Beruflich Dokumente

Kultur Dokumente

Single Hole Vs Multi Hole Orfice DP

Hochgeladen von

Peter RhoadsOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Single Hole Vs Multi Hole Orfice DP

Hochgeladen von

Peter RhoadsCopyright:

Verfügbare Formate

ISSN (Online) 2456-1290

International Journal of Engineering Research in Mechanical and Civil Engineering

(IJERMCE)

Vol 2, Issue 4, April 2017

Discharge Coefficient Prediction for Multi hole

Orifice Plate in a Turbulent Flow through Pipe:

Experimental and Numerical Investigation

[1]

Mahendra Babu .K.J, [2] Dr. Gangadhara Gowda C.J,[3] Ranjith K

[1][2][3]

Department of Mechanical Engineering, PES College of Engineering., Mandya

Abstract: -- The multi hole orifice plate is one of the effective devices for measuring flow rate accurately. In this study an experimental

and numerical investigation of the flow characteristics behavior caused by a water flow through a multi hole orifice configuration is

reported. A circular centered single hole orifice and a multi hole orifices are tested. Orifices of interest for present study have an area

ratio of 0.36, equivalent diameter ratio of 0.6 and number holes between 4 to 25. Discharge coefficients for flow through multi hole

orifices are evaluated. Parameters investigated were hole numbers, orifice pressure drop, Reynolds number and effect of plate design.

Computational fluid dynamics calculations (CFD) using the k-ε turbulence model to predict velocity fields, pressure loss and

discharge coefficient around this device. Advantages gained by using multiple holes in an orifice plate instead of single hole are

discussed. It is shown that number of holes, hole diameter and aspect ratio influences the discharge coefficients. Tests were conducted

under laboratory conditions. The experimental results were compared with numerical modeling and appropriate conclusions are

discussed.

Keywords: Multi hole orifice, Equivalent diameter ratio, Discharge coefficient, Reynold’s Number

INTRODUCTION D. Maynes G. J. Holt J. Blotter [6] experimentally

investigated the loss coefficient and cavitation caused by

Flow measurement is one of the most complex and

water flow through perforated plates. Plates with n = 4 to

demanding task in industry. Even today there does not

1800, beta ratio = 0.11 to 0.6, and t/d = 0.25 t0 0.33 were

exist a universal measuring instrument for all applications.

considered.

Orifice plates are mainly used as a device of flow

measurement for fluid delivery systems is based on the

A literature review shows that a great deal of work has

measurement of the pressure difference created when

been done on the pressure drop characteristics of orifice

forcing the fluid to flow through a restriction in the pipe.

plates in pipe flows. The performance characteristics of

The multi hole orifice plates or perforated plates are

the multi hole orifice meter are not available in open

assumed to be composed of number of individual orifices

literature. CFD has not been used by the earlier

acting independently and parallel, will have flow

investigators to predict the performance of multi-hole

characteristics different compared to the flow

orifice flow meter, but whatever little information

characteristics of a single hole orifice plate having same

available shows that for an orifice plate whose axis is

flow area [1]. This is basically because of the flow

coincident with that of duct or for a multi hole orifice

restriction due to small flow area of each hole.

plate with regularly spaced holes, the factors influencing

flow characteristics of the multi hole plates are area ratio

Tianyi Zhao et al.[2] investigated the key factors affecting

of the plate (m), the number of holes and its distribution

multi-hole orifices throttle or flow control characteristics.

on the plate. Past research has also shown that the value of

Nine test plates were selected with various combinations

Cd is primarily considered to be a function of aspect ratio

of diameter ratio and different Orifice distribution density.

