Beruflich Dokumente

Kultur Dokumente

Turnouts: - A Flow Control Structure Providing Irrigation Water at The Head (Beginning) of An

Hochgeladen von

ton carolinoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Turnouts: - A Flow Control Structure Providing Irrigation Water at The Head (Beginning) of An

Hochgeladen von

ton carolinoCopyright:

Verfügbare Formate

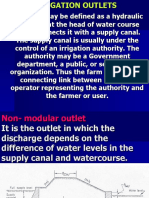

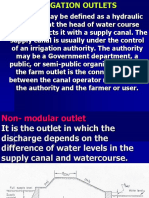

TURNOUTS

- A flow control structure; Providing irrigation water at the head (beginning) of an

offtaking (the actual irrigating) canal, from a supply/distribution canal (conveyance

canal);

from a Lateral (as supply/distribution canal) to a Main Farmditch (as offtake irrigating

canal).

- The connecting link between the supply or distribution canal operator (the NIA

or the Irrigator’s Association) representing the authority and the users (the

farmers). It follows that the design and operation of turnouts must satisfy the needs of

both parties as far as possible. For example, the farmer will want to be satisfied that

he receives his due share of the water at the right time; and the operator will want to

be satisfied that the turnout structures exercise effective control over the distribution of

the supplies.

- At the very stage of general layout preparation & canal lining design, data for

tributary areas and ricefield elevations for turnouts should be pre-determined;

And a sufficient head at least 10 - 15 cm. reckoned from the water surface in the

lateral should be provided for a later turnout design. (Since the discharge

requirement through the turnout is greater during land soaking stage than during crop

maintenance stage, at least 15 cm. head reckoned from the water surface in the

lateral should be provided.)

- Depending on topographical constraints and limitations, the service area of turnout or

Turnout Service Farm may consist of three 10-hectare, four 10-hectare or five 10-

hectare Sub-farms, giving total areas of 30 hectares, 40 hectares and 50 hectares,

respectively. A sub-farm may vary in size but in no case shall its area fall beyond

the lower limit of 8 hectares and upper limit of 12 hectares. Under this scheme,

the maximum service area of the turnout should not exceed 50 hectares to be

served by 5 SFDs.

Orifice

- Water flows under a gate or opening; Highly recommended for turnouts, coupled with

a head regulator at U/S and a flow measuring device at D/S.

Q = Cd * A * √(2gH) *(General Equation)

where,

A = area of the orifice *(by T&E)

H = relative head

H = WSU/S - WSD/S *(for Submerged or Flowing Full)

H = WSU/S – elev’n at center of orifice *(for Non-submerged or Free Flow)

Cd = Coefficient of discharge. Depends on relative head & orifice opening.

Cd = Cc* Cvf; for practical purposes, we calibrate but there is no need to

know the exact Cc & Cvf.

Thus for preliminary sizing of the orifice; the discharge equation can be taken as:

Q = (0.60 – 0.65) * A * √(2gH)

TURNOUT DESIGN EXAMPLE (Submerged Orifice):

PRE-DETERMINED DATA:

Turnout’s tributary area, ATO. = 9 has.

WS at supply canal’s turnout station, WSU/S = El. 86.38

Ricefield elev’n at MFD, RF = El. 86.25

Water duty, WD = 2 lit / sec / has.

HYDRAULIC DESIGN COMPUTATION:

- Draft preliminary design section & data, to verify if a submerged or a free flow design.

1. DETERMINE “QREQ’D” & “HA”:

QREQ’D = (ATO * WD) / 1000 *(Req’d discharge for the turnout’s mfd, in cu. m./s)

QREQ’D = [(9 * 2)(1.20)] / 1000 *(1 cu. m. = 1,000 liter)

QREQ’D = 0.0216 cu. m./s

HA = WSU/S - WSD/S = 86.38 – (86.25 + 0.05) = 0.08 m.

2. DETERMINE “HL” & “A”:

(NOTE: “A” subject for T&E; until “HA >/= HL” satisfied)

Try, A = 0.30 m. X 0.10 m. (orifice opening)

Apply values to the formula with “H” unknown…

Q = 0.65 * A * √(2gH)

0.0216 = 0.65 * (0.30 * 0.10) * √[2 (9.81) (HL)] *(say H = HL)

HL = 0.063 m. < HA = 0.08 m

THEREFORE, 0.30 m. X 0.10 m. ORIFICE OPENING OK TO BE ADAPTED…

3. CHECK IF WATER DEPTH AT D/S OF THE ORIFICE OPENING IS ENOUGH;

BY THE BOOK THE MINIMUM IS 8 cm; IF NOT ADJUST DESIGN.

4. FINALLY, AFTER DRAFTING, CHECK EVERY DETAIL IF YOUR DESIGN WAS

PROPERLY INTERPRETED INTO A WORKING PLAN. AND DRAFTING WORKS

DONE AS PER “MC-36”.

*(See, “LECTURE- TURNOUTS- Attachment 1”; DESIGN AT SUBMERGED ORIFICE, in “.pdf” format)

TURNOUT DESIGN EXAMPLE (Non-submerged Orifice):

PRE-DETERMINED DATA:

Turnout’s tributary area, ATO. = 9 has.

WS at supply canal’s turnout station, WSU/S = El. 84.73

Ricefield elev’n at MFD, RF = El. 84.40

Water duty, WD = 2 lit / sec / has.

HYDRAULIC DESIGN COMPUTATION:

- Draft preliminary design section & data, to verify if a submerged or a free flow design.

