Beruflich Dokumente

Kultur Dokumente

VOL II SEC 3B-6 TECH SPEC CONTROL Aek Sibundong PDF

Hochgeladen von

Komang SuantikaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

VOL II SEC 3B-6 TECH SPEC CONTROL Aek Sibundong PDF

Hochgeladen von

Komang SuantikaCopyright:

Verfügbare Formate

Volume II, Section 3B‐6

SECTION 3B : TECHNICAL REQUIREMENTS FOR

GENERATING EQUIPMENTS

TABLE OF CONTENTS

Page

6 CONTROL, MEASURING, AND PROTECTIVE RELAYING

EQUIPMENT 1

6.1 GENERAL ......................................................................................................................... 1

6.2 PROTECTION PHILOSOPHY ....................................................................................... 1

6.3 PROTECTION DEVICES ........................................................................................................ 2

6.4 INDICATION AND CONTROL FACILITIES ................................................................ 5

6.5 WORK TESTS ................................................................................................................. 9

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐i

Volume II, Section 3B‐6

SECTION 3B

TECHNICAL REQUIREMENTS FOR GENERATING

EQUIPMENTS

6 CONTROL, MEASURING, AND PROTECTIVE RELAYING

EQUIPMENT

6.1 GENERAL

The equipment provided under this Section of the Contract shall include all protection,

alarm and control devices as indicated in the Schedules, Drawings and Specification and

shall include all equipment provided loose from the turbine and generator manufacturers

as well as all contact multiplying relays required for the complete protection, indication and

control of the turbine/generator sets and the 20 kV generator transformer.

6.2 PROTECTION PHILOSOPHY

(1) Generator Transformer Protection

Overcurrent relay will provide overcurrent protection for the 20 kV/6300 V generator

transformers.

Each generator transformer shall be provided with earth fault protection facilities.

(2) Generator Protection

Each generator is cabled directly to its associated 20 kV/6300 V transformer. The

Generator is synchronized to the 20 kV system at the 20 kV side of step up Transformer

via the unit 20 kV circuit breaker. All generator and turbine trips, either electrical or

mechanical, also the transformer earth fault protection shall trip the unit 20 kV circuit

breaker.

Synchronizing of the generator to the 20kV system shall be accomplished from the

synchronizing facilities on the control panel.

All protection equipment, measuring devices and associated transducers as well as all

loose supply equipment from the turbine/generator manufacturers shall be included in the

generator panel and displayed by flag relays.

All other protection equipment in and around the generator/turbine shall be separated

indicated by flag relays mounted on the generator (unit} control panel.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐1

Volume II, Section 3B‐6

Generally all machine protection shall be divided into two classes, electrical trips that

cause immediate opening of the circuit breaker and normal trips that cause a normal shut

down of the turbine generator set.

6.3 PROTECTION DEVICES

(1) General

The application, performance and testing of protective devices shall be in -accordance

with IEC 255 or equivalent national standard.

Protection equipment shall be designed and applied to provide maximum discrimination

between faulty and healthy circuits. All protection equipment shall remain inoperative

during transient phenomena which may occur during switching or other disturbances to

other parts of the system.

Current transformers, which shall all have 5A secondary windings, shall be located so as

to include the associated circuit breaker within the protected zone and shall be located

generally as indicated on schematic drawings.

Relays shall be of approved types complying with IEC 255 or equal, shall have approved

characteristics and be flush mounted in dust and moisture proof cases with preferably

withdrawable type enclosures to IEC 68.

Relays shall be arranged so that adjustments, testing and replacement can be affected

with the minimum of time and labor. Relays of the hand reset type shall be capable of

being reset without opening the case.

Relay contacts shall be suitable for making and breaking the maximum currents which

they may be required to control in normal service but where contacts of the protective

relays are unable to deal directly with the tripping currents, approved auxiliary contactors,

relays or auxiliary switches shall be provided. Separate contact shall make firmly without

bounce and the whole of the relay mechanisms shall be unaffected by vibration or

external magnetic fields.