(t/d), Equivalent diameter ratio (β = d/D) and Nature of

Shanfang Huang et al. [3] presented the discharge

flow defined using the pipe/hole Reynolds number (Re).

coefficient of a perforated orifice, Twelve square-edged

The paper therefore addresses the problem of relating

perforated orifices with n = 6 to 25, t = 3 and t/D is 0.1,

flow rate to pressure drop and the discharge coefficient

0.21, 0.31. Stefano Malavasi et al [4] has conducted two

prediction by experiments and numerical simulations

experimental campaigns to investigate the dissipation

through single orifice over multi hole orifice geometries

characteristics of multi-hole orifices under cavitation-free

and operating conditions. The main objective is to validate

conditions. B. Laribi and M. Mehdi [5] presents a

the numerical simulations with experimental data to

numerical experimentation on the perforated plate flow

predict pressure loss, velocity fields and discharge

conditioner with a 90° double bend and a valve 50%

coefficient Cd.

closed. The simulation is done with air as fluid in 100 mm

pipe diameter with Reynolds numbers 104, 105 and 106.

All Rights Reserved © 2017 IJERMCE 697

ISSN (Online) 2456-1290

International Journal of Engineering Research in Mechanical and Civil Engineering

(IJERMCE)

Vol 2, Issue 4, April 2017

The present paper is subdivided into three sections. The Discharge coefficient, d the Orifice diameter in meter, D

experimental setup is first presented. Numerical models the Diameter of pipe, is the Equivalent diameter

are then detailed. The experimental data are presented and

compared with numerical simulations in the last section ratio√ , H is the Pressure differential across the

metering tap in meters of water.

II. EXPERMENTAL ARRANGEMENT AND

MEASUREMENTS:

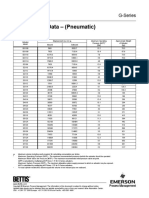

The physical data and other dimensions for all the orifices

used for the computations and experiments are

The experiments were conducted to measure pressure

summarized in Table I.

drop across multi hole orifice plates at known flow rates.

Water, the only fluid used was obtained from a collecting

tank available in the laboratory. The multi hole orifice Table I: The relevant parameters in these

plates were flanged between two sections of 50 mm inner experiments/Computations

diameter GI pipe. The test section had a length of 30D

Number of Diameter of Aspect Equivalent

upstream and 50D downstream of the orifice. Flange

holes the hole mm Ratio Diameter Ratio

pressure taps used here were located 50 mm upstream and t/d d/D

25.4 mm downstream from the orifice plate. The pressure

differences were measured by water- mercury

manometers which could read accuracy of 0.05 cm. The 1.5 mm thickness of the Orifice plate

discharges were measured volumetrically by means of the 1 30 0.05 0.6

collecting tank. The experiments were conducted at room 9 10 0.15 0.6

temperature. A systematic method was used in making the 16 7.5 0.2 0.6

orifice plates so that a practical range of variables might 25 6 0.25 0.6

be tested. Twenty square edged orifice plates were studied Overall Range: 0.05 < t/d < 0.25 and d/D = 0.6

during this work. All holes were drilled on a vertical drill

press with plates backed by wooden blocks to prevent

excess burring. After drilling, the plates were drawn III. NUMERICAL APPROACH

across No. 0 emery paper on a flat surface to knock off the

burrs. A. Computational model

Numerical investigation using the CFD code “Fluent” was

A strict set of test procedures was established to ensure implemented in the present work for multi hole orifice

the collection of repeatable and accurate data for each plate. The main objective is to minimize the pressure loss

orifice plate. Whenever the orifice plate was changed, it and maximize the discharge coefficient of the multi hole

was necessary ensure that air was removed from the orifice plate. The computational domain was extended 15

system. This was accomplished by the help of knob D upstream and 20D downstream of the

providing for the purpose. Once the air was removed by plate.Thedistance15D upstream the plate was used to

this method, the system was run for approximately 15 ensure a fully developed flow at inlet during the

minutes in the maintenance configuration. For each orifice simulation. Numerical simulation was performed by

plate, about seven to eight data points were taken solving the standard k-ε model with enhanced wall

corresponding to a pressure head across the orifice meter treatment was used to model turbulence and simulate the

using mercury manometer. To get a good sample of the near wall flow. Discretization was performed using the

data, five to six runs were made independently on the finite volume technique. The applied discretization

same plate to check the consistency of the data. For all the schemes are second order scheme for pressure, SIMPLE

orifice plates, the coefficient of discharge Cd was scheme for pressure–velocity coupling and second order

upwind scheme for momentum, kinetic energy (k) and

Cd Ao 2 gH turbulence dissipation rate (ε). Convergence was

obtained and is given by the relation Q

1 4 considered to be achieved when the residuals of mass,

momentum and turbulence are less than 1x10-6.

