 12 inch, ANSI Class 150 Unless otherwise noted, stud and bolt lengths are based

on the following data: Minimum flange thickness of weld-

Fully lined wafer swing check valves are ideal for use in ing neck flanges per ANSI B16.5 and heavy hex nuts.

totally lined piping systems or to replace costly high alloy

valves in corrosive applications. The valve can be Wafer Style (Flangeless) Figure 070, Class 150

mounted horizontally or vertically with upward flow.

*

Tufline wafer swing check valves are of two piece con-

struction with only one moving part. Integral hinge pins

fit into the valve body recess; there are no springs or

pins to corrode or wear.

Read Carefully.

The following procedures and

illustrations have been prepared to Valve Torque** Hex Head Bolt Stud Length

assist you in the installation, mainte- Size Quantity Ft. Lbs. Length (L1) (L2)*

nance and repair of your Tufline valves. 2" 4 75 5/8-11 x 4.50 5/8-11 x 5.50

Please read these instructions

carefully. 3" 4 110 5/8-11 x 4.75 5/8-11 x 5.75

4" 8 95 5/8-11 x 5.00 5/8-11 x 6.00

READ INSTRUCTIONS BEFORE 6" 8 125 3/4-10 x 5.50 3/4-10 x 6.50

INSTALLING OR USING THIS

8" 8 190 3/4-10 x 6.00 3/4-10 x 7.00

VALVE. Failure to follow instructions

could result in death or serious 10" 12 200 7/8-9 x 6.50 7/8-9 x 7.75

injury. If there are any questions,

12" 12 260 7/8-9 x 7.00 7/8-9 x 8.25

contact your Tufline Representative

or the factory at 513-745-6000. ** Torque values are those typically used in industry

as standard for lightly lubricated B7 bolts/studs.

Please note that mating pipe I.D. must meet the installa- * Note: Pressure vessel studs are measured from the

tion requirement. (See Dimensions chart). If the mating first full thread to the last full thread - NOT from end to end.

pipe/flange I.D. is outside of this requirement a spacer is

required for proper disc retention.

General installation of this valve is performed by insert-

ing the bottom most studs/bolts between the mating

flanges, resting the valve on these and then inserting the

remaining studs/bolt. All the pre-cast scallops should be

lined up with the flange bolt holes. NOTE: 3”, 10” and

12” valves are manufactured to align with DIN flanges.

These valves should be held slightly above the bottom

studs/bolts while centering the valve waterway with the

flange/pipe waterway. Failure to center the valve may

allow the disc to be forced out of the valve body and

flow downstream.

Dimensions (inches)

Mating Pipe I.D.+

Size A B C D F G Wt. Lbs. Min. Max.

3 1.81 2.28 1.65 2.20 5.04 7.00 7 2.88 3.23

4 1.81 3.31 2.56 3.20 6.38 8.88 13 3.74 4.17

6 2.25 5.02 4.37 4.90 8.35 11.00 28 5.71 6.22

8 2.63 6.91 5.24 6.77 10.51 13.50 50 7.56 7.87

10 2.67 8.74 7.24 8.70 12.48 15.50 63 9.53 10.23

12 3.07 10.71 9.13 10.50 14.45 17.40 93 11.50 12.20

+Required to retain disc in valve body. Designed to fit schedule 40

lined pipe. Pressure to unseat ( ∆P) in horizontal or vertical pipeline:

less than 1 psi.

PN335696 - 8/03 Printed in USA

CRANE ChemPharma Flow Solutions™

XOMOX Headquarters XOMOX International GmbH & Co. OHG

4444 Cooper Road, Von-Behring-Straße 15,

Cincinnati, OH 45242, U.S.A. D-88131 Lindau/Bodensee

Tel.: (513) 745-6000 Tel.: (49) 8382-702-0

Fax: (513) 745-6086 Fax. (49) 8382-702-144

CP-XOMOX-070-IOM-IM-EN-CI-8/03 - PN335696

www.flowoffluids.com

brands you trust.

CRANE ChemPharma Flow Solutions Include: Pipe - Valves - Fitting - Actuators - Pumps

Crane Co., and its subsidiaries cannot accept responsibility for possible errors in catalogues, brochures, other printed materials, and web-

site information. Crane Co. reserves the right to alter its products without notice, including products already on order provided that such

alteration can be made without changes being necessary in specifications already agreed. All trademarks in this material are property of

the Crane Co. or its subsidiaries. The Crane and Crane brands logotype (DEPA®, ELRO®, Krombach®, PSI®, Resistoflex®, ResistoPure™, Revo®,

Saunders®, and XOMOX®) are registered trademarks of Crane Co. All rights reserved.