Relays where appropriate shall be provided with flag indicators, phase coloured where

applicable. Flag indicators shall be of the hand reset pattern and shall be capable of being

reset without opening the case. Where two or more phase elements are included in one

case separate indicators shall be provided for each element.

Relays which rely for their operation on an external d.c. supply shall utilize for this purpose

the trip supply of the associated circuit breaker. This supply shall be monitored and an

alarm provided in the event of failure.

Relays with provision for manual operation from outside the case, other than for resetting,

will not be accepted and time delay relays shall not be of the dashpot type.

Relays, whether mounted on panels or not, shall be provided with clearly inscribed labels

describing their application and rating in addition to the general purpose labels.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐2

Volume II, Section 3B‐6

To minimize the effect of electrolysis, relay coils operating on d.c. shall be so connected

that the coils are not continuously energized from the positive pole of the battery.

In addition, all relays shall include all suppression circuitry required to ensure that

maloperation does not occur due to normal switching transients on the substation d.c.

supply.

Protection relays shall be of the electromechanical types that have been well proven in

service for at least 10 years.

(2) Static Relays

Electromechanical relays are preferred, however, static relays or relays employing solid

state techniques will be considered. In addition to complying with the requirements of Sub-

Section 6.3, Clause 6.3 (1) the following information shall be supplied.

(i) Evidence of satisfactory in-service experience and component reliability.

(ii) Full details stating how maloperation or component damage due to transient voltage

is eliminated with particular reference to spike voltages originating via current

transformers, cables, d.c. supply and other sources.

Relays with separate internal batteries shall be unacceptable.

(3) Test Facilities

Test facilities shall be provided for the complete on site testing of each relay. This shall

include test plugs and sockets or links as appropriate for secondary injection into the

relay. Provision shall be made for open circuiting all voltage transformer and alarm and

trip connections and for short circuiting all current transformer connections.

Test facilities shall be provided for each current and voltage transformer secondary circuit

so as to give access for testing of protection relays and associated circuits. The facilities

shall comprise test terminals of approved type for front of panel mounting with provision

for automatic short circuiting of current transformer secondary circuit by means of a switch

or by movement of links from their normal operation position. Alternatively the same ' may

be accomplished by use of test sockets and plugs.

Each current circuit shall be earthed through a removable link at one point only. Links

shall be provided for isolation of protection trip circuits.

(4) Flag and Tripping Relays

All alarm and trip conditions shall be indicated by flag relays. Each relay shall be fully

labeled and complete with resetting features. Relays shall be resettable from outside their

enclosure.

Tripping relays may be provided for commoning the shunt trip contacts of the flag relays if

the contact rating of the flag relays should not be sufficient for the circuit breakers

provided. As previously stated the protection equipment for the generator shall be

segregated into two sections, electrical to trip the circuit breaker and normal to trip the

breaker when the guide vane opening has been reduced to its speed no load condition.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐3

Volume II, Section 3B‐6

(5) Auxiliary and Contact Multiplying Relays

All relays shall be provided with sufficient contacts for its proposed protection schemes

but shall have a minimum of 1 spare changeover contact.

The contacts shall be rated at 500 VA with maxima of 660 volts and 5 amps.

Auxiliary or contact multiplying relays shall be provided as required to provide all

necessary control, synchronizing indication and protection functions as required.

(6) Protection Supply Segregation

All protection switching or control shall be made from the 110V DC battery supply.

Supplies shall be assessed and miniature circuit breakers or fuses adequately rated for

the particular application.

(7) Synchronizing Facilities and Dead Bus Relays

(a) Check Synchronizing Relay

This device is required to compare voltage, frequency and phase relationships of two

supplies across a circuit breaker prior to closure of that breaker, and permit closure

only if certain preset conditions are met.

The relays required under this Contract shall generally block closure of the circuit

breaker under the following conditions:

i) Voltage less than a preselected value, ranging between 80 and 90% of the

calibrated value. The range setting shall be continuously variable within these

limits.

ii) Phase difference greater than a preselected value, ranging between 0 and ± 45°.

