Beruflich Dokumente

Kultur Dokumente

RMD Housing

Hochgeladen von

Dave Joseph CondeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

RMD Housing

Hochgeladen von

Dave Joseph CondeCopyright:

Verfügbare Formate

Mass Housing: RMD

RMD Technology For Mass Housing

(Rapid -Monolithic -Disaster Proof Technology)

A Game changer with case study

G Sreenivasa

General Manager – Business Development

UltraTech Cement Limited

Housing scenario in India What is RMD Technology?

Besides, food and clothing, shelter is a basic human need. The construction in which, all the elements are cast together

India has been successful in meeting the food and clothing with reinforced cement concrete (r c c) by using aluminium

requirements of its vast population; however the problem of form/similar form work, which supports wall, beam, column,

providing shelter of all is defying solutions. “While there has roof slab and other elements together for concreting at single

been an impressive growth in the total housing stock from go. This ensures absolutely no joints (monolithic) between

65 million in 1947 to 187.05 million in 2001, and As estimated the elements with great surface finish, hence highly durable

that, 26 million homes are required by 2012, to meet the large & earthquake resistant. This is nothing but strong concrete

gap still exists between the demand and supply of housing house.

units. The shortage of housing is acutely felt in urban areas

The construction process which involves minimum number

–more so in the 35 Indian cities, which according to the 2001

of activities, such activities can be simultaneously carried

census have a population of more than a million”. ….. (Carol.,

out with less time, exhibits highest quality and brings most

2005).

durable, disaster proof, cost effective buildings.

Trends in Housing Industry

Earlier, The monolithic construction practice limited only

With improve in economy, growth in IT/BT, Retail Business to the dome structures, huge shell roof structures, special

which attract major young unskilled, unemployed youths, architectural buildings, large footings for foundation etc,,

shows least interest in construction jobs where one has to where, the structures has to have no joints, the performance

sweat very hard to earn his wages. With this, huge shortage of and durability was utmost important. Similar practices were

skilled/unskilled labour, construction of quality houses become never used in housing construction rather never specified for

difficult, lead to abnormal delays in completion of projects with monolithic construction in housing by designers may be due

cost overrun. The conventional method of construction in to less advancement in form-work technology and concrete

house building, labour availability & labour cost is going to technology.

be very critical & challenging for Housing industry in coming

RMD Technology –As a Game Changer!

days, considering the Welfare Schemes announced by State/

Central Govts towards improving the quality life of poor people The R M D construction works on following principles:

in India.

- Rapid and best quality construction

Hence, for undertaking mass housing works, it is necessary

- Offer un-surpassed customer satisfaction

to have less labour dependency, innovative technologies with

mechanization, which are capable of fast rate construction and - Competitive price

are able to deliver good quality and durable structure in cost - Affords large degree of controls

effective manner - Change in Trust level between the Govt Agency &

The rapid- monolithic- disaster proof (RMD) construction Beneficiary or Owner & Contractor community by way of

practice is one of the option, to meet above all challenges, and quality, timely completion and at same cost

thus, reduce the labour dependency, improves quality in con- - With motto in mind, “Cost is long forgotten, but Quality is

struction, early delivery of project with budgeted cost. remembered forever” and “House for all”.

168 The Masterbuilder - May 2014 • www.masterbuilder.co.in

Mass Housing: RMD

Importance of RMD Technology in Mass Housing dirty working environment, hard work, poor recognition, less

legitimate wages, over working hours etc.. de-motivates

- Design & Reinforcement

younger generation to join the construction industry, which

- Selection of Shuttering

will compound the labour problems in future.

- Selection of Concrete mixes

- Skills to handle Hence, with the above cited reasons, surely the RMD

- Cycle time or No. of repetitions Technology - A Game Changer in the field of Mass Housing

Constructions

Focus Areas

A Case Study

Speed – By adopting RMD Technology the Houses will be

delivered in record time – 1/4the of conventional time, in real - Project: Cluster of EWS Houses – 350 Nos

time situation, this will be much faster considering labour - Client: Karnataka Housing Board Govt of Karnataka.

issues. By casting all the building elements at one go, - Project Implementing Agency: Rajiv Gandhi Housing

which is monolithic in nature results in elimination of stage Corporation/Karnataka Habitat Centre

construction practice, thus drives RMD Technology in bigger - Technology Support: UltraTech Cement Limited, Unit -

