Beruflich Dokumente

Kultur Dokumente

BCD4 000 44 SPC 4 010 00 - Rev0 REC Flanges

Hochgeladen von

Ricardo NapitupuluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BCD4 000 44 SPC 4 010 00 - Rev0 REC Flanges

Hochgeladen von

Ricardo NapitupuluCopyright:

Verfügbare Formate

PetroChina International Jabung Ltd.

Specification

Flanges

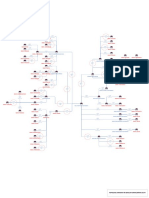

TABULATION OF REVISED PAGES

PAGE REVISIONS PAGE REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 X X X X 52

2 X X X X 53

3 X X X X 54

4 X X X 55

5 X X X 56

6 X X 57

7 X X 58

8 X X 59

9 X X 60

10 X X X 61

11 X X X 62

12 X X 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT

42 1

43 2

44 3

45 4

46 5

47 6

48 7

49 8

50 9

51 10

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 2 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

Table of Contents

Section Title Page

1.0 SCOPE ............................................................................................................ 4

2.0 REFERENCES ................................................................................................ 4

2.1 Project Specification ..................................................................................... 4

2.2 Code and Standard........................................................................................ 4

3.0 CONFLICT ...................................................................................................... 5

4.0 DESIGN........................................................................................................... 5

5.0 MATERIAL ...................................................................................................... 5

5.1 Carbon Steel Flange...................................................................................... 6

5.1.1 Base Material.................................................................................................. 6

5.2 Low Temperature Carbon Steel Flange....................................................... 6

5.2.1 Base Material.................................................................................................. 6

5.3 Stainless Steel Flange .................................................................................. 6

5.3.1 Base Material.................................................................................................. 6

5.4 Duplex Stainless Steel Flange...................................................................... 7

5.4.1 Base Material.................................................................................................. 7

5.4.2 Special requirement for Duplex Flanges ..................................................... 7

5.5 Overlay Welded Flange ................................................................................. 8

5.5.1 Base Material.................................................................................................. 8

5.5.2 Special requirement for Overlay Flanges .................................................... 8

6.0 NOTES ............................................................................................................ 9

7.0 MANUFACTURING ........................................................................................ 9

8.0 SHOP INSPECTION AND TEST .................................................................. 10

9.0 MARKING ..................................................................................................... 10

10.0 STORAGE AND HANDLING ........................................................................ 10

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 3 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

1.0 SCOPE

This Specification covers the minimum requirements for the material, design

manufacture and certification of flanges use on inline piping for plant piping and

pipeline for Petrochina International Jabung Ltd. (PCI) Betara Complex Development

phase 4 (BCD4) Project.

2.0 REFERENCES

The following applicable section of the latest edition of the code and standards,

including addenda and referenced documents, project’s specification shall form an

integral part of this specification.

Where the requirement of the subject is defined by two or more references, the more

stringent reference shall govern.

2.1 Project Specification

• BCD4-000-44-SPC-4-007-00 Specification for Piping Material Class

Including Commodity Code.

• BCD4-000-44-SPC-4-015-00 Specification for Piping Material Code

And Stamping.

• BCD4-000-44-SPC-4-016-00 Specification for Piping Material Color Coding

2.2 Code and Standard

The following code and standard shall be applied unless otherwise specified.

ASME Code and standard:

• B31.3 Process Piping

• B31.4 Pipeline Transportation System for Hydrocarbon and Other

Liquids

• B31.8 Gas Transportation and Distribution Piping System

ASME Code and standard:

• B16.5 Pipe Flanges and Flanged Fittings.

• B1.20.1 Pipe Thread, General Purpose (Inch).

• B16.25 Butt-welding Ends.

• B16.34 Steel Valves, Flanged, Threaded and Butt-Welding.

• B16.47 Series B Large Diameter Carbon Steel Flanges.

• B36.10M Welded and Seamless Wrought Steel Pipe.

• B36.19M Stainless Steel Pipe.

