Beruflich Dokumente

Kultur Dokumente

A Unified Database of Ring Shear Steel-Interface Tests

Hochgeladen von

xangCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A Unified Database of Ring Shear Steel-Interface Tests

Hochgeladen von

xangCopyright:

Verfügbare Formate

Proceedings of the XVII ECSMGE-2019

Geotechnical Engineering foundation of the future

ISBN 978-9935-9436-1-3

© The authors and IGS: All rights reserved, 2019

doi: 10.32075/17ECSMGE-2019-0268

A unified database of ring shear steel-interface tests on

sandy-silty soils

Une base de données unifiée de résultats d'essais de cisaillement

annulaire avec interface en acier sur des sols sablo-limoneux

T. F. Liu1, V. S. Quinteros1,2, R. J. Jardine1, J. A. H. Carraro1, J. Robinson2

1

Department of Civil and Environmental Engineering, Imperial College, London, UK

2

Norwegian Geotechnical Institute, Oslo, Norway

ABSTRACT: Characterisation of shearing behaviour at soil-structure interfaces is critical in the analysis and

design of a wide range of geotechnical structures. Large-displacement ring shear interface testing employing pre-

shearing stages has been recognised as a robust approach for characterising interface resistance, particularly when

large relative displacements are developed between soil and interface during either installation or operation. Such

tests are applied in practical design approaches, for example in the ICP method for driven piles (Jardine et al.,

2005). This paper presents a database of interface shearing tests involving sandy-silty soils that contain low

percentage (≤ 20%) of non-plastic fines, integrating outcomes from research and project studies conducted at

Imperial College London and the Norwegian Geotechnical Institute using Bishop Ring Shear apparatuses. The

outcomes enable a critical review of the potential effects of a wide range of factors, including: soil physical index

properties (grading, fines content); interface characteristics (material type, surface roughness); and applied test-

ing conditions (shear rate and normal effective stress). Trends identified from the datasets are integrated with

previously reported studies to indicate the interface shear strength parameters that may be adopted for preliminary

design with non-plastic sandy-silty soils on the basis of simple index tests.

RÉSUMÉ: La caractérisation du comportement en cisaillement aux interfaces sol-structure est essentielle pour

l'analyse et la conception d'un large éventail de structures géotechniques. L'essai de cisaillement annulaire à grand

déplacement utilisant des étapes de pré-cisaillement a été reconnu comme une approche robuste pour caractériser

la résistance d'une interface, en particulier lorsque de grands déplacements relatifs se développent entre le sol et

l’interface, que ce soit lors de l’installation ou de l’exploitation. Ces essais sont utilisés pour les approches de

conception pratiques, par exemple dans la méthode ICP pour les pieux battus (Jardine et al., 2005). Cet article

présente une base de données d’essais de cisaillement d’interface avec des matériaux sablo-limoneux, intégrant

les résultats de recherches et d’études de projets conduites à l’Imperial College London (ICL) et à l’Institut géo-

technique de Norvège (NGI) à l’aide d’appareils Bishop Ring Shear. Les résultats permettent un examen critique

des effets potentiels d’un large éventail de facteurs. Les tendances identifiées à partir des jeux de données sont

intégrées à des études précédentes, pour indiquer les paramètres de résistance au cisaillement d'interface qui

peuvent être adoptés pour la conception préliminaire avec des sols sablo-limoneux sur la base d'essais d'indice.

Keywords: Bishop ring shear; interface friction angle; pile design

IGS 1 ECSMGE-2019 - Proceedings

A.1 - Investigation by laboratory tests

1 INTRODUCTION interface materials and surface characteristics af-

fect interface shear resistance. Trends are identi-

Practical analysis and design of a wide range of fied that can help guide initial parameter selection

offshore and onshore geotechnical structures, in-

for preliminary design involving similar soils.

cluding piles, suction buckets, pipelines, oil ris-

The value of project-specific testing is empha-

ers, shallow foundations and retaining structures, sised as the most secure means of deriving repre-

require accurate characterisation of soil-structure sentative parameters for detailed design.

interface shearing behaviour and rationalised se-

lection of design parameters (Andersen et al.,

2013). Soil-pile shaft interface shear resistance is 2 EQUIPMENT AND PROCEDURES

one of the major factors governing shaft capacity

of axially loaded driven piles, and the interface

2.1 Equipment and modifications

shearing parameters need to be determined with

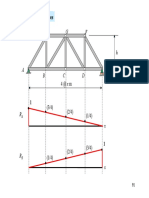

high confidence (Jardine et al., 2005). Interface Bishop ring shear apparatus, as shown in Figure

shearing is also potentially important when ana- 1, has been widely used for investigation of the

lysing laterally loaded caissons and monopiles, residual states of soils undergoing very large

whose behaviour can depend on their shaft and shearing strains (Lupini et al., 1981, Coop et al.,

base shear resistances (Byrne et al., 2017). 2004), landslide analysis and design of piles