& faster way in mass housing sectors, presently this sector UltraTech Concrete

strive to deliver the houses for urban poor and middle class

due to lack of technology. The timely delivery of houses for Specifications

construction agency, is the challenging one and even more

challenging in future due to scarcity of labour/ skills in coming - E W S House – for Urban Poor

days. Hence, RMD Technology will be the only solution for - Area of Plinth - 285 sft. – Single storey, 1 Hall, 1 Kitchen, 1

successful implementation of mass housing projects. Bed room & 1 Bath cum toilet

- Cost of a House - Rs 2 lacs

Cost – The cost will be same as that of conventional or little

- Technology – RMD Technology adopted

less, if the cycle time maintained as scheduled or planned.

- Grade of Concrete – M20 Dynamic grade for wall & M20

The cost can be reduced by increasing the efficiency of

for Roof & Foundation

manpower by training, upgrading the skills, adopting or using

latest technologies available nearby etc.. - Shuttering – Aluminium shuttering (Mivan or equivalent)

Quality – The houses built with RMD Technology, no where Description of Conventional RMDC (in Re-

Sl No

Works (in days) days) marks

comparable with any quality parameters that of conventional

one, the RMD Technology has its in built controls, by way Excavation for

1 ¼ day ¼ day

of design details, shuttering, reinforcement & concrete (the foundation

materials used), and all the building components casting 2 Foundation 4 3 days

together to become monolithic (no joints), hence earth 3 Plinth 2 Nil

quake resistant, disaster- proof (Tornado’s), highly energy 4 Superstructure 3 3 days

efficient and maintenance free or little maintenance during its

4 +3 =7(Cur-

life period. The houses built with RMD Technology, certainly 5 Lintel & Chajja Nil

ing)

last for longer period than the conventional and asset to the

generations. The RMD Technology will change the perception 4+7

6 Roof concreting Nil

=11(Curing)

of house owners who always feel/ rather true to some extent

that the poor quality prevailed in most of the mass housing 5 +7 =

7 Plastering Nil

projects. 12(Curing)

Electrical &

Labour – The number of items in RMD Technology reduced 8 2 2 days

Plumbing

to minimum, hence less labour force required and this can

be reduced further by adopting more mechanisation, use 9 Flooring 2 2 days

of readymade steel in mass housing project etc.. The acute

shortage of labours, poor skills and cost of labour are the 10 Painting 2 2 days

major issues which contain the speed of the construction

industry. More so, the planning of the large infrastructure 10( labour

11 Miscellaneous 2 days

issues)

projects both by Central & State Govt and Private companies

will create huge shortfall in labour force in coming days. Total 55 days 15 days

Apart, Construction industry has got its own issues (by nature)

related to labour force like zero social security, the unsafe, Speed of Construction of Mass Housing Project at Rajankunte site Bangalore

www.masterbuilder.co.in • The Masterbuilder - May 2014 169

Mass Housing: RMD

Sl No Item (Description of work) Amount(`) Remarks

1 Earth work excavation & refilling 1000 LS

2 Reinforcement for Foundn & Plinth wall 17850 0.35MT @ Rs 51000/MT includes fabrication

3 Concreting for Foundn. & Plinth wall 24000 3 cum @ Rs 4000/cum

4 Reinforcement for Wall & Roof 20400 0.4MT @51000/MT includes fabrication

5 Shuttering for foundn, wall & roof 25000 Consider 200 repetitions & investment

6 Concrete for wall 41850 9 cum @Rs 4650/cum

7 Concrete for roof 12000 3 cum @ Rs 4000/cum

8 Curing compound spray 2000 Wax based

9 Fixing Doors & Windows 8000 2 Nos Flush + 1 No PVC for Bath

10 Electrical fittings 4000 2 Plug points & 4 lighting

11 Sanitary fittings 1200 1 Orissa pan & 1 basin

12 Flooring 8000 C C Flooring – 4’’ thick

13 Whitewashing/Colouring 3000 Snowcem/Whitewash

14 Labour 30000 ` 100/sqmt approx

15 Miscellaneous 2000

Total 2,00,000

Rate/Sqm 702

10% can be reduced 632 By adopting ready made steel & l w concrete

Actual Cost of EWS House with RMD Technology (Concrete House )at Rajanakunte Project - Bangalore

The increase in carpet area in the above case is about 22.35 and more comfortable for the occupants—all qualities that

sft of the total 285 sft. Hence, increase in carpet area will be 7.8% are easily achieved by using concrete.

