Beruflich Dokumente

Kultur Dokumente

Sss

Hochgeladen von

Sunil Kumar YelisettyOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sss

Hochgeladen von

Sunil Kumar YelisettyCopyright:

Verfügbare Formate

G5 Final Tester

Modular. Scalable. Flexible.

Introducing the JOT G5 Final Tester, the all-in-one making sure you don’t pay for features you don’t need is

product-level testing platform built for your specific always easier on the budget.

testing needs. And that doesn’t mean the G5 has so

many features that you’re sure to find the ones you The fully customizable G5 Final Tester can be produced

need. It means the G5 can literally be produced per your for RF, Audio & RF, and Vision test environments. Plus,

specific testing requirements. JOT’s proven modular there are two tester versions available: a test chamber

design thinking can always be traced back to our with a hatch that’s helpful for manual test operation,

customers’ wishes. It’s all about making testing as and a test chamber with a slide that’s easier for

reliable, efficient, and cost-effective as possible. And automated testing.

The G5 is an excellent solution for:

• RF testing • Energy management testing

• Audio testing • Data and communication interfaces testing

• Camera testing with lights and targets • Multimedia interfaces testing

• Display & touch testing by vision camera • Inspections (e.g. keypad lights & symbols)

and test fingers • Sensors testing

• Buttons testing

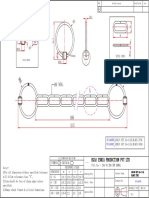

MACHINE NAME AND CODE:

G5 Final Tester, G50-1536

and must not be copied, reproduced or disclosed to any third party without prior written permission. Contravention will be prosecuted.

1 2 3 4 5 6 7

A 373,75

910

B

+60

685 - 60

600 182 700

D

No. Item No TITLE

1 MA015185 Main assembly,mecha

2 MA015207 Audio isolation assem

3 MA016168 Isolation assembly Fo

This document and its contents are the property of JOT Automation Ltd.

STANDARD FEATURES OPTIONS INSTALLATION REQUIREMENTS

4 MA015203

5 MA015958

Axle assembly

RF Plate assembly, D

• Ethernet for the tester control • Audio isolation Power supply:

6 MA015938 Tool changer Magazin

7 MA015774 Master tool changer a

• RF -shielded chamber • Vision test enviroment • 220-240 VACOptional

/ 50 Hz / 38AMA015939 Finger Tips Magazine

• Sliding door for product

E

handling • Configurable PSP interface • 100-120 VAC / 60 Hz / 510AME031854

9 MA013699 Teach pendant assem

Control box assembly

» Possibility for robot feeding • Cartesian Robot with x-, y-, and z-axels 11 ME031855 Control box assembly

• Integrated ADC/DAC for analog signal » Support interpolation Compressed air connection:12 MA014885 Rack assembly

analyzing, signal generation » Support tool changer functionality 0.6 MPa (87 psi)

13 SX004085

14 SX004086

Power supply cable Sc

Power supply cable C

and DC-measurements » Active and passive tools 15 SX004087 Power supply cable U

• Easy software integration with RESTful API » Active and passive tool magazine 16 EL001559

Material:

Main Assembly, Autom

and open source client implementations with » Different tools according Finish:

.NET/C#, python and LabVIEW customer needs Item note: IFS Update

Drw note: IFS Update

• Performance statics

F and service • Possibility to add camera for Designed: lamsjuh 24.05.2018 Title

Released: lamsjuh 24.05.2018

counter for machine maintenance Vision inspection Drawn: lamsjuh 24.05.2018

• Platform independent • General interface for External Data Drw Rlsd:

Mass:

lamsjuh 24.05.2018

271.05 kg

Test Sequencer integration Acquisition (DAQ) Card for signal Copyright (C) Metric:mm

All rights A3

• CE-safety compliant 1 2

generation

3

and analyzing 4 5 6

reserved

Model file: G50-1536-1

• DUT Interfaces:

» RF lines

TECHNICAL CHARACTERISTICS » GigE Ethernet

• Machine dimension (L x D X H mm) » USB 3.0 with USB Type-C functionality

600 x 718 x 595 » HDMI

• Weight 160 kg (without rack) » Expanded according customer

• Audio Isolation requirements

» 30dB 200Hz - 2kHz • Integrated Power supply:

» 40db above 2kHz » Up to four isolated high current

• RF chamber attenuation >45 dB up to 6 GHz output voltages with sense inputs

• Robot work area 300 x 330 x 100 mm (xyz) » Precision current measurement,

• Product Specific Part (PSP) source and sink

» Replaceable fixture • Instrument Rack

» Handled product size: 250 x 300 x 100 mm (xyz) » 11 U space for 19” instrument

» Capable to handle 3 DUT (Device Under Testing)

» General IO lines

» IO controllable pneumatics

» I2C and USB 3.0 bus

CONTACT INFO » WWW.JOTAUTOMATION.COM G5 FINAL TESTER, G50-1536 DATASHEET

© COPYRIGHT JOT AUTOMATION LTD. ALL RIGHTS RESERVED

Das könnte Ihnen auch gefallen

- Energy Storage Unit Service - Manual PDFDokument28 SeitenEnergy Storage Unit Service - Manual PDFathinabeba100% (2)

- Radio 4415Dokument2 SeitenRadio 4415dsfdnasd100% (5)

- SG6427 Na4030 01 602 N0gad001 092Dokument2 SeitenSG6427 Na4030 01 602 N0gad001 092umer hayatNoch keine Bewertungen

- AutoCAD Exercises For TutorialsDokument23 SeitenAutoCAD Exercises For TutorialsIbrahimElKelanyNoch keine Bewertungen

- KY-031 Knock-Sensor ModuleDokument3 SeitenKY-031 Knock-Sensor Modulegabusmdq60Noch keine Bewertungen

- ACER ASPIRE S7 Wistron Storm - 12223-1 R-1 0625Dokument102 SeitenACER ASPIRE S7 Wistron Storm - 12223-1 R-1 0625sam tabNoch keine Bewertungen

- Vesda Arrange Fire Alarm SystemDokument1 SeiteVesda Arrange Fire Alarm SystemGaurav Kumar SharmaNoch keine Bewertungen

- Defender sm6150 0430 1Dokument69 SeitenDefender sm6150 0430 1Danilo RibeiroNoch keine Bewertungen

- Alps Electric (Malaysia) SDN BHD: Part No. Name Spec Material Finish QuantityDokument1 SeiteAlps Electric (Malaysia) SDN BHD: Part No. Name Spec Material Finish QuantityAzrul AzimNoch keine Bewertungen

- NH.0900.03.0017 R1Dokument1 SeiteNH.0900.03.0017 R1Wahyu Tirta NugrahaNoch keine Bewertungen

- Eeeegggglllloooo Iiiinnnnddddiiiiaaaa Pppprrrroooodddduuuuccccttttiiiioooonnnn PPPPVVVVTTTT LLLLTTTTDDDDDokument1 SeiteEeeegggglllloooo Iiiinnnnddddiiiiaaaa Pppprrrroooodddduuuuccccttttiiiioooonnnn PPPPVVVVTTTT LLLLTTTTDDDDShree BalajiNoch keine Bewertungen

- Engineering Controlled Manufacturer:: AD1353-1 XADokument1 SeiteEngineering Controlled Manufacturer:: AD1353-1 XAnobamoNoch keine Bewertungen

- Pra Da 050 0040 0 2 2 1 1 1 Bas - 1 - 10436 - 20180626144909Dokument4 SeitenPra Da 050 0040 0 2 2 1 1 1 Bas - 1 - 10436 - 20180626144909Anirudh JavagalNoch keine Bewertungen

- SK73 - IEC160: Date Name Drawn SystemDokument1 SeiteSK73 - IEC160: Date Name Drawn SystemHugo AcevedoNoch keine Bewertungen