• B46.1 Surface Texture

ASTM Standard :

• A105 Forgings, Carbon Steel, for Piping Components

• A182 Forged or Rolled Alloy-Steel Pipe Flanges, Forged

Fitting and Valves and Parts for High-Temperature Service

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 4 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

• A350 Forging, Carbon and Low-Alloy Steel Requiring Notch

Toughness Testing for Piping Components Plate for spectacle

blind or Blind and Spacer

• A240 Heat-Resisting chromium and Chromium-Nickel

Stainless Steel Plate, sheet, and strip for Fusion Welded

unfired Pressure Vessel

• A516 Carbon Steel Plates for Pressure Vessels for Moderate

And Lower Temperature Service

• A694 Carbon and Alloy Steel Forging for Pipe Flanges,

Valves and Parts for High Pressure Transmission Service

MSS Standard :

• SP-25 Standard Marking System for Valves, Fittings, Flanges

And Unions

API Standard :

• API 590 Steel Line Blank for Spectacle Blind

3.0 CONFLICT

If any conflict exists between this specification and other Technical Requirements and

the applicable codes and standards, it shall be submitted in writing to PCI for

resolution.

4.0 DESIGN

Piping components shall as minimum, be designed, manufactured, inspected and

tested in accordance with the ASME B31.3 code, unless otherwise specified in the

individual service class.

5.0 MATERIAL

Material specifications shall conform to the requirements of applicable code and

standard.

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 5 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

5.1 Carbon Steel Flange

5.1.1 Base Material

The base material shall be in accordance with ASTM A105 and ASTM 694-F52.

The chemical composition (in %) of steel shall conform to the requirement

prescribed below, the percentages indicated are maximum unless indicated :

Chemical ASTM A105 ASTM A694-F52

Carbon (C ) 0.35 0.20

Manganese (Mn) 0.60 – 1.05 0.90 – 1.60

Phosporus (P) 0.035 0.035

Sulphur (S) 0.04 0.025

Silicon (Si) 0.10 – 0.35 0.10 – 0.5

Copper (Cu) 0.40 -

Nickel (Ni) 0.40 -

Chromium (Cr) 0.30 -

Molybdenum (Mo) 0.12 -

The maximum carbon equivalent shall be 0.43.

5.2 Low Temperature Carbon Steel Flange

5.2.1 Base Material

The base material shall be in accordance with ASTM A350 Grade LF2.

The chemical composition (in %) of steel shall conform to the requirement

prescribed below, the percentages indicated are maximum unless indicated:

Chemical ASTM A350-LF2

Carbon (C ) 0.35

Manganese (Mn) 0.60 – 1.35

Phosporus (P) 0.035

Sulphur (S) 0.04

Silicon (Si) 0.15 – 0.35

Nickel (Ni) 0.40

Chromium (Cr) 0.30

Copper 0.40

Molybdenum (Mo) 0.12

The maximum carbon equivalent shall be 0.43.

5.3 Stainless Steel Flange

5.3.1 Base Material

The base material shall be in accordance with ASTM A182 Grade F304L and A182

Grade F316L

The chemical composition (in %) of steel shall conform to the requirement

prescribed below, the percentages indicated are maximum unless indicated :

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 6 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

ASTM A182

F304L F316L

Chemical

Carbon (C ) 0.035 0.035

Manganese (Mn) 2.00 2.00

Phosporus (P) 0.045 0.045

Sulphur (S) 0.03 0.03

Silicon (Si) 1.00 1.00

Chromium (Cr) 18 – 20 16 – 18

Nickel (Ni) 8 – 13 10 – 15

Molybdenum (Mo) - 2–3

Nitrogen (N) 0.10 0.10

5.4 Duplex Stainless Steel Flanges

5.4.1 Base Material

The base material shall be in accordance with ASTM A182 Grade F51. The

chemical composition (in %) of steel shall conform to the requirement as follows,

the percentages indicated are maximum unless indicated :

Chemical A182-F51

Carbon (C ) 0.030

Manganese (Mn) 2.00

Phosporus (P) 0.030

Sulphur (S) 0.020

Silicon (Si) 1.00

Chromium (Cr) 21– 23

Nickel (Ni) 4.5 – 6.5

Molybdenum (Mo) 2.5 – 3.5

Nitrogen (N) 0.14 (min)

5.4.2 Special requirement for Duplex Flanges

(1) The forging shall be solution annealed followed by water quenching.