The range setting shall be continuously variable within these limits.

iii) Percentage frequency difference greater than a preset value, ranging from 0.02

to 0.1%. The range setting shall be continuously adjustable within these limits.

Voltage relays, connected to measure line to line voltage shall be provided to allow,

closure of the circuit breakers into a dead line or dead busbar. These relays shall only

permit closure of the breaker if the line or busbar voltage is below 30% nominal.

(b) Synchroscope

Phase to phase measuring synchroscopes shall be provided to show the phase

relationship of the incoming and running supplies. This unit shall be of the

electromagnetic type. The synchroscope and synchronizer incoming, and running

voltage terminals will be selected to the appropriate bus by the synchronizer plug

selection.

(8) Overcurrent and Earth Fault Inverse Time Protection

The protection device shall generally comply with the requirements of Sub-Section 6.3,

Clause (1) and (2) and shall have similar performance the protection relay described

below.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐4

Volume II, Section 3B‐6

Over current elements shall be supplied with adjustable settings for both operating current

and time, the design of the relay being such that the adjustment can be carried out on

load. The range of current setting adjustment for phase faults shall be 50 to 200 percent of

rated full load with tappings at 25 percent intervals and the time setting adjustment shall

be 0 to 3 seconds at 10 times the setting current.

Inverse time earth fault elements shall comply with the foregoing but shall have a range of

setting from 10 to 40 percent with tappings at a maximum of 10 percent intervals.

All overcurrent and earth fault relays shall be fitted with high set instantaneous elements

adjustable in the range of 50 to 200 percent of 5A nominal.

(9) Overvoltage Relays

Instantaneous overvoltage relays and their associated timers shall be provided for each

generator protection system. The relays shall be 2 pole types supplied from the 110V

secondaries of the generator potential transformers.

Pick up setting and time delay of time relays shall be :

110 to 140% of nominal voltage and 0-10 sec adjustable time.

Both voltage and time delays shall be adjustable over or including the ranges specified.

(10) Earth Fault Relays

Instantaneous earth fault relays together with time delay relays shall be supplied. The

relays shall be suitable for operation with a current transformer with 5A secondary. The

range of settings shall be 10-40%. The time delay relays shall be adjustable from 0-3 sec.

(11) Power Relay

Alarm for small power generation shall be provided by power relay on the generator

circuit. The relay shall be suitable for detection of generating output of 20 - 40 % rated.

(12) Spares and Special Tools

The Contractor shall provide the following spares and any special tools required for the

maintenance of the equipment offered.

Two only test plugs or means of testing the relays offered.

Two spare auxiliary relays of each type

Two spare flag relays of each type.

Two sets or any special maintenance tools or relay extraction tools.

6.4 INDICATION AND CONTROL FACILITIES

(1) General

It is required that all control and indication facilities provided under this Contract shall be

as simple yet as comprehensive as possible. The Contractor shall make every effort to

achieve those aims.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐5

Volume II, Section 3B‐6

The stations are to be run manually, and the arrangement of the controls should be

selected to ease operator use.

All controls, indication and tripping equipment associated with the turbines and generators

shall be contained within the generator control panel.

(2) Meters and Instrument

All indicating instruments shall be of flush mounted back connected, dustrproof and heavy

duty switchboard type. Each indicating meter and instrument shall have a removable

cover, either transparent or with a transparent window. Each meter and instrument shall

be suitable for operation with the instrument transformers under both normal and short

circuit conditions.

Scale plates shall have a permanent white circular or rectangular finish with black pointer

or markings. The scale ranges shall be determined from current transformers and voltage

transformer ratio.

The wattmeter and watt-hour meters for the generator and 20 kV line circuits shall be of 2

element, 3 phase, 3 wire type those for the station service circuits shall be of 3 element, 3

phase, 4 wire type.

Each wattmeter and watt-hour meters shall be fitted with a reverse running stop. All

indicating instruments shall be approximately 110 mm square enclosures and shall be

provided with clearly readable long scale, approximately 2.40 degrees. The maximum

error shall be not more than one and a half (1.5) percent of full scale range.

Shunts for use with D.C. ammeter with calibrated shunt leads of required length shall be

provided by the Contractor.