Where Q is the Volume flow rate, m3/s, Cd the

All Rights Reserved © 2017 IJERMCE 698

ISSN (Online) 2456-1290

International Journal of Engineering Research in Mechanical and Civil Engineering

(IJERMCE)

Vol 2, Issue 4, April 2017

B. Governing equations

In the modeling, mass, momentum, energy conservation

equations (if necessary) must be satisfied. The governing

equations for present study are:

Continuity :∇.( ρV) =0.

momentum:

∇.(ρuV)=-(∂p/∂x)+(∂τxx/∂x) +(∂τyx/∂y) + (∂τzx/∂z) +ρ g

ρvV)=-(∂p/∂y)+(∂τxy/∂x) +(∂τzy/∂y) + (∂τzx/∂z) +ρ g

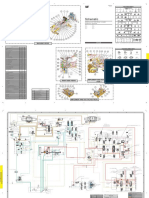

∇ .(ρwV)=-(∂p/∂z)+(∂τxz/∂x) + (∂τyz/∂y) + (∂τzz/∂z) +ρ g Fig.2. section plane detail of discretized fluid domain for

Nine orifice holes model with 3D hexahedral mesh

C. Boundary conditions

The present three-dimensional flow field is solved by Convergence study with k- ε model

considering water as incompressible fluid. There are three

boundaries: inlet, outlet and the wall. The boundary Table III: The mesh principal parameters

conditions are summarized in Table II. Element Number of Number Skewness Aspect Orthogonal

size Elements of nodes ratio quality

(mm)

Table II: Boundary conditions 1 1.6x106 166526 0.098 1.182 0.989

Sl.No Quantities Condition/value

1 Working fluid Water 1.2 9.2x105 964627 0.108 1.207 0.989

2 Inlet velocity 0.5 to 1.5 m/sec

3 outlet Zero Pascals 1.3 7.5x105 792270 0.112 1.220 0.988

4 Wall No slip

1.4 5.7x105 608990 0.117 1.215 0.987

D. Grid independence study

A hexahedral block structured mesh is employed for the 1.5 4.5x105 484219 0.136 1.237 0.984

entire computational domain of the plate using mesh

application from ANSYS Workbench. In order to test the E. Validation

adequacy of the discretization, the number of elements is The validation of the CFD analysis has been done by

varied in the range 4.5×105 to 1.6×106. comparing the CFD results with the results

The computational meshes employed for simulation with Obtained by experiments for single hole orifice plate with

full domain and section plane detail of discretized fluid mass flow rate of 2.091x10-3 m3/sec in terms of

domain for nine orifice holes model with 3D hexahedral discharge coefficient and pressure drop. The validation

mesh is presented in Fig.1 and Fig.2. The mesh principal results are presented in table IV.

parameters are presented in Table III.

Table IV: Validation results

Elemen Number Pressure drop Coefficient of Relative error

t size of ΔP (Pa) discharge C d %

(mm) Element

Exp Num Exp Num ΔP Cd

s

1 1.6x106 8528.8 9002.2 0.668 0.650 5.25 2.6

1 2 4 6

1.2 9.2x105 8862.8 0.655 3.76 1.8

5 6 8

1.3 7.5x105 8602.7 0.665 0.85 0.4

5 8 0

1.4 5.7x105 8829.3 0.656 3.4 1.6

5 9 9

5

1.5 4.5x10 9181.2 0.644 7.12 3.6

Fig.1 Discretized fluid domain for nine orifice holes 1 1

model with 3D hexahedral mesh

All Rights Reserved © 2017 IJERMCE 699

ISSN (Online) 2456-1290

International Journal of Engineering Research in Mechanical and Civil Engineering

(IJERMCE)

Vol 2, Issue 4, April 2017

It is observed that for all the meshes studied the agreement

between computed and experimental values C d and ΔP is

reasonably good. On the basis of this study a mesh size of

7.5×105 and element size of 1.3mm with finer mesh

around the orifice plate is adequate for ensuring accurate

computation.