(2) The hardness shall be less than 28 HRC (or alternatively 271 HB or 290

HV10) for the base material, HAZ and the weld metal.

(3) Charpy V-notch testing according to ASTM A370 at – 46 OC is required for

the thickness > 6 mm (thickness at the weld neck). The minimum absorbed

energy shall satisfy 45 J average and 35 J single. Reduction factor for

subsize specimens shall be:

7.5 mm – 5/6 and 5 mm –2/3.

(4) The micrographic examination shall be carried out at the same are as

location of specimens for mechanical. The area shall be minimum 10 x 10

mm. The ferrite content shall be determined according to ASTM E 562 or

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 7 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

equivalent and shall be within 35% to 55%. The microstructure, as

examined at 400X magnification on a suitably etched specimen, shall be

free from intermetallic phases and precipitates.

(5) Impact test, tensile test, hardness test and microstructure examination shall

be carried out for each heat and heat treatment load. A test lot shall not

exceed 2000 kg for forgings with as forged weight < 50 kg, and 5000 kg for

forgings with as forged weight > 50 kg.

(6) Samples for production testing shall realistically reflect the properties in

the actual component.

(7) Dye penetrant testing shall apply 10% of forging above from 2 NPS. The

testing shall be carried out after final machining. Non machined surfaces

shall be pickled prior to the testing. The acceptance criteria shall be ASME

VIII, Division 1, Appendix 8.

5.5 Overlay Welded Flanges

5.5.1 Base Material

The base material shall be in accordance with ASTM A105, overlay layer shall be in

accordance with ASTM A240-316L. The chemical composition (in %) of steel shall

conform to the requirement as follows, the percentages indicated are maximum

unless indicated :

Chemical A105 A240-316L

Carbon (C ) 0.35 0.03

Manganese (Mn) 0.60 - 1.05 2.00

Phosporus (P) 0.035 0.045

Sulphur (S) 0.040 0.03

Silicon (Si) 0.10 – 0.35 0.75

Copper 0.40 -

Nickel (Ni) 0.40 10 – 14

Chromium (Cr) 0.30 16 – 18

Molybdenum (Mo) 0.12 2–3

The maximum carbon equivalent shall be 0.43.

5.5.2 Special requirement for Overlay Flanges

(1) Flange shall be A105 base material with minimum 2.5 mm A240-316L SS

welded overlay. Vendor shall verify dimension so that finish dimension such

as raised face diameter shall conform to ASME B16.5 or B16.47-B

(2) Weld overlay shall be a minimum of two passes. Weld overlay shall be

undertaken in accordance with an approved WPS. Weld overlay shall be

100% DPI.

(3) Supplier shall demonstrate mechanical properties of the carbon steel forging

following weld overlay.

(4) Chemical composition of weld overlay shall meet the requirements of UNS

S31603 0.5 mm below the surface.

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 8 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

6.0 NOTES

(1) Material Certificate

Material certificate shall be supplied for all materials; Carbon, Alloy, Stainless

Steel and others.

The certificate shall include chemical analysis, Mechanical Properties, heat

treatment and other test required per the applicable material standard as well

as calibration record of equipment used.

(2) Material Description

Material description shown in Piping Material Class or other material lists

generally are simplified description, and for full description shall refer to

Commodity Code list of Doc. No. BCD4-000-44-SPC-4-007-00 ”Specification

for Piping Material Class Including Commodity Code”.

(3) Flange for non metallic piping and for mating to cast iron elements or mating to

nozzle equipment with flat face surface shall be flat faced and use with full face

gaskets.

(4) ASME Class 150 through 1500 flanges shall be raised face and shall be in

accordance with the standard specified in paragraph 6 item (1) and (2).

(5) Unit to be used for flange’s size shall be inch, other dimensions shall be

converted to millimeter (mm) when Vendor submits drawing, by multiplying with

the following factor: 1 inch = 25.4 millimeter

7.0 MANUFACTURING

(1) Outside diameters and wall thicknesses on mating pipes shall be in

conformance with ASME B36.10M or B36.19M, either one depending on the

schedule or material type. The outside diameter not specified in the standard

shall be corresponding to the nominal pipe size.