© 2010 CRANE ChemPharma Flow Solutions, www.cranechempharma.com

Das könnte Ihnen auch gefallen

- Series YD - YS Instruction ManualDokument16 SeitenSeries YD - YS Instruction ManualEnerprec SASNoch keine Bewertungen

- Model 54's 2" Thru 12": Eccentric Check Valves Flo-E-Centric Installation Instructions Flomatic CorporationDokument2 SeitenModel 54's 2" Thru 12": Eccentric Check Valves Flo-E-Centric Installation Instructions Flomatic CorporationMASOUDNoch keine Bewertungen

- Armstrong FTVDokument6 SeitenArmstrong FTVMaxi452Noch keine Bewertungen

- Check-Trol: Isolation Flow Control FlangeDokument2 SeitenCheck-Trol: Isolation Flow Control FlangeAnonymous 7xHNgoKE6eNoch keine Bewertungen

- Install and maintain gate, globe valvesDokument4 SeitenInstall and maintain gate, globe valvesModassir ZaheenNoch keine Bewertungen

- TuflineSideEntry3-way 335080 05-05Dokument4 SeitenTuflineSideEntry3-way 335080 05-05Marcio NegraoNoch keine Bewertungen

- Imo-66en 09-10Dokument8 SeitenImo-66en 09-10HASBUL AZIZI BIN MAHMUNNoch keine Bewertungen

- General Twin Seal IOMDokument28 SeitenGeneral Twin Seal IOMbuckwheet1100% (1)

- Gate Valve Installation InstructionsDokument20 SeitenGate Valve Installation InstructionsRomi Kristanto100% (1)

- Manual Pinch Valves BrochureDokument9 SeitenManual Pinch Valves BrochureVenkatesh GangadharNoch keine Bewertungen

- Flomatic Model 109 NRS Intrucciones de InstalacionDokument3 SeitenFlomatic Model 109 NRS Intrucciones de InstalacionJairo Javier Díaz MontenegroNoch keine Bewertungen

- Mercer 9100 ManualDokument11 SeitenMercer 9100 Manualanara.aidNoch keine Bewertungen

- Check Valve - Type CK4ADokument4 SeitenCheck Valve - Type CK4AHuong QuangNoch keine Bewertungen

- Valvula de Retencao PortinholaDokument1 SeiteValvula de Retencao PortinholaDeivid MiquelinoNoch keine Bewertungen

- Quick Couplers Mechanical Hydraulic 068700 PDFDokument26 SeitenQuick Couplers Mechanical Hydraulic 068700 PDFSTEVHEN MARTHINNoch keine Bewertungen

- Manual ValvesDokument20 SeitenManual ValvesLuis Enrique Barreto GarciaNoch keine Bewertungen

- PVC-PP-PVDF Swing Check Valve SpecificationsDokument4 SeitenPVC-PP-PVDF Swing Check Valve SpecificationsthangNoch keine Bewertungen

- SM 50 150 InstructionDokument8 SeitenSM 50 150 Instructionramon duldulaoNoch keine Bewertungen

- Installation and Maintenance Instructions for Naval Gas Ball ValveDokument5 SeitenInstallation and Maintenance Instructions for Naval Gas Ball ValveMaria MarcanoNoch keine Bewertungen

- Butterfly TrainingDokument24 SeitenButterfly TrainingOlawale John AdeotiNoch keine Bewertungen

- Flush Bottom Tank Valves: High Performance 3-Piece Ball ValveDokument4 SeitenFlush Bottom Tank Valves: High Performance 3-Piece Ball ValveErkan TakNoch keine Bewertungen

- Cryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDokument8 SeitenCryogenic Ball Valves: Installation, Operation and Maintenance InstructionsDv Maria PradhikaNoch keine Bewertungen

- Style 841Dokument7 SeitenStyle 841Ummes AhmedNoch keine Bewertungen

- FS4-3 - Installation Instructions (MM-601J)Dokument8 SeitenFS4-3 - Installation Instructions (MM-601J)mendozaNoch keine Bewertungen

- File - 116 - 116 - 20-Butterfly ValveDokument4 SeitenFile - 116 - 116 - 20-Butterfly Valvephuong daoNoch keine Bewertungen

- 04 - Butterfly Valves - MegaDokument14 Seiten04 - Butterfly Valves - MegalusiNoch keine Bewertungen

- Air Valve CatalogDokument58 SeitenAir Valve CatalogJohn Holding100% (2)