IV. RESULTS AND DISCUSSION

Fig.5 Variation of coefficient of discharge with

Reynold’s number for single and multi hole orifice plate

Pressure drops in single and multi hole orifice meter at

various flow rate were calculated by experiments and

simulation. Figure 4 shows graph of volumetric flow rate

vs. pressure drop and Figure 5 shows graph of coefficient

discharge vs. Renold’s number. It can be seen that the

pressure drop increases with increase in flow rate also as

Fig. 3 Pressure plot (For Q =2.091e-3 m3/s) the number of hole increases pressure drop decreases. As

observed from figure 5 that higher coefficient of discharge

obtained for multi hole orifice plate. It can be seen that

the Cd found out from simulation is greater than that

found from experimentation. This is because losses are

not considered in CFD. The Cd obtained through

simulations is 1% - 4% greater than experimental Cd.

.

V. CONCLUSIONS

In this analysis, multi hole orifices have been

experimentally and numerically studied in terms of

discharge coefficient and pressure drop and compared

with a single hole orifice plate which is generally used in

orifice meters to measure flow. The following points are

obtained as the results of this study. Multi hole orifice

plate has better performance characteristics than a single

hole orifice plate. Through simulation and

experimentation, the 25 holes orifice plate is found to be

having the highest value of coefficient of discharge i.e.

0.82 with an actual discharge of 2.09x10-3 m3/s.

Compared with single hole orifice plate, the coefficient of

Fig.4 Variation of pressure drop with volume flow rate discharge of 25 holes orifice plate is 24.2% greater. The

for single and multi hole orifice plate Cd found out from CFD is greater than that found from

experimentation because of the losses occurring in the

All Rights Reserved © 2017 IJERMCE 700

ISSN (Online) 2456-1290

International Journal of Engineering Research in Mechanical and Civil Engineering

(IJERMCE)

Vol 2, Issue 4, April 2017

physical model due to friction inside the pipe, leakage,

impurities present in the fluid, etc. which are not

considered in CFD.

VI. REFERENCES

1. Kolodizie .P. A, Jr and Mathew Van Winkle

“Discharge coefficients through perforated plates”

A.I.Chemical Journal, vol. 3, 1957.

2. TianyiZhao,Jili Zhang and Liangdong Ma “A

general structural design methodology for multi-hole

orifices and its experimental application” Journal of

Mechanical Science and Technology 25 (9), 2237~2246,

2011

3. Shanfang Huang, Taiyi Ma, Dong Wang,

Zonghu Lin “Study on discharge coefficient of perforated

orifices as a new kind of flowmeter” Experimental

Thermal and Fluid Science, ETF 7881, 2012

4. Stefano Malavasi, Gianandrea Messa,Umberto

Fratino, Alessandro Pagano “On the pressure losses

through perforated plates” Flow Measurement and

Instrumentation , vol.28,pp. 57–66, 2012

5. B.Laribi and M. Mehdi “Effectiveness of

Perforated Plate in the Development and Establishment of

Turbulent Flow for Better Metrological Performances”

International Journal of Applied Physics and Mathematics

Vol. 2, No. 6, November 2012

6. D. Maynes G. J. Holt J. Blotter “Cavitation

Inception and Head Loss Due to Liquid Flow Through

Perforated Plates of Varying Thickness” Journal of Fluids

Engineering Vol. 135, MARCH 2013

All Rights Reserved © 2017 IJERMCE 701

Das könnte Ihnen auch gefallen

- 08 - FPS01 Subsea Series (Issue 4 Feb 05)Dokument4 Seiten08 - FPS01 Subsea Series (Issue 4 Feb 05)Peter RhoadsNoch keine Bewertungen

- Regulator Type 92Dokument1 SeiteRegulator Type 92Peter RhoadsNoch keine Bewertungen

- G-Series Pneumatic Performance Data MetricDokument5 SeitenG-Series Pneumatic Performance Data MetricPeter RhoadsNoch keine Bewertungen