Soil-interface shearing angles (δʹ) and dila- driven in clays, sands and chalk (Ramsey et al.,

tancy properties have been characterised through 1998, Yang et al., 2010, Barmpopoulos et al.,

direct shear, simple shear and torsional (ring) 2010, Ho et al., 2011, Quinteros et al., 2017, Liu,

shear laboratory tests, as well as tilting table and 2018, Chan et al., 2019).

other specialised apparatuses; see for example

Liu (2018). The Bishop ring shear apparatus

(Bishop et al., 1971) provides a robust tool for

interface shear testing as it can: (i) apply nomi-

nally unlimited shear displacements; (ii) impose

uniform interface shear stresses and (iii) enable

direct measurement of side friction. Pre-condi-

tioning stages may also be applied that represent

practical scenarios, for example pile installation

or re-striking.

This paper presents a database of Bishop ring

shear interface tests performed at Imperial Col-

lege London (ICL) and at the Norwegian Ge-

otechnical Institute (NGI) on sandy-silty soils Figure 1. Soil interface configuration of Bishop ring

containing relatively low percentage (≤ 20%) of shear apparatus (Bishop et al., 1971, Ramsey et al.,

non-plastic fines inclusions. Many of the tests 1998)

were performed to derive interface friction angles

for axial pile capacity assessment following the The apparatus can accommodate soil-soil or

‘ICP’ procedures of Jardine et al. (2005). The da- soil-interface testing of intact, reconstituted or re-

taset is integrated with previously reported tests moulded soils. Soil-interface testing can be con-

to allow assessments of how soil index properties, figured in lower interface and upper interface

ECSMGE-2019 – Proceedings 2 IGS

A unified database of ring shear steel-interface tests on sandy-silty soils

manners, as outlined by Ho et al. (2011). The ap- (4) Slow shearing is then applied. This should be

paratuses have been upgraded at ICL and NGI in conducted at rates that ensure full drainage

the following aspects that include: that may be assessed from the earlier consol-

(1) Electrical transducers to measure displace- idation stages. The default rate for clays and

ments and loads; silts is 0.005 mm/min.

(2) Torsional shearing at a wide range of shear-

ing rates (from 10-3 to 103 mm/min) with nor- Jardine et al. (2005) proposed equations for the

mal effective stresses up to 1.2 MPa; radial effective stresses (σʹr0 and σʹrc) applying to

(3) An automated electro-pneumatic system reg- tubular steel or concrete piles driven in silica

sands:

ulated by in-house software to enable contin-

uous control of normal stresses; 𝜎′r0 = 𝐾0 ∙ 𝜎′v0 (1)

(4) NGI’s use of an aluminium loading yoke and

loading arm (see Figure 1) to allow normal 𝜎′rc = 0.029 ∙ 𝑞c ∙ (𝜎′v0 ⁄𝑃a )0.13 (ℎ⁄𝑅∗ )−0.38 (2)

stresses as low as 10 kPa to be applied. For

applying stresses < 10 kPa, a polyethylene 𝜏rzf = 𝜎ʹrf ∙ tan𝛿′ult (3)

yoke is also available.

where σʹv0 and σʹr0 are the local free-field vertical

2.2 Specimen reconstitution and testing and radial effective stress and K0 is the earth pres-

procedures sure coefficient at rest; σʹrc denotes radial effec-

tive stress after installation and equalisation,

Sandy-silty soil specimens are prepared by either which depends on σʹv0, local CPT resistance qc,

dry pluviation or moist tamping to achieve tar- relative depth to pile tip h, and equivalent pile ra-

geted initial dry density. NGI employ Ladd’s dius R* = (R2outer-R2inner)0.5 for open- or closed-

(1978) recommendations for moist tamping. In- ended tubular piles. Pa equals to atmospheric

situ conditions of water content and density are pressure (=101.3 kPa). τrzf and σʹrf represent shear

replicated wherever possible. The ICP proce- stress and effective radial stress at pile shafts at

dures recommended by Jardine et al. (2005) are failure, which are correlated through ultimate in-

often adopted in the context of determining fric- terface friction angle δʹult. Different expressions

tion angles for the design of axially loaded driven apply to other pile cross-sections.