- Schedule 80 - PVC: Pressure FittingsDokument12 SeitenSchedule 80 - PVC: Pressure FittingsCesar PreciadoNoch keine Bewertungen

- Butterfly ValveDokument14 SeitenButterfly ValveSingSareblakKanaManahNoch keine Bewertungen

- 2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuideDokument2 Seiten2 Piece Threaded and Solder End Ball Valves Installation, Operation, & Maintenance GuidemajoNoch keine Bewertungen

- Orifice Plate - Multi-Holes: DatasheetDokument10 SeitenOrifice Plate - Multi-Holes: DatasheetMarcelo PellizzaNoch keine Bewertungen

- Válvula DurcoDokument12 SeitenVálvula DurcoJames Henrry López EspejoNoch keine Bewertungen

- Butterfly Valve Installation Guide Series ADokument10 SeitenButterfly Valve Installation Guide Series Asaxenamech_ariesNoch keine Bewertungen

- Bronze Relief Valve DN10 DN15 DN20Dokument2 SeitenBronze Relief Valve DN10 DN15 DN20billNoch keine Bewertungen

- Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Dokument8 SeitenTechnical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500mohammadazraiNoch keine Bewertungen

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDokument8 SeitenSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyNoch keine Bewertungen

- Butterfly Valve Technical Specs & Installation GuideDokument4 SeitenButterfly Valve Technical Specs & Installation GuideMiguel RondinelNoch keine Bewertungen

- GIW Technical Series: Pipe Flange BoltsDokument4 SeitenGIW Technical Series: Pipe Flange BoltsTravis SkinnerNoch keine Bewertungen

- 08-INSTALLATION - (A) Ball ValvesDokument4 Seiten08-INSTALLATION - (A) Ball ValvesModassir ZaheenNoch keine Bewertungen

- Vortex Float ValveDokument3 SeitenVortex Float ValveFrancisco Javier Villegas AndersonNoch keine Bewertungen

- Supplemental Guide: Directional Control Valve ProductsDokument4 SeitenSupplemental Guide: Directional Control Valve Productsscibduser001Noch keine Bewertungen

- Hand Expansion Valves GuideDokument12 SeitenHand Expansion Valves GuideАлександр ЩербаковNoch keine Bewertungen

- Ulfm Butterfly ValveDokument7 SeitenUlfm Butterfly ValveFranklin Esteban CárdenasNoch keine Bewertungen

- ROSOV Manual - L & TDokument122 SeitenROSOV Manual - L & TMuneeshNoch keine Bewertungen

- CheckTrol43 PDFDokument2 SeitenCheckTrol43 PDFAnonymous 7xHNgoKE6eNoch keine Bewertungen

- Section - B - Fittings 1Dokument40 SeitenSection - B - Fittings 1mhaznNoch keine Bewertungen

- Fireball Tool Vise Build GuideDokument15 SeitenFireball Tool Vise Build GuideRadu RA100% (2)

- Install and maintain check valvesDokument6 SeitenInstall and maintain check valvesHimanshu PatilNoch keine Bewertungen

- Transicion C900 - Brida Tyler UnionDokument3 SeitenTransicion C900 - Brida Tyler UnionJohanAndrésVillarrealNoch keine Bewertungen

- Operations and Maintenance ManualDokument18 SeitenOperations and Maintenance ManualSupakanit LimsowanNoch keine Bewertungen

- Water Control Valve DV-5Dokument8 SeitenWater Control Valve DV-5Christian FherNoch keine Bewertungen

- Gate Valves, Chokes, Manifolds, Wellheads & Cementing HeadsDokument2 SeitenGate Valves, Chokes, Manifolds, Wellheads & Cementing Headshitesh kumarNoch keine Bewertungen

- Schedule 80 - PVC: Pressure FittingsDokument12 SeitenSchedule 80 - PVC: Pressure FittingspartidalbertoNoch keine Bewertungen

- Series 30, 31 & 32 Three Way Valves SpecificationsDokument6 SeitenSeries 30, 31 & 32 Three Way Valves SpecificationsJovenal TuplanoNoch keine Bewertungen

- Chillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentDokument18 SeitenChillersapikhubdocuments5wpq Iw7UC NV6ZJjGVizgcontentsyhnhpc7qmNoch keine Bewertungen

- Iom WKM 310FDokument4 SeitenIom WKM 310FNasir NaqviNoch keine Bewertungen

- M8456 2 TrusealDokument3 SeitenM8456 2 Trusealk_tevenNoch keine Bewertungen

- Testing For Excessive Cylinder Blowby in 3500 EnginesDokument10 SeitenTesting For Excessive Cylinder Blowby in 3500 EnginesPILAR MARTINEZNoch keine Bewertungen