(2) Dimensions, pressure rating bolting and facing of all flanges shall be in

accordance with the following standard:

• NPS 24” and smaller: ASME B16.5

• NPS 26” and larger: ASME B16.47B.

(3) Dimensional tolerances on flanges shall be within the limit specified in

applicable ASME standard.

(4) Threaded ends shall have NPT internal taper pipe thread conforming to ASME

B1.20.1.

(5) Galvanized flanges shall be coated with zinc by hot-dip process in

conformance with ASTM A153.

(6) Beveled ends shall conform to details shown on Figure 2a for thickness 22

millimeters and smaller, and Figure 3a for thickness greater than 22 millimeters

in ASME B16.25.

(7) The flange facing shall be serrated finished and generated either concentrically

or as a continuous spiral groove by a round nosed tool, with a roughness

shown in the following table that defines the acceptable ranges of contact

surface finishes for each gasket. The surface finishes are specified AARH

(Arithmetical Average Roughness Height).

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 9 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

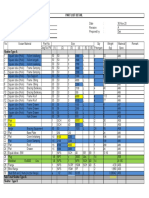

Allowable Allowable

Gasket Type Minimum Maximum

• Sheet Gasket (where allowed) 125 250

• Spiral wound 125 250

Note: All dimensions above are in micro-inches.

(8) No circumferential or longitudinal weld is permitted.

(9) Weld Neck flange shall be used for size NPS 2” and larger in all services and

for size NPS 1-1/2” and smaller use Socket Weld type, except for the

following;

• For Instrument Air, small bore piping (NPS 2” and smaller) use galvanized

threaded flanges, for NPS 3” and larger use Weld Neck flanges.

8.0 SHOP INSPECTION AND TEST

(1) Shop inspection and test shall be carried out in conformance with the

requirements of applicable ASME and ASTM standard.

(2) PCI, Contractor and their designated inspection agency have the right to inspect

and witness test at Vendor’s premises to ensure confirming with the

requirements in accordance with the approved Shop Inspection and Test Plan.

(3) Alloy elements check (PMI examination) by metascope or other equipment shall

be required for Alloy flanges.

(4) ASTM A350–LF2 flanges shall be subjected to impact test at -46oC in

conformance with ASTM standard.

9.0 MARKING

(1) Each flange shall be legibly and conspicuously marked in conformance with the

requirements of applicable ASME / ASTM standard, and MSS Standard.

Marking on flanges in size NPS 26” and larger shall be in conformance with

MSS SP-25.

(2) Piping commodity code shall be marked on each flange in conformance with

Doc. No. BCD4-000-44-SPC-4-015-00 “Specification for Piping Material Code

and Stamping”.

(3) Color Coding shall be provided on each flange in conformance with Doc. No.

BCD4-000-44-SPC-4-016-00 “Specification for Piping Material Color Coding”.

(4) Paint or ink for color coding of stainless steel flanges shall not contain any

harmful metal or metal salts, such as zinc, lead or copper which causes

corrosive attack on heating. Chloride shall not also be contained.

(5) Marking shall be stamped by low stress method.

10.0 STORAGE AND HANDLING

The followings are minimum requirement for protection of flange materials. The flange

shall be prepared in such manner as to provide suitable protection during

transportation and storage, and the requirement for protection shall not be limited by

the followings.

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 10 Updated – 16-Oct-09

PetroChina International Jabung Ltd. Specification

Flanges

(1) Flanges shall be protected from rust, corrosion, and mechanical damage during

transportation, shipment, and storage.

(2) Flanges shall be dry, clean, and free from moisture, dirt, and loose foreign

materials of any kind.

(3) Exterior surface on each flange shall be coated with rust preventive except for

galvanized flanges.

(4) Rust preventive on Carbon Steel flange’s face shall be of grease type.

(5) Rust preventive on machined surfaces to be welded shall be easily removable

with a petroleum solvent, or not harmful to welding.

(6) Each end of flange shall be protected with the following materials:

Threaded end : Plastic Plug

Socked Welding end : Vendor’s Recommendation

Slip-on end : - ditto -

Beveled end : Wood, metal or plastic cover

Flange face : - ditto -

(7) End protectors to be used on flange face shall not be smaller than the outside

diameter of the flange face.