- Techtop ODPDokument3 SeitenTechtop ODPHydro Energy GroupNoch keine Bewertungen

- VMGD 032Dokument7 SeitenVMGD 032VIMA MACHINERYNoch keine Bewertungen

- Modular Lube Lubrication Systems: Divider ValvesDokument6 SeitenModular Lube Lubrication Systems: Divider ValvesIbrahimAmroNoch keine Bewertungen

- Piping Isometric - 4Dokument1 SeitePiping Isometric - 4CosminMarianNoch keine Bewertungen

- Installation & Technical Information: Code No: Voltage: Light Source: CurrentDokument2 SeitenInstallation & Technical Information: Code No: Voltage: Light Source: CurrentsdfkjgskfNoch keine Bewertungen

- Prototype Drawing Elife Solution PLT by MR ALiDokument8 SeitenPrototype Drawing Elife Solution PLT by MR ALitessar hanamasterNoch keine Bewertungen

- FIC MR055 MR056 Rev 02Dokument53 SeitenFIC MR055 MR056 Rev 02nemesis 81Noch keine Bewertungen

- BCT Iv IDokument50 SeitenBCT Iv IRonnie's goalsNoch keine Bewertungen

- Earth Busbar - MergedDokument18 SeitenEarth Busbar - Mergedengineeringcem99Noch keine Bewertungen

- SapcsDokument1 SeiteSapcsMarcius Diego da SilvaNoch keine Bewertungen

- ZX300MV2 2022frame 12143-ADokument1 SeiteZX300MV2 2022frame 12143-AMohd Afifi JusohNoch keine Bewertungen

- Civil - SOR - 2019 20 Pages 11 41Dokument484 SeitenCivil - SOR - 2019 20 Pages 11 41jns 22495Noch keine Bewertungen

- Terminal Block LegrandDokument1 SeiteTerminal Block LegrandRava OshopNoch keine Bewertungen

- Industrial Engineering Vaibhav G. Bandekar M2020096Dokument20 SeitenIndustrial Engineering Vaibhav G. Bandekar M2020096Vaibhav BandekarNoch keine Bewertungen

- Fm400tu-07a eDokument5 SeitenFm400tu-07a egab johnNoch keine Bewertungen

- Fora - Maior - Chapa Aço Sae 1020 2420#1,50mmDokument1 SeiteFora - Maior - Chapa Aço Sae 1020 2420#1,50mmmythicppsetupsNoch keine Bewertungen

- MAS1006026R5 CAD DrawingDokument1 SeiteMAS1006026R5 CAD Drawingluis.chuquimiaNoch keine Bewertungen

- Canadian Solar-Datasheet - KuDymond (Bifacial) CS3U-MB-FG (IEC1500V) v5.55...Dokument2 SeitenCanadian Solar-Datasheet - KuDymond (Bifacial) CS3U-MB-FG (IEC1500V) v5.55...André VictorNoch keine Bewertungen

- Airsoft MeletinDokument1 SeiteAirsoft MeletinitzyexxNoch keine Bewertungen

- VR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFDokument6 SeitenVR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFAhmed Nasr (By NAZRi)Noch keine Bewertungen

- 125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1Dokument1.944 Seiten125256-22072 LCG3015AJM2 (PL940) (AMNC3i - FS31i-LB) (EXP) Ver1.1jturnerNoch keine Bewertungen

- 432 950sh01r1Dokument1 Seite432 950sh01r1Ahmed KassemNoch keine Bewertungen

- 4-PM - NH Fuse PDFDokument2 Seiten4-PM - NH Fuse PDFAnthonyNoch keine Bewertungen

- 340c-103 Internal Full DrawingDokument11 Seiten340c-103 Internal Full Drawingalhad.maNoch keine Bewertungen

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Dokument1 SeitePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNoch keine Bewertungen

- 100RT-MS Two Stage Clear View: Arts ManualDokument12 Seiten100RT-MS Two Stage Clear View: Arts ManualRonaldo Alves de MedeirosNoch keine Bewertungen

- Ensamble de Oreja de PistonDokument1 SeiteEnsamble de Oreja de PistonRommel CalleNoch keine Bewertungen