- Forged Pipe FittingsDokument38 SeitenForged Pipe FittingsGonzaloMartinezRNoch keine Bewertungen

- Aveva Bocad NCDokument2 SeitenAveva Bocad NCsennimalaiNoch keine Bewertungen

- Dimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9Dokument3 SeitenDimensions and Dimensional Tolerances of Long Radius Elbows 45 and 90 Degrees and 3D Elbows, NPS 1 - 2 To NPS 48, ASME B16.9sennimalaiNoch keine Bewertungen

- Standarde Din FlangeDokument45 SeitenStandarde Din Flangeadri2Noch keine Bewertungen

- AVEVA Bocad Roof and WallDokument2 SeitenAVEVA Bocad Roof and WallsennimalaiNoch keine Bewertungen

- AVEVA Case Study Schlattner 0114Dokument4 SeitenAVEVA Case Study Schlattner 0114sennimalaiNoch keine Bewertungen

- Industrial Insulation: MeasuringDokument20 SeitenIndustrial Insulation: MeasuringHuu TungNoch keine Bewertungen

- Forged Pipe FittingsDokument38 SeitenForged Pipe FittingsGonzaloMartinezRNoch keine Bewertungen

- Globe Valve BrochureDokument5 SeitenGlobe Valve Brochurevk1234Noch keine Bewertungen

- Aveva Bocad NCDokument2 SeitenAveva Bocad NCsennimalaiNoch keine Bewertungen

- AutoColourRule ENGDokument4 SeitenAutoColourRule ENGtrongtu2002Noch keine Bewertungen

- AVEVA Bocad TowerDokument2 SeitenAVEVA Bocad Towersennimalai100% (1)

- Bocad To PdmsDokument13 SeitenBocad To Pdmssennimalai100% (1)

- Energies 12 02593Dokument26 SeitenEnergies 12 02593sennimalaiNoch keine Bewertungen

- AVEVA Bocad Steel PDFDokument2 SeitenAVEVA Bocad Steel PDFAslam KhanNoch keine Bewertungen

- AVEVA Bocad Offshore PDFDokument2 SeitenAVEVA Bocad Offshore PDFsennimalaiNoch keine Bewertungen

- Label /repeat ID@ HANDLE (61,528) Return Error 1 'JOB DONE!!!' Endhandle Repr Ppoints On Repr Ppoints Numb On Autocolour On Rem Ce Add Ce RefreshDokument1 SeiteLabel /repeat ID@ HANDLE (61,528) Return Error 1 'JOB DONE!!!' Endhandle Repr Ppoints On Repr Ppoints Numb On Autocolour On Rem Ce Add Ce RefreshsennimalaiNoch keine Bewertungen

- Aveva Bocad Admin 22 enDokument24 SeitenAveva Bocad Admin 22 enambhadNoch keine Bewertungen

- PDMS Interview Questions: Top 15 Modules, Components, Modeling TechniquesDokument2 SeitenPDMS Interview Questions: Top 15 Modules, Components, Modeling TechniquessennimalaiNoch keine Bewertungen

- PlateDokument3 SeitenPlateSwaminathan BalajiNoch keine Bewertungen

- AVEVA Bocad Offshore PDFDokument2 SeitenAVEVA Bocad Offshore PDFsennimalaiNoch keine Bewertungen

- AVEVA Bocad OnshoreDokument2 SeitenAVEVA Bocad OnshoresennimalaiNoch keine Bewertungen

- AVEVA Bocad Steel PDFDokument2 SeitenAVEVA Bocad Steel PDFAslam KhanNoch keine Bewertungen

- PDMS Database Error 406Dokument1 SeitePDMS Database Error 406sennimalaiNoch keine Bewertungen

- Iso CutpipelengthDokument1 SeiteIso CutpipelengthsennimalaiNoch keine Bewertungen

- Isometric ADP 12 Advisory NotificationDokument2 SeitenIsometric ADP 12 Advisory NotificationsennimalaiNoch keine Bewertungen

- Error (69,85)Dokument1 SeiteError (69,85)sennimalaiNoch keine Bewertungen

- Employee Leave Vacation Tracker v1 3 SampleDokument9 SeitenEmployee Leave Vacation Tracker v1 3 SamplesennimalaiNoch keine Bewertungen

- Process Safety Management of Highly Hazardous & Explosive ChemicalsDokument31 SeitenProcess Safety Management of Highly Hazardous & Explosive ChemicalssennimalaiNoch keine Bewertungen