- Customized Seals and Critical Components For Completion and Production SystemsDokument4 SeitenCustomized Seals and Critical Components For Completion and Production SystemsPeter RhoadsNoch keine Bewertungen

- Micropulse® BTL7 TA12 Explosion Proof Linear Position SensorsDokument2 SeitenMicropulse® BTL7 TA12 Explosion Proof Linear Position SensorsPeter RhoadsNoch keine Bewertungen

- BILIT Module 10.2 10-12Dokument156 SeitenBILIT Module 10.2 10-12Peter RhoadsNoch keine Bewertungen

- Module4E Comp Guide v3Dokument92 SeitenModule4E Comp Guide v3Peter RhoadsNoch keine Bewertungen

- Series 61 Booster RelaysDokument2 SeitenSeries 61 Booster RelaysPeter RhoadsNoch keine Bewertungen

- Hand!Wheel!Dimensions:! Measurement!Guide!Dokument4 SeitenHand!Wheel!Dimensions:! Measurement!Guide!Peter RhoadsNoch keine Bewertungen

- Fluoroloy A19: Material Data SheetDokument1 SeiteFluoroloy A19: Material Data SheetPeter RhoadsNoch keine Bewertungen

- Model 91-HF Filter-RegulatorDokument2 SeitenModel 91-HF Filter-RegulatorPeter RhoadsNoch keine Bewertungen

- Rotork Gears Gearbox Ab1250N-Pr4: Torque: Mounting Holes: DescriptionDokument1 SeiteRotork Gears Gearbox Ab1250N-Pr4: Torque: Mounting Holes: DescriptionPeter RhoadsNoch keine Bewertungen

- ICoT 5200 - 5300 - 5400 Ordering GuideDokument1 SeiteICoT 5200 - 5300 - 5400 Ordering GuidePeter RhoadsNoch keine Bewertungen

- Bill of Materials: RevisionsDokument1 SeiteBill of Materials: RevisionsPeter Rhoads100% (1)

- Engineering: GREAT SolutionsDokument4 SeitenEngineering: GREAT SolutionsPeter RhoadsNoch keine Bewertungen

- TYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsDokument4 SeitenTYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsPeter RhoadsNoch keine Bewertungen

- Operation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enDokument108 SeitenOperation Instructions - Multi-Turn - Actuators - SAEx - 07.2-SAEx - 16.2 - SAREx - 07.2-SAREx - 16.2 - Control - HART - enPeter RhoadsNoch keine Bewertungen

- IQMK3 Size 2 Cover Tube Adapter DrawingDokument1 SeiteIQMK3 Size 2 Cover Tube Adapter DrawingPeter RhoadsNoch keine Bewertungen

- Instruction Manual Fisher 4200 Electronic Position Transmitters en 124158Dokument44 SeitenInstruction Manual Fisher 4200 Electronic Position Transmitters en 124158Peter RhoadsNoch keine Bewertungen

- Floppy Hop FlipbookDokument3 SeitenFloppy Hop FlipbookPeter RhoadsNoch keine Bewertungen

- Asco 327 SeriesDokument7 SeitenAsco 327 SeriesPeter RhoadsNoch keine Bewertungen

- Mastergear CatalogDokument10 SeitenMastergear CatalogPeter RhoadsNoch keine Bewertungen

- Data Sheet - Item Number: 221-502 Mounting Carrier For 2-Conductor Terminal Blocks 221 Series - 4 MM For Screw Mounting WhiteDokument2 SeitenData Sheet - Item Number: 221-502 Mounting Carrier For 2-Conductor Terminal Blocks 221 Series - 4 MM For Screw Mounting WhitePeter RhoadsNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Introduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFDokument5 SeitenIntroduction To Pressure Relief Valve Design Part 3 - Sizing Orifices and Piping PDFonizuka-t2263Noch keine Bewertungen

- Flow in Pipes CompleteDokument21 SeitenFlow in Pipes CompleteSYaz WAni67% (6)

- Dimensions of End Caps According To Asme b16Dokument2 SeitenDimensions of End Caps According To Asme b16jfl2096Noch keine Bewertungen

- Connection DiagramsDokument96 SeitenConnection DiagramsCarlos Rovello GandoNoch keine Bewertungen