The following meters and any associated transducers shall be provided on control panels.

kWattmeter

kVarmeter

ammeter : for each phase

Voltmeter complete with three phase selector switch scaled 0-6300 V (Generator

Voltage).

Voltmeter complete with three phase selection switch scaled 0-25 kV line.

Frequency meter reading 45,50,55 HZ, electromagnetic type

Hour run meter reading up to 9999 hours run, non reset table.

Kilowatt hour meter

(3) Alarm Flag Relays

All alarm conditions shall be indicated by flag relays and shall be of the same style as

supplied for Sub-Section 6.3, Clause (4) of this specification. Alarm and trip indicators

where contained in the same enclosure shall be segregated to ease operator

understanding.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐6

Volume II, Section 3B‐6

If so required group alarms or trips may be indicated on the machine control panel e.g.

excitation alarm, provided that each alarm condition is separately indicated on the

associated equipment to which it relates.

(4) Generator Control and Indication

The Contractor shall provide the necessary controls required for the complete and

successful operation of the equipment offered. A minimum of control switches are to be

provided, allowing however for the operator to fully control the machines for normal or

'black' start up and for normal or emergency shutdown. The following description has

been prepared as a guideline of the controls desired and their suggested function.

Raise/lower push buttons for speed and load adjustment of the governor provided.

Raise and lower push buttons for the voltage adjustment of the A.V.R.

Governor shutdown/start up control switch or push button. This control interlocks with

tripping functions to provide close down of the turbine for any trip function.

Governor speed no load or starting controls as appropriate.

Emergency stop push button stopping the turbine, and opening the circuit breakers.

Indication lamps shall be provided to indicate the status of selected operational

features i.e. guide vanes closed, inlet valve, governor speed motor operative etc.

(5) Loose Equipment - Temperature Monitoring, Speed Monitoring

The Contractor shall install within the generator control panel all equipment provided loose

by other manufacturers that is necessary for the complete and successful operation of the

station, such as temperature monitors and speed monitors.

(6) Auxiliary and Contact Multiplying Relays

Auxiliary or contact multiplying relays shall be provided as required to provide all

necessary control and indication functions. Relays provided shall be identical to those

supplied under Sub-Section 6.3, Clause (5) of this Specification.

(7) Kilowatt Hours Meter

Kilowatt hour integrating meters shall be of the induction disc, 3 phase unbalanced load

type and shall be mounted in robust flush metal cases.

All integrating meters shall be of approved manufacture. Kilowatt hour meter shall be

provided with maximum demand type indicators arranged for half hour resetting. Provision

shall be made for testing the meters without disturbing any permanent wiring.

(8) Weir Water Level Indicator

One head transducer shall be supplied for the measurement of weir water level.

Transducer shall be calibrated to measure over the normal working range of water level at

the weir.

Transducer shall preferably be fitted with a mechanical indicator scaled identically to the

water level meters in powerhouse

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐7

Volume II, Section 3B‐6

Transducer shall be installed, in a stilling chamber supplied under this Contract and

mounted adjacent to the weir.

(9) Low Head Alarm

A low head alarm unit, indicating on the alarm panel shall be provided. The alarm signal

shall be obtained from a float switch mounted in the penstock intake structure downstream

of the screen.

(10) Automatic Water Level Control

A controller shall be provided to modulate the output of the turbine generator to maintain

optimum head of water during periods when water flow is less than that required for

maximum generator output. The controller shall be initiated by the Low Head Alarm

described in Sub-Section 6.3, Clause (9) and shall consist of a pulsing system which

closes down the guide vanes of the turbine by adjusting the speed setting on the governor

of the synchronous machines.

Close pulses shall be adjustable between 0 - 30 seconds and the time between pulses

shall be adjustable between 0 - 30 minutes.

When the Low Head Alarm is reset by rising water level, the controller shall, after time

delay variable between 0-10 minutes, reset the output of the turbine generators to

maximum by a similar pulsing action.

The water level control system shall be complete with all necessary equipment and

selector switch to disable the control system when automatic operation is not required.

