Beruflich Dokumente

Kultur Dokumente

SControll Manual

Hochgeladen von

prabuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SControll Manual

Hochgeladen von

prabuCopyright:

Verfügbare Formate

Axiom Technologies L.L.

C

Telephone: 281 931 0907

15731 W. Hardy Rd., Suite 7 Fax: 281 231 6562

Houston, Texas 77060 www.axiomsafe ty.com

XH3-HE

USER’S MANUAL

SELF-CONTAINED, SINGLE PUMP

WELLHEAD CONTROL PANEL

FOR HARSH ENVIRONMENTS

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

GENERAL

The XH3-HE is a self-contained system is a device designed and built for protecting oil

and gas production wells in harsh environments where extreme temperatures and

corrosive/dusty environment is expected . It includes a switch-gauge to detect high and

low pressures as well as hydraulic interface for fire and manual ESD.

The XH3-HE is self-sufficient and doesn’t need external sources of energy or supply

pressure for keeping a wellhead open and protected. It uses hydraulic fluid for driving

the surface valve and it has a hand pump and dump valve for controlling the SSV.

The detection of High and Low pressures is done by a switch-gauge with adjustable

contacts for detecting when the monitored pressure is out of acceptable limits. The

switch-gage connects to an electronic module that indicates High and Low pressure

conditions as well as initiates the shutdown when a pressure alarm is detected. The

electronic circuits are fed by a battery module with an expected operating life of five (5)

years.

The XH3-HE is built to operate exposed to the desert environment as all hydraulic

components are enclosed in a stainless steel box while the electronic circuits and battery

module are enclosed in an explosion proof box inside the stainless steel box. The front of

the panel includes the gauges and controls as shown in Fig. 1 while the inside

components are shown in Fig. 2.

Flow Pressure w/

LED Indicators High and Low

- High Pressure Pressure Alarm

- Low Pressure

- Low Battery

Actuator Pressure

- Pulse Indication

“Reset” – “Test”

Switch

“Actuator – Pilot”

“Pilot” Pressure Selector Valve

“In Service – ESD”

Selector Valve

Hydraulic Pump

Fig. 1 XH3-HE Front Panel

XH3-HE Manual Rev.0 Dec 30, 2006 Page 2 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

Electronic Enclosure

Battery Module Replaceent

1. Lose the four nuts of the enclosure cover

2. Ensure No flammable gaseous

Pilot Pressure

within the battery module area

Accumulator

3. Lose Four Pin Holding the battery

4. Remove the Battery from its Place

5. Place the New Battery in Position

6. Fasten the four Pin Holding the battery

7. Close the Cover and tight the four nuts Switch-gage

8. See the Led Light from the LCD Solenoid

Valve

Hydraulic

Hand Pump High Pressure

Accumulator

Dump

Valve

Capillary

Tube

Level

Transit Indicator

Plate Hydraulic

Filter

Fig. 2 – XH3-HE Enclosure’s Interior

INSTALLATION – PRELIMINARY STEPS AND TESTS

The XH3-HE is sent with the battery module mounted backwards to prevent the system

from operating while in transit. Also, as needed to meet shipping regulations, the device

is typically shipped without hydraulic fluid in the reservoir and without Nitrogen pre-

charge in the high pressure (larger) accumulators. (The pre-charge pressure for the pilot

(small) accumulator is only 30 psi and considered safe for shipment)

Before installing , the system is to be inspected to confirm that there is no external

damage or indication of rough handling during shipment.

XH3-HE Manual Rev.0 Dec 30, 2006 Page 3 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

In case of overseas shipments it is recommended that the XH3-HE is tested in a work

shop near the final destination to facilitate the commissioning and allow the operators to

become familiar with the unit.

NOTE

It is recommended that the operator becomes familiar with the Hydraulic Schematic

(Appendix “B”) and have a copy handy during the tests described below to better

understand the system’s behavior.