- NRR, PointsDokument2 SeitenNRR, PointssennimalaiNoch keine Bewertungen

- DLP Din8Dokument2 SeitenDLP Din8KOUDJIL MohamedNoch keine Bewertungen

- Guimaras State CollegeDokument5 SeitenGuimaras State CollegeBabarianCocBermejoNoch keine Bewertungen

- Lolita An Intelligent and Charming Holstein Cow Consumes Only TwoDokument1 SeiteLolita An Intelligent and Charming Holstein Cow Consumes Only Twotrilocksp SinghNoch keine Bewertungen

- Sinavy Pem Fuel CellDokument12 SeitenSinavy Pem Fuel CellArielDanieli100% (1)

- 21st Century Literature Exam SpecsDokument2 Seiten21st Century Literature Exam SpecsRachel Anne Valois LptNoch keine Bewertungen

- (Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsDokument43 Seiten(Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsRhea OciteNoch keine Bewertungen

- Studying Supply and Demand of Software Maintenance and Evolution ServicesDokument6 SeitenStudying Supply and Demand of Software Maintenance and Evolution ServicesJorge Arturo Moreno VeasNoch keine Bewertungen

- Test Unit 7 m.2Dokument6 SeitenTest Unit 7 m.2Petchara SridakunNoch keine Bewertungen

- Popular Mechanics 2010-06Dokument171 SeitenPopular Mechanics 2010-06BookshebooksNoch keine Bewertungen

- Proposed - TIA - 1392 - NFPA - 221Dokument2 SeitenProposed - TIA - 1392 - NFPA - 221Junior TorrejónNoch keine Bewertungen

- Small Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dokument20 SeitenSmall Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dipti PatilNoch keine Bewertungen

- IPA Assignment Analyzes New Public AdministrationDokument8 SeitenIPA Assignment Analyzes New Public AdministrationKumaran ViswanathanNoch keine Bewertungen

- GCSE H3 02g4 02 3D TrigonometryDokument2 SeitenGCSE H3 02g4 02 3D TrigonometryAndrei StanescuNoch keine Bewertungen

- Lecture 6-Design For ShearDokument14 SeitenLecture 6-Design For ShearMarkos DanielNoch keine Bewertungen

- Mil B 49430BDokument36 SeitenMil B 49430Bparam.vennelaNoch keine Bewertungen

- Usage Instructions - Hengro PoolProtect 1 - 5Dokument3 SeitenUsage Instructions - Hengro PoolProtect 1 - 5Brian VisserNoch keine Bewertungen

- Objective QuestionsDokument19 SeitenObjective QuestionsDeepak SharmaNoch keine Bewertungen

- Individual Moving Range (I-MR) Charts ExplainedDokument18 SeitenIndividual Moving Range (I-MR) Charts ExplainedRam Ramanathan0% (1)

- Volvo S6 66 Manual TransmissionDokument2 SeitenVolvo S6 66 Manual TransmissionCarlosNoch keine Bewertungen

- CorentineDokument559 SeitenCorentinejames b willardNoch keine Bewertungen

- The Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaDokument4 SeitenThe Ethological Study of Glossifungites Ichnofacies in The Modern & Miocene Mahakam Delta, IndonesiaEry Arifullah100% (1)

- Maths Note P1 and P3Dokument188 SeitenMaths Note P1 and P3Afeefa SaadatNoch keine Bewertungen

- Spectro Xepos Brochure 2016Dokument8 SeitenSpectro Xepos Brochure 2016Mary100% (1)

- 230kv Cable Sizing CalculationsDokument6 Seiten230kv Cable Sizing Calculationsrajinipre-1Noch keine Bewertungen

- Transportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDokument11 SeitenTransportation Geotechnics: Tirupan Mandal, James M. Tinjum, Tuncer B. EdilDaniel Juan De Dios OchoaNoch keine Bewertungen

- CTM Catalogue 2015-2016Dokument100 SeitenCTM Catalogue 2015-2016Anonymous dXcoknUNoch keine Bewertungen

- Documentation For UStarDokument26 SeitenDocumentation For UStarthunder77Noch keine Bewertungen

- Country Wing Auto-Mobile GarageDokument25 SeitenCountry Wing Auto-Mobile GarageDmitry PigulNoch keine Bewertungen

- HR MasterlistDokument6 SeitenHR MasterlistLeychelle AnnNoch keine Bewertungen

- Conductivity NickelDokument2 SeitenConductivity Nickelkishormujumdar998Noch keine Bewertungen