In the stations with two generating sets, the controller shall initially modulate the output of

one generator. When this is at minimum value the output of the generator should then be

modulated.

(11) Mimic

As indicated on the control panel a simplified mimic shall be supplied to show connection

of the turbine generating sets to the 20 kV. This mimic shall be fully annotated as to

feeder names, circuit breaker designations and metering. The mimic shall be constructed

from 10 mm wide copper or brass bars secured to the panel face.

Mimics for 20 kV lines shall be colored red.

(12) Spares and Special Tools

The Contractor shall provide the following spares and any special tools required for the

maintenance of the equipment offered.

200 % of each type of lamp offered.

2 discrepancy switches

2 of each type of switch offered

One (1) sets of any special extraction tools or maintenance tools.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐8

Volume II, Section 3B‐6

6.5 WORK TESTS

Works tests in accordance with the Employer’s General Requirements shall be performed

on all equipment provided. The tests shall include but not be limited to:

(1) Routine tests

(a) Arrangement of Wiring and Equipment

All wiring and equipment shall be checked for arrangement, compliance with the

requirements of the specification and for conformity with the approved drawings.

(b) Insulation of Wiring and Equipment

All wiring and equipment which will become energized in the course of operation shall

be tested for satisfactory insulation of in accordance with IEC 540.

(c) Instrument Transformers

Instrument transformers shall be routine tested to the relevant approved national

standard.

(d) Operation of Ancillary Equipment

All contactors, relays and protective devices shall be checked to establish compliance

with the approved values of setting and tolerance.

(e) Other Tests

Other routine tests on the complete equipment shall be carried out in accordance with

the relevant approved national standard.

(2) Type Tests

All items of electrical equipment shall have been type tested and evidence of this

produced if requested by the Engineer or shall be so tested at the works.

(3) Function Tests

Where items of equipment are connected together to form a functional group, then an

operational test shall be carried out at the Manufacturer's Works on each such group to

demonstrate satisfactory operation. This includes testing all control sequence.

The Contractor shall provide all necessary power supplies of adequate capacity to enable

these tests to be carried out.

(4) Electronic Equipment

Equipment containing semi-conductor devices shall be tested to demonstrate satisfactory

operation and satisfactory continuous energizesation for 100 (one hundred) hours.

Tender Document Aek Sibundong MHEPP - Generating Equipment II. 3B‐6‐9

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 25 - E65-66 IhkaDokument55 Seiten25 - E65-66 IhkaKent WaiNoch keine Bewertungen

- VIN LED Lighting E-Catalogue VER 2.12Dokument88 SeitenVIN LED Lighting E-Catalogue VER 2.12poonam_ranee3934Noch keine Bewertungen

- Telehandlers: Parts AccessoriesDokument36 SeitenTelehandlers: Parts AccessoriesWilliam Gonzalez EscobarNoch keine Bewertungen

- Gambar 2-6 Energy - 3unit - Kap - SamaDokument1 SeiteGambar 2-6 Energy - 3unit - Kap - SamaKomang SuantikaNoch keine Bewertungen

- Section 3B: Technical Requirements For Generating EquipmentsDokument9 SeitenSection 3B: Technical Requirements For Generating EquipmentsKomang SuantikaNoch keine Bewertungen

- VOL IV Sec-6 Drawing MekanikalDokument9 SeitenVOL IV Sec-6 Drawing MekanikalKomang SuantikaNoch keine Bewertungen

- 03-Denah Desain Plta Sawangan-POWERHOUSEDokument1 Seite03-Denah Desain Plta Sawangan-POWERHOUSEKomang SuantikaNoch keine Bewertungen

- Executive Summary - Sintang 12 MW BTG Biomass Power PlantDokument11 SeitenExecutive Summary - Sintang 12 MW BTG Biomass Power PlantKomang SuantikaNoch keine Bewertungen

- Chieftec Aps 650cbDokument26 SeitenChieftec Aps 650cbbatamazurNoch keine Bewertungen

- Electrolytic CapasitorDokument8 SeitenElectrolytic Capasitorgema ilham pangestuNoch keine Bewertungen

