Beruflich Dokumente

Kultur Dokumente

Color Code Specification for PetroChina Phase 4 Project

Hochgeladen von

Ricardo NapitupuluOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Color Code Specification for PetroChina Phase 4 Project

Hochgeladen von

Ricardo NapitupuluCopyright:

Verfügbare Formate

PetroChina International Jabung Ltd.

Specification

Color Coding

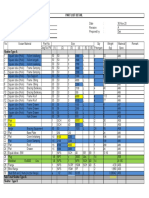

TABULATION OF REVISED PAGES

PAGE REVISIONS PAGE REVISIONS

A B C D 0 1 2 3 A B C D 0 1 2 3

1 X X X 52

2 X X X 53

3 X X X 54

4 X X 55

5 X X 56

6 X X 57

7 X X 58

8 59

9 60

10 61

11 62

12 63

13 64

14 65

15 66

16 67

17 68

18 69

19 70

20 71

21 72

22 73

23 74

24 75

25 76

26 77

27 78

28 79

29 80

30 81

31 82

32 83

33 84

34 85

35 86

36 87

37 88

38 89

39 90

40 91

41 ATTACHMENT

42 1 X X

43 2 X X

44 3 X X

45 4 X X

46 5 X X

47 6 X X

48 7 X X

49 8

50 9

51 10

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 2 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

REVISION LIST

Sign Date

Prepared by 08-09-09

Checked by 08-09-09

Approval by 08-09-09

Doc/DWG No.: BCD4-000-44-SPC-016-00 Rev. No: 0

No. Para./Section Items Explanation/Reason

Add “Petrochina International Jabung

1 Para 1.0 Scope

Ltd. (PCI)” and “Phase 4 (BCD4)”.

2 Para 2.1 Project Specification Change “BCD3” to “BCD4”.

Add Color Coding for Ball and

3 Attachment Attachment-5 (2/2)

Butterfly valves.

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 3 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

Table of Contents

Section Title Page

1.0 SCOPE ............................................................................................................ 5

2.0 REFERENCES ................................................................................................ 5

2.1 Project Specification ..................................................................................... 5

2.2 Standard ......................................................................................................... 5

3.0 GENERAL ....................................................................................................... 5

4.0 PAINT.............................................................................................................. 5

5.0 STANDARD COLOR ...................................................................................... 6

6.0 COLOR CODE AND IDENTIFICATION METHOD FOR MATERIAL............. 6

7.0 ATTACHMENT ............................................................................................... 7

Attachment 1 Color Codes for Plates and Bars

Attachment 2 Color Codes for Pipes and Tubes

Attachment 3 Color Codes for Pipes Fittings

Attachment 4 Color Codes for Flanges

Attachment 5 Color Codes for Valves

Attachment 6 Color Codes for Bolts and Nuts

Attachment 7 Color Codes for Gaskets

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 4 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

1.0 SCOPE

This specification prescribes the methods of visual materials identification by color

code for metalic piping materials for Petrochina International Jabung Ltd. (PCI) Betara

Complex Development phase 4 (BCD4) Project. The following materials shall be

delivered with color identification to the extent called for in the requisition:

Plates, bars, pipes, pipe fittings (elbows, tees, etc.), flanges valves, bolts and nuts and

gaskets.

2.0 REFERENCES

The following applicable section of the latest edition of the standards, including

addenda and referenced documents, project’s specification shall form an integral part

of this specification. Where the requirement of the subject is defined by two or more

references, the more stringent reference shall govern.

2.1 Project Specification

• BCD4-000-44-SPC-4-007-00 Specification for Piping Material Class Including

Commodity Code

• BCD4-000-44-SPC-4-015-00 Specification for Piping Material Code and

Stamping

2.2 Standard

The following standard shall be applied unless otherwise specified.

• Munsell Book of Color

3.0 GENERAL

Color identification is not required for non-ferrous metals, such as copper, Lead, FRP,

PVC and Aluminum, which can be easily distinguished by their peculiar color and

character. A procedure shall be established to ensure that each material is identified

correctly before the color coding is applied.

4.0 PAINT

Paint materials used for coding shall be durable, bright, and distinctive. Paint with zinc

dust or, chloride rubber or vinyl chloride resin paint shall not be used for the austenitic

materials. The paint shall be easily removable.

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 5 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

5.0 STANDARD COLOR

Standard colors based on the Munsell Color system (refer To Munsell Book of Color)

are given in table below.

STANDARD COLORS

Tolerance

Color Munsell No. Hue Lightness Saturation

(value) (Chrome)

White N-9.5 9 and over

Grey N-6.0 - +1 0.5 or less

Black N-1.0 2 or less

Pink 7.5R 8.5/4 +2

Brown 5YR 3.5/4 +2

+ 2 - 2.5

Red 5R 4/13

Orange 7.5YR 7.5/16

Yellow 2.5Y 8/6 +2 11 and over

+ 0.5

Green 2.5G 4/5

Light Green 10YG 4/5

Sky Blue 10B 7/6 +2

+ 2.5

Blue 5PB 3/9

Purple 2.5P 5/5 + 2 –1

Silver - - - -

6.0 COLOR CODE AND IDENTIFICATION METHOD FOR MATERIAL

Color codes and identification methods for materials shall be per the following :

(1) Color codes for identifying plates and bars are shown in Attachment 1, for

identifying pipe and tubes in Attachment 2, for identifying pipe fittings in

Attachment 3, for identifying flanges in Attachment 4, for identifying valves in

Attachment 5, for identifying bolts and nuts in Attachment 6, and for gaskets in

Attachment 7.

(2) Bevel end shall not be painted.

(3) A color band width shall be minimum 13 mm for NPS 2-1/2” and smaller size

and 25 mm for NPS 3” and larger size, unless otherwise specified.

(4) For two combination colors, piping materials shall have two parallel color

bands.

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 6 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

7.0 ATTACHMENT

The following Attachment shall form a part of this specification:

No. Title Refer to :

1 Color Codes for Plates and Bars Section 6

2 Color Codes for Pipes and Tubes Section 6

3 Color Codes for Pipes Fittings Section 6

4 Color Codes for Flanges Section 6

5 Color Codes for Valves Section 6

6 Color Codes for Bolts and Nuts Section 6

7 Color Codes for Gaskets Section 6

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 7 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 1

Color Codes for Plates and Bars

Plate Bar

Material ASTM Designation Color Code

Carbon Steel A36 A283 - Gr. C None

Carbon Steel A516-70 Yellow

Low Temp. Carbon A516 – 70N Green

Steel

Stainless Steel (Type 304L) None

Stainless Steel (Type 316L) Black

Duplex A240-S31803 Pink

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 1 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 2

Color Codes for Pipes and Tubes

Pipe Heat Transfer Tube

Single

Color

Two

Colors

Single Color Two Colors

Material ASTM Designation Color Code

Carbon Steel A106-B SMLS Yellow

A106-B GALV. None

API 5L-B Light Green / Yellow

API 5L X-52 Yellow / White

Low Temp. Carbon Steel A333-6 SMLS Green

A671-CC60 EFW Green

Stainless Steel A312-TP304L SMLS None

(Type 304L) A358-304L CL 1 EFW None

Stainless Steel A312-TP316L SMLS Black

(Type 316L) A358-316L CL 1 EFW Black / Red

Duplex A790-S31803 Pink

A928-S31803 Pink

API 5LC65-2205 Pink/Black

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 2 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 3

Color Codes for Fittings

Elbow Tee Reducer

Cap Coupling

Material ASTM Designation Color Code

Carbon Steel A234 WPB Yellow

A105 Yellow

A860-WPHY52 Yellow / White

API 5L-X52 Yellow / White

Low Temp. Carbon A420 - WPL6 Green

Steel

A350 - LF2 Green

Stainless Steel A182 – F304L None

A403 – WP304L None

Stainless Steel A182 – F316L Black

A403 – WP316L Black

Duplex A182-F51 Pink

A815-S31803 Pink

API 5LC65-2205 Pink/Black

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 3 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 4

Color Codes for Flanges

Single Color Two Colors

Material ASTM Designation Color Code

Carbon Steel A105 Yellow

A694-F52 Yellow / White

Low Temp Carbon A350 - LF2 Green

Steel

Stainless Steel A182 - F304L None

Stainless Steel A182 - F316L Black

Duplex A182-F51 Pink

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 4 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 5 (1/2)

Color Codes for Valves

1. Body Material

Material ASTM Designation Color Code

Carbon Steel A105 Yellow

A216 – WCB Yellow

Low Temp. Carbon A350 - LF2 Green

Steel

A352 – LCC Green

Stainless Steel A182 - F316 None

Stainless Steel A182 - F316L Black

A890 – CF8M Black

Duplex SS A182-F51 Pink

A351-CD3MN Pink

Bronze B61 Red / White

B62 Red

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 5 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 5 (2/2)

2. Trim Material

Material Color Code

Iron Grey

HF Yellow

13 Cr. + Stellite (HF) Light Green

(Type F316) Orange

(Type F316L) Orange/Black

(Type F51) Pink

Monel Pink / Black

Bronze Red

3. Identification

Figure -1 Figure - 2

Color for trim material

Color for body material

(1) For gate and globe valves, identification color shall be indicated on the

hand wheel as shown in figure 1.

(2) For check valves, identification color shall be indicated on the top

covers shown in figure 2.

(3) For ball and butterfly valves identification color shall be indicated on

the valve body for 2 piece construction and on the edge of the flange

for 1 piece construction, as shown on figure 3

1 PIECE

OPPOSITE SIDE SAME AS TO

COLOR FOR BODY TWO COLOR OR ONE PAINTING

MATERIAL

TWO COLOR

ONE COLOR

SECTION B-B

2 PIECE

FIGURE 3

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 6 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 6

Color Codes for Bolts and Nuts

Stud Bolt Hexagon Head Bolt

Nut

Material Color

Bolt Nut

A307 Gr. B x A563 Gr. A White

A307 Gr. B x A563 Gr. A (Galv.) None

A193 Gr. B7M x A194 Gr. 2HM Yellow

A193 Gr. B7 x A194 Gr. 2H None

A193 Gr. B8 x A194 Gr. 8 None

A320 Gr. B8 x A194 Gr. 8CA None

B211 Gr. 2024 T4 x B211 Gr. 2024 T4 None

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 7 Updated – 8-Sept-09

PetroChina International Jabung Ltd. Specification

Color Coding

ATTACHMENT – 7

Color Codes for Gaskets

1. Spiral Wound Gasket

Rating (#) Color

150 Red

300 Green

600 Orange

900 White

1500 Blue

Color identification of gasket

With Inner and Centre Ring

• Spiral Wound gasket with Inner Ring and Centre Ring shall be painted on

full circumference surface with dashed line.

Doc: BCD4-000-44-SPC-4-016-00_rev0 Page 8 Updated – 8-Sept-09

Das könnte Ihnen auch gefallen

- Painting and Galvanizing Specification SummaryDokument22 SeitenPainting and Galvanizing Specification SummaryRicardo NapitupuluNoch keine Bewertungen

- BCD4-000-47-SPC-4-006-00 - rev0-REC General InstrumentationDokument23 SeitenBCD4-000-47-SPC-4-006-00 - rev0-REC General InstrumentationRicardo NapitupuluNoch keine Bewertungen

- Surface Preparation and Painting PlanDokument13 SeitenSurface Preparation and Painting PlanRido100% (1)

- VCS DD in DS 016 BDokument10 SeitenVCS DD in DS 016 BMahdi PaknejadNoch keine Bewertungen

- Specification For Piping Stress Analysis P-07-1002 Rev0Dokument25 SeitenSpecification For Piping Stress Analysis P-07-1002 Rev0faisal jasim100% (1)

- Specification For Piping SupportsDokument17 SeitenSpecification For Piping SupportsMehdi Nouri0% (1)

- Specification For Bolts and NutsDokument9 SeitenSpecification For Bolts and NutsMehdi NouriNoch keine Bewertungen

- Specification For GasketsDokument8 SeitenSpecification For GasketsMehdi NouriNoch keine Bewertungen

- Specification For Hydrostatic Test ProceduresDokument17 SeitenSpecification For Hydrostatic Test ProceduresMehdi NouriNoch keine Bewertungen

- Nioec230 02 Eb Me DS TK0201Dokument12 SeitenNioec230 02 Eb Me DS TK0201amini_mohiNoch keine Bewertungen

- Specification For ValvesDokument24 SeitenSpecification For ValvesMehdi NouriNoch keine Bewertungen

- Specification For FlangesDokument16 SeitenSpecification For FlangesMehdi NouriNoch keine Bewertungen

- 151 G1 GS BC# PR Doc 0063 B1Dokument8 Seiten151 G1 GS BC# PR Doc 0063 B1rezaNoch keine Bewertungen

- Piping Material SpcificationDokument16 SeitenPiping Material SpcificationMehdi NouriNoch keine Bewertungen

- ID-TUN-NG-SME-010302 Rev C - FINAL - Approved PJTDokument13 SeitenID-TUN-NG-SME-010302 Rev C - FINAL - Approved PJTabdelmalek boudjemaaNoch keine Bewertungen

- Specification For Atmospheric Storage TanksDokument18 SeitenSpecification For Atmospheric Storage TanksHamid MansouriNoch keine Bewertungen

- Specification For FittingsDokument16 SeitenSpecification For FittingsMehdi NouriNoch keine Bewertungen

- SSIV TUTU Data SheetDokument7 SeitenSSIV TUTU Data SheetReza SalimiNoch keine Bewertungen

- Qot BD 1 22 Me SPC 10364 00Dokument16 SeitenQot BD 1 22 Me SPC 10364 00Hamid MansouriNoch keine Bewertungen

- 151 G1 GS Gly PR Doc 0008 B0Dokument5 Seiten151 G1 GS Gly PR Doc 0008 B0rezaNoch keine Bewertungen

- Fire Gas Detection Philosophy 1641849168Dokument44 SeitenFire Gas Detection Philosophy 1641849168f5crdfwhg9Noch keine Bewertungen

- Qot BD 1 22 Me SPC 10357 00Dokument16 SeitenQot BD 1 22 Me SPC 10357 00Hamid MansouriNoch keine Bewertungen

- Lubrication Shaft Sealing Control Oil System SpecificationDokument22 SeitenLubrication Shaft Sealing Control Oil System SpecificationHamid MansouriNoch keine Bewertungen

- Specification For PipesDokument26 SeitenSpecification For PipesMehdi NouriNoch keine Bewertungen

- Project Datasheet for Echo Compressor Bleed RingDokument6 SeitenProject Datasheet for Echo Compressor Bleed RingTamyizudin Kodri100% (1)

- Integrated Control and Safety System (ICSS) TGS Bill of MaterialDokument9 SeitenIntegrated Control and Safety System (ICSS) TGS Bill of MaterialFatholla SalehiNoch keine Bewertungen

- 1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateDokument9 Seiten1308-306-MEC-DTS-012 - Rev 1 - Vapour Return Blower - UpdateAyahKenzieNoch keine Bewertungen

- CO-13-100-100-00-PR-L-003 - RevA - Requisition For SP ItemDokument18 SeitenCO-13-100-100-00-PR-L-003 - RevA - Requisition For SP Itemsaiful anwarNoch keine Bewertungen

- ICSS BOMDokument15 SeitenICSS BOMFatholla SalehiNoch keine Bewertungen

- Engineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignDokument28 SeitenEngineering Services for Abadan Petrochemical Plant VCM Unloading Station Piping DesignMehdi NouriNoch keine Bewertungen

- Earthing & Lightning Calculation for Koohdasht-Charmale Gas Pipeline ProjectDokument17 SeitenEarthing & Lightning Calculation for Koohdasht-Charmale Gas Pipeline Projectamini_mohi100% (1)

- 151 G1 GS Gly PR Doc 0012 B0Dokument4 Seiten151 G1 GS Gly PR Doc 0012 B0rezaNoch keine Bewertungen

- ID-TUN-NG-SME-010301 Rev C - FINAL - Approved PJTDokument85 SeitenID-TUN-NG-SME-010301 Rev C - FINAL - Approved PJTabdelmalek boudjemaaNoch keine Bewertungen

- 151 G1 GS Gly PR Doc 0003 B0Dokument3 Seiten151 G1 GS Gly PR Doc 0003 B0rezaNoch keine Bewertungen

- Yokogawa ExaQuantum Usage Procedure Rev1Dokument34 SeitenYokogawa ExaQuantum Usage Procedure Rev1adadehNoch keine Bewertungen

- MRQ For Storage Tank For Low Quality Water: Water Treatment Plant Engineering DepartmentDokument5 SeitenMRQ For Storage Tank For Low Quality Water: Water Treatment Plant Engineering Departmentreza mehvariNoch keine Bewertungen

- SSIV CP SpecDokument23 SeitenSSIV CP SpecrezaNoch keine Bewertungen

- CT & VT Calculation RungkutDokument15 SeitenCT & VT Calculation RungkutAlif Maulana FirdausNoch keine Bewertungen

- TANKDokument29 SeitenTANKrizky hardiNoch keine Bewertungen

- ID-TUN-NG-SME-011282 Rev B - FINAL - Approved PJTDokument22 SeitenID-TUN-NG-SME-011282 Rev B - FINAL - Approved PJTabdelmalek boudjemaaNoch keine Bewertungen

- Overhead Cranes Mechanical Data SheetDokument9 SeitenOverhead Cranes Mechanical Data SheetMohammad AminiNoch keine Bewertungen

- Specification For Dual-Layer FBEDokument19 SeitenSpecification For Dual-Layer FBEali saidNoch keine Bewertungen

- D 100 MBH WHP PRS 029 D PDFDokument398 SeitenD 100 MBH WHP PRS 029 D PDFHaryono100% (1)

- MRQ For Storage Tank For High Quality Water: Water Treatment Plant Engineering DepartmentDokument5 SeitenMRQ For Storage Tank For High Quality Water: Water Treatment Plant Engineering Departmentreza mehvariNoch keine Bewertungen

- Laporan Acc, HP, DLL: Kode Jenis Harga QTY Total KeteranganDokument2 SeitenLaporan Acc, HP, DLL: Kode Jenis Harga QTY Total KeteranganWahyu FauzanNoch keine Bewertungen

- 1308-306-Pip-Rpt-001 Pipe Stress Analysis Kolaka Rev.1 Re-IfiDokument151 Seiten1308-306-Pip-Rpt-001 Pipe Stress Analysis Kolaka Rev.1 Re-IfiDheska AgungNoch keine Bewertungen

- Consumption Report of Sand PlantDokument1 SeiteConsumption Report of Sand PlantInam KhanNoch keine Bewertungen

- RaffleDokument2 SeitenRaffleScribdTranslationsNoch keine Bewertungen

- MCC-Switch Gear Room Mechanical CalculationDokument20 SeitenMCC-Switch Gear Room Mechanical Calculationm khaeronNoch keine Bewertungen

- ID-TUN-NG-SME-010704 Rev D - FINAL - Approved PJTDokument31 SeitenID-TUN-NG-SME-010704 Rev D - FINAL - Approved PJTabdelmalek boudjemaaNoch keine Bewertungen

- NCE-Sample SizingDokument6 SeitenNCE-Sample SizingrezaNoch keine Bewertungen

- D-100-MDA-WHP-PRS-032 MDA Pile Load Out Procedure Rev. C - Part A PDFDokument32 SeitenD-100-MDA-WHP-PRS-032 MDA Pile Load Out Procedure Rev. C - Part A PDFHaryonoNoch keine Bewertungen

- Inventory Form EIPEX 08Dokument1 SeiteInventory Form EIPEX 08api-3732731Noch keine Bewertungen

- Process Report For Saturator Blow Down Drum D-6002: Marjan Petrochemical CompanyDokument9 SeitenProcess Report For Saturator Blow Down Drum D-6002: Marjan Petrochemical Companyfatemeh afariNoch keine Bewertungen

- PAS-JBG-400-D-002 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2020B Rev DDokument7 SeitenPAS-JBG-400-D-002 Pipe Stress Report For Line Pipe Fuel Gas System Supply To GTCP 2020B Rev DElias EliasNoch keine Bewertungen

- Nioec SP 70 52Dokument12 SeitenNioec SP 70 52Mohammad AminiNoch keine Bewertungen

- Sahovski Formular-En Lite1Dokument2 SeitenSahovski Formular-En Lite1premil91Noch keine Bewertungen

- MengundiDokument2 SeitenMengundiScribdTranslationsNoch keine Bewertungen

- SN1-31-070-304-F-0-DDokument28 SeitenSN1-31-070-304-F-0-DrezaNoch keine Bewertungen

- Liquid Penetrant Examination ProcedureDokument16 SeitenLiquid Penetrant Examination ProcedureRicardo NapitupuluNoch keine Bewertungen

- Leak Test Procedure for Atmospheric VesselDokument9 SeitenLeak Test Procedure for Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Dokument2 SeitenVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Motor)Dokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Motor)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDokument9 SeitenVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNoch keine Bewertungen

- KNPC LPG Train-4 Project ARV Section Drawing & Part ListDokument3 SeitenKNPC LPG Train-4 Project ARV Section Drawing & Part ListRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDokument3 SeitenVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNoch keine Bewertungen

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDokument1 SeiteDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNoch keine Bewertungen

- KNPC LPG Train-4 Project Motor Data SheetDokument3 SeitenKNPC LPG Train-4 Project Motor Data SheetRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDokument4 SeitenVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-004 P&id For Pump (Steam Turbine)Dokument3 SeitenVp-15-109-001-A01-P-237-004ab-Sk-004 P&id For Pump (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-065 Heat Exchanger Drawing For Mechanical SealDokument2 SeitenVp-15-109-001-A01-P-237-004abc-Sk-065 Heat Exchanger Drawing For Mechanical SealRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam TurbinDokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam TurbinRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004c-Sk-004 P&id For Pump (Motor)Dokument2 SeitenVp-15-109-001-A01-P-237-004c-Sk-004 P&id For Pump (Motor)Ricardo NapitupuluNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Shell-and-Tube Heat Exchanger Design TableDokument2 SeitenShell-and-Tube Heat Exchanger Design TableSK TomarNoch keine Bewertungen

- Heat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)Dokument1 SeiteHeat Exchanger Tube - Principal BWG Sizes: Outside Diameter Birmingham Wire Gauge (BWG)amr kouranyNoch keine Bewertungen

- Heat Exchanger Types and CalculationsDokument16 SeitenHeat Exchanger Types and CalculationsAudrey Patrick KallaNoch keine Bewertungen

- Ga R 101 Rev-0Dokument1 SeiteGa R 101 Rev-0Ricardo NapitupuluNoch keine Bewertungen

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Dokument4 SeitenSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNoch keine Bewertungen

- S Curve Instrument CepuDokument1 SeiteS Curve Instrument CepuRicardo NapitupuluNoch keine Bewertungen

- 0 Cover Page & Work ScopeDokument1 Seite0 Cover Page & Work ScopeRicardo NapitupuluNoch keine Bewertungen

- 6 BLP Spesifikasi Teknis 49 SMA 14920Dokument6 Seiten6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNoch keine Bewertungen

- Outstanding Flame Arrestor Schedule for PetroChina ProjectDokument1 SeiteOutstanding Flame Arrestor Schedule for PetroChina ProjectRicardo NapitupuluNoch keine Bewertungen

- PLD - Shelter - 30 11 2020Dokument3 SeitenPLD - Shelter - 30 11 2020Ricardo NapitupuluNoch keine Bewertungen

- Nm-Dairy Planning Data SheetDokument16 SeitenNm-Dairy Planning Data SheetRicardo NapitupuluNoch keine Bewertungen

- Recovery Schedule Plan 3 PDFDokument1 SeiteRecovery Schedule Plan 3 PDFRicardo NapitupuluNoch keine Bewertungen

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDokument2 SeitenTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNoch keine Bewertungen

- Eng - M - Lifting Lug Cal - 2Dokument6 SeitenEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNoch keine Bewertungen

- Support and Non Pressure Part Calculation of Foul ProductionDokument34 SeitenSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNoch keine Bewertungen

- TIA Selection Tool: Release Notes V2022.05Dokument10 SeitenTIA Selection Tool: Release Notes V2022.05Patil Amol PandurangNoch keine Bewertungen

- Usjr Temfacil Balance of Work Schedule Aug 25, 2022Dokument5 SeitenUsjr Temfacil Balance of Work Schedule Aug 25, 2022Maribeth PalumarNoch keine Bewertungen

- Chemistry Implementation: Name: Rasheed Campbell School: Kingston College Candidate #.: Centre #: 100057Dokument12 SeitenChemistry Implementation: Name: Rasheed Campbell School: Kingston College Candidate #.: Centre #: 100057john brownNoch keine Bewertungen

- QP (2016) 2Dokument1 SeiteQP (2016) 2pedro carrapicoNoch keine Bewertungen

- Ancient MesopotamiaDokument69 SeitenAncient MesopotamiaAlma CayapNoch keine Bewertungen

- The Temple of ChaosDokument43 SeitenThe Temple of ChaosGauthier GohorryNoch keine Bewertungen

- Steam Turbines: ASME PTC 6-2004Dokument6 SeitenSteam Turbines: ASME PTC 6-2004Dena Adi KurniaNoch keine Bewertungen

- g4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDokument144 Seiteng4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDevin DickenNoch keine Bewertungen

- Flood FillDokument1 SeiteFlood FillshubhamNoch keine Bewertungen

- SB Z Audio2Dokument2 SeitenSB Z Audio2api-151773256Noch keine Bewertungen

- Background of The Study Statement of ObjectivesDokument4 SeitenBackground of The Study Statement of ObjectivesEudelyn MelchorNoch keine Bewertungen

- NDE Procedure - Radiographic TestingDokument43 SeitenNDE Procedure - Radiographic TestingJeganeswaranNoch keine Bewertungen

- Artifact and Thingamy by David MitchellDokument8 SeitenArtifact and Thingamy by David MitchellPedro PriorNoch keine Bewertungen

- Madu Rash Tak AmDokument4 SeitenMadu Rash Tak AmAdv. Govind S. TehareNoch keine Bewertungen

- 中美两国药典药品分析方法和方法验证Dokument72 Seiten中美两国药典药品分析方法和方法验证JasonNoch keine Bewertungen

- Aleister Crowley and the SiriansDokument4 SeitenAleister Crowley and the SiriansJCMNoch keine Bewertungen

- Baseline Program Rev 3A Presentation 25 July 2020Dokument24 SeitenBaseline Program Rev 3A Presentation 25 July 2020Shakti Sourava RautrayaNoch keine Bewertungen

- Motor GraderDokument24 SeitenMotor GraderRafael OtuboguatiaNoch keine Bewertungen

- Casio AP-80R Service ManualDokument41 SeitenCasio AP-80R Service ManualEngkiong Go100% (1)

- Gauss Contest: Grade 8Dokument4 SeitenGauss Contest: Grade 8peter100% (1)

- F-16c.1 Ginkgo Ginkgolic AcidDokument2 SeitenF-16c.1 Ginkgo Ginkgolic AcidNarongchai PongpanNoch keine Bewertungen

- The Art of Now: Six Steps To Living in The MomentDokument5 SeitenThe Art of Now: Six Steps To Living in The MomentGiovanni AlloccaNoch keine Bewertungen

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDokument40 SeitenPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroNoch keine Bewertungen

- Survey Report on Status of Chemical and Microbiological Laboratories in NepalDokument38 SeitenSurvey Report on Status of Chemical and Microbiological Laboratories in NepalGautam0% (1)

- Descripcion Unidad 9, Dos CiudadesDokument13 SeitenDescripcion Unidad 9, Dos CiudadesGabriela ValderramaNoch keine Bewertungen

- WK 43 - Half-Past-TwoDokument2 SeitenWK 43 - Half-Past-TwoKulin RanaweeraNoch keine Bewertungen

- Pitch Manual SpecializedDokument20 SeitenPitch Manual SpecializedRoberto Gomez100% (1)

- Oecumenius’ Exegetical Method in His Commentary on the RevelationDokument10 SeitenOecumenius’ Exegetical Method in His Commentary on the RevelationMichał WojciechowskiNoch keine Bewertungen

- Virchow TriadDokument6 SeitenVirchow Triadarif 2006Noch keine Bewertungen

- 2 - Elements of Interior DesignDokument4 Seiten2 - Elements of Interior DesignYathaarth RastogiNoch keine Bewertungen