- Paf002 V0006 Me DRG 0009 - B - ADokument1 SeitePaf002 V0006 Me DRG 0009 - B - Asareluis2727Noch keine Bewertungen

- Top Power Entry90Mm Dia: Small Enclosure 480V Ip54/N12Dokument1 SeiteTop Power Entry90Mm Dia: Small Enclosure 480V Ip54/N12omarNoch keine Bewertungen

- Elevasi Vibrating ScreenDokument5 SeitenElevasi Vibrating ScreenFaundri GaungNoch keine Bewertungen

- 800 W Beo Stripline Terminations and ResistorsDokument1 Seite800 W Beo Stripline Terminations and ResistorsMarcos MillerNoch keine Bewertungen

- Regal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDokument1 SeiteRegal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANoch keine Bewertungen

- 33 KV Siemens 3005184633 - Sri Hari Construction Ac APTRANSCO - J8555 - 110 - 6xDokument24 Seiten33 KV Siemens 3005184633 - Sri Hari Construction Ac APTRANSCO - J8555 - 110 - 6xveera chaitanyaNoch keine Bewertungen

- Blower CrematoryDokument1 SeiteBlower CrematorySalima DwiNoch keine Bewertungen

- Soporte Pantallas Dyno PreDokument1 SeiteSoporte Pantallas Dyno PreGuillermo Osorio BaezaNoch keine Bewertungen

- Teclock SungshinDokument64 SeitenTeclock Sungshinsomkiat kongprasiatNoch keine Bewertungen

- R4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 SpeedDokument8 SeitenR4A51 / V4A51 / R5A51 / V5A51: RWD 4 & 5 Speedmarran almarranyNoch keine Bewertungen

- New Wellhead 10 PH4589 01 STKUPDokument2 SeitenNew Wellhead 10 PH4589 01 STKUPNguyen Binh PhuongNoch keine Bewertungen

- AAV8790601-00 MergedDokument7 SeitenAAV8790601-00 Mergedengineeringcem99Noch keine Bewertungen

- Control Unit ECUDokument2 SeitenControl Unit ECUjag1961Noch keine Bewertungen

- UGH Drain PipeDokument2 SeitenUGH Drain PipeQuoc LeHoaiNoch keine Bewertungen

- LG 55lw5700-Ue Chassis La12c SCHDokument27 SeitenLG 55lw5700-Ue Chassis La12c SCHGustavoNoch keine Bewertungen

- Configuration Documentation Pneumatic Cylinder: Type Code Material Number DescriptionDokument5 SeitenConfiguration Documentation Pneumatic Cylinder: Type Code Material Number DescriptionHerdyan EkaNoch keine Bewertungen

- Winche LM75 - H400 - 110Dokument12 SeitenWinche LM75 - H400 - 110Macalas Macalupu Ramos100% (1)

- LM 75 - Partes - 4Dokument17 SeitenLM 75 - Partes - 4Raul VergarayNoch keine Bewertungen

- CS3W-395 Panel SolarDokument2 SeitenCS3W-395 Panel SolarGabriel GonzalezNoch keine Bewertungen

- Missing Parts: 1-Bolts x8 2 - Surfase 1mm x2 3 - Helix x3 4-O-Ring x2Dokument3 SeitenMissing Parts: 1-Bolts x8 2 - Surfase 1mm x2 3 - Helix x3 4-O-Ring x2Hamed RajabiNoch keine Bewertungen

- EED LabDokument7 SeitenEED LabVINITA AGARWALNoch keine Bewertungen

- IotDokument6 SeitenIotSathiyaSeelaNoch keine Bewertungen

- Lab 1 RC CircuitsDokument12 SeitenLab 1 RC CircuitsReyson pearsNoch keine Bewertungen

- Navy Training System Plan: For TheDokument237 SeitenNavy Training System Plan: For TheNasr Pooya100% (1)

- A New Lifetime Diagnostic System For Photovoltaic MaterialsDokument5 SeitenA New Lifetime Diagnostic System For Photovoltaic Materialsbib123456789huNoch keine Bewertungen