The above calculation does not includes the additional cost-

benefits such early occupational cost (4-5 months), and saving

in interest cost, resources holding charges (4-5months)etc.. as

in case of conventional construction. The wastage of materials

at site not accounted (3-5%). Also not considered the scrap

value of Aluminium forms after 100 repetition (generally scrap

value is higher compared to steel). Considering above all

cost aspects, by adopting RMD Technology, about 15-20% of

overall cost shall be saved.

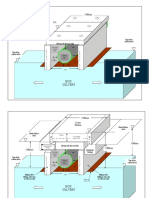

RMD Technology as sustainable Aluminium wall shuttering with reinforcement

Mass Housing involves designing and building a home—on

the inside and out—to maximize performance and conserve

resources. A Concrete home consumes less energy, water

and natural resources; creates less waste; and is healthier

Plinth wall with reinforcement Aluminium Shuttering with roof reinforcement

170 The Masterbuilder - May 2014 • www.masterbuilder.co.in

Mass Housing: RMD

Day 1

Finish of the wall after De-shuttering

Day 2

Cluster of Houses Completed

Case Study: 2

Execution Model House: Location Bankapura – Shigao

– Dharawd Dist.

- Day 1: Marking of foundation, Earth work excavation by

JCB at 4.00 pm

- Day 2: Sand Piling and Sand Bed filling, Steel fabrication

for Foundation & Plinth Beam, Concreting of Foundation

& Plinth Beam, fabrication of reinforcement of steel for wall

& roof

Day 3

- Day 3: Erection of shuttering with reinforcement for wall &

roof and Concreting for wall & roof

- Day 4: De -shuttering of wall & roof, curing compound

application, filling the holes etc..

- Day 5: Doors & Windows fitting, Sanitary & electrical

fittings, Whitewashing/colouring, flooring, finishing

- Day 6: Ready for Opening at 10.30 am morning by Chief

Minister of Karnataka & His Cabinet colleagues and

opened at 2.30 pm by CM & His Cabinet

Take away

With adaptation of RMD Technology, it has been proven

- Perception Change (Reputation): The perception on that the perception has been totally changed. The RMD

quality in mass housing among the public is very poor. Technology brings pride & appreciation to the designer,

172 The Masterbuilder - May 2014 • www.masterbuilder.co.in

Mass Housing: RMD

Day 4 owner, contractor, agencies who associated with the

project by the end users.

- On Speed –At site, 3 day/ 4 day cycle can be easily

achievable and can complete the entire house in a week

time. The Foundation, Wall & Roof components has to be

designed, based on the soil & structural considerations.

All the details of Electrical & Plumbing has to be precise

and shall be placed in position before concreting. The

RMD Technology is widely acceptable, and the fastest

technology available at present, however, the precast

technology is yet to mature enough to replace RMD

Technology in terms of cost, assembly of elements at site,

issues associated with Joints & its sealants etc..

- On Quality- The de-shuttering shall be done for wall & roof

after 24 hours of concreting, by leaving adequate props

to support roof concrete. Hence quality houses are built

at one go. The RMD Technology is the only technology

which can deliver the quality parameters as designed &

targeted without much deviation. The maintenance of

these houses over period will be very less/minimum. In all

other methods, considerable change in design, manual

errors, rectification, repetitions of works etc.. is seen

during the project period and subsequently demands

high maintenance cost.

- On Labour – The requirement of Labour and Skills are very

minimum and hence, the less quality issues, speedier

construction.

- On Technology – The RMD Technology delivers the strong

Day 5 Releasing shuttering & curing

houses which are more durable & sustainable against

tornado’s, earthquakes etc,, compare to any other methods

of construction

- On Cost – The RMD Technology for Mass Housing is

comparable and economical for Mass Housing Projects or

the similar projects are repeated across many locations

/sites

Limitations

- Generally, used in mass housing project with same plan

and the multi-storey structures having same plan area at

Day 6 Finishing & Ready for Inaguration all floors.