- ddr3 PDFDokument18 Seitenddr3 PDFsnvvNoch keine Bewertungen

- ITB InstallationDokument11 SeitenITB Installationapi-3739726100% (1)

- Optoma Ex631 SchematicDokument48 SeitenOptoma Ex631 SchematicBoopathi RameshNoch keine Bewertungen

- Single-Chip 16C X 2L Dot-Matrix LCD Controller / Driver: FeaturesDokument31 SeitenSingle-Chip 16C X 2L Dot-Matrix LCD Controller / Driver: FeaturesRicardo Ernesto Jasso PonceNoch keine Bewertungen

- Silicon NPN Power Transistors: Savantic Semiconductor Product SpecificationDokument3 SeitenSilicon NPN Power Transistors: Savantic Semiconductor Product SpecificationSsr ShaNoch keine Bewertungen

- Laguna Tech MANUAL F5R ENGINE - f5r700 PDFDokument120 SeitenLaguna Tech MANUAL F5R ENGINE - f5r700 PDFJeanclaude NgangueNoch keine Bewertungen

- Thermocouple: VoltageDokument7 SeitenThermocouple: Voltage9897856218Noch keine Bewertungen

- CableCALC BS 7671 Operating ManualDokument17 SeitenCableCALC BS 7671 Operating Manualjodie_patrickNoch keine Bewertungen

- Preconnectorized "Stubbed" Hardware: Features and BenefitsDokument12 SeitenPreconnectorized "Stubbed" Hardware: Features and BenefitsSergio Denis UCNoch keine Bewertungen

- SAFE WORK PROCEDURE (Lathe)Dokument1 SeiteSAFE WORK PROCEDURE (Lathe)Rehan orchidNoch keine Bewertungen

- Mls 2300 AcdcDokument26 SeitenMls 2300 AcdcCesar ObesoNoch keine Bewertungen

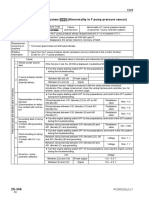

- Service Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224Dokument4 SeitenService Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224ariy yuli styawan100% (1)

- En Acs800 Igbt Sprs Brochure ADokument5 SeitenEn Acs800 Igbt Sprs Brochure AshankarumsNoch keine Bewertungen

- Diode Semiconductor Korea: Plastic Silicon RectifiersDokument2 SeitenDiode Semiconductor Korea: Plastic Silicon RectifiersJerry EscalonaNoch keine Bewertungen

- 2021 Designer Inclusions Brochure Coral HomesDokument25 Seiten2021 Designer Inclusions Brochure Coral Homeskmae dizonNoch keine Bewertungen

- Regard 2400-Arq-Mod Bus 485Dokument8 SeitenRegard 2400-Arq-Mod Bus 485Julio Andres Garcia PabolaNoch keine Bewertungen

- ELBI General CatalogDokument68 SeitenELBI General CatalogTapelea CristianNoch keine Bewertungen

- Consew 40 RB Sewing ManualDokument30 SeitenConsew 40 RB Sewing ManualBig jim swennieNoch keine Bewertungen

- C002A-Propylene Compressor LLFDokument1 SeiteC002A-Propylene Compressor LLFPwan KhuranaNoch keine Bewertungen

- Mine Venting DuctDokument28 SeitenMine Venting DuctSergej SchlegelNoch keine Bewertungen

- VR6Dokument20 SeitenVR6sareluis30Noch keine Bewertungen

- Mf15 Performance Diagnostics Eged535Dokument14 SeitenMf15 Performance Diagnostics Eged535Trung hiếu Nguyễn lêNoch keine Bewertungen

- 7628 SCRAPER: Engine PerformanceDokument4 Seiten7628 SCRAPER: Engine PerformanceJorgeBravoG.Noch keine Bewertungen

- Friends Niga MemesDokument61 SeitenFriends Niga MemesrewtreatewrtawertNoch keine Bewertungen

- Direct Memory Access (DMA)Dokument9 SeitenDirect Memory Access (DMA)Doris MwimaliNoch keine Bewertungen