- Pipe Rack Load CalculationDokument3 SeitenPipe Rack Load CalculationKrunalpanchalNoch keine Bewertungen

- IpoDokument2 SeitenIpoNasrien KadirNoch keine Bewertungen

- FM Minor Losses 1Dokument14 SeitenFM Minor Losses 1mahesh100% (1)

- Chiller Plant Control - Io Summary: Chilled Water SystemDokument2 SeitenChiller Plant Control - Io Summary: Chilled Water SystemMohammed AminuddinNoch keine Bewertungen

- Horizontal Transport of Dredged Mixtures Part 2 - ENDokument64 SeitenHorizontal Transport of Dredged Mixtures Part 2 - ENedraket145Noch keine Bewertungen

- 2 - 1.5 BAH DS - Rev - 00 PDFDokument2 Seiten2 - 1.5 BAH DS - Rev - 00 PDFGuiver Santisteban IbañezNoch keine Bewertungen

- Hydraulic Piston PumpDokument5 SeitenHydraulic Piston Pumpvictor javier nuñezNoch keine Bewertungen

- Equate Approved ListDokument115 SeitenEquate Approved ListRenil PeterNoch keine Bewertungen

- Boiler Mountings and AccessoriesDokument4 SeitenBoiler Mountings and AccessorieshumshkhNoch keine Bewertungen

- Pipingpresentationmaster 170219125347Dokument61 SeitenPipingpresentationmaster 170219125347Vignesh Nadimuthu100% (1)

- Chapter - 6Dokument10 SeitenChapter - 6BennyNoch keine Bewertungen

- Hydraulic Schematic 966M PDFDokument2 SeitenHydraulic Schematic 966M PDFAhmed AbdelghanyNoch keine Bewertungen

- Jet Pump - InstallationDokument12 SeitenJet Pump - InstallationRaja Pathamuthu.G100% (2)

- Corken Pump Indpzp100bDokument12 SeitenCorken Pump Indpzp100bFlávio CoutinhoNoch keine Bewertungen

- Pressure Loss in Pipe - NeutriumDokument16 SeitenPressure Loss in Pipe - Neutriumsiva242245Noch keine Bewertungen

- LAB REPORT RotameterDokument13 SeitenLAB REPORT RotameterZareen Rashid Choudhury100% (1)

- Nioec-Sp-00-50 Criteria For Process and MechanicsDokument37 SeitenNioec-Sp-00-50 Criteria For Process and MechanicsCalNoch keine Bewertungen

- College - Be - 2010 - 2010nov - Mech - Me 2305 - Applied Hydraulics and PneumaticsDokument3 SeitenCollege - Be - 2010 - 2010nov - Mech - Me 2305 - Applied Hydraulics and Pneumatics9600257003Noch keine Bewertungen

- Steel Pipe Is 1161Dokument5 SeitenSteel Pipe Is 1161Shuvro ChakravortyNoch keine Bewertungen

- Offshore Piping Design CriteriaDokument1 SeiteOffshore Piping Design CriteriaDhakshina K100% (1)

- Handbook For Control Valve Sizing: Bulletin 1-IDokument21 SeitenHandbook For Control Valve Sizing: Bulletin 1-IPradeep JoshuaNoch keine Bewertungen

- PUMPSDokument151 SeitenPUMPSAZIZ97% (30)

- 140 H Motor GraderDokument2 Seiten140 H Motor Graderdiabalziab86% (7)

- Cluster - 7 Well Platforms Project Appendix A-11: Bid Package FORDokument30 SeitenCluster - 7 Well Platforms Project Appendix A-11: Bid Package FORajaykgNoch keine Bewertungen

- Hazen Williams Equation CalculationDokument3 SeitenHazen Williams Equation CalculationheshambmNoch keine Bewertungen

- Pipe & Fittings List (Preliminary) : Customer Plant Contract No Project No. Date Revision No. 1.0) PIPEDokument22 SeitenPipe & Fittings List (Preliminary) : Customer Plant Contract No Project No. Date Revision No. 1.0) PIPEponimin83Noch keine Bewertungen