(8) Steel protectors to be used on galvanized flanges shall be galvanized

(9) End protectors to be used on the beveled end shall be securely and tightly

attached with belt or wire.

(10) Packing and securing shall be designed to offer adequate protection against

method of transport (inland and overland) until delivery at job site and storage

area. Packing shall refer to Section 4.8 of BCD3-000-50-PCD-4-007-00 Rev 0

“Packing and Marking Procedure”.

(11) All flanges shall not be laid direct to the ground. The wooden base is required,

with sufficient width and length to prevent direct contact flanges to the ground,

and to store flange in the warehouse. The storage classification and instruction

shall refer to BCD3-000-60-PCD-4-018-00 Rev 0 “Procedure Field Material

Handling for Warehouse”

(12) Duplex or Stainless Steel flanges shall be stored separately from other steel

flanges and steel materials to avoid receiving rust. Protective plastic, wood, or

carpet strips can be used to prevent contact between those steel and to protect

from rainwater.

(13) Care should be taken to prevent damage to the overlaid surface flange,

especially when using clamps and hooks.

Doc: BCD4-000-44-SPC-4-010-00_rev0-AFC~Flanges Page 11 Updated – 16-Oct-09

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- F1a F1C P1d32s001e 02.06Dokument456 SeitenF1a F1C P1d32s001e 02.06Alejandro Di Gregorio100% (1)

- Nm-Dairy Planning Data SheetDokument16 SeitenNm-Dairy Planning Data SheetRicardo NapitupuluNoch keine Bewertungen

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDokument6 SeitenChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNoch keine Bewertungen

- Pipe Support Basic - Seminar III, G.palaniDokument67 SeitenPipe Support Basic - Seminar III, G.palaniAnonymous Xy309m9Sm9100% (2)

- Foamglas Application GuidelinesDokument36 SeitenFoamglas Application GuidelinesArgiliathNoch keine Bewertungen

- BOQ English VersionDokument15 SeitenBOQ English VersionEzequiel Dos SantosNoch keine Bewertungen

- Gas Networks - Technical OverviewDokument93 SeitenGas Networks - Technical OverviewLamHotNoch keine Bewertungen

- Leak Test Procedure of Atmospheric VesselDokument9 SeitenLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- Spinning Wrench Ssw-30Dokument8 SeitenSpinning Wrench Ssw-30George Hans Sterling100% (1)

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDokument4 SeitenVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNoch keine Bewertungen

- Piping InspectionDokument6 SeitenPiping InspectionFs100% (1)

- User Manual Vaillant VCW 25 1 t3w eDokument10 SeitenUser Manual Vaillant VCW 25 1 t3w edusanNoch keine Bewertungen

- GS EP PVV 142 EN-minDokument202 SeitenGS EP PVV 142 EN-minManickam GanapathyNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDokument9 SeitenVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNoch keine Bewertungen

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Dokument4 SeitenSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNoch keine Bewertungen

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDokument1 SeiteDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNoch keine Bewertungen

- It - PT - Asme - 01 - Rev 00Dokument16 SeitenIt - PT - Asme - 01 - Rev 00Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDokument3 SeitenVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Dokument2 SeitenVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorDokument3 SeitenVp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorRicardo NapitupuluNoch keine Bewertungen

- S Curve Instrument CepuDokument1 SeiteS Curve Instrument CepuRicardo NapitupuluNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvDokument3 SeitenVp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvRicardo NapitupuluNoch keine Bewertungen

- API Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsDokument5 SeitenAPI Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsRicardo NapitupuluNoch keine Bewertungen

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDokument2 SeitenTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNoch keine Bewertungen

- PLD - Shelter - 30 11 2020Dokument3 SeitenPLD - Shelter - 30 11 2020Ricardo NapitupuluNoch keine Bewertungen

- 6 BLP Spesifikasi Teknis 49 SMA 14920Dokument6 Seiten6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNoch keine Bewertungen

- Support and Non Pressure Part Calculation of Foul ProductionDokument34 SeitenSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNoch keine Bewertungen

- Eng - M - Lifting Lug Cal - 2Dokument6 SeitenEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceDokument1.274 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceRicardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandDokument295 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandRicardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainDokument228 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainRicardo NapitupuluNoch keine Bewertungen

- Chapter 13. Fire Severity Calculations: Input ParametersDokument20 SeitenChapter 13. Fire Severity Calculations: Input ParametersRicardo NapitupuluNoch keine Bewertungen

- Mto Instrument Condensate RecoveryDokument1 SeiteMto Instrument Condensate RecoveryRicardo NapitupuluNoch keine Bewertungen

- B-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantDokument3 SeitenB-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantRicardo NapitupuluNoch keine Bewertungen

- Rex DWC Catalogue IS-14930..Dokument2 SeitenRex DWC Catalogue IS-14930..ajeetNoch keine Bewertungen

- 1303 MANUAL Ussc Hotblast StoveDokument24 Seiten1303 MANUAL Ussc Hotblast StoveMark100% (1)

- Instrument ManualDokument58 SeitenInstrument Manualnijju2009Noch keine Bewertungen

- Dep 30.10.02.16 - 2012Dokument11 SeitenDep 30.10.02.16 - 2012karthicbc2020Noch keine Bewertungen

- Compendiu Aer Comprimat PDFDokument230 SeitenCompendiu Aer Comprimat PDFVisan GheorgheNoch keine Bewertungen

- Foley Catalog PDFDokument229 SeitenFoley Catalog PDFmikea030Noch keine Bewertungen

- Flyer TycoDokument8 SeitenFlyer TycoAchraf BoudayaNoch keine Bewertungen

- Industrial Filters PDFDokument48 SeitenIndustrial Filters PDFhaggNoch keine Bewertungen

- 160 67-N2 PDFDokument44 Seiten160 67-N2 PDFh1234bNoch keine Bewertungen

- PSR Puducherry 2011 12Dokument1.020 SeitenPSR Puducherry 2011 12Anil BishtNoch keine Bewertungen

- ENG2068 SampleofcontentsDokument10 SeitenENG2068 SampleofcontentsKlich77Noch keine Bewertungen

- DRC0042-006-FS - 6.75in Drill Collars DS50Dokument2 SeitenDRC0042-006-FS - 6.75in Drill Collars DS50Andre FjeldeNoch keine Bewertungen

- AER Directive 066Dokument57 SeitenAER Directive 066Immanuel SNoch keine Bewertungen

- Stacking of Pipes: Functional SpecificationDokument17 SeitenStacking of Pipes: Functional SpecificationMohammed HijaziNoch keine Bewertungen

- Disassembly Remove Push Rod (3), Bellows (4), Air Vent (25) and Bolt (28) - 2)Dokument74 SeitenDisassembly Remove Push Rod (3), Bellows (4), Air Vent (25) and Bolt (28) - 2)hamdi galipNoch keine Bewertungen

- Ful Flo A SeriesDokument10 SeitenFul Flo A Seriesrodruren01Noch keine Bewertungen

- Satema: Flowuaf200 Based VersionsDokument12 SeitenSatema: Flowuaf200 Based VersionsMohd Firdaus Mohd NasirNoch keine Bewertungen

- Flanges and Their Joints - Circular Flanges For Valves, and Acce:sories, PN Designated - Part 2: Cast Iron FlangesDokument30 SeitenFlanges and Their Joints - Circular Flanges For Valves, and Acce:sories, PN Designated - Part 2: Cast Iron FlangesAlvin AuNoch keine Bewertungen

- IOP Pipe Sizing For Fushing WaterDokument12 SeitenIOP Pipe Sizing For Fushing WaterChiuhangTsang0% (1)

- Technofibre International SDN BHD: Welder Qualification Test Reord (WQT)Dokument1 SeiteTechnofibre International SDN BHD: Welder Qualification Test Reord (WQT)dandiar1100% (1)

- Sterile Tube Fuser - DRY: GE Healthcare Life SciencesDokument50 SeitenSterile Tube Fuser - DRY: GE Healthcare Life SciencesCarlos Alberto Ramirez GarciaNoch keine Bewertungen