- Huge initial investment for formwork procurement- Clients

can invest and issue to contractor

- Large number of repetitions makes this technology cost

–effective.

- About 70-80% of form work elements shall be useful for

new project (new plan)after first project, rest shall be

suitably designed and procured for next projects

- Initial setting of formwork at site (as demo), as per drawing

dimension, may take more time

- The training of labour to handle designed formworks at

www.masterbuilder.co.in • The Masterbuilder - May 2014 173

Mass Housing: RMD

site- however, this would overcome with support of formwork 9. Block/Brick masonry eliminated thus Internal & External

suppliers Plaster eliminated

- All the utilities, has to lay & embedded in concrete walls/slabs, 10. Environmental friendly – no wood/timber used

hence relocation, repair of these will be very difficult 11. Form work -Lightweight section are used –hence easy to

- Since, structure is monolithic and wall thickness is less, lift and used

these houses are little warmer than the conventional 12. Only hammer required to erect – joining by simple pins &

during summer/ sunny days. However, this problem can wedges and horizontal ties

overcome by using Light weight concrete( Foam Concrete) 13. Aluminium shuttering material has higher scrap value

or thermal insulated paint for external wall or by adopting compared to plywood/steel

simple thermal insulation techniques or growing creepers UTCL as Technology supporter - UltraTech Cement Limited

& plants around the external walls. (Unit- UltraTech Concrete) is associated with RGHCL for

Conclusions promotion of RMD Technology in Mass Housing and its

successful implementation. Also, extend the technical support by

Population explosion has always been a bottleneck to the way of training, testing of concrete & other building materials

development for Indian society especially providing housing at site etc..

for economically weaker sections(EWS) and low income

groups is both gigantic and a complex problem. India RGHCL as Housing Implementing Agency - The first & foremost

desperately needs a lot of rapid dwelling units. Mass housing Govt Agency to adopt this RMD technology in Mass Housing

projects with RMDC technique is one of the solutions to the project successfully through their Habitat Centre. Rajiv Gandhi

overgrowing problem. The speed & quality construction drives Housing Corporation Limited (RGHCL) is one of the leading

this technology; Govt agency, which aggressively pursuing the fast-track, new

technologies which are cost effective and highly qualitative-

1. Cost effective – average 15% cost saving for load bearing one in their projects.

wall over conventional timber/plywood shuttering

2. Increased Carpet area/Usable floor space of (5 - 8%) over Thanks to

Conventional Design Mr Mahadeva Prasad Managing Director – RGHCL Govt of

3. Speedy construction - 1/4th - 1/6th of time required to Karnataka Bangalore

complete construction against the conventional Mr S V Patil – Executive President - UltraTech Cement Ltd Bangalore

4. Easy to use, since it’s simplified design Mr Vasudevmurthy Genaral Manager (Technical) – RGHCL Govt

5. Monolithic construction-box type strong structures with of Karnataka Bangalore

minimum/ no joints Special Thanks to - Team UltraTech Concrete Bangalore

6. Structures are better earth quake and wind resistant

Publishers Note: This paper was presented at the Proceedings of the Exhibition-Cum-

7. Highly durable structures – required least maintenance Seminar on Emerging Fast Track Technologies for Mass Housing Held in Chennai, TN

8. Smooth finish of wall/roof/floor- ready to take the paint The Masterbuilder was the official Media Partner for the above event.

174 The Masterbuilder - May 2014 • www.masterbuilder.co.in

Das könnte Ihnen auch gefallen

- A Case StudyDokument3 SeitenA Case StudyJithesh DharmadasNoch keine Bewertungen

- Microsoft Hybrid Cloud Enables Cement DecarbonizationDokument31 SeitenMicrosoft Hybrid Cloud Enables Cement DecarbonizationRizal MuhammadNoch keine Bewertungen

- Growth of Engineering Consultancy Sector India AbroadDokument3 SeitenGrowth of Engineering Consultancy Sector India AbroadDiamond TriNoch keine Bewertungen

- Pre Cast StructureDokument7 SeitenPre Cast StructureRohit TangriNoch keine Bewertungen

- Modern Formwork Systems Speed ConstructionDokument10 SeitenModern Formwork Systems Speed ConstructionvishaliNoch keine Bewertungen

- Low-Cost Housing MethodologiesDokument6 SeitenLow-Cost Housing MethodologiesBasavaraju SNoch keine Bewertungen

- RC ReviewDokument9 SeitenRC ReviewMarco PlebaniNoch keine Bewertungen

- High-Rise PrecastDokument7 SeitenHigh-Rise PrecastAshu JainNoch keine Bewertungen

- 10th_Prefabrication_Modular_Construction_Asia_Summit_2018Dokument72 Seiten10th_Prefabrication_Modular_Construction_Asia_Summit_2018rezaNoch keine Bewertungen

- Prefabrication and Its Adoption in India PDFDokument5 SeitenPrefabrication and Its Adoption in India PDFAbhinav SainiNoch keine Bewertungen

- Prefabrication and Its Adoption in IndiaDokument84 SeitenPrefabrication and Its Adoption in IndiaAtul JaiswalNoch keine Bewertungen

- Adapting BIM For Ffordable Housing in IndiaDokument34 SeitenAdapting BIM For Ffordable Housing in IndiaAshfan SangeNoch keine Bewertungen

- BIM To BIMDokument10 SeitenBIM To BIMcontactoNoch keine Bewertungen

- Sustainable Building Services in Developing CountrDokument8 SeitenSustainable Building Services in Developing CountrMani Preetham ReddyNoch keine Bewertungen

- An Rfi-Free World: Take These Steps To Avoid Round After Round of RfisDokument8 SeitenAn Rfi-Free World: Take These Steps To Avoid Round After Round of RfisekaciptaNoch keine Bewertungen

- Low Cost Housing PDFDokument4 SeitenLow Cost Housing PDFkalimNoch keine Bewertungen

- New Perspectives and Solutions For The Production of 3D Volumetric Precast Concrete ElementsDokument4 SeitenNew Perspectives and Solutions For The Production of 3D Volumetric Precast Concrete ElementsBenjeddou OmraneNoch keine Bewertungen

- Technology Validation: Eco Building Advisory UnitDokument2 SeitenTechnology Validation: Eco Building Advisory UnitSithesh RNoch keine Bewertungen

- Smart BankDokument30 SeitenSmart BankAthiraNoch keine Bewertungen

- President's Desk..... : Advancement in Tunnel TechnologyDokument16 SeitenPresident's Desk..... : Advancement in Tunnel TechnologyAabidNoch keine Bewertungen

- 9 4 Comparative Study and Decision Making For A FormworkDokument5 Seiten9 4 Comparative Study and Decision Making For A Formworknazi nazNoch keine Bewertungen

- 28 Sme Mining Engineering HandbookDokument1 Seite28 Sme Mining Engineering HandbookYeimsNoch keine Bewertungen

- Akram CV Final 2Dokument5 SeitenAkram CV Final 2akram husseinNoch keine Bewertungen

- Buildings 11 00460 v2Dokument36 SeitenBuildings 11 00460 v2Mosalah DiehardfanNoch keine Bewertungen

- Classifications of Construction Works and ContractorsDokument2 SeitenClassifications of Construction Works and ContractorsjudeNoch keine Bewertungen

- Prefabrication Industry - A Solution To GCC's HousingCrisisDokument2 SeitenPrefabrication Industry - A Solution To GCC's HousingCrisisSharique AnwarNoch keine Bewertungen

- Design and Analysis of Low Cost Multi Stored Building Using Staad ProDokument131 SeitenDesign and Analysis of Low Cost Multi Stored Building Using Staad ProShaik ZuberNoch keine Bewertungen

- _2024.03__AMODA_Product_CatalogueDokument36 Seiten_2024.03__AMODA_Product_Catalogueyogpratama25Noch keine Bewertungen

- AITECH-Accredited Technology Nov. 2019Dokument12 SeitenAITECH-Accredited Technology Nov. 2019Jesus Villaflor Jr.100% (1)

- 05 BG Shirk e ConstructionDokument46 Seiten05 BG Shirk e ConstructionganeshNoch keine Bewertungen

- Quantity Surveying and BillingDokument10 SeitenQuantity Surveying and BillingSayed DanishNoch keine Bewertungen

- PEB Article Engineered To SucceedDokument5 SeitenPEB Article Engineered To SucceedBennoDsouzaNoch keine Bewertungen

- Cost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajDokument32 SeitenCost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajAditya VermaNoch keine Bewertungen

- Modern Brick Construction Third Edition 1Dokument23 SeitenModern Brick Construction Third Edition 1rubarema robertNoch keine Bewertungen

- Mivan ShutteringDokument4 SeitenMivan ShutteringWanda BeasleyNoch keine Bewertungen

- Vivekanandha College of Engineering For Women: Elayampalayam, Thiruchengode-637205Dokument14 SeitenVivekanandha College of Engineering For Women: Elayampalayam, Thiruchengode-637205azharamaNoch keine Bewertungen

- Technologies of BeDokument19 SeitenTechnologies of BePooja ThakurNoch keine Bewertungen

- Today's Plan: N C State University Department of Civil, Construction, and Environmental EngineeringDokument43 SeitenToday's Plan: N C State University Department of Civil, Construction, and Environmental EngineeringMaile DuffyNoch keine Bewertungen

- Confront The RFI Problem: Addressing The Information GapDokument6 SeitenConfront The RFI Problem: Addressing The Information GapekaciptaNoch keine Bewertungen

- HOMM E-BrochureDokument54 SeitenHOMM E-BrochureAmitabh RanjanNoch keine Bewertungen

- Module 1 - Presentation 3Dokument78 SeitenModule 1 - Presentation 3Karthik UNoch keine Bewertungen

- Week 8 Housing ReviewerDokument7 SeitenWeek 8 Housing ReviewerSebastian CincoNoch keine Bewertungen

- Central GEO Part 1 - v3 PDFDokument3 SeitenCentral GEO Part 1 - v3 PDFodri5Noch keine Bewertungen

- Praveen Kumar's CVDokument5 SeitenPraveen Kumar's CVNijandhan HNoch keine Bewertungen

- Ibrahim Abdelhamid - CVDokument4 SeitenIbrahim Abdelhamid - CVIbrahim EldesoukyNoch keine Bewertungen

- Chapter 1 - Intro To CTDokument38 SeitenChapter 1 - Intro To CTKhairi AzharNoch keine Bewertungen

- Precast IFCDokument42 SeitenPrecast IFCar_raghvendra4151Noch keine Bewertungen

- Modulus Housing Business Problem: What Does Prefabrication Construction Mean?Dokument3 SeitenModulus Housing Business Problem: What Does Prefabrication Construction Mean?ShefaliNoch keine Bewertungen

- BPAS Edition 9Dokument5 SeitenBPAS Edition 9tony.slash.pageNoch keine Bewertungen

- Cast in Situ Vs Pre CastDokument4 SeitenCast in Situ Vs Pre CastShubham SinghNoch keine Bewertungen

- BESSDokument17 SeitenBESSChirag JainNoch keine Bewertungen

- Tailings Report 2022Dokument18 SeitenTailings Report 2022Leandro OliveiraNoch keine Bewertungen

- CHAPTER-1 HIGHLIGHTSDokument41 SeitenCHAPTER-1 HIGHLIGHTSSOMSUBHRA SINGHA82% (11)

- ConstrctionDokument3 SeitenConstrctiondonna benitoNoch keine Bewertungen

- Bryden Wood UKDokument21 SeitenBryden Wood UKwkchanxxNoch keine Bewertungen

- Why, What and How Should/could It Be ChangedDokument5 SeitenWhy, What and How Should/could It Be ChangedBrhane GadiyonNoch keine Bewertungen

- Housing for All: Tunnel Form Construction TechniquesDokument38 SeitenHousing for All: Tunnel Form Construction TechniquesApurva SrivastavaNoch keine Bewertungen

- Comparative Analysis of Conventional Formwork and Mivan Formwork Based On Duration and CostDokument5 SeitenComparative Analysis of Conventional Formwork and Mivan Formwork Based On Duration and CostJulianne RamonedaNoch keine Bewertungen

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresVon EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNoch keine Bewertungen

- Santa Monica, CaliforniaDokument20 SeitenSanta Monica, CaliforniaPrajwal PrakashNoch keine Bewertungen

- Planilla 2Dokument88 SeitenPlanilla 2Christian Marcelo Moyano TobarNoch keine Bewertungen

- Post - Tensioning in BridgesDokument52 SeitenPost - Tensioning in BridgesVicky Faras Barunson Panggabean0% (1)

- Master List RevisionDokument56 SeitenMaster List RevisionSumedh KulkarniNoch keine Bewertungen

- ITEMDokument2 SeitenITEMArdie DomingoNoch keine Bewertungen

- Interiors Analysis - Restaurant Interior AnalysisDokument47 SeitenInteriors Analysis - Restaurant Interior AnalysisPinkElla DecorNoch keine Bewertungen

- 1 Ce131-1 Introduction To Structural AnalysisDokument17 Seiten1 Ce131-1 Introduction To Structural AnalysisIan Trinidad100% (1)

- ALE June 2017 Utilities Systems Structural Conceptualization Building MateriDokument26 SeitenALE June 2017 Utilities Systems Structural Conceptualization Building MateriShav T GilfilanNoch keine Bewertungen

- Presentation Rumah KedahDokument36 SeitenPresentation Rumah KedahsyafikalzahraqiNoch keine Bewertungen

- By Karuneshwar Jha Lovely Professional University, G.T. Road, Phagwara (144401), PunjabDokument6 SeitenBy Karuneshwar Jha Lovely Professional University, G.T. Road, Phagwara (144401), PunjabKaruneshwar JhaNoch keine Bewertungen

- Two-Storey ResidenceDokument3 SeitenTwo-Storey ResidenceIvory Leigh Suguitan AntoniNoch keine Bewertungen

- Lv3 Supports List Rev0Dokument9 SeitenLv3 Supports List Rev0euric82Noch keine Bewertungen

- Interior construction drawings for Dillibazar projectDokument15 SeitenInterior construction drawings for Dillibazar projectSaurav ShresthaNoch keine Bewertungen

- Stegbar Aluminium Technical Manual PDFDokument117 SeitenStegbar Aluminium Technical Manual PDFNavin JollyNoch keine Bewertungen

- Plot Area For Psychiatric HospitalDokument12 SeitenPlot Area For Psychiatric HospitalEsayase AsnakeNoch keine Bewertungen

- Lgu Masinloc Ihcs HSDCDokument11 SeitenLgu Masinloc Ihcs HSDCMalson GutierrezNoch keine Bewertungen

- Design IBSTOCK BRICK 150dpi PDFDokument48 SeitenDesign IBSTOCK BRICK 150dpi PDFrnastaseNoch keine Bewertungen

- Settlement Reducing Piles in Piled Basements and ShaftsDokument3 SeitenSettlement Reducing Piles in Piled Basements and ShaftsNaveen BansalNoch keine Bewertungen

- Drawing 3 New-ModelDokument1 SeiteDrawing 3 New-Modelk.k.baminiNoch keine Bewertungen

- Timber DesignDokument13 SeitenTimber DesignRoseanne Loguinsa OleaNoch keine Bewertungen

- Flat SlabsDokument12 SeitenFlat SlabsNani Tirumalasetti100% (2)

- Brick Masonry Work: Masonry Work For FT Masonry Work For MeterDokument5 SeitenBrick Masonry Work: Masonry Work For FT Masonry Work For MeterRauf BeşerNoch keine Bewertungen

- Box Culvert Overcross SketchDokument5 SeitenBox Culvert Overcross SketchAnghel CastilloNoch keine Bewertungen

- RR Rate Analysis 2Dokument1 SeiteRR Rate Analysis 2ansar700Noch keine Bewertungen

- Shell Structures-13-4-20Dokument19 SeitenShell Structures-13-4-20sanket pawarNoch keine Bewertungen

- Floor Slab LIFTDokument3 SeitenFloor Slab LIFTV.m. RajanNoch keine Bewertungen

- Detailed Bill of QuantitiesDokument14 SeitenDetailed Bill of Quantitieslenah_22Noch keine Bewertungen

- Multimatic - Crtezi-Klizna Staklena-VrataDokument6 SeitenMultimatic - Crtezi-Klizna Staklena-VrataJelena GraovčevićNoch keine Bewertungen

- Composite Design: 11.1 General RemarksDokument7 SeitenComposite Design: 11.1 General Remarkssultan1046Noch keine Bewertungen

- IStrucE Detailing Manual BS8110Dokument1 SeiteIStrucE Detailing Manual BS8110Thoong Yew Chan0% (1)