Beruflich Dokumente

Kultur Dokumente

24abs3 1W PDF

Hochgeladen von

Nawab AnsariOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

24abs3 1W PDF

Hochgeladen von

Nawab AnsariCopyright:

Verfügbare Formate

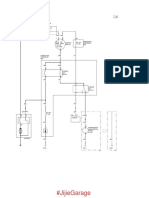

24ABS3

Baset Series Air Conditioner with Puronr

1---1/2 To 5 Nominal Tons

Wiring Diagrams

BLU CAP BLU

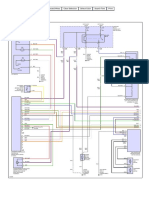

CONNECTION SCHEMATIC DIAGRAM (LADDER FORM)

BRN YEL *ST +t

DIAGRAM 2 1 *SC

H YEL L1 L2

COMP

*SR CONT R

(NOTE #8) 5 C

C

BLU 11 21

BLK F COMP

*CHS S

*CH C S

BLK BLK 5 2 *ST

or BLK BLK R *SC

RED EQUIP +t

(NOTE #9) YEL GND 1

RED or BLK YEL H

CONT CONT

*SR

L1 *CHS OFM

11 21 BRN C 23 23

208/230 1Ø L2 OFM

POWER 23 23 *CH F

BLK CAP

SUPPLY (NOTE #14)

EQUIP GND CONT

YEL

*HPS *DTS *LPS

(NOTE #14) BRN/YEL T2

YEL/ BLU BLK LOGIC

VIO

*CTD T1 T3

*LPS *DTS *HPS T2 *LLS * CTD

YEL YEL BLK BLK BLU BLU LOGIC

T1 T3 Y IFR

*LLS BRN/YEL G

EXTERNAL

BLK BLK POWER R C

C R

YEL/ BLU SUPPLY

R 24 V INDOOR

THERMOSTAT EXTERNAL POWER SUPPLY 24 V

(NOTE #3)

LEGEND

Y G R

INDOOR THERMOSTAT (NOTE #6) INDOOR BLOWER MOTOR

FACTORY POWER WIRING

FACTORY CONTROL WIRING

CONDENSING UNIT CHARGING INSTRUCTIONS FIELD CONTROL WIRING

For use with units using R-22 refrigerant FIELD POWER WIRING

REQUIRED LIQUID LINE TEMPERATURE COOLING ONLY COMPONENT CONNECTION

Liquid (PSIG) Required Subcooling CHARGING PROCEDURE FIELD SPLICE

Pressure 1. Only use sub cooling charging method when OD JUNCTION

at Service Temperature (ºF) ambient is greater than 70ºF and less than 100ºF, PLUG RECEPTACLE

Valve 5 10 15 20 indoor temp is greater than 70ºF and less than CONT CONTACTOR

163 83 78 73 68 80ºF, and line set is less than 80 ft.

2. Operate unit a minimum of 15 minutes before CAP CAPACITOR (DUAL RUN)

171 86 81 76 71

checking the charge. *CH CRANKCASE HEATER

179 89 84 79 74

3. Measure liquid service valve pressure by attaching *CHS CRANKCASE HEATER SWITCH

187 92 87 82 77 an accurate gauge to the service port.

196 95 90 85 80 4. Measure the liquid line temperature by COMP COMPRESSOR

205 98 93 88 83 attaching an accurate thermistor type or *CTD COMPRESSOR TIME DELAY

101 96 91 86 electronic thermometer to the liquid line *DTS DISCHARGE TEMP SWITCH

214

near the outdoor coil.

223 104 99 94 89 *HPS HIGH PRESSURE SWITCH

5. Refer to unit rating plate for required

233 107 102 97 92 subcooling temperature. IFR INDOOR FAN RELAY

243 110 105 100 95 6. Find the point where the required subcooling *LLS LIQ LINE SOLENOID VALVE

temperature intersects the measured liquid LOW PRESSURE SWITCH

253 113 108 103 98 *LPS

service valve pressure.