To commission the system follow with the steps listed below:

i. Pre-charge 30 CU IN High Pressure Accumulator with 1,500 psi of

Nitrogen

ii. Confirm 30 psi of Nitrogen pre-charge on 5 CU IN Pilot Accumulator .

iii. Confirm that the plugs on the bulkhead connectors are tight before

proceeding with the following steps.

iv. Add hydraulic fluid to the reservoir, approximately two gallons if

reservoir is empty. Filling is to be done with care not to exceed the

“High” level mark in the liquid gauge.

v. Open Explosion Proof Box mounted inside the stainless steel box, remove

battery module and re-install after rotating 180º as indicated in Appendix

“A”. The electronic circuit becomes energized and the green LED blinks

every two seconds (heartbeat) to indicate that the electronic circuit is

operating without problem.

vi. Before applying pressure it is recommended that hydraulic fluid is

circulated throughout the system to flush any particle and contaminants

that could be present within the hydraulic lines. With this purpose

proceed as follows:

a) Set valve “In Service – ESD” to “ESD”.

b) Set valve “Pilot - Actuator” to “Pilot”

c) Manually pump in a fast mode for approximately one minute while

observing the “Pilot” pressure gauge. This gauge should display

pressure oscillating above “0” with each pump strike.

d) Set valve “Actuator – Pilot” to “Actuator ”

e) Again, pump in a fast mode for approximately one minute while

observing the “Actuator ” pressure gauge. This gauge should stay

in “0” psi

vii. Set valve “In Service – ESD” to “In Service”.

viii. Set valve “Pilot - Actuator” to “Pilot”

ix. Press “Reset” on toggle switch “Test – Reset”.

x. Pump while observing the “Pilot” pressure gauge. Pump until reaching 50

to 60 psi. Inspect hydraulic lines to confirm that there is no leakage.

xi. Set valve “Pilot - Actuator” into “Actuator”

xii. Pump “Pilot - Actuator” pump while observing the “Actuator ” pressure

gauge. Pump until reaching 2,000 psi. Inspect hydraulic lines to confirm

XH3-HE Manual Rev.0 Dec 30, 2006 Page 4 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

that there is no leakage. It is normal for the pressure to fall about 10%

after finishing the pumping.

xiii. Set valve “In Service – ESD” to “ESD” to return all pressures to zero

before moving the XH3-HE to the field for installation.

FIELD INSTALLATION

With the panel firmly mounted on a concrete pad or other solid foundation , proceed to

connect the field devices. Exercise care when installing the sensing pressure to the

chemical seal assembly.

The connection to the ESD station is to be branched to the fire plugs. It is to be noted

that the connections to the ESD station and fire plugs is a low pressure hydraulic circuit

(50 psi) with limited flow volume.

If the fire plug used does not have a return line a small amount of hydraulic fluid

(approximately 2 CU IN) will be released in the event of a fire.

OPERATION AND ADJUSTMENTS

The operation of the installed panel is as follows:

Starting Production :

1- Set valve “In Service – ESD” to “In Service”

2- Set valve “Pilot - Actuator” to “Pilot”.

3- Press “Reset” on switch “Test – Reset”.

4- Pump “Pilot/ Actuator ” while observing the “Pilot” pressure gauge until

reaching 50 psi.

5- Set valve “Pilot - Actuator” into “Actuator ”.

6- Pump “Pilot - Actuator” pump while observing the “Actuator ” pressure gauge.

Pump until reaching 2,000 psi. It is normal for the pressure to fall about 10%

after finishing the pumping. Do not exceed 2,200 psi.

7- Check all hydraulic connections (internal and external to the panel) to confirm

that there is no leakage.

8- Adjust High and Low Alarm set point on switch-gauge.

Closing Actuator:

9- Turn “In Service – ESD” valve to “ESD”. The system responds closing the

Actuator.

Re-opening the Actuator:

10- If any of the red LEDs is flashing Press “Reset”. The Alarm LED stops

blinking while the green LED (Heartbeat) blinks every two seconds.