1. DETERMINE “QREQ’D”:

QREQ’D = (ATO * WD) / 1000 *(Req’d discharge for the turnout’s mfd, in cu. m./s)

QREQ’D = [(9 * 2)(1.20)] / 1000 *(1 cu. m. = 1,000 liter)

QREQ’D = 0.0216 cu. m./s

2. DETERMINE “QACTUAL”:

(NOTE: “A” & “HL” subject for T&E; until “QACTUAL>/= QREQ’D” satisfied)

Try, A = 0.25 m. X 0.10 m. (orifice opening) & H = 0.09 m.

Apply values to the formula with “QACTUAL” unknown…

Q = 0.65 * A * √(2gH)

QACTUAL = 0.65 * (0.25 * 0.10) * √[2 (9.81) (0.09)] *(say H = HL)

QACTUAL = 0.0216 m. = QREQ’D = 0.0216 m.

THEREFORE, 0.25 m. X 0.10 m. ORIFICE OPENING & 0.09 m. HEAD OK TO BE

ADAPTED…

3. FINALLY, AFTER DRAFTING, CHECK EVERY DETAIL IF YOUR DESIGN WAS

PROPERLY INTERPRETED INTO A WORKING PLAN. AND DRAFTING WORKS

DONE AS PER “MC-36”.

*(See, “LECTURE- TURNOUTS- Attachment 2”; DESIGN AT NON-SUBMERGED ORIFICE, in “.pdf” format)

*(See, “LECTURE- TURNOUTS- Attachment 3”; TURNOUT USING PIPE CONDUIT, in “.pdf” format)

Das könnte Ihnen auch gefallen

- Tcvbfcvbbfurnouts: - A Flow Control Structure Providing Irrigation Water at The Head (Beginning) of AnDokument6 SeitenTcvbfcvbbfurnouts: - A Flow Control Structure Providing Irrigation Water at The Head (Beginning) of Anton carolinoNoch keine Bewertungen

- Navigation & Voyage Planning Companions: Navigation, Nautical Calculation & Passage Planning CompanionsVon EverandNavigation & Voyage Planning Companions: Navigation, Nautical Calculation & Passage Planning CompanionsNoch keine Bewertungen

- Storm Water Design ExampleDokument5 SeitenStorm Water Design ExampleAndre RoyNoch keine Bewertungen

- Calibration of Orifice MeterDokument5 SeitenCalibration of Orifice Meteramarparimi67% (3)

- Southern Marine Engineering Desk Reference: Second Edition Volume IVon EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INoch keine Bewertungen

- Dip - Orifices and Mouth PiecesDokument19 SeitenDip - Orifices and Mouth PiecesDan KiswiliNoch keine Bewertungen

- Fluid MechanicsDokument14 SeitenFluid MechanicsEngr Muhammad Asif JavaidNoch keine Bewertungen

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- To Determine Coefficient of DischargeDokument7 SeitenTo Determine Coefficient of DischargeUmair NawazNoch keine Bewertungen

- Environmental Engineering DesignDokument31 SeitenEnvironmental Engineering DesignXin YiNoch keine Bewertungen

- ECK Rainage Esign: B D A - O 2006Dokument20 SeitenECK Rainage Esign: B D A - O 2006HundeejireenyaNoch keine Bewertungen

- INDIAN - Hydaulic - Design - of - SHP - ProjectDokument116 SeitenINDIAN - Hydaulic - Design - of - SHP - ProjectYasir IqbalNoch keine Bewertungen

- (Instrumentation) Measurement of Flow of FluidsDokument40 Seiten(Instrumentation) Measurement of Flow of FluidsLWYenNoch keine Bewertungen

- FM Lab PDFDokument29 SeitenFM Lab PDFamitNoch keine Bewertungen

- Chapter 8 Drainage Design SlidesDokument17 SeitenChapter 8 Drainage Design SlidesShivek SinghNoch keine Bewertungen

- MIT Academy of Engineering AlandiDokument5 SeitenMIT Academy of Engineering AlandiManish UikeNoch keine Bewertungen

- AE1256 AerodynamicslabmanualsDokument48 SeitenAE1256 AerodynamicslabmanualsSenthil ArumugamNoch keine Bewertungen

- Centrifugal Pump DesignDokument15 SeitenCentrifugal Pump Designzakibrant23Noch keine Bewertungen

- Venturimeter Lab Submitfinal (1) PDFDokument6 SeitenVenturimeter Lab Submitfinal (1) PDFchinmay dasNoch keine Bewertungen

- Chapter 6Dokument31 SeitenChapter 6Camille LardizabalNoch keine Bewertungen

- Calibration of VenturimeterDokument5 SeitenCalibration of VenturimeteramarparimiNoch keine Bewertungen

- Fluid Report 2 2Dokument12 SeitenFluid Report 2 2Jin AhmedNoch keine Bewertungen

- Me2134 2Dokument18 SeitenMe2134 2FlancNoch keine Bewertungen

- Civil Works ExampleDokument52 SeitenCivil Works ExampleSushmit SharmaNoch keine Bewertungen

- CVEN 3323 Weirs LabDokument5 SeitenCVEN 3323 Weirs LabJJ Sean CruzNoch keine Bewertungen

- V NotchDokument2 SeitenV NotchRahul Kumar0% (1)

- Fluid Lab ManualDokument27 SeitenFluid Lab ManualvenkiteshksNoch keine Bewertungen

- Chapter 6Dokument31 SeitenChapter 6Camille LardizabalNoch keine Bewertungen

- Venturi Meter Lab Sheet For StudentsDokument16 SeitenVenturi Meter Lab Sheet For StudentsDeepak Ramesh100% (1)

- A Generic Method of Design of Osd StoragesDokument7 SeitenA Generic Method of Design of Osd StoragesvstojnicNoch keine Bewertungen

- Flow Through Orifices and Mouthpieces: TheoryDokument6 SeitenFlow