piles. The procedures, which may be modified to

represent specific conditions or shearing histo-

ries, consist of: 3 DATABASE OF INTERFACE RING

(1) Consolidation to a vertical effective stress SHEAR TESTS

equivalent to the initial in-situ free-field hor-

izontal effective stress σʹr0. The soils included in the database span a wide

range of particle sizes from coarse sand to fine

(2) Pre-shearing for 1 m up to five times at fast

silt, with the majority being medium to fine

rates (100-500 mm/min) to represent pile sands, as shown in Figure 2. The D50 values range

driving. from 0.07 mm to 0.25 mm, CU from 1.4-27, and

(3) Consolidation follows to the radial effective fines contents (FC, defined as the percentage

stress σʹrc expected at the pile shaft after all passing 0.063 mm standard sieve aperture) of up

effects of pile installation have equalised. to 20 %. Further details are given in Table 1. At-

terberg limit tests were attempted on the soils

IGS 3 ECSMGE-2019 - Proceedings

A.1 - Investigation by laboratory tests

with fines content (FC) greater than 10% to ex- normal effective stress level (σn′) and shear rates

amine the plasticity of the fines inclusions, and affect the ultimate interface friction angles (δ′ult)

no measurable plastic limit was attained. The attained at shear displacement of around 50 mm.

fines inclusions can therefore be generally con- The latter are independent of initial relative den-

sidered as non-plastic, which is in agreement with sity and control ultimate pile capacity (Jardine et

the geological history of the soils tested. al., 2005). Peak (δ′peak) and intermediate angles

Most tests were performed with mild steel in- depend on soils’ initial states.

terfaces that had been air-abraded or rusted to

reach average centre-line roughness (RCAL) of 10- 4.1 Effects of soils’ index properties

15 μm to represent industrial steel piles. How-

Considering first the effects of soils’ D50 and FC

ever, other interface materials and surface rough-

on the ultimate friction angles, Figure 3(a) plots

ness conditions were considered including: (i)

the δ′ult-D50 data against the trends proposed from

polished stainless steel interfaces with RCAL < 2

direct shear tests by Jardine et al. (1992) and later

μm that may represent CPT or model pile shafts

updated by Ho et al. (2011) from Bishop ring

with smooth surfaces; (ii) stainless steel inter-

shear interface tests. Also indicated in the plot are

faces with RCAL in the range of 3-5 μm to repre-

the conditions under which the interface tests

sent the conditions of the ‘mini-ICP’, see Yang et

were performed, noting the variations in soils’

al. (2010); (iii) smooth painted steel, PVC or

D50 and normal effective stress levels (σn′) as well

plastic interfaces with RCAL < 5 μm representing

as the steel interfaces’ material and roughness.

pipelines, see Quinteros et al. (2017); (iv) con-

The Authors’ δ′ult values deviate from the δ′ult

crete interfaces manufactured to form RCAL

= 29° value prescribed by CRU (2001) and scatter

around 14 μm, as used by Barmpopoulos et al.

around the trends proposed by Ho et al. (2011),

(2010).

from ICP style Bishop ring shear tests on clean

GRAVEL SAND SILT

Fine Coarse Medium Fine Coarse Medium Fine Clay silica sands and non-plastic silts against stainless

100 steel interfaces, which exhibited a modest de-

pendency on normal effective stress σn′ and indi-

80 cated less distinct variations of δ′ult against D50

Percentage passing (%)

A AI than were seen in direct shear tests that involved

60 H AJ smaller displacements and no pre-conditioning

O AK

P AL stages. The greater scatter seen with the current

40 T AM database reflect wider ranges of normal effective

V AN

X AW stresses, soil uniformity, fines content, particle

20 Z CA shape and mineralogical composition. Soils with

AE CN

AF CR higher proportions of non-plastic fines tended to

0

10 1 0.1 0.01 0.001

1E-3 develop higher δ′ult values, as shown in Figure

Particle size (mm) 3(b).

Figure 2. Ranges of grain size distribution of the soils

4.2 Effects of normal effective stress

4 DISCUSSION OF RESULTS Figure 4 demonstrates the correlation between

This paper focuses on the outcomes of tests em- δ′ult and n' observed in the dataset of tests that

ploying rough mild steel (RCLA within 814 μm) imposed fast conditioning shearing before slow

interfaces that represent industrial piles and re- shearing which indicated δ′ult increasing with n'.

visits the questions of how fines content (FC), Tests performed under low stresses (n' < 30 kPa)

ECSMGE-2019 – Proceedings 4 IGS

A unified database of ring shear steel-interface tests on sandy-silty soils

inevitably manifest greater variations in δ′ult and 4.3 Effects of interface characteristics

are not plotted here to aid clarity.