11- If “In Service – ESD” valve is on “ESD” turn it to “In Service”

12- Set valve “Pilot - Actuator” to “Pilot”.

13- Pump while observing the “Pilot” pressure gauge until reaching 50 psi.

14- Set valve “Pilot - Actuator” into “Actuator ”.

XH3-HE Manual Rev.0 Dec 30, 2006 Page 5 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

15- Pump “Pilot - Actuator” pump while observing the “Actuator ” pressure gauge.

Pump until reaching 2,000 psi. It is normal for the pressure to fall about 10%

after finishing the pumping. Do not exceed 2,200 psi.

Adjusting High and Low Pressure Alarms:

16- Turn red knob to adjust High pressure Alarm to the desired High Pressure

Alarm. Repeat the same with the black knob to set the Low Pressure Alarm.

HYDRAULIC CIRCUITS

The hydraulic system has been designed and built to withstand wide ambient temperature

variations while minimizing the probabilities of leakages. This is achieved by avoiding

the use of components with sliding seals or devices such as pressure regulators or “quick

exhaust” valves that have proven leakage-prone.

To address thermal expansions the system is provided with hydraulic accumulators that

absorb the thermal expansions of the fluids while maintaining the system within

acceptable pressures. This is achieved by the proper sizing of the accumulator and

careful determination of the pre-charge pressure.

As a rule of thumb the pre-charge pressure is to be at least equal to the minimal working

pressure of the system, i.e. if the actuator needs a minimum of 1,500 psi to maintain the

valve open, then the high pressure accumulator is to be pre-charged with no less than

1,500 psi of Nitrogen. Lower pre-charge pressure will lead to higher pressure variations

due to temperature changes.

It is normal to see pressure changing with changes in temperatures. The goal is to keep

the pressures within proper working range; i.e. if the actuator will maintain the valve

open with 1,500 psi but is rated to operate up to 3,000 psi, then the proper working

pressure will be between 1,500 and 3,000 psi.

The hydraulic circuits are shown on appendix “B”.

PRESSURE SENSING ASSEMBLY

The pressure sensing assembly includes a chemical seal, capillary tube and switch-gage

with electric contacts. The complete assembly is integrated in a single unit with weld-

sealed connections to insure a long and reliable life. If this assembly would fail, the

complete unit can be replaced by removing the transit plate which allows the chemical

seal to come through and the complete unit may be removed without any further

disassembling. The handling of pressure sensing assembly is to be done with care to

avoid damaging the capillary tube or switch-gage.

Do not attempt to repair the assembly in the field; this can be properly done only on a

well equipped and clean hydraulic shop. Field servicing is to be limited to the replacing

of the complete assembly.

XH3-HE Manual Rev.0 Dec 30, 2006 Page 6 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

ELECTRONIC SYSTEM

By replacing most of the hydraulic logic with electronic circuits, many hydraulic

components are removed and the hydraulics greatly simplified to a few reliable

components. By having self diagnostic in the electronics and a simplified hydraulic

circuit, the XH3-HE offers a reliability level not seen on any of the typical self-contained

wellhead control panels. Furthermore, if a failure would occur, the diagnostic and

correction of the problem is a much simpler job.

The electronic circuit and battery module are enclosed in an explosion proof box that

makes the system suitable for Class 1 hazardous areas, where ignitable mixtures of

combustible gases may exist.

Fig. 3 – Wiring to the interface module

The wiring from the Pressure Switch-Gauge to the Interface Module as well as the wiring

from the Interface Module to the Electronic Module is color coded as shown in Fig. 3

The interface module includes the indicator LEDs, the “Test –Reset”. The circuits

connecting to the Interface Module use energy level so low that they are incapable of

igniting the type of combustible mixtures found in the oil industry and the circuits have

been designed to meet the “Intrinsically Safe” criteria.

XH3-HE Manual Rev.0 Dec 30, 2006 Page 7 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

When operating under normal conditions (no alarms) the electronic system flashes the

green LED every two seconds (heartbeat) to indicate that the electronic system is

operating without problems.

If a High or Low Pressure alarm is detected the green LED stops flashing, the solenoid

valve trips to initiate shutdown and the red LED corresponding to the detected alarm

starts flashing. Once detected, the alarm is latched in such way that even if the alarm

would go away or a new one detected; the first alarm detected will continue to flash to

hold the information for the operator to see the cause of the shutdown. For example, if a

High Pressure Alarm would occur the corresponding High Pressure Alarm LED will flash

and keep on flashing even if the high pressure alarm goes away and now the needle is

touching the Low Pressure contact. The first detected alarm will keep displaying until

the operator presses “Reset”

Once the operator presses “Reset” the system resets the solenoid valve to allow the re-

opening of the well and flashes the green LED even if the alarm still present. However,

the system tolerates the existing alarm for only 30 minutes before re-initiating the

shutdown to prevent the system from being left in production while operating in an

abnormal condition.

It is to be noted that when the switch-gauge is on alarm condition , it is sensitive to shock

and vibration where the gauge’s needle may bounce against the contact point,

disconnecting for brief moments. This could cause that the system to read a condition

where the alarm goes away and returns, causing it to re-initiate the shutdown. Therefore,

it is recommended that the pumping action is done with some care. Otherwise, the

operator may choose to temporarily move the alarm point so it is no longer in contact

with the needle while doing the pumping. Once the well returns to its normal flowing

pressure the alarms settings are to be restored to their safe setting.

The “Test” function allows the operator to see the last alarm condition and also onfirm

that all the indicator LEDs are working properly. When pressing “Test”, the system

respond by flashing the last detected alarm for about two seconds and then flashes the

three red LEDs in sequence.

The battery module provides two separate voltages, 3.6 VDC to feed the microcontroller

circuits and 14.4 VDC to operate the solenoid valve. Both voltages are periodically

monitored by the system to confirm it has the proper battery supply to operate reliably.

If the system would detect low voltage on the solenoid supply (14.4 VDC) the green LED

stops flashing and the “Low Battery” red LED flashes instead but the system remains in

operation. However, if the system detects the solenoid supply too far down (below 10.0

VDC) it will initiate shutdown as the voltage is reaching a point where the solenoid valve

operation would not be reliable.

If the low voltage is detected on the 3.6 VDC, the green LED stops blinking to save

energy on the battery. To confirm the system still operating the operator may press

XH3-HE Manual Rev.0 Dec 30, 2006 Page 8 of 9

Axiom Technologies XH3-HE User’s Manual

15731 W. Hardy Rd., Suite 7, Houston, TX 77060 Telephone 281 931-0907

“Test” to confirm the red LEDs are operating. If the 3.6 VDC batteries go below 3.0

VDC, the system will initiate shutdown.

Given the low power consumption of the system it is expected that the operator will be

able to detect the warning signs of low battery with plenty of time (weeks) to replace the

battery module before it gets to the point where the system causes shutdown because low

battery.

The battery module is to be replaced as soon as the system shows signs of low voltage to

insure the system continues operating reliably. The battery module has an expected life

of five years

WARNING!

Do not attempt to recharge the batteries on the

battery module as this may cause an instable

condition that may result in a violent explosion.

Return the spent battery modules to Axiom

Technologies or to any lithium battery recycling

facility.

See the instructions shown on Appendix “A” for replacing the battery module.

XH3-HE Manual Rev.0 Dec 30, 2006 Page 9 of 9

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- EEHA Inspection Sheet TemplateDokument3 SeitenEEHA Inspection Sheet Templatedavid.bradley83Noch keine Bewertungen

- 3 LEVEL SVPWM Fpga PDFDokument61 Seiten3 LEVEL SVPWM Fpga PDFKarthi KumarNoch keine Bewertungen

- Mitsubishi Meldas 2M Memoria FormatDokument4 SeitenMitsubishi Meldas 2M Memoria FormatangelNoch keine Bewertungen

- Saral Jeevan Bima Brochure-BRDokument10 SeitenSaral Jeevan Bima Brochure-BRprabuNoch keine Bewertungen

- Jun'22 - On Road Price - JazzDokument1 SeiteJun'22 - On Road Price - JazzprabuNoch keine Bewertungen

- SBI Life - Smart Annuity Plus - Brochure 1Dokument15 SeitenSBI Life - Smart Annuity Plus - Brochure 1prabuNoch keine Bewertungen

- Nema MG P4-2020 Watermarked - 2021-07-25Dokument4 SeitenNema MG P4-2020 Watermarked - 2021-07-25prabuNoch keine Bewertungen

- Study MaterialDokument2 SeitenStudy MaterialprabuNoch keine Bewertungen

- 5SL43327 Datasheet enDokument4 Seiten5SL43327 Datasheet enprabuNoch keine Bewertungen

- 5SL42167 Datasheet enDokument4 Seiten5SL42167 Datasheet enprabuNoch keine Bewertungen

- Manual CGPower DT Installation Instructions ENG 29-10-10Dokument24 SeitenManual CGPower DT Installation Instructions ENG 29-10-10prabuNoch keine Bewertungen

- Cold vs. Flu vs. Allergies vs. COVID-19Dokument1 SeiteCold vs. Flu vs. Allergies vs. COVID-19prabuNoch keine Bewertungen

- S.N NOTEBOOK Specification Unit Price (KD.) : 14-Ax000neDokument9 SeitenS.N NOTEBOOK Specification Unit Price (KD.) : 14-Ax000neprabuNoch keine Bewertungen

- XH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsDokument9 SeitenXH3-HE User'S Manual: Self-Contained, Single Pump Wellhead Control Panel For Harsh EnvironmentsprabuNoch keine Bewertungen

- Noor Capital Market Contract Specification (1) enDokument12 SeitenNoor Capital Market Contract Specification (1) enprabuNoch keine Bewertungen

- CAT EMCP 3 3 Control Systems Operation Manual PDFDokument19 SeitenCAT EMCP 3 3 Control Systems Operation Manual PDFprabuNoch keine Bewertungen

- Buy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCDokument3 SeitenBuy APC Smart-UPS RT 2000VA 230V For China - Technical Specifications and Information - APCprabuNoch keine Bewertungen

- Compressor Drive Allison 501-KB Gas TurbineDokument4 SeitenCompressor Drive Allison 501-KB Gas Turbineprabu50% (2)

- All India Chess Federation: Player Registration Form For The Year: 2013 2014Dokument1 SeiteAll India Chess Federation: Player Registration Form For The Year: 2013 2014prabuNoch keine Bewertungen

- TMEB2 Datasheet eDokument2 SeitenTMEB2 Datasheet eJurun_BidanshiNoch keine Bewertungen

- PQSI Coil Lock Model 1003Dokument2 SeitenPQSI Coil Lock Model 1003prabuNoch keine Bewertungen

- Wansa AO-7003 Oil Heater 2500W (Million $$ Draw) - Oil Heaters - Heaters - Small AppliancesDokument2 SeitenWansa AO-7003 Oil Heater 2500W (Million $$ Draw) - Oil Heaters - Heaters - Small AppliancesprabuNoch keine Bewertungen

- Compact, Flexible, Highest Availability.: MotorsDokument10 SeitenCompact, Flexible, Highest Availability.: MotorsssNoch keine Bewertungen

- Taken From Course Structure 3 Phase Induction MachinesDokument18 SeitenTaken From Course Structure 3 Phase Induction MachinesSyed Ahmed MasoodNoch keine Bewertungen

- MAN SICAM P850 P855 7KG85xx V2.2 USDokument302 SeitenMAN SICAM P850 P855 7KG85xx V2.2 USIvanNoch keine Bewertungen

- Cold Fusion Replication ExperimentsDokument14 SeitenCold Fusion Replication ExperimentsXR500Final100% (6)

- A Dual-Feed Dual-Band L-Probe Patch AntennaDokument3 SeitenA Dual-Feed Dual-Band L-Probe Patch AntennaCRoberto Wah GonzalezNoch keine Bewertungen

- BOTONERASDokument61 SeitenBOTONERASRonald LupaNoch keine Bewertungen

- SONY KDL-40EX520 Chassis AZ2G DIAGRAMA SERVICE MANUALDokument154 SeitenSONY KDL-40EX520 Chassis AZ2G DIAGRAMA SERVICE MANUALJorge VasquezNoch keine Bewertungen

- BiCMOS TechnologyDokument17 SeitenBiCMOS TechnologyJacob ChakoNoch keine Bewertungen

- 16 Samss 521Dokument8 Seiten16 Samss 521Moustafa BayoumiNoch keine Bewertungen

- 60 GHZ Beamforming Transmitter Design For Pulse Doppler RadarDokument135 Seiten60 GHZ Beamforming Transmitter Design For Pulse Doppler Radarcowboy1980Noch keine Bewertungen

- Warning Caution: ECM3000 Control Motor User's ManualDokument8 SeitenWarning Caution: ECM3000 Control Motor User's ManualLukaszNoch keine Bewertungen

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Dokument1 SeiteFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsNoch keine Bewertungen

- Aia360 - Training Manuel - Rev7.1Dokument115 SeitenAia360 - Training Manuel - Rev7.1Hary John Tsivery Rakotonjak'sParowNoch keine Bewertungen

- Tran Smiss Io N Li NeDokument17 SeitenTran Smiss Io N Li NesinghrichaNoch keine Bewertungen

- DC Machine61 74Dokument3 SeitenDC Machine61 74Charina PinlacNoch keine Bewertungen

- P-Channel Enhancement Mode Power Mosfet: Product SummaryDokument5 SeitenP-Channel Enhancement Mode Power Mosfet: Product Summaryserrano.flia.coNoch keine Bewertungen

- Design and Study On The State of Charge Estimation For Lithium-Ion Battery Pack in Electric VehicleDokument5 SeitenDesign and Study On The State of Charge Estimation For Lithium-Ion Battery Pack in Electric VehiclekhasimNoch keine Bewertungen

- Seville Classic Tower Fan 2011 - Instruction Sheet (31!08!2011)Dokument6 SeitenSeville Classic Tower Fan 2011 - Instruction Sheet (31!08!2011)scribe2000Noch keine Bewertungen

- GDTE en PDFDokument80 SeitenGDTE en PDFIsrael JosueNoch keine Bewertungen

- LED Seminar PPT By, Er. Swapnil V. KawareDokument14 SeitenLED Seminar PPT By, Er. Swapnil V. Kawareswapnil50% (2)

- Basic Electronics Mcqs 2Dokument4 SeitenBasic Electronics Mcqs 2khananuNoch keine Bewertungen

- Fanuc Page 8 (Para Spindle and Pro 9000)Dokument16 SeitenFanuc Page 8 (Para Spindle and Pro 9000)Hoangvinh Duong100% (1)

- Lect01 (MT 353)Dokument14 SeitenLect01 (MT 353)Afzal Khan sulemaniNoch keine Bewertungen

- List of IEC Standards Wikipedia, The FRDokument5 SeitenList of IEC Standards Wikipedia, The FRSrikant RanjanNoch keine Bewertungen

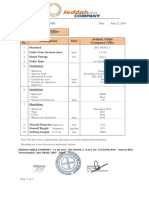

- Jeddah Cable Cu Xlpe-PvcDokument2 SeitenJeddah Cable Cu Xlpe-PvcSoltani AliNoch keine Bewertungen

- Electrical Viva 100 QuestionDokument63 SeitenElectrical Viva 100 QuestionMd. Farhan ShahriorNoch keine Bewertungen

- Printed Circuit BoardDokument16 SeitenPrinted Circuit BoardAjayChandrakarNoch keine Bewertungen