- Beol - CL 636 (2) (10759)Dokument37 SeitenBeol - CL 636 (2) (10759)shubhamNoch keine Bewertungen

- AE 242 Aerospace Measurements LaboratoryDokument23 SeitenAE 242 Aerospace Measurements LaboratoryAnubhavNoch keine Bewertungen

- Manual QuartusIIDokument73 SeitenManual QuartusIIoperezNoch keine Bewertungen

- Antenna Theory: Chapter 6.1 - 6.2Dokument21 SeitenAntenna Theory: Chapter 6.1 - 6.2RahulMondolNoch keine Bewertungen

- Digital Design With An Introduction To The Verilog HDL VHDL and Systemverilog 6 E Sixth Edition Global Edition Ciletti Full ChapterDokument52 SeitenDigital Design With An Introduction To The Verilog HDL VHDL and Systemverilog 6 E Sixth Edition Global Edition Ciletti Full Chapterflorence.hernandez892100% (3)

- Computer Networks: R. Acedo-Hernández, M. Toril, S. Luna-Ramírez, I. de La Bandera, N. FaourDokument13 SeitenComputer Networks: R. Acedo-Hernández, M. Toril, S. Luna-Ramírez, I. de La Bandera, N. FaourRoland KirNoch keine Bewertungen

- SM-J120H.HZ Galaxy J1 2016Dokument8 SeitenSM-J120H.HZ Galaxy J1 2016New LeoNoch keine Bewertungen

- UntitledDokument258 SeitenUntitledSaanounNoch keine Bewertungen

- Ar Uno Mini Le - en - 10044128Dokument13 SeitenAr Uno Mini Le - en - 10044128nyolczas.aronNoch keine Bewertungen

- 43uj740v - Ud71p PDFDokument63 Seiten43uj740v - Ud71p PDFtaviNoch keine Bewertungen

- Introduction To OpenFlow ProtocolDokument5 SeitenIntroduction To OpenFlow ProtocolAtt SamNoch keine Bewertungen

- Six Functions Serial Module USB TTL 232 485 User ManualDokument6 SeitenSix Functions Serial Module USB TTL 232 485 User ManualElecmasterNoch keine Bewertungen

- Digital Electronics Text Book Info SheetDokument2 SeitenDigital Electronics Text Book Info SheetpasenthNoch keine Bewertungen

- Zealsound USB Microphone, Condenser Mic For PC Phone PS4&5 Tablet, WAdapter For Smartphone, MuteEchoGain, For Studio, ComputeDokument1 SeiteZealsound USB Microphone, Condenser Mic For PC Phone PS4&5 Tablet, WAdapter For Smartphone, MuteEchoGain, For Studio, Computelucasd5412Noch keine Bewertungen

- Prosilica GC DataSheet 650 v2.0Dokument4 SeitenProsilica GC DataSheet 650 v2.0aezixNoch keine Bewertungen

- Metal Detector Circuit ReportDokument4 SeitenMetal Detector Circuit Reportpratik kushwahaNoch keine Bewertungen

- DC 18 RCDokument36 SeitenDC 18 RCPéter Farkas (fpjanos)Noch keine Bewertungen

- WCDMA BTS Alarm Descriptions PDFDokument125 SeitenWCDMA BTS Alarm Descriptions PDFCung LevanNoch keine Bewertungen

- Zwf22!02!051 Atm Over E1Dokument27 SeitenZwf22!02!051 Atm Over E1likameleNoch keine Bewertungen

- LT-493 FA-1025T Installation and Operation ManualDokument22 SeitenLT-493 FA-1025T Installation and Operation ManualpaulNoch keine Bewertungen

- Waveform Digitizers: Digitizer Families Waveform Recording Digital Pulse Processing (DPP) ToolsDokument38 SeitenWaveform Digitizers: Digitizer Families Waveform Recording Digital Pulse Processing (DPP) ToolsScarduelliNoch keine Bewertungen

- Itu-T: Ethernet Service Activation Test MethodologyDokument38 SeitenItu-T: Ethernet Service Activation Test MethodologyJamez STNoch keine Bewertungen