The ultimate shear angles are plotted as tan(δ′ult)

50 and correlated in Figure 5 with the normalised

Direct shear (a)

Mild steel, RCLA ≈ 10 m pre-test interface surface roughness (RCLA/D50)

40 50 < n' < 100 kPa Ring shear

Stainless steel, RCLA ≈ 4.3 m trend reported from direct shear tests by Jardine

n' = 800 kPa et al. (1992). The ring-shear interface tests per-

30 formed with relatively high RCLA/D50 ratios (>

'ult (o)

0.05) scatter around the direct shear trend, which

20 Current database shows a linear tan(δ′ult) - RCLA/D50 trend until a

Jardine et al. (1992)

CUR (2001)

Ring shear

Stainless steel, RCLA ≈ 4.3 m plateau is approached that represents soils’ criti-

10 Lower interface (Ho et al. 2011) n' = 100 kPa cal state shearing resistance angle.

Upper interface (Ho et al. 2011)

Large displacement (8 m) (Ho et al. 2011) However, at lower RCLA/D50 ratios the ring

0 shear tan(δ′ult)-RCLA/D50 data invariably plot

0.01 0.1 1 10

D50 (mm) above the direct shear trend. Liu (2018) argued

50 that higher δ′ult values develop in the ‘ICP-style’

(b) ring shear tests because: (i) the fast conditioning

40 shearing stages lead to grain crushing and inter-

face smoothening; (ii) the confining conditions of

30 direct shear tests are less representative than

'ult (o)

those applying in the Bishop ring shear interface

20 apparatus.

1.0

10

0.9

0.8

0

0 5 10 15 20 25 0.7

Non-plastic fines content (FC) (%) 0.6

tan 'ult

Figure 3. (a) Comparison of 'ult against D50 with pub- 0.5

lished trends; (b) Correlation between 'ult and fines 0.4

content (FC) 0.3

50 0.2

Direct shear trend (Jardine et al., 1992)

0.1

Current database

40 0.0

Upper bound 0 20 40 60 80 100 120 140 160 180 200

RCLA/D50 (x1000)

30

Figure 5. Correlation between tan('ult) and pre-test

'ult (o)

normalised roughness RCLA/D50

20

Lower bound

4.4 Relation between δ′20mm and δ′ult

10

Interface friction angles at 20 mm shear displace-

0 ment (δ′20mm) are often required in pile design

10 100 1000 practice. Figure 6 shows the correlation between

n' (kPa)

the ratio δ′20mm/δ′ult against σn′, suggesting that

Figure 4. Correlation between δ′ult and n' δ′20mm is marginally higher than δ′ult by about 2 %.

IGS 5 ECSMGE-2019 - Proceedings

A.1 - Investigation by laboratory tests

2.0 5 SUMMARY AND CONCLUSIONS

This paper presents a summary of about 50

Bishop ring shear interface tests performed at

1.5

ICL and NGI on sandy-silty soils that contain low

'20mm / 'ult

'20 mm / 'ult ≈ 1.02 proportion (≤ 20%) of non-plastic fines. Most of

the tests followed the ‘ICP’ procedures proposed

1.0 by Jardine et al., (2005) for use in the design of

driven piles, which are used widely in offshore

oil, gas and wind-energy projects. The following

0.5

conclusions can be drawn from the results ob-

10 100 1000 tained:

n' (kPa) (1) The δ′ult angles varied with D50 data in a sim-

Figure 6. Correlation between '20mm/'ult against n' ilar way to that described by Ho et al. (2011),

although factors such as fines content, inter-

4.5 Shearing rate effects face roughness and normal stress level play

Shear rates effects were investigated through important roles that can lead to significant

parallel tests on two silty sands (Sand A and variations;

AW). Shearing rates from 0.007 mm/min to 500 (2) Neither the simplifying assumption of δ′ult =

mm/min were applied and the corresponding 29o or the use of direct shear interface tests

ultimate friction angles are summarised in Figure are as satisfactory as conducting site-specific

7. A moderate trend for δʹult to reduce by around ring shear tests;

1˚ over five orders of displacement rate can be (3) The ring shear δ′ult values generally increased

observed in test A series over the rate ranges with the fraction of non-plastic fines;

considered. No reduction of δʹult is observed for

(4) Ring shear δ′ult values manifested clear stress

sand AW.