264 116 111 106 101 7. To obtain the required subcooling temperature OFM OUTDOOR FAN MOTOR

274 119 114 109 104 at specific liquid line pressure, add refrigerant *SC START CAPICATOR

if liquid line temperature is higher than indicated. *SR START RELAY

285 122 117 112 107 When adding refrigerant, charge in liquid form

using a flow restricting device into suction *ST START THERMISTOR

297 125 120 115 110

service port. Recover refrigerant if temperature

309 128 123 118 113 is lower. Allow a tolerance of +/- 3ºF.

* MAY BE FACTORY INSTALLED

NOTES:

1. Symbols are electrical representation only.

CAUTION

2. Compressor and fan motor furnished with inherent thermal protection. 1. Compressor damage may occur if system is over charged.

3. To be wired in accordance with National Electric N.E.C. and local codes. 2. This unit is factory charged with R-22 in accordance with

4. N.E.C. class 2, 24 V circuit, min. 40 VA required, 60 VA on units installed with LLS. the amount shown on the rating plate. The charge is

5. Use copper conductors only. Use conductors suitable for at least 75ºC (167ºF).

6. Connection for typical cooling only thermostat. For other arrangements see installation adequate for most systems using matched coils and tubing

instructions. not over 15 feet long. Check refrigerant charge for maximum

7. If indoor section has a transformer with a grounded secondary, connect the grounded efficiency. See Product Data Literature for required Indoor

side to the BRN/YEL lead.

8. When start relay and start capacitor are installed, start thermistor is not used. air Flow Rates and for use of line lengths over 15 feet.

9. CH not used on all units. 3. Relieve pressure and recover all refrigerant before system

10. If any of the original wire, as supplied must be replaced, use the same or equivalent wire. repair or final disposal. Use all service ports and open all

11. Check all electrical connections inside control box for tightness.

12. Do not attempt to operate unit until service valves have been opened. flow-control devices, including solenoid valves.

13. Do not rapid cycle compressor. Compressor must be off 3 minutes to allow pressures to 4. Never vent refrigerant to atmosphere. Use approved

equalize between high and low side before starting. recovery equipment.

14. Wire not present if HPS, LPS or CTD are used. 330361-101 REV. F

Fig. 1 – Wiring Diagram — Model sizes 1--1/2 -- 5 tons, 208/230--1

CONNECTION DIAGRAM SCHEMATIC DIAGRAM (LADDER FORM)

*CHS * CH L1 L2 L3

RED or BLK BLK

PRM L2

L2 RED or BLK L3 L1

208/23 0 3Ø BLU

CONT COMP

OR L1 T1 T2

11 21 BLK

460 3Ø

L3 T3

POWER 13 23 CONT T2

CAP EQUIP T1

SUPPLY YEL 11 21 COMP

YEL GND

T3

EQUIP GND OFM CAP CONT

BRN

BLK 23 13

YEL BLK

*CHS

BLU OFM

PRM *CH

YEL

BLU PRM

L1 L3 L2

CONT 24V COM

CONT 24 COM

BLK

BRN/YEL BRN/YEL

*LPS *HPS

VIO T2 CONT

YEL/BLU

LOGIC

T1 T3

*LPS *HPS * CTD *LLS * CTD

T2

YEL YEL BLU BLU LOGIC Y

T1 T3

IFR

G

BRN/YEL

R C

*LLS R

EXTERNAL INDOOR

BLK BLK THERMOSTAT EXTERNAL POWER SUPPLY 24 V

POWER

C

R SUPPLY

IFR LEGEND NOTES:

24 V

(NOTE #3)

NOTE 1. Symbols are electrical

PRM LED INDICATOR FACTORY POWER WIRING

representation only.

Y G R OFF: NO 24VAC FACTORY CONTROL WIRING

2. Compressor and fan motor

ON: OK furnished with inherent

INDOOR THERMOSTAT (NOTE #6) INDOOR BLOWER MOTOR FLASH: PHASE PROBLEM FIELD CONTROL WIRING

thermal protection.

FIELD POWER WIRING

3. To be wired in accordance

CONDENSING UNIT CHARGING INSTRUCTIONS with National Electric

COMPONENT CONNECTION

N.E.C. and local codes.

For use with units using R-22 refrigerant FIELD SPLICE

4. N.E.C. class 2, 24 V circuit,

min. 40 VA required,

JUNCTION

REQUIRED LIQUID LINE TEMPERATURE COOLING ONLY CHARGING 60 VA on units installed

CONT CONTACTOR with LLS.

Liquid (PSIG) Required Subcooling PROCEDURE 5. Use copper conductors

Pressure CAP CAPACITOR (DUAL RUN) only. Use conductors

Temperature (ºF) 1. Only use sub cooling charging method suitable for at least

at Service when OD ambient is greater than 70ºF *CH CRANKCASE HEATER 75ºC (167ºF).

Valve 5 10 15 20

and less than 100ºF, indoor temp is *CHS CRANKCASE HEATER SWITCH 6. Connection for typical

cooling only thermostat.

greater than 70ºF and less than 80ºF, COMP COMPRESSOR For other arrangements

163 83 78 73 68 see installation instructions.

and line set is less than 80 ft. *CTD COMPRESSOR TIME DELAY 7. If indoor section has a

171 86 81 76 71 2. Operate unit a minimum of 15 minutes

*HPS HIGH PRESSURE SWITCH transformer with a

179 89 84 79 74 before checking the charge. grounded secondary,

IFR INDOOR FAN RELAY connect the grounded

187 92 87 82 77 3. Measure liquid service valve pressure by side to the BRN/YEL lead.

*LLS LIQ LINE SOLENOID VALVE

196 95 90 85 80 attaching an accurate gauge to the 8. If any of the original wire,

service port. *LPS LOW PRESSURE SWITCH as supplied must be

205 98 93 88 83 replaced, use the same or

4. Measure the liquid line temperature by OFM OUTDOOR FAN MOTOR equivalent wire.

214 101 96 91 86 attaching an accurate thermistor type or PRM PHASE ROTATION MONITOR 9. Check all electrical

connections inside control

223 104 99 94 89 electronic thermometer to the liquid line * MAY BE FACTORY INSTALLED box for tightness.

92 near the outdoor coil. 10. Do not attempt to operate

233 107 102 97

95 5. Refer to unit rating plate for required

CAUTION

unit service valves have

been opened.

243 110 105 100 1. Compressor damage may occur if system is 11. Do not rapid cycle

subcooling temperature.

253 113 108 103 98 6. Find the point where the required over charged. compressor.

2. This unit is factory charged with R-22 in Compressor must be off

264 116 111 106 101 subcooling temperature intersects the 3 minutes to allow

accordance with the amount shown on the

274 119 114 109 104 measured liquid service valve pressure. pressures to equalize

rating plate. The charge is adequate for most between high and low

285 122 117 112 107 7. To obtain the required subcooling systems using matched coils and tubing not side before starting.

temperature at specific liquid line over 15 feet long. Check refrigerant charge 12. It is imperative to connect

297 125 120 115 110 for maximum efficiency. See Product Data 3Ø field power to unit with

pressure, add refrigerant if liquid line correct phasing. The

309 128 123 118 113 temperature is higher than indicated.

Literature for required Indoor air Flow Rates

Phase Rotation Monitor

and for use of line lengths over 15 feet. will not allow the contactor

When adding refrigerant, charge in liquid 3. Relieve pressure and recover all refrigerant

to be energized if the

form using a flow restricting device into before system repair or final disposal. Use all phasing is not correct. If

suction service port. Recover refrigerant service ports and open all flow-control phasing is reversed,

devices, including solenoid valves. simply inter change any

if temperature is lower. Allow a two of the three power

4. Never vent refrigerant to atmosphere. Use

330757-101 REV.C tolerance of +/- 3ºF. connections on field side.

approved recovery equipment.

Fig. 2 – Wiring Diagram — Model sizes 2--1/2 -- 5 tons, 208/230--3 and Model sizes 3 -- 5 tons, 460--3

Copyright 2009 Carrier Corp. S 7310 W. Morris St. S Indianapolis, IN 46231 Printed in U.S.A. Edition Date: 09/09 Catalog No: 24ABS3---1W

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations. Replaces: New

Das könnte Ihnen auch gefallen

- Wiring Diagrams: PA16NADokument2 SeitenWiring Diagrams: PA16NAMarlou RabinaNoch keine Bewertungen

- RS6 FuelInjection ComponentLayoutDokument15 SeitenRS6 FuelInjection ComponentLayoutgrushe100% (1)

- Gefran GTF ManualDokument37 SeitenGefran GTF ManualLavanyaNoch keine Bewertungen

- Writenow! Isp Programmer Device List: Updated October 2018Dokument59 SeitenWritenow! Isp Programmer Device List: Updated October 2018Djams HamsNoch keine Bewertungen

- Pioneer DEH546Dokument77 SeitenPioneer DEH546Alessandro SilvaNoch keine Bewertungen

- ECU SID 901 IESA Stand Alone (PPC 462 100 Xyz) : Common Rail Schematic Wiring Harness - Siemens VdoDokument1 SeiteECU SID 901 IESA Stand Alone (PPC 462 100 Xyz) : Common Rail Schematic Wiring Harness - Siemens VdoEurico MesquitaNoch keine Bewertungen

- Electronic Component Identification ListDokument4 SeitenElectronic Component Identification ListPedro Almeida JuniorNoch keine Bewertungen

- lcsv05 enDokument10 Seitenlcsv05 enAlessandro MacenaNoch keine Bewertungen

- ECT and A/T Indicator Engine Control GuideDokument13 SeitenECT and A/T Indicator Engine Control GuideSeptianNoch keine Bewertungen

- Samsung GT I8190 PDFDokument43 SeitenSamsung GT I8190 PDFvictor guerraNoch keine Bewertungen

- Esquema Elétrico Da Injeção Eletrônica Chevrolet Onix LTZ 1.4 8VDokument32 SeitenEsquema Elétrico Da Injeção Eletrônica Chevrolet Onix LTZ 1.4 8VmarlonNoch keine Bewertungen

- Sistema Manual 1 de 2Dokument2 SeitenSistema Manual 1 de 2julian colinaNoch keine Bewertungen

- Speeduino Manual Setup GuideDokument134 SeitenSpeeduino Manual Setup GuideLuciano Silvestre TavaresNoch keine Bewertungen

- Marca Modelo ANO Injeção Código Tipo Eprom #Eprom Classe Checksum ArquivoDokument9 SeitenMarca Modelo ANO Injeção Código Tipo Eprom #Eprom Classe Checksum ArquivoRosivaldo da Silva SantosNoch keine Bewertungen

- Toyota Hilux 2018 Overall EWD Engine - Hybrid System Stop - Start SystemDokument3 SeitenToyota Hilux 2018 Overall EWD Engine - Hybrid System Stop - Start Systemgabrielzinho43100% (1)

- Operation Manual: Suntech International LTDDokument66 SeitenOperation Manual: Suntech International LTDoriana cardenasNoch keine Bewertungen

- SC15ADokument2 SeitenSC15Asugeda100% (1)

- Status: User ManualDokument95 SeitenStatus: User ManualGladyz Rivera100% (1)

- Vegas Sklkbl-U 17841-1 Rev A00Dokument72 SeitenVegas Sklkbl-U 17841-1 Rev A00Vefa ÖzdemirNoch keine Bewertungen

- 06 02 00 1FT PDFDokument2 Seiten06 02 00 1FT PDFRam MugeshNoch keine Bewertungen

- 08-CHERY - Tips Inmobilizador.Dokument24 Seiten08-CHERY - Tips Inmobilizador.Santiago Henao VillegasNoch keine Bewertungen

- Motores GM, SAIDokument54 SeitenMotores GM, SAIRonCarNoch keine Bewertungen

- Esquema EletricoDokument24 SeitenEsquema EletricoMilton Pereira da SilvaNoch keine Bewertungen

- Cb250fa-2016 2017Dokument278 SeitenCb250fa-2016 2017Repuestos VitacuraNoch keine Bewertungen

- Modulo Taramp T400 X4Dokument3 SeitenModulo Taramp T400 X4az31t0n4Noch keine Bewertungen

- Samsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualDokument51 SeitenSamsung LCD Monitor 2032BW 2232BW 2232GW Plus Parts and Service ManualroldskiNoch keine Bewertungen

- Opel KadettDokument15 SeitenOpel KadettRoberto Ortega MicalizziNoch keine Bewertungen

- Maintenance Schedule and Parts for D232 EngineDokument21 SeitenMaintenance Schedule and Parts for D232 EngineDP100% (1)

- Keeway Wiring DiagramDokument1 SeiteKeeway Wiring DiagramDave AndersonNoch keine Bewertungen

- Captiva 2010 - Direção Elétrica - Diagrama ElétricoDokument1 SeiteCaptiva 2010 - Direção Elétrica - Diagrama ElétricoWiterMarcosNoch keine Bewertungen

- Esquema Eletrico Aca 280 BlackDokument1 SeiteEsquema Eletrico Aca 280 BlackEletrônica Prime0% (1)

- Design Max: 2A DC power supply input boardDokument16 SeitenDesign Max: 2A DC power supply input boardyhyzhjNoch keine Bewertungen

- Prener LC PDFDokument3 SeitenPrener LC PDFAnonymous O1xkZINNoch keine Bewertungen

- Projeto Mini Torno de BancadaDokument71 SeitenProjeto Mini Torno de BancadaMega MonstruoNoch keine Bewertungen

- Honda Civic 2015 LX PartsDokument19 SeitenHonda Civic 2015 LX PartsvbhardNoch keine Bewertungen

- 2004 Cerato-G 1.6-DohcDokument6 Seiten2004 Cerato-G 1.6-DohcHenry alberto Castaño borjasNoch keine Bewertungen

- Diagrama de EPB Hyundai Azera 2012Dokument2 SeitenDiagrama de EPB Hyundai Azera 2012Jairo GodoyNoch keine Bewertungen

- ASIA MOTORS MODEL INDEX AND CAMSHAFT REPLACEMENT TIPSDokument4 SeitenASIA MOTORS MODEL INDEX AND CAMSHAFT REPLACEMENT TIPScorrales_86Noch keine Bewertungen

- Diagrama Electro R 1200 GsDokument11 SeitenDiagrama Electro R 1200 GsFelipe Tudela DfgNoch keine Bewertungen

- Schematis HP V3000 DV2000 IntelDokument47 SeitenSchematis HP V3000 DV2000 Intelmadoo0% (2)

- Bianchi Vending Group - Spare Parts Catalog:: Bv931Es03Na - BVM 931 E 5S MC PD M/SDokument69 SeitenBianchi Vending Group - Spare Parts Catalog:: Bv931Es03Na - BVM 931 E 5S MC PD M/SanbrkNoch keine Bewertungen

- Service Manual: CDX-FM677Dokument63 SeitenService Manual: CDX-FM677Edgar SosaNoch keine Bewertungen

- Prospek Reklamowy MAN - TGX - 2016 - de PDFDokument29 SeitenProspek Reklamowy MAN - TGX - 2016 - de PDFDar100% (1)

- UPS700 657Dokument6 SeitenUPS700 657Marcio Antonio MachadoNoch keine Bewertungen

- 1997 Volkswagen Golf Wiring DiagramsDokument44 Seiten1997 Volkswagen Golf Wiring Diagramsemerson frankNoch keine Bewertungen

- 2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Dokument25 Seiten2005 Seadoo Rotax 1503 4 Tech Shop Manual - 26 50Oscar Eduardo GomezNoch keine Bewertungen

- TAD1242GEDokument191 SeitenTAD1242GEkhaled fathy100% (2)

- Shiriko-Fitting Locations FusesDokument48 SeitenShiriko-Fitting Locations FusesDardan HusiNoch keine Bewertungen

- Xt1100-2a-Eec-Standard Einzelteile Kunstoff OrangeDokument21 SeitenXt1100-2a-Eec-Standard Einzelteile Kunstoff Orangeapi-26422514Noch keine Bewertungen

- SONY Cdxgt35u STÉREO CON CD PDFDokument38 SeitenSONY Cdxgt35u STÉREO CON CD PDFEnrique MontenegroNoch keine Bewertungen

- Catalogo Motor UkDokument26 SeitenCatalogo Motor UkLeopoldo WilleNoch keine Bewertungen

- 16 Su Brazil-Kd WMDokument88 Seiten16 Su Brazil-Kd WMGustavo Sostenes Rodrigues Nunes100% (1)

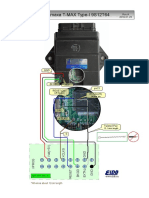

- Yamaxa T-MAX Type-I 9S12T64: Rev.A 2016.01.29Dokument1 SeiteYamaxa T-MAX Type-I 9S12T64: Rev.A 2016.01.29cairo carNoch keine Bewertungen

- Qdoc - Tips - Atsg GM 6t30 40 45 50Dokument1 SeiteQdoc - Tips - Atsg GM 6t30 40 45 50Luzia RamosNoch keine Bewertungen

- 24acb7 1w PDFDokument2 Seiten24acb7 1w PDFelekossNoch keine Bewertungen

- Wiring Diagrams - CarrierDokument2 SeitenWiring Diagrams - CarrierMinh nhut LưuNoch keine Bewertungen

- Starting System Circuit Diagram Except '18-21 L12B4, M/TDokument2 SeitenStarting System Circuit Diagram Except '18-21 L12B4, M/TTomyNoch keine Bewertungen

- Jazz GK5 Starting System Circuit Diagram Build-In Type MICUDokument1 SeiteJazz GK5 Starting System Circuit Diagram Build-In Type MICUTomyNoch keine Bewertungen

- Jazz GK5 Charging System Circuit Diagram Build-In Type MICUDokument1 SeiteJazz GK5 Charging System Circuit Diagram Build-In Type MICUTomyNoch keine Bewertungen

- Open B70 1DC Istruzioni IS117 Rev13-En PDFDokument56 SeitenOpen B70 1DC Istruzioni IS117 Rev13-En PDFivoivan99Noch keine Bewertungen

- HVAC ListDokument3 SeitenHVAC ListNawab AnsariNoch keine Bewertungen

- VRF Systems PDFDokument11 SeitenVRF Systems PDFhonismeNoch keine Bewertungen

- Fridge Parts GuideDokument10 SeitenFridge Parts GuideNawab Ansari100% (1)

- 9091ddf1 LargeDokument1 Seite9091ddf1 LargeNawab AnsariNoch keine Bewertungen

- HVAC Interview Q&ADokument4 SeitenHVAC Interview Q&ANawab AnsariNoch keine Bewertungen

- VFDDokument1 SeiteVFDNawab AnsariNoch keine Bewertungen

- Img 20191206 162148Dokument3 SeitenImg 20191206 162148Nawab AnsariNoch keine Bewertungen

- Capacitor Use Relay 1024x575Dokument1 SeiteCapacitor Use Relay 1024x575Nawab AnsariNoch keine Bewertungen

- Wiring Diagram of AcDokument2 SeitenWiring Diagram of AcNawab AnsariNoch keine Bewertungen

- Just Do Focus On That What Do You Wanna To Do ?Dokument1 SeiteJust Do Focus On That What Do You Wanna To Do ?Nawab AnsariNoch keine Bewertungen

- 356 System Diagnostics and Troubleshooting ProceduresDokument2 Seiten356 System Diagnostics and Troubleshooting ProceduresNawab AnsariNoch keine Bewertungen

- Hvac NotesDokument1 SeiteHvac NotesNawab AnsariNoch keine Bewertungen

- Refrigeration a-WPS OfficeDokument1 SeiteRefrigeration a-WPS OfficeNawab AnsariNoch keine Bewertungen

- Hvac NotesDokument1 SeiteHvac NotesNawab AnsariNoch keine Bewertungen

- Hvac NotesDokument1 SeiteHvac NotesNawab AnsariNoch keine Bewertungen

- 10 B Plas List PPR Eng GreenDokument15 Seiten10 B Plas List PPR Eng GreenZakaria ChouliNoch keine Bewertungen

- Stroke RecoveryDokument20 SeitenStroke RecoveryVanessa SnowNoch keine Bewertungen

- A.686 (17) Cod AlarmeDokument39 SeitenA.686 (17) Cod Alarmeciocioi iancuNoch keine Bewertungen

- Pidato Bahasa InggrisDokument4 SeitenPidato Bahasa InggrisAriya Manikmaya100% (1)

- Análisis de Estabilidad de TaludesDokument4 SeitenAnálisis de Estabilidad de TaludesJosue Acosta EspinozaNoch keine Bewertungen

- Pyrogen and Endotoxins GuideDokument13 SeitenPyrogen and Endotoxins GuideAnil Kumar GuptaNoch keine Bewertungen

- Changes in Demand and Supply of Face Masks Under CovidDokument3 SeitenChanges in Demand and Supply of Face Masks Under CovidHanh HoangNoch keine Bewertungen

- Magnum 3416 SC: Product InformationDokument2 SeitenMagnum 3416 SC: Product InformationDridi BadredineNoch keine Bewertungen

- Quality and Functionality of Excipients-Art (Alumnos-S) PDFDokument14 SeitenQuality and Functionality of Excipients-Art (Alumnos-S) PDFLaura PerezNoch keine Bewertungen

- Spring Creek Sun August 27Dokument24 SeitenSpring Creek Sun August 27amoses88Noch keine Bewertungen

- Report On Baby Food Industry in BangladeshDokument5 SeitenReport On Baby Food Industry in BangladeshIffatur RahmanNoch keine Bewertungen

- ApiDokument4 SeitenApiMahmoud Alwasif100% (1)

- 29 TM5 Kireina Akhlak AnnisaDokument30 Seiten29 TM5 Kireina Akhlak AnnisaTamaraNoch keine Bewertungen

- Caffeine's Effect on Daphnia Heart RateDokument2 SeitenCaffeine's Effect on Daphnia Heart RateMianto NamikazeNoch keine Bewertungen

- Schedule Examination 2010 2011Dokument5 SeitenSchedule Examination 2010 2011pawan15588rediffmailNoch keine Bewertungen

- FAT Form Winch UnitDokument7 SeitenFAT Form Winch UnitYadi KusmayadiNoch keine Bewertungen

- R02.4 Standard III (A) - AnswersDokument11 SeitenR02.4 Standard III (A) - AnswersShashwat DesaiNoch keine Bewertungen

- Anthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDokument9 SeitenAnthropometric Measurements Options For Identifying Low Birth Weight Newborns in Kumasi, GhanaDani KusumaNoch keine Bewertungen

- HLF Sharing Fitness Business CooperationDokument17 SeitenHLF Sharing Fitness Business Cooperationbhardwajharsh2706Noch keine Bewertungen

- Success On The Wards 2007Dokument32 SeitenSuccess On The Wards 2007mnNoch keine Bewertungen

- Asrs For AutomationDokument25 SeitenAsrs For AutomationJavedNoch keine Bewertungen

- Hoja de Seguridad Magnafloc 155 (EN) PDFDokument6 SeitenHoja de Seguridad Magnafloc 155 (EN) PDFIván Martínez-CostaNoch keine Bewertungen

- Lembar Latihan - P1 - PD MitraDokument123 SeitenLembar Latihan - P1 - PD MitratiengcityNoch keine Bewertungen

- Sheet 01Dokument1 SeiteSheet 01Rajeshwari YeoleNoch keine Bewertungen

- Face Port Port Retainer Nose Block HiDokument7 SeitenFace Port Port Retainer Nose Block HiOzan EgemenNoch keine Bewertungen

- Installation and Operating Instructions DPV and DPLHS PumpsDokument36 SeitenInstallation and Operating Instructions DPV and DPLHS PumpsSergeyNoch keine Bewertungen

- Palm Avenue ApartmentsDokument6 SeitenPalm Avenue Apartmentsassistant_sccNoch keine Bewertungen

- BG Nexus Storm 2G Twin WP22RCD IP66 Weatherproof Outdoor Switched Socket 13ADokument4 SeitenBG Nexus Storm 2G Twin WP22RCD IP66 Weatherproof Outdoor Switched Socket 13AAnonymous 8guZVX3ANoch keine Bewertungen

- MEMBERS AREA IndexDokument13 SeitenMEMBERS AREA IndexshahidsarkNoch keine Bewertungen

- Form-Ii (See Regulation 4) Postal Bill of Export - II (To Be Submitted in Duplicate)Dokument1 SeiteForm-Ii (See Regulation 4) Postal Bill of Export - II (To Be Submitted in Duplicate)mrthilagamNoch keine Bewertungen