Beruflich Dokumente

Kultur Dokumente

Warning: ESD5100 Series Speed Control Unit

Hochgeladen von

instrumentacion.hsrOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Warning: ESD5100 Series Speed Control Unit

Hochgeladen von

instrumentacion.hsrCopyright:

Verfügbare Formate

ENGINE

G OVERNORS

GOVERNING ESD5100 Series A MERICA

SYSTEM Speed Control Unit C ORP.®

Installation Start Engine

The ESD5100 Series speed control unit is rugged enough The speed control unit governed speed setting is factory set

to be placed in a control cabinet or engine mounted enclo- at approximately engine idle speed. (1000 Hz., speed sen-

sure with other dedicated control equipment. If water, mist, sor signal)

or condensation may come in contact with the controller, it

should be mounted vertically. This will allow the fluid to drain Crank the engine with DC power applied to the governor sys-

away from the speed control unit. Extreme heat should be tem. The actuator will energize to the maximum fuel position

avoided. until the engine starts. The governor system should control

the engine at a low idle speed. If the engine is unstable after

starting, turn the GAIN and STABILITY adjustments counter-

⚠WARNING clockwise until the engine is stable.

An overspeed shut down device, indepen- Governor Speed Setting

dent of the governor system, should be

provided to prevent loss of engine control, The governed speed set point is increased by clockwise ro-

which may cause personal injury or equip- tation of the SPEED adjustment pot. Remote speed adjust-

ment damage. Do not rely exclusively on the ment can be obtained with an optional 5K Speed Trim Con-

governor system electric actuator to prevent trol. (See Diagram 2)

overspeed. A secondary shut off device,

such as a fuel solenoid, must be used. Governor Performance

Once the engine is at operating speed and at no load, the

Wiring following governor performance adjustment can be made.

Basic electrical connections are illustrated in Diagram 2. Ac- A. Rotate the GAIN adjustment clockwise until instability

tuator and battery connections to Terminals A, B, E, and F develops. Gradually move the adjustment counterclock-

should be #16 AWG (1.3 mm sq.) or larger. Long cables wise until stability returns. Move the adjustment one

require an increased wire size to minimize voltage drops. division further counterclockwise to insure stable perfor-

mance (270° pot).

The battery positive (+) input, Terminal F, should be fused for

15 amps as illustrated. The ESD5100 series is suitable for B. Rotate the STABILITY adjustment clockwise until insta-

12 VDC and 24 VDC operation. bility develops. Gradually move the adjustment coun-

terclockwise until stability returns. Move the adjustment

Magnetic speed sensor wires connected to Terminals C and one division further to insure stable performance (270°

D MUST BE TWISTED AND/OR SHIELDED for their entire pot).

length. The speed sensor cable shield should ideally be C. Gain and stability adjustments may require minor chang-

connected as shown in Diagram 2. The shield should be es after engine load is applied. Normally, adjustments

insulated to insure no other part of the shield comes in con- made at no load achieve satisfactory performance. A

tact with engine ground, otherwise stray speed signals may strip chart recorder can be used to further optimize the

be introduced into the speed control unit. With the engine adjustments.

stopped, adjust the gap between the magnetic speed sensor

and the ring gear teeth. The gap should not be any smaller If instability cannot be corrected or further performance im-

than 0.020 in. (0.45 mm). Usually, backing out the speed provements are required, refer to the SYSTEM TROUBLE-

sensor 3/4 turn after touching the ring gear teeth will achieve SHOOTING section. In this section, information can be found

a satisfactory air gap. The magnetic speed sensor voltage regarding troubleshooting procedures as well as instructions

should be at least 1 VAC RMS during cranking. on adjusting the DIP switch positions of the ESD5131.

Idle Speed Setting

Adjustments

After the governor speed setting had been adjusted, place

Before Starting Engine the optional external selector switch in the IDLE position.

The idle speed set point is increased by clockwise of the

Check to insure the GAIN and STABILITY adjustments, and IDLE adjustment control. When the engine is at idle speed,

if applied, the external SPEED TRIM CONTROL are set to the speed control unit applies droop to the governor System

mid position. to insure stable operation.

Governors America Corp., 720 Silver Street Agawam, MA 01001

phone: 413.786.5600 fax: 413.789.7736

www.governors-america.com ISO 9001

info@governors-america.com CERTIFIED

1

Speed Droop Operation small amount of droop can be added using the DROOP ad-

justment. At the maximum speed setting the governor per-

Droop is typically used for the paralleling of engine driven formance will be near isochronous, regardless of the droop

generators. adjustment setting.

Place the optional external selector switch in the DROOP Contact GAC for assistance if difficulty is experienced in ob-

position. DROOP is increased by clockwise rotation of the taining the desired variable speed governing performance.

DROOP adjustment control. When in droop operation, the

engine speed will decrease as engine load increases. The TABLE 1 Variable range potentiometer value

percentage of droop is based on the actuator current change

from engine no load to full load. A wide range droop is avail- Speed Range Potentiometer Value

able with the internal control. Droop level requirements 900 Hz 1K

above 10% are unusual. 2,400 Hz 5K

If droop levels experienced are higher or lower then these 3,000 Hz 10 K

required, contact the GAC for assistance. 3,500 Hz 25 K

After the droop level has been adjusted, the rated engine 3,700 Hz 50 K

speed setting may need to be reset. Check the engine speed

and adjust that speed setting accordingly.

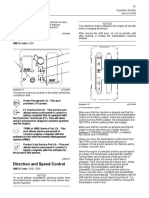

Diagram 1 Potentiometer Wiring

Accessory Input G J K L

The Auxiliary Terminal N accepts input signals from load

sharing units, auto synchronizers, and other governor sys-

tem accessories, GAC accessories are directly connected to

this terminal. It is recommended that this connection from

accessories be shielded, as it is a sensitive input terminal. *

If the auto synchronizer is used alone, not in conjunction with cw

a load-sharing module, a 3 M ohm resistor should be con-

nected between Terminals N and P. This is required to match *Select proper potentiometer value from Table 1

the voltage levels between the speed control unit and the

synchronizer.

When an accessory is connected to Terminal N, the speed

will decrease and the speed adjustment must be reset.

When operating in the upper end of the control unit frequen- System Troubleshooting

cy range, a jumper wire or frequency trim control may be

required between Terminals G and J. This increases the fre- Insufficient Magnetic Speed Signal

quency range of the speed control to over 7000 Hz.

A strong magnetic speed sensor signal will eliminate the

Accessory Supply possibility of missed or extra pulses. The speed control unit

will govern well with 0.5 volts RMS speed sensor signal. A

The +10 volt regulated supply, Terminal P, can be utilized speed sensor signal of 3 volts RMS or greater at governed

to provide power to GAC governor system accessories. Up speed is recommended. Measurement of the signal is made

to 20 ma of current can be drawn from this supply. Ground at Terminals C and D.

reference is Terminal G.

The amplitude of the speed sensor signal can be raised

Wide Range Remote Variable Speed Operation by reducing the gap between the speed sensor tip and the

engine ring gear. The gap should not be any smaller than

Simple and effective remote variable speed can be obtained 0.020 in (0.45 mm). When the engine is stopped, back the

with the ESD5100 Series speed control unit. speed sensor out by 3/4 turn after touching the ring gear

tooth to achieve a satisfactory air gap.

A single remote speed adjustment potentiometer can be

used to adjust the engine speed continuously over a specific Electromagnetic Compatibility (EMC)

speed range. Select the desired speed range and corre-

sponding potentiometer value. (Refer to TABLE 1.) If the EMI SUSCEPTIBILITY - The governor system can be ad-

exact range cannot be found, select the next higher range versely affected by large interfering signals that are conduct-

potentiometer. An additional fixed resistor may be placed ed through the cabling or through direct radiation into the

across the potentiometer to obtain the exact desired range. control circuits.

Connect the speed range potentiometer as shown in Dia-

gram 1 All GAC speed control sensors contain filters and shielding

designed to protect the unit’s sensitive circuits from moder-

To maintain engine stability at the minimum speed setting, a ate external interfering sources.

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PIB1000 C

2

Although it is difficult to predict levels of interference, appli- frequency of instability and vice versa. In this case, the re-

cations that include magnetos, solid sate ignition systems, moval of E6 to E7 jumper will reduce the speed control unit’s

radio transmitters, voltage regulators or battery chargers sensitivity to high frequency signals. Readjust the GAIN

should be considered suspect as possible interfering sourc- and STABILITY 1 or optimum control. Should instability still

es. be present, the removal of E1 to E2 jumper may help stabi-

lize the engine. Post locations are illustrated in Diagram 2.

If it is suspected that external fields, either those that are Again, readjust the GAIN and STABILITY for optimum con-

radiated or conducted, are or will affect the governor sys- trol. Interference from powerful electrical signals can also be

tems operation, it is recommended to use shielded cable for the cause. Turn off the battery chargers or other electrical

all external connections. Be sure that only one end of the equipment to see if the system instability disappears.

shields, including the speed sensor shield, is connected to a

single point on the case of the speed control unit. Mount the Slow instability can have many causes. Adjustment of the

speed control to a grounded metal back plate or place it in a GAIN and STABILITY usually cures most situations by

sealed metal box. matching the speed control unit dynamics. If this is unsuc-

cessful, the dead time compensation can be modified. Add

Radiation is when the interfering signal is radiated directly a capacitor from posts E2 to E3 (negative on E2). Post lo-

through space to the governing system. To isolate the gover- cations are illustrated in Diagram 2. Start with 10 mfds, and

nor system electronics from this type of interference source, increase until instability is eliminated. The control system

a metal shield or a solid metal container is usually effective. can also be optimized for best performance by following this

procedure.

Conduction is when the interfering signal is conducted

through the interconnecting wiring to the governor system If slow instability is unaffected by this procedure, evaluate

electronics. Shielded cables and installing filters are com- the fuel system and engine performance. Check the fuel

mon remedies. system linkage for binding, high friction, or poor linkage. Be

sure to check linkage during engine operation. Also look at

In severe high-energy interference locations such as when the engine fuel system. Irregularities with carburetion or fuel

the governor system is directly in the field of a powerful injection systems can change engine power with a constant

transmitting source, the shielding may require to be a spe- throttle setting. This can result in speed deviations beyond

cial EMI class shielding. For these conditions, contact GAC the control of the governor system. Adding a small amount

application engineering for specific recommendations. of droop can help stabilize the system for troubleshooting.

Instability NON-PERIODIC instability should respond to the GAIN con-

trol. If increasing the gain reduces the instability, then the

Instability in a closed loop speed control system can be problem is probably with the engine. Higher gain allows the

categorized into two general types. PERIODIC appears to governor to respond faster and correct for disturbance. Look

be sinusoidal and at a regular rate. NON-PERIODIC is a for engine misfirings, an erratic fuel system, or load changes

random wandering or an occasional deviation from a steady on the engine generator set voltage regulator. If the throttle

state band for no apparent reason. is slightly erratic, but performance is fast, removing the jump-

er from E6 to E7 will tend to steady the system.

The ESD5131 Sped Control Unit was derived from the stan-

dard GAC ESD5111 Speed Control Unit. All specifications, If unsuccessful in solving instability, contact GAC for assis-

installation procedures, and adjustments, except those not- tance.

ed are identical.

The difference between the ESD5131 and the ESD5111 lies

in the two DIP switches located under the upper access hole.

Switch 1 controls the “Lead Circuit” found in the ESD5111.

The normal position is “ON.” Move the switch to the “OFF”

position if there is fast instability in the system.

Switch 2 controls an additional circuit added in the ESD5131

that is designed to eliminate fast erratic governor behav-

ior, caused by very soft or worn couplings in the drive train

between the engine and generator. The normal position is

“OFF.” Move to the “ON” position if fast erratic engine behav-

ior due to a soft coupling is experienced.

The PERIODIC type can be further classified as fast or slow

instability. Fast instability is a 3 Hz. or faster irregularity of

the speed and is usually a jitter. Slow periodic instability is

below 3 Hz., can be very slow, and is sometimes violent.

If fast instability occurs, this is typically the governor respond-

ing to engine firings. Raising the engine speed increases the

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PIB1000 C

3

System Inoperative

If the engine governing system does not function, the fault may be determined by performing the voltage tests described

in Steps 1 through 4. Positive (+) and negative (-) refer to meter polarity. Should normal values be indicated during trouble-

shooting steps, and then the fault may be with the actuator or the wiring to the actuator. Tests are performed with battery

power on and the engine off, except where noted. See actuator publication for testing procedure on the actuator.

Step Terminals Normal Reading Probable Cause of Abnormal Reading

1 F(+) & E(-) Battery Supply Voltage 1. DC battery power not connected. Check for blown fuse

(12 or 24 VDC) 2. Low battery voltage.

3. Wiring error

2 C&D 1.0V AC RMS min. while cranking 1. Gap between speed sensor and gear teeth too great. Check gap.

2. Improper or defective wiring to the speed sensor.

Resistance between D and C should be 30 to 1200 ohms.

3. Defective speed sensor.

3 P(+) & G(-) 10V DC, Internal Supply 1. Short on Terminal P. (This will cause a defective unit.)

2. Defective speed control unit

4 F(+) & A(-) 1.0 - 2.0V DC while cranking 1. SPEED adjustment set too low.

2. Short/open in actuator wiring.

3. Defective speed control.

4. Defective actuator. See Actuator Troubleshooting.

Unsatisfactory Performance

If the governing system functions poorly, perform the following tests.

Symptom Test Probable Fault

Engine overspeed 1. Do Not Crank. Apply DC power to the 1. Actuator goes to full fuel. Then disconnect speed sensor

governor system. at Terminal C & D. If actuator still at full fuel-speed con-

trol unit defective. If actuator at minimum fuel position,

erroneous speed signal. Check speed sensor cable.

2. Manually hold the engine at the desired 1. If the voltage reading is 1.0 to 2.0 VDC,

running speed. Measure the DC voltage a) SPEED adjustment set above desired speed

between Terminals A(-) & F(+) on the b) Defective speed control unit.

speed control unit. 2. If the voltage reading is above 2.0 VDC, actuator or

linkage binding.

3. Set point of overspeed shutdown device set too low.

4. If the voltage reading is below 1.0 VDC, defective speed

control unit.

Overspeed shuts down engine after run- 1. Speed adjustment set too high.

ning speed is reached. 2. OVERSPEED set to close to running speed.

3. Actuator or linkage binding.

4. Speed control unit defective.

Overspeed shuts down engine before 1. Check impedance between Terminals C & 1. OVERSPEED set too low. Adjust 5-6 turns CW.

running speed is reached. D. Should be 30 to 1200 ohms. 2. Erroneous speed sensor signal. Check wiring.

Actuator does not energize fully while 1. Measure the voltage at the battery while 1. If the voltage is less than 7V for a 12V system, or 14V

cranking. cranking. for a 24V system, check or replace the battery.

2. Momentarily connect Terminals A and F. 1. Actuator or battery wiring in error.

The actuator should move to the full fuel 2. Actuator or linkage binding.

position. 3. Defective actuator.

4. Fuse opens. Check for short in actuator or harness.

Engine remains below desired governed 1. Measure the actuator output, Terminals A & 1. If voltage measurement is within 2 volts or more of the

speed B, while running under governor control. battery supply voltage level, then fuel control restricted

from reaching full fuel position. Possibly due to mechani-

cal governor, carburetor spring, or linkage interference.

2. Speed setting too low.

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PIB1000 C

4

Diagram 2 System Wiring and Outline

5.00

(127)

LEAD CIRCUIT

JUMPER

ESD5131, ESD5131H,

GA OVERNORS

MERICA and ESD5151 only

C ORP.

1 OFF 1 2 ON 2

SPEED CONTROL SPEED E7 E6 LEAD CIRCUIT

ON

SOFT COUPLING

OFF

UNIT

MODEL: ESD51xx GAIN 1 2

S/N :

MADE IN AGAWAM, MA U.S.A. STABILITY

CAUTION

E1 E2 E3

5.00

(127)

ENGINE SPEED CONTROL

COMPONENT. WHEN INSTALLING

DROOP

OR SERVICING REFER TO

PRODUCT PUBLICATION.

PICK-UP - + IDLE DEAD TIME

ACTUATOR BATTERY COMPENSATION

AUX 10V JUMPER

A B C D E F GH J K L MN P

Ø0.27

(6,8)

OPTIONAL ACTUATOR

CABLE SHIELDING TO ACCESSORY POWER SUPPLY

MEET CE DIRECTIVE

ACCESSORY INPUT

*

ADD JUMPER TO INCREASE

DROOP RANGE

ACTUATOR

CW GROUND REFERENCE

MAGNETIC

PICK-UP IDLE

ISOCHRONOUS

SPEED TRIM

DROOP

_ + S1

EXTERNAL SELECTOR

BATTERY FUSE SWITCH

15A MAX (NOT REQUIRED FOR SINGLE

SPEED ISOCHRONOUS OPERATION)

SEE SPECIFIC ACTUATOR PUBLICATION FOR PROPER

WIRING OF ACTUATOR BASED ON BATTERY VOLTAGE

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PIB1000 C

5

Specifications

Performance Vibration……………...............................................................1G, 20-100 Hz

Isochronous Operation…................................................… ±0.25 % or better Testing..................................................................100% Functionally Tested

Speed Range /Governor...........................................1K - 7.5K Hz Continuous

Speed Drift with Temperature……....……...............................±0.5% Typical Environmental

Idle Adjust CW.......………….…................…Min. 1200 Hz. Below set speed Ambient Operating Temperature Range......-40° to +185°F (-40° to +85°C)

Idle Adjust CCW…………….….................…Min. 4100 Hz. Below set speed Relative Humidity……………………………………........…………up to 95%

Droop Range....................................................................1 - 5% Regulation* All Surface Finishes.........................Fungus proof and corrosion resistance

Droop Adj. Max. (K-L Jumpered).................875 Hz., 75 Hz. per 1.0 A change RoHS Regulation...........................................................................Compliant

Droop Adj. Min. (K-L Jumpered)...................15 Hz., 6 Hz. per 1.0 A change

Speed Trim Range...........................................................................±200 Hz. Input POWER

Remote Variable Speed Range................................................500 - 3.7 kHz. DC Supply.........................................12 or 24 ± 20% VDC Battery Systems**

Terminal Sensitivity (Transient and Reverse Voltage Protected)

J..........................................-115 Hz., ±15 Hz/Volt @ 5 K Impedance Polarity......................................................Negative Ground (case isolated)

L.......................................-735 Hz., ±60 Hz/Volt @ 65 K Impedance Power Consumption......................................100 mA (No actuator current)

N........................................-148 Hz., ±10 Hz/Volt @ 1 M Impedance Speed Signal Range..................................................................0.5 – 50 VAC

P.........................................................10 VDC Supply @ 20 ma Max. Actuator Current Range @ 77°F (25°C).....................10 Amps continuous***

Physical COMPLIANCE / STANDARDS

Dimensions…………...…....................................................See DIAGRAM 2 Agency…...........................................................................CE Requirements

Weight………………………………………………...….........1.2 lb. (0.545 kg)

Mounting.........................……………………Any Position, vertical preferred

RELIABILITY

*Droop is based on a speed sensor frequency of 4000 Hz. and an actuator current change of 1 amp from no load to full load. Applications with higher

speed sensor signals will experience less percentage of droop. Applications with more actuator current change will experience higher percentages of

droop. See droop description for specific details on operation of droop ranges. When used with the ADC100 actuator the droop percentage will be less

due to the actuators low current consumption.

**Protected against reverse voltage by a series diode. A 15 amp fuse must be installed in the positive battery lead.

***Protected against short circuit to actuator (shuts off current to actuator), unit automatically turns back on when short is removed.

Declaration of Conformity

Application to Council Directives Heavy and Light Industrial Applications

Standard to which Conformity is Declared EN55011, EN50081-2, and EN50082-2

Manufacturer’s Name GOVERNORS AMERICA CORP.

Manufacturer’s Address Agawam, MA 01001 USA

Importer’s Name _______________________________

Importer’s Address _______________________________

Type of Equipment Electronic Speed Control Unit

Model Number ESD5100 Series

Serial Number Above V 0000

Year of Manufacture 1999 and later

I, the undersigned, hereby declare that the equipment specified above conforms to the above

Directive and Standards.

Place: Agawam, MA USA Full Name:

Date: May 6, 1999 Position: President and CEO

In order to be in compliance with the above directives, the installer is obligated to install the equipment in strict accordance with the

following special instructions and guidelines.

1. The speed control unit must be mounted against the metal ground plane with four bolts, which make positive electrical

connections between the case and the back plane.

2. The magnetic pickup must be connected to the speed control using shielded cable as shown in the wiring diagram.

3. All shielded cable connections to the speed control must be connected to the case at the corner threaded connections per the wiring diagram.

4. Shielded cable for the actuator is recommended to minimize the actuator’s slight movement during fast high voltage

transients. The installer’s choice of not using shielded cable may cause the actuator to move more than slightly during

these transients. However, no failures should be experienced.

5. The installer must refer to the wiring diagram in the literature for proper electrical connections.

This document is subject to change without notice.

Caution: None of GAC products are flight certified controls including this item.

PIB1000 C

6

Das könnte Ihnen auch gefallen

- Warning: ESD5200 Series Speed Control UnitDokument6 SeitenWarning: ESD5200 Series Speed Control UnitAnas BasarahNoch keine Bewertungen

- Esd2400 Series: Ngine Overning YstemsDokument6 SeitenEsd2400 Series: Ngine Overning YstemsAnas BasarahNoch keine Bewertungen

- Esd5500E Series Speed Control Tlnit: WarningDokument5 SeitenEsd5500E Series Speed Control Tlnit: WarningKarla HolandaNoch keine Bewertungen

- ESD-5550/5570 Series - Speed Control Unit: Technical InformationDokument12 SeitenESD-5550/5570 Series - Speed Control Unit: Technical InformationCarlos Molina100% (1)

- Ngine Overning Ystems: Generator Frequency Sensing Speed Control UnitDokument6 SeitenNgine Overning Ystems: Generator Frequency Sensing Speed Control Unitjuan narvaezNoch keine Bewertungen

- Warning: ESD5500E Series Speed Control UnitDokument6 SeitenWarning: ESD5500E Series Speed Control UnitLuis Alberto LopezNoch keine Bewertungen

- ESD5100 Series Speed Control UnitDokument2 SeitenESD5100 Series Speed Control UnitJaimeCoelloNoch keine Bewertungen

- Speed Control GAC ESD5500Dokument8 SeitenSpeed Control GAC ESD5500Manuel Otero80% (5)

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDokument7 SeitenEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNoch keine Bewertungen

- Reg. Velocidade GAC ESD 5550 5570Dokument8 SeitenReg. Velocidade GAC ESD 5550 5570thyagoenerg100% (1)

- Manual Regulador de Velocidade Gac Esd 5111 PDFDokument2 SeitenManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- ESD5100 Series Speed Control UnitDokument2 SeitenESD5100 Series Speed Control Unitajcapetillog100% (2)

- Table 1.: InstallationDokument12 SeitenTable 1.: InstallationRicardo MonteroNoch keine Bewertungen

- Electronic Governor CatalogDokument26 SeitenElectronic Governor CatalogAung Mh100% (1)

- GOB EG1065x Manual en PDFDokument8 SeitenGOB EG1065x Manual en PDFRonaldCarrasquelNoch keine Bewertungen

- Generator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Dokument8 SeitenGenerator Automatic Voltage Regulator Operation Manual: Tel: - Fax: - @Syed Mohammad Naveed100% (1)

- EG1065X Governor McPhersonDokument7 SeitenEG1065X Governor McPhersonOrlando GalvanNoch keine Bewertungen

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDokument8 SeitenDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad Naveed100% (1)

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDokument8 SeitenDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad NaveedNoch keine Bewertungen

- ESD-5500E Series: Analogue Speed GovernorsDokument4 SeitenESD-5500E Series: Analogue Speed GovernorsVasil Stoianov100% (1)

- CAT-777F-Direction and Speed ControlDokument2 SeitenCAT-777F-Direction and Speed ControlCybergoNoch keine Bewertungen

- Esd-5200 DS en 03.2011 V1.0Dokument4 SeitenEsd-5200 DS en 03.2011 V1.0BryanLeonardoOspinoReinaNoch keine Bewertungen

- Gen Stepper CTRLDokument1 SeiteGen Stepper CTRLsparky1Noch keine Bewertungen

- ESD5522E Generator Speed Control UnitDokument2 SeitenESD5522E Generator Speed Control UnitKhaled KamelNoch keine Bewertungen

- Eg1069x Manual en PDFDokument24 SeitenEg1069x Manual en PDFtecnigenelecNoch keine Bewertungen

- Manual Regulador de Velocidade Gac Esd 5111Dokument2 SeitenManual Regulador de Velocidade Gac Esd 5111Paulo Alves100% (2)

- FSK-628D Gobernador Electronico de MotorDokument35 SeitenFSK-628D Gobernador Electronico de Motorsoldadores motoresNoch keine Bewertungen

- Gac Esd5500Dokument7 SeitenGac Esd5500christramNoch keine Bewertungen

- Detector Service ManualDokument4 SeitenDetector Service Manualkhanh khanhNoch keine Bewertungen

- 2301A Speed Control: ApplicationsDokument4 Seiten2301A Speed Control: ApplicationsFabio Andres Plata TorresNoch keine Bewertungen

- Tarjeta VelocidadDokument9 SeitenTarjeta Velocidaddiego100% (1)

- Gac Ecc328 ManualDokument4 SeitenGac Ecc328 ManualAnonymous d2ofVvJNoch keine Bewertungen

- ADD 103 Series PTI2045ADokument4 SeitenADD 103 Series PTI2045ALeonardo LimbergerNoch keine Bewertungen

- Ec5000 6-09 PDFDokument5 SeitenEc5000 6-09 PDFAnonymous M0OEZEKoGiNoch keine Bewertungen

- 2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFDokument13 Seiten2110 V1.0 ESD 5330 Technical Information 09 07 10 MH en PDFSamir KhanNoch keine Bewertungen

- ht-hsg100 Ds en 04-2014 v1-1Dokument4 Seitenht-hsg100 Ds en 04-2014 v1-1Basaveswar KorlaNoch keine Bewertungen

- EG3000 Manual PDFDokument7 SeitenEG3000 Manual PDFrepelindNoch keine Bewertungen

- BPM24RT100BL Specspecifications UpdateDokument8 SeitenBPM24RT100BL Specspecifications UpdatemalleNoch keine Bewertungen

- EG3000 ManualDokument7 SeitenEG3000 ManualJose Armando Perez AcostaNoch keine Bewertungen

- Pti1000 Esd5100 SeriesDokument2 SeitenPti1000 Esd5100 SeriesRamon Thales DomeniconiNoch keine Bewertungen

- E 391 Manual 1Dokument6 SeitenE 391 Manual 1naruto akatcyNoch keine Bewertungen

- 2301A Speed Control: ApplicationsDokument4 Seiten2301A Speed Control: ApplicationsS M NaveedNoch keine Bewertungen

- Product Information: DYNA ControllersDokument4 SeitenProduct Information: DYNA ControllersmarceloNoch keine Bewertungen

- Woodward Ug40d GovernorDokument4 SeitenWoodward Ug40d Governorbuat akun100% (2)

- 2301A Speed Control: ApplicationsDokument4 Seiten2301A Speed Control: ApplicationsAshly JosephNoch keine Bewertungen

- VOLVO Speed Governor ESD 5500E Technical InformationDokument10 SeitenVOLVO Speed Governor ESD 5500E Technical Informationdaniel_ting_1Noch keine Bewertungen

- Woodward Speed Droop PDFDokument8 SeitenWoodward Speed Droop PDFedgarlimas100% (1)

- 2301A Speed Control: ApplicationsDokument4 Seiten2301A Speed Control: ApplicationsSandeep Kumar KaloniyaNoch keine Bewertungen

- 4500e DC Motor Controller InstructionsDokument1 Seite4500e DC Motor Controller InstructionsKalyani GangulianNoch keine Bewertungen

- Introduction To Turbine Governing SystemsDokument33 SeitenIntroduction To Turbine Governing SystemsSam100% (1)

- PGG Governor: Sets Speed/power Output From A Remote LocationDokument4 SeitenPGG Governor: Sets Speed/power Output From A Remote LocationDima ZayatsNoch keine Bewertungen

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationVon EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNoch keine Bewertungen

- Control of DC Motor Using Different Control StrategiesVon EverandControl of DC Motor Using Different Control StrategiesNoch keine Bewertungen

- Diesel Engine Care and Repair: A Captain's Quick GuideVon EverandDiesel Engine Care and Repair: A Captain's Quick GuideBewertung: 5 von 5 Sternen5/5 (1)

- Marine Electrics Made Simple or How to Keep the Batteries ChargedVon EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNoch keine Bewertungen

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesVon EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- MV Trafo SB - SMC - STP TI US - en 10 PDFDokument6 SeitenMV Trafo SB - SMC - STP TI US - en 10 PDFVictor ToledanoNoch keine Bewertungen

- S-18 3150 Overvoltages and Insulation Coordination PDFDokument63 SeitenS-18 3150 Overvoltages and Insulation Coordination PDFroyclhorNoch keine Bewertungen

- Ti-Spc-Psi-Protct-6070 (9 08) PDFDokument49 SeitenTi-Spc-Psi-Protct-6070 (9 08) PDFsrdeetrdsbc100% (2)

- Determination of The Electron Specific MassDokument2 SeitenDetermination of The Electron Specific MassAdina BlazeNoch keine Bewertungen

- Aluminum Lithium Alloy Welding Process FeaturesDokument82 SeitenAluminum Lithium Alloy Welding Process FeaturesMitone DiazNoch keine Bewertungen

- 9311 - CMOS Analog Design Chapter 10Dokument23 Seiten9311 - CMOS Analog Design Chapter 10raju.kprr8862Noch keine Bewertungen

- CfbampDokument1 SeiteCfbampIr GarNoch keine Bewertungen

- EL1021L Ohms Law Basic Electrical Fundamental - WK3Dokument27 SeitenEL1021L Ohms Law Basic Electrical Fundamental - WK3Dexrey John QuizanNoch keine Bewertungen

- Project Report On Input Power Factor Correction of Ac To DC Converter CircuitDokument57 SeitenProject Report On Input Power Factor Correction of Ac To DC Converter CircuitAkshyat Das100% (7)

- DHP-Series Operation Manual M550004-01Dokument56 SeitenDHP-Series Operation Manual M550004-01Dumi BogdanNoch keine Bewertungen

- Power Electronics Chapter#11Dokument25 SeitenPower Electronics Chapter#11Bilal HussainNoch keine Bewertungen

- RK 49 - Ds - en PDFDokument5 SeitenRK 49 - Ds - en PDFPedro Javier Castro SanchezNoch keine Bewertungen

- Trends in Electrical TransmissionDokument47 SeitenTrends in Electrical TransmissionSumit Kumar DattaNoch keine Bewertungen

- Integrated Science Form 2 June 2010Dokument9 SeitenIntegrated Science Form 2 June 2010asjawolverine0% (2)

- Product/Process Change Notice (PCNDokument2 SeitenProduct/Process Change Notice (PCNJoseph BernardNoch keine Bewertungen

- EXPERIMENT Capacitor RC CircuitDokument4 SeitenEXPERIMENT Capacitor RC Circuitfaiz shukriNoch keine Bewertungen

- Electronics RLDokument6 SeitenElectronics RLSheharyar MunirNoch keine Bewertungen

- Gate Turn Off Thyristors GTODokument16 SeitenGate Turn Off Thyristors GTOElrich Joseph JalandoniNoch keine Bewertungen

- Basic ECEDokument2 SeitenBasic ECEmarkvillaplazaNoch keine Bewertungen

- Yx 360 TRDokument14 SeitenYx 360 TRNovian ArmaNoch keine Bewertungen

- ITC - Power Factor CorrectionDokument92 SeitenITC - Power Factor Correctiongopir28Noch keine Bewertungen

- DIY DC ArcWelderDokument3 SeitenDIY DC ArcWeldersituationsNoch keine Bewertungen

- Slim TV Service Manual - Sy33 ChassisDokument45 SeitenSlim TV Service Manual - Sy33 ChassisUmar MajeedNoch keine Bewertungen

- Design and Simulation of an Inverter With High Frequency Sinusoidal PWM Switching Technique for Harmonic Reduction in a Standalone Utility Grid Harmonic Reduction in a Standalone Utility Grid Synchronized Photovoltaic SystemDokument6 SeitenDesign and Simulation of an Inverter With High Frequency Sinusoidal PWM Switching Technique for Harmonic Reduction in a Standalone Utility Grid Harmonic Reduction in a Standalone Utility Grid Synchronized Photovoltaic SystemS.m. FerdousNoch keine Bewertungen

- Iu.e5.116.0 XCSW240Dokument2 SeitenIu.e5.116.0 XCSW240FolpoNoch keine Bewertungen

- Features Description: 2K X 8 Asynchronous CMOS Static RAMDokument8 SeitenFeatures Description: 2K X 8 Asynchronous CMOS Static RAMKontak SynthetizadorNoch keine Bewertungen

- Electrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyDokument5 SeitenElectrical Steel, Also Called Lamination Steel, Silicon Electrical Steel, Silicon Steel or Transformer Steel, Is SpecialtyShobhit MauryaNoch keine Bewertungen

- Wharfedale TITAN SUB-A12 - 1-400wDokument13 SeitenWharfedale TITAN SUB-A12 - 1-400wNguyễn Quang TrânNoch keine Bewertungen

- Iv RepotDokument16 SeitenIv Repotneethurj9Noch keine Bewertungen

- AC Measurements and Diode CircuitsDokument3 SeitenAC Measurements and Diode CircuitsJenina Margareth Aldaba CastroNoch keine Bewertungen