(σnʹ) dependency and increase with σnʹ over

40

Sand A, FC = 11% (n' = 200 kPa) relatively high stress range (σnʹ > 30 kPa);

(Quinteros et al., 2017) (5) The friction angles at 20 mm shear displace-

Sand AW, FC = 20% (n' = 332 kPa)

35 ment (δ′20mm) were about 2 % higher than

those at ultimate states (δ′ult);

'ult (o)

30

(6) Ultimate friction angles were moderately af-

fected by shearing rates. Approximately 1˚

decrease in δʹult was noted for one sand over

25 five orders of shear rate magnitude.

While the established database and correla-

20

10 -2

10 -1

10 0

10 1

10 2

10 3 tions facilitate the preliminary section of inter-

Shear rate (mm/min) face friction angles as design parameters,

Figure 7. Shear rate effects: 'ult against shear rates soil/project-specific interface testing is highly

recommended to derive detailed design inputs

that can represent in-situ soil conditions, inter-

face characteristics, effective stress level and his-

tory, as well as consolidation (ageing) time.

ECSMGE-2019 – Proceedings 6 IGS

A unified database of ring shear steel-interface tests on sandy-silty soils

Table 1. Soils and testing conditions for the database

Soil1 Interface2 Pre-shearing3 Slow shearing

Soil 'peak '20mm 'ult Tested

ID. Shear rate 'v Shear rate 'v at

D50 CU FC Type RCLA () () ()

mm/min kPa mm/min kPa

A 0.18 2.8 11 RRS 13 99.8 207 0.028 277 32.8 29.7 27.5 NGI

B - - - RRS 13 98.2 249 0.031 270 32.9 28.8 27.0 NGI

C - - - RRS 13 99.7 281 0.031 353 32.1 28.9 28.9 NGI

D - - - RRS 13 99.7 371 0.030 1000 31.8 29.7 29.4 NGI

E - - - RRS 13 99.0 249 0.032 126 40.7 33.0 29.2 NGI

F - - - RRS 13 99.9 258 0.030 882 33.2 30.1 29.3 NGI

G - - - RRS 13 99.2 308 0.029 900 31.5 30.5 29.0 NGI

H 0.15 - 10 RRS 13 99.2 371 0.033 900 31.5 29.9 28.2 NGI

O 0.15 2.4 5 RRS 13 NA NA 0.651 130 35.0 30.1 29.0 NGI

O 0.15 2.4 5 RRS 13 NA NA 0.653 200 33.3 29.8 28.8 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 10 62.2 39.4 28.8 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 30 32.8 27.3 26.6 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 60 32.0 28.8 27.9 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 100 31.9 29.9 29.7 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 100 32.8 30.1 29.7 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 60 33.7 28.8 28.8 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 30 36.9 28.8 26.6 NGI

P 0.18 1.4 0 RRS 13 NA NA 4.200 10 42.0 27.5 21.8 NGI

T 0.14 2.3 3.7 RMS 8.5 500.9 169 0.005 326 32.8 31.0 28.5 NGI

V 0.19 1.7 6 RMS 8.5 500.5 253 0.006 515 33.8 32.2 32.0 NGI

X 0.19 1.6 2.9 RMS 8.5 503.6 321 0.006 664 31.9 30.0 29.3 NGI

Z 0.15 2.0 3.2 RMS 8.5 502.3 158 0.005 363 35.3 31.0 29.8 NGI

AE 0.12 2.4 13 RMS 8.7 500.1 29 0.515 29 40.4 26.6 26.6 NGI

AF 0.32 17.1 15 RMS 8.3 500.0 290 0.006 290 31.3 31.0 30.6 NGI

AG - - 20 RMS 8.4 500.0 216 0.007 216 32.5 31.4 31.4 NGI

AI 0.12 6.8 20 RMS 8.5 500.0 242 0.006 242 32.1 31.4 30.8 NGI

AJ 0.12 24.8 20 RMS 8.5 500.0 271 0.006 271 34.0 33.0 32.6 NGI

AK 0.12 23.3 19 RMS 8.3 499.1 24 0.005 24 42.6 33.0 33.0 NGI

AL 0.13 26.7 14 RMS 8.3 498.3 59 0.006 59 40.0 33.4 32.0 NGI

AM 0.12 7.2 20 RMS 8.6 499.6 85 0.007 85 35.0 30.1 27.5 NGI

AN 0.14 2.9 9 RMS 8.7 500.5 126 0.004 126 34.2 33.0 30.1 NGI

AW 0.09 - 20 RRS 8.2 500.0 332 0.008 332 29.8 28.8 28.8 NGI

CA 0.25 1.7 0 RSS 12.5 500.0 100 0.016 100 25.0 24.1 24.0 ICL

CB 0.25 1.7 0 RSS 12.5 500.0 100 0.016 100 25.0 24.1 24.0 ICL

CC 0.25 1.7 0 RSS 12.5 500.0 200 0.016 200 26.5 25.7 25.0 ICL

CD 0.25 1.7 0 RSS 12.5 500.0 400 0.016 400 31.0 29.5 29.5 ICL

CE 0.25 1.7 0 RSS 12.5 500.0 400 0.016 400 29.5 29.4 29.4 ICL

CF 0.25 1.7 0 RMS 15.1 500.0 200 0.016 200 29.0 27.5 27.5 ICL

CG 0.25 1.7 0 RMS 13.5 500.0 400 0.016 400 29.5 28.8 29.0 ICL

CH 0.25 1.7 0 RMS 12.9 500.0 600 0.016 600 31.0 30.5 30.4 ICL

CI 0.25 1.7 0 RMS 12.9 500.0 800 0.016 800 31.5 31.2 31.3 ICL

CJ 0.25 1.7 0 RMS 12.9 500.0 1200 0.016 1200 35.1 32.5 32.5 ICL

CN 0.21 2.9 4 RMS 8.0 500.0 100 0.016 100 26.5 25.5 25.5 ICL

CO 0.21 2.9 4 RMS 8.0 500.0 200 0.016 200 30.3 29.5 29.9 ICL

CP 0.21 2.9 4 RMS 13.0 500.0 200 0.016 200 30.0 29.7 29.3 ICL

CQ 0.21 2.9 4 RMS 13.0 500.0 400 0.016 400 37.0 34.0 34.5 ICL

CR 0.16 2.4 3 RMS 13.0 500.0 200 0.016 200 31.0 27.8 28.5 ICL

CS 0.16 2.4 3 RMS 13.0 500.0 400 0.016 400 32.1 30.1 30.0 ICL

1

Grading curves and fines contents of sands B to G were similar to specimens A and H which were from identical boreholes and close-by

depths; 2 RRS = Rusted rough steel, RMS = Rough mild steel, RSS = Rough stainless steel; 3 NA = Non applicable

IGS 7 ECSMGE-2019 - Proceedings

A.1 - Investigation by laboratory tests

6 ACKNOWLEDGEMENTS Coop, M., Sorensen, K., Freitas, T. B. &

Georgoutsos, G. (2004) Particle breakage

The support of the Norwegian Geotechnical In- during shearing of a carbonate sand.

stitute and the Norwegian Research Council NRC Géotechnique 54(3):157-164.

is acknowledged with gratitude. The authors also Ho, T., Jardine, R. J. & Anh-Minh, N. (2011)

thank Mr. Steven Ackerley and Mr. Graham Large-displacement interface shear between

Keefe at ICL for upgrading the ring shear appa- steel and granular media. Géotechnique

ratuses. Financial support provided by an IC- 61(3):221.

CSC scholarship and Ørsted to the first Author is Jardine, R. J., Lehane, B. M. & Everton, S. J.

sincerely acknowledged. (1992) Friction coefficients for piles in sands

and silts. In Offshore Site Investigation and

Foundation Behaviour. (Ardus, D. A., et al

7 REFERENCES (eds)) Society for Underwater Technology,

Dordrecht, pp. 661-677.

Andersen, K. H., Puech, A. A. & Jardine, R. J. Jardine, R. J., Chow, F. C., Overy, R. F. &

(2013) Cyclic resistant geotechnical design Standing, J. R. (2005) ICP design methods for

and parameter selection for offshore driven piles in sands and clays. London,

engineering and other applications. In 18th Thomas Telford.

International Conference on Soil Mechanics Ladd, R. (1978) Preparing test specimens using

and Geotechnical Engineering. (Al, D. E. (ed)) undercompaction. Geotechnical Testing

des Ponts, Paris, vol. 1. Journal, 1(1): 16-23.

Barmpopoulos, I., Ho, T., Jardine, R. J. & Anh- Liu, T. F. (2018) Advanced laboratory testing for

Minh, N. (2010) The large displacement shear offshore pile foundations under monotonic and

characteristics of granular media against cyclic loading, PhD thesis, Imperial College

concrete and steel interfaces. In Proceedings of London.

the Research Symposium on Characterization Lupini, J. F., Skinner, A. E. & Vaughan, P. R.

and Behavior of Interfaces. (Frost, J. (ed)) IOS (1981) The drained residual strength of

press, Atlanta, USA. cohesive soils. Géotechnique 31(2):181-213.

Bishop, A. W., Green, G. E., Garga, V. K., Quinteros, V. S., Dyvik, R. & Mortensen, N.

Andresen, A. & Brown, J. D. (1971) A new (2017) Interface friction angle from ring shear

ring shear apparatus and its application to the tests on offshore North Sea sands. In

measurement of residual strength. Geotechnical Frontiers 2017. (Brandon, T. L.,

Géotechnique 21(4):273-328. and Valentine, R. J. (eds)) ASCE, Orlando,

Byrne, B., McAdam, R., Burd, H., Houlsby, G., USA, vol. GSP 280.

Martin, C., Beuckelaers, W., Zdravkovic, L., Ramsey, N., Jardine, R. J., Lehane, B. & Ridley,

Taborda, D., Potts, D., Jardine, R., Ushev, E., A. (1998) A review of soil-steel interface

Liu, T. F., Abadias, D., Gavin, K., Igoe, D., testing with the ring shear apparatus. In

Doherty, P., Gretlund, J. S., Andrade, M. P., Offshore Site Investigation and Foundation

Wood, A. M., Schroeder, F., Turner, S. & Behaviour. Society of Underwater

Plummer, M. (2017) PISA: New design Technology, London, UK.

methods for offshore wind turbine monopiles. Yang, Z. X., Jardine, R. J., Zhu, B. T., Foray, P.

In 8th International Conference on Offshore & Tsuha, C. H. C. (2010) Sand grain crushing

Site Investigation & Geotechnics, London, and interface shearing during displacement

UK. pile installation in sand. Géotechnique

Chan, L., H, D, Buckley, R. M., Liu, T. F. & 60(6):469-482.

Jardine, R. J. (2019) Laboratory investigation

of interface shearing in chalk. In IS-Glasgow

ECSMGE-2019 – Proceedings 8 IGS

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- DesignBuilder v6 Documentation A4Dokument1.832 SeitenDesignBuilder v6 Documentation A4Shiva MohanNoch keine Bewertungen

- M1STR S12Dokument1 SeiteM1STR S12xangNoch keine Bewertungen

- Calcul Des Tunnels - Methodes Conventionnels CofinnementDokument179 SeitenCalcul Des Tunnels - Methodes Conventionnels CofinnementdarcisNoch keine Bewertungen

- Exemple Trusses Influence LineDokument10 SeitenExemple Trusses Influence LinexangNoch keine Bewertungen

- Exemple Influence Line For TrussesDokument30 SeitenExemple Influence Line For TrussesxangNoch keine Bewertungen

- Truss Infl Line ExampleDokument27 SeitenTruss Infl Line ExamplexangNoch keine Bewertungen

- Structural Engineering IDokument48 SeitenStructural Engineering ITonymeriNoch keine Bewertungen

- M1voa S13Dokument1 SeiteM1voa S13xangNoch keine Bewertungen

- M1voa S111 PDFDokument1 SeiteM1voa S111 PDFxangNoch keine Bewertungen

- M1voa S191 PDFDokument1 SeiteM1voa S191 PDFxangNoch keine Bewertungen

- M1voa S19 PDFDokument1 SeiteM1voa S19 PDFxangNoch keine Bewertungen

- M1voa S110Dokument1 SeiteM1voa S110xangNoch keine Bewertungen

- Design TableDokument2 SeitenDesign TablexangNoch keine Bewertungen

- M1voa S112 PDFDokument1 SeiteM1voa S112 PDFxangNoch keine Bewertungen

- M1voa S17Dokument1 SeiteM1voa S17xangNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument21 SeitenStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument15 SeitenStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument37 SeitenStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: A Trans-National ApproachDokument18 SeitenStructural Steelwork Eurocodes: A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: A Trans-National ApproachDokument18 SeitenStructural Steelwork Eurocodes: A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument1 SeiteStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Eurocode Fire Engineering DesignDokument58 SeitenEurocode Fire Engineering DesignxangNoch keine Bewertungen

- Eurocode Fire Engineering DesignDokument58 SeitenEurocode Fire Engineering DesignxangNoch keine Bewertungen

- Lecture 18 Worked ExampleDokument4 SeitenLecture 18 Worked ExampleAnonymous qjoKrp0oNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument19 SeitenStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDokument23 SeitenStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNoch keine Bewertungen

- Lecture 18Dokument14 SeitenLecture 18xangNoch keine Bewertungen

- Calculation ProcedureDokument5 SeitenCalculation ProcedurexangNoch keine Bewertungen

- Lecture 17aDokument8 SeitenLecture 17axangNoch keine Bewertungen

- Lecture 17cDokument6 SeitenLecture 17cxangNoch keine Bewertungen

- Column Web Under Transverse ForcesDokument3 SeitenColumn Web Under Transverse ForcesxangNoch keine Bewertungen

- Vastu HouseDokument15 SeitenVastu HouseRoshani ShresthaNoch keine Bewertungen

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDokument55 SeitenProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshNoch keine Bewertungen

- Four Pile Cap: Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanDokument1 SeiteFour Pile Cap: Plan Showing Piles Reinforcement Plan Showing Pile Cap Reinforcement PlanVinayakNoch keine Bewertungen

- Load Calculation For Stair CaseDokument2 SeitenLoad Calculation For Stair CaseSantosh Bapu100% (1)

- 03300Dokument27 Seiten03300uddinnadeemNoch keine Bewertungen

- Steel-Concrete Composite Slab Design Using ExcelDokument9 SeitenSteel-Concrete Composite Slab Design Using ExcelTasnuva NazmulNoch keine Bewertungen

- 1.hornos RotatoriosDokument493 Seiten1.hornos RotatoriosRonald100% (4)

- Analysis of Alternative Composite Material For High Speed Precision Machine Tool Structures PDFDokument14 SeitenAnalysis of Alternative Composite Material For High Speed Precision Machine Tool Structures PDFfunkyNoch keine Bewertungen

- Tunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoDokument15 SeitenTunnelling and Underground Space Technology: L.X. Xie, W.B. Lu, Q.B. Zhang, Q.H. Jiang, M. Chen, J. ZhaoKatty MonsalveNoch keine Bewertungen

- ZCP Mu13947 PDFDokument36 SeitenZCP Mu13947 PDFsugirinNoch keine Bewertungen

- Asco - Jkh8551g401mmsDokument4 SeitenAsco - Jkh8551g401mmsBiến tần MICNONoch keine Bewertungen

- PEC Requirements For Adequate Wiring Sigle & Multi Family DwellingDokument20 SeitenPEC Requirements For Adequate Wiring Sigle & Multi Family DwellingEm PeeNoch keine Bewertungen

- Kirchhoffs Laws WSDokument1 SeiteKirchhoffs Laws WSMr BaconNoch keine Bewertungen

- Steel Grade: Material Data SheetDokument3 SeitenSteel Grade: Material Data SheetHDNoch keine Bewertungen

- Design Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesDokument9 SeitenDesign Equations For Flexural Strengthening of Singly Reinforced RC Rectangular Section With Steel PlatesMagdy Bakry100% (1)

- RVC05 150FLG Ex PDFDokument5 SeitenRVC05 150FLG Ex PDFengp3077Noch keine Bewertungen

- Swimming Pool Heat PumpDokument2 SeitenSwimming Pool Heat PumpMohammed ErshadNoch keine Bewertungen

- TDS Nitomotar 30 IndiaDokument2 SeitenTDS Nitomotar 30 Indiasmkrishnan89Noch keine Bewertungen

- Is.8364.1989 0Dokument10 SeitenIs.8364.1989 0NPD QualityNoch keine Bewertungen

- Di H2O Supply: External Calibration Gas PortDokument2 SeitenDi H2O Supply: External Calibration Gas Portanwar sadatNoch keine Bewertungen

- Control Valve Interview Questions and AnswersDokument11 SeitenControl Valve Interview Questions and Answersakmal100% (2)

- Performance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFDokument14 SeitenPerformance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFsandeeppandey0789Noch keine Bewertungen

- PVDF PolyvinyldenfluorideDokument2 SeitenPVDF Polyvinyldenfluoridehudi_leksonoNoch keine Bewertungen

- ALTECH PE-HD A 2010/506 GF10: Technical Data SheetDokument2 SeitenALTECH PE-HD A 2010/506 GF10: Technical Data SheetPhung LucNoch keine Bewertungen

- 2 1-Thermodynamics PDFDokument34 Seiten2 1-Thermodynamics PDFBrielle 'Noch keine Bewertungen

- Hinge: Door HingesDokument4 SeitenHinge: Door HingesWee Yong KeeNoch keine Bewertungen

- Air Cond Instructor Guide Lesson PlanDokument29 SeitenAir Cond Instructor Guide Lesson PlanWilliam Kibbe100% (1)

- HSR Basic Rate 2018Dokument10 SeitenHSR Basic Rate 2018R A P RathnaseeliNoch keine Bewertungen

- Evergreen Modular Kitchen KitplyDokument1 SeiteEvergreen Modular Kitchen KitplydhineshNoch keine Bewertungen