Beruflich Dokumente

Kultur Dokumente

BCD4 000 44 SPC 4 012 00 - Rev0 REC Boltings

Hochgeladen von

Ricardo NapitupuluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BCD4 000 44 SPC 4 012 00 - Rev0 REC Boltings

Hochgeladen von

Ricardo NapitupuluCopyright:

Verfügbare Formate

PetroChina International Jabung Ltd.

Specification

Boltings

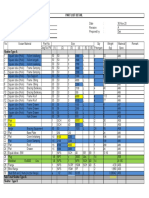

TABULATION OF REVISED PAGES

PAGE REVISIONS PAGE REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 X X X X 52

2 X X X X 53

3 X X X 54

4 X X X 55

5 X X 56

6 X X 57

7 X X 58

8 X X 59

9 X X 60

10 61

11 62

12 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT

42 1

43 2

44 3

45 4

46 5

47 6

48 7

49 8

50 9

51 10

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 2 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

Table of Contents

Section Title Page

1.0 SCOPE ............................................................................................................ 4

2.0 REFERENCES ................................................................................................ 4

2.1 Project Specification ..................................................................................... 4

2.2 Code and Standard........................................................................................ 4

3.0 CONFLICT ...................................................................................................... 5

4.0 NOTES ............................................................................................................ 5

4.1 Material ........................................................................................................... 5

4.2 Material Certificate ........................................................................................ 5

4.3 Material Description ...................................................................................... 5

4.4 Unit standard ................................................................................................. 5

4.5 Flange combinations .................................................................................... 5

4.6 Stud Bolt Torquing ........................................................................................ 6

5.0 MANUFACTURING ........................................................................................ 7

6.0 SHOP INSPECTION AND TEST .................................................................... 7

7.0 MARKING ....................................................................................................... 7

8.0 STORAGE AND HANDLING .......................................................................... 8

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 3 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

1.0 SCOPE

This Specification covers the minimum requirements for the material, design

manufacture and certification of bolts use on in-line piping for plant piping and pipeline

for Petrochina International Jabung Ltd. (PCI) Betara Complex Development phase 4

(BCD4) Project.

2.0 REFERENCES

The following applicable section of the latest edition of the code and standards,

including addenda and referenced documents, project’s specification shall form an

integral part of this specification.

Where the requirement of the subject is defined by two or more references, the more

stringent reference shall govern.

2.1 Project Specification

• BCD4-000-44-SPC-4-007-00 Specification for Piping Material Class

Including Commodity Code

• BCD4-000-44-SPC-4-010-00 Specification for Flanges

• BCD4-000-44-SPC-4-016-00 Specification for Pipe Material Color

Coding

• BCD4-000-44-SPC-4-017-00 Specification for Piping Fabrication,

Erection and Testing

• BCD4-000-44-STD-3-003-00 Standard Pipe Support Drawing

2.2 Code and Standard

The following code and standard shall be applied unless otherwise specified.

ASME Code / Standard:

• B31.3 Process Piping

• B31.8 Gas Transportation and Distribution Piping System

• B1.1 Unified Inch Screw Threads

• B18.2.1 Square and Hex Bolts and Screw Inch Series

• B18.2.2 Square and Hex Nuts (Inch Series)

ASTM Standards:

• A193 Alloy Steel and Stainless Steel Bolting Materials for High

Temperature Service

• A194 Carbon and Alloy Steel Nuts for Bolts for High Pressure and

High-Temperature Service

• A307 Carbon Steel Externally Threaded Service

• A320 Alloy Steel Bolting Materials for Low-Temperature Service

• B766 Electrodeposited Coating of Cadmium

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 4 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

3.0 CONFLICT

If any conflict exists between this specification or other Technical Requirements and

the applicable codes and standards, it shall be submitted in writing to PCI for

resolution.

4.0 NOTES

4.1 Material

(1) All bolting, including studs, bolts, cap screws, jacking bolts, nut, washers, “U”

bolt, etc, used in piping systems and pipe support shall be carbon, low alloy

steel, or stainless steel in accordance with the material class, document no:

BCD4-000-44-SPC-4-007-00 for piping system, and pipe support standard

document no: BCD4-000-44-STD-3-003-00.

(2) Material specification for bolts and nuts shall conform to the requirement of

applicable code and standard.

• Alloy Steel Stud Bolts : ASTM A193 GR.B7,

ASTM A193 GR B7M.

• Stainless Steel Stud Bolts : ASTM A193 GR.B8.

• SS Heavy Hex. Nuts : ASTM A194 GR.8

• CS Heavy Hex. Nuts : ASTM A194 GR.2H,

ASTM A194 GR. 2HN.

• SS Washers : ASA B27.2 TP “B” regular.

• Aluminum Stud Bolts : ASTM B211-2024-T4.

(3) ASTM A307 Grade B machine bolts with ASTM A563 Grade A nuts are to be

used at cast iron equipment nozzles, and/or cast iron valves, except for wafer

type butterfly/check valves shall use stud bolts.

4.2 Material Certificate

Material certificate shall include the result and record of heat treatment, together with

calibration of equipment use, impact test and hardness test as well as results of

chemical analysis and mechanical property tests.

4.3 Material Description

Material description shown in Piping Material Class or other material lists generally

are simplified description, and for full description shall refer to Commodity Code list of

Doc. No. BCD4-000-44-SPC-4-007-00 ”Specification for Piping Material Class

including Commodity Code”.

4.4 Unit standard

Unit to be used for bolt’s size shall be inch, and for length of bolt dimension shall be

Metric unit.

4.5 Flange combinations

Material grade of studs to be used and requirement for use of washers shall be in

accordance with the following table ‘A’.

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 5 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

TABLE ‘A’

Nuts(2 per

Flange Combination Studs Washers

stud)

SS - SS SS SS Not Required

Al. – SS SS SS 1 Required St. Steel *

Al. – Al. Al. SS 2 Required St. Steel

SS –CS SS SS Not Required.

CS –CS Alloy Steel CS Not Required.

Duplex – Duplex SS SS Not Required.

Duplex - SS SS SS Not Required.

Duplex - CS SS SS Not Required.

* For Aluminum (Al.) – Stainless Steel (SS) flange combination, the S.S washer shall

be used on the back of the aluminum flange.

4.6 Stud Bolt Torquing

(1) Approved lubricant-threads, both side of washer, and the bearing surface of

the nuts shall be lubricated with a thin application of Molyslip ADF

Molybdenum Disulfide high pressure lubricant.

(2) Tightening Pattern

All stud bolt shall be gradually pulled up by a crossover sequence. An

example for an eight bolt flange is illustrated below.

A similar pattern shall be used in accordance with the number of stud bolts

required. A minimum of one thread shall extend beyond the top of each nut.

Where more than one thread extends, the stud bolts shall be pulled up to

ensure that an equal number of threads is expose beyond the nut on each

stud.

START

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 6 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

5.0 MANUFACTURING

(1) Threads on bolt and nuts shall be unified coarse treads (UNC) inch sizes 1

inch and smaller, unified 8 threads (8 UN) in sizes 1-1/8 inch and larger

conforming to ASME B1.1 having Class 2A for bolts and Class 2B for nuts.

Low Alloy Steel studs shall be rolled treads with cadmium plating per ASTM

B766, Type II Class 12. Stainless Steel studs shall be rolled treads with

lubricant or compound which is suitable for the service.

(2) For machine bolts the head bolts shall be hexagon types having no washer

face conforming to ASME B18.2.1.

(3) Nuts shall be heavy semi finished hexagon type having washer face

conforming to ASME B18.2.2.

(4) Stud bolts shall be threaded full lengths with continuous threads.

(5) End of bolts shall be flat

(6) Length of machine bolts shall be measured from bearing of head, including

end point.

(7) Stud bolts dimensions shall be per ASME B16.5 with exception of length

being equal to ASME B16.5 plus one stud diameter.

(8) All bolts sizes 1-1/4” and above for flanges class 900 and above shall have

one bolt diameter extra length for hydraulic tensioning. The extra length shall

protrude on one side only and the threads shall be protected.

(9) Dimensional tolerances on bolts and nuts shall be within the limit specified in

applicable ASME/ ASTM standard.

(10) Low alloy steel bolting for offshore/saline environments shall be hot dip

galvanized. Stainless steel bolting for offshore/saline environments shall be

316L SS.

6.0 SHOP INSPECTION AND TEST

Shop inspection and test shall be carried out in conformance with the requirements of

applicable ASME and ASTM standard.

7.0 MARKING

(1) Each bolt and nut shall be legibly and conspicuously marked in conformance

with the requirements of applicable ASME/ASTM standard.

(2) Colors Coding shall be provided on each bolt and nut in conformance with

Doc. No. BCD4-000-44-SPC-4-016-00 “Specification for Piping Material Color

Code”.

(3) Paint or ink for color-coding of stainless steel bolts and nuts shall not contain

any harmful metal or metal salts, such as zinc, lead or copper which causes

corrosive attack on heating.

(4) Marking on charpy impact tested steel and austenitic stainless steel bolts and

nuts shall be stamped by low stress method.

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 7 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Boltings

8.0 STORAGE AND HANDLING

The followings are minimum requirement for protection of bolts and nuts. The bolts and

nuts shall be prepared in such manner as to provide suitable protection during

transportation and storage, and requirement for protection shall not be limited by the

followings.

(1) Bolts and nuts shall be protected from rust, corrosion, and mechanical

damage during transportation, shipment, and storage.

(2) Bolts and nuts shall be dry, clean, and free from moisture, dirt, and loose

foreign materials of any kind.

(3) Carbon and low alloy steel bolts and nuts shall be coated with a lubricant for

rust preventive. (Stainless steel bolts and nuts shall not be coated).

(4) Packing and securing shall be designed to offer adequate protection against

method of transport (inland and overland) until delivery at job site and storage

area

a. All bolts and nuts types and all sizes shall be by moisture-proof box.

b. All bolts and nuts shall be stored in warehouse, on the rack or wooden

base and shall not be laid direct contact to the ground.

(5) Stainless Steel Bolt and Nuts shall be stored separately from other steel bolt

and steel material to avoid receiving rust.

Doc: BCD4-000-44-SPC-4-012-00_rev0-AFC~Boltings Page 8 Updated – 16-Oct-09

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Architectural Consultancy AgreementDokument6 SeitenArchitectural Consultancy AgreementprashinNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- ITG-Internal Control MatrixDokument14 SeitenITG-Internal Control Matrixbladexdark67% (3)

- Nm-Dairy Planning Data SheetDokument16 SeitenNm-Dairy Planning Data SheetRicardo NapitupuluNoch keine Bewertungen

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDokument6 SeitenChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNoch keine Bewertungen

- Aws c2.25 2002 Thermal Spray Feedstock PDFDokument27 SeitenAws c2.25 2002 Thermal Spray Feedstock PDFneyzaNoch keine Bewertungen

- Astm A-817Dokument4 SeitenAstm A-817mukeshNoch keine Bewertungen

- Concrete Quality Control Plan Sample PDFDokument20 SeitenConcrete Quality Control Plan Sample PDFKishan ChauhanNoch keine Bewertungen

- Norma ASTM-A641Dokument5 SeitenNorma ASTM-A641Dilmer CV100% (2)

- Leak Test Procedure of Atmospheric VesselDokument9 SeitenLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- 06.standard Specification PDFDokument308 Seiten06.standard Specification PDFshareyhouNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDokument4 SeitenVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNoch keine Bewertungen

- Masterformat: Prepared By: Ar. MelaDokument22 SeitenMasterformat: Prepared By: Ar. MelaEricksonNoch keine Bewertungen

- E-Notice Announcement and Management System SRSDokument19 SeitenE-Notice Announcement and Management System SRSJëbê Béløñgs Tö Jêsüs100% (1)

- Case Study of Woody Woodworking CompanyDokument11 SeitenCase Study of Woody Woodworking CompanyRenz Edward Corral100% (1)

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDokument9 SeitenVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNoch keine Bewertungen

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Dokument4 SeitenSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNoch keine Bewertungen

- IQCM Final For Industry-12!06!2015Dokument142 SeitenIQCM Final For Industry-12!06!2015raj dasNoch keine Bewertungen

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDokument1 SeiteDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNoch keine Bewertungen

- It - PT - Asme - 01 - Rev 00Dokument16 SeitenIt - PT - Asme - 01 - Rev 00Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDokument3 SeitenVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Dokument2 SeitenVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorDokument3 SeitenVp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorRicardo NapitupuluNoch keine Bewertungen

- S Curve Instrument CepuDokument1 SeiteS Curve Instrument CepuRicardo NapitupuluNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvDokument3 SeitenVp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvRicardo NapitupuluNoch keine Bewertungen

- API Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsDokument5 SeitenAPI Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsRicardo NapitupuluNoch keine Bewertungen

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDokument2 SeitenTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNoch keine Bewertungen

- PLD - Shelter - 30 11 2020Dokument3 SeitenPLD - Shelter - 30 11 2020Ricardo NapitupuluNoch keine Bewertungen

- 6 BLP Spesifikasi Teknis 49 SMA 14920Dokument6 Seiten6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNoch keine Bewertungen

- Support and Non Pressure Part Calculation of Foul ProductionDokument34 SeitenSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNoch keine Bewertungen

- Eng - M - Lifting Lug Cal - 2Dokument6 SeitenEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceDokument1.274 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceRicardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandDokument295 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandRicardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainDokument228 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainRicardo NapitupuluNoch keine Bewertungen

- Chapter 13. Fire Severity Calculations: Input ParametersDokument20 SeitenChapter 13. Fire Severity Calculations: Input ParametersRicardo NapitupuluNoch keine Bewertungen

- Mto Instrument Condensate RecoveryDokument1 SeiteMto Instrument Condensate RecoveryRicardo NapitupuluNoch keine Bewertungen

- B-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantDokument3 SeitenB-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantRicardo NapitupuluNoch keine Bewertungen

- Interconnect v10.1 SP2 Technical GuideDokument388 SeitenInterconnect v10.1 SP2 Technical GuideSaeed M. KhoshbakhtNoch keine Bewertungen

- FlexRay Protocol Specification V3.0.1Dokument341 SeitenFlexRay Protocol Specification V3.0.1Amine Fourati100% (1)

- Standard Bidding Document - Drugs & Medicines For DHQ THQDokument86 SeitenStandard Bidding Document - Drugs & Medicines For DHQ THQAbdul SattarNoch keine Bewertungen

- NS127Dokument172 SeitenNS127துரைராஜ் இலட்சுமணன்Noch keine Bewertungen

- GeM Bidding 3131079Dokument7 SeitenGeM Bidding 3131079Gurpreet SinghNoch keine Bewertungen

- Draft General Overhaul (GO) Tender ContractDokument120 SeitenDraft General Overhaul (GO) Tender ContractVictor UngureanuNoch keine Bewertungen

- METHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFDokument5 SeitenMETHOD OF WORK - ELEVATION WORK PROCEDURE WITH CHAIN BLOCK Pump GFCarlos ImmanuelNoch keine Bewertungen

- ETSI TS 155 205: Technical SpecificationDokument17 SeitenETSI TS 155 205: Technical Specificationanu12346973Noch keine Bewertungen

- Vendor Directory Qa CivilDokument200 SeitenVendor Directory Qa CivilAashish AhujaNoch keine Bewertungen

- Tool-Resisting Steel Bars, Flats, and Shapes For Detention and Correctional FacilitiesDokument11 SeitenTool-Resisting Steel Bars, Flats, and Shapes For Detention and Correctional Facilitiesist93993Noch keine Bewertungen

- MS 4062 Rev A 2008Dokument6 SeitenMS 4062 Rev A 2008Bartek HajaNoch keine Bewertungen

- Specification For Consumable InsertsDokument18 SeitenSpecification For Consumable InsertsSarvesh MishraNoch keine Bewertungen

- ITP Service PL 001 RWPDokument1 SeiteITP Service PL 001 RWPDedi KartiwaNoch keine Bewertungen

- L1-Che-Spe-299-Techniques & Materials For The Jointing & Repair of Railway Signalling Multi Core and Power Supply CableDokument51 SeitenL1-Che-Spe-299-Techniques & Materials For The Jointing & Repair of Railway Signalling Multi Core and Power Supply CableHong GongNoch keine Bewertungen

- Openrtb Mobile RTB API - 1.0Dokument18 SeitenOpenrtb Mobile RTB API - 1.0misnomer42Noch keine Bewertungen

- 3BDD010435R0201 A en S900 I O Digital I O Relay Module DO930NDokument30 Seiten3BDD010435R0201 A en S900 I O Digital I O Relay Module DO930Nilke HANNoch keine Bewertungen

- Software Requirements SpecificationDokument12 SeitenSoftware Requirements Specificationshahghani khanNoch keine Bewertungen

- A 1010 - A 1010m - 01 QtewmtavqtewmtbnDokument2 SeitenA 1010 - A 1010m - 01 QtewmtavqtewmtbnfekihassanNoch keine Bewertungen

- SAP SD Consultant (S4 HANA) : Nitin KumarDokument3 SeitenSAP SD Consultant (S4 HANA) : Nitin KumarBappi BiswasNoch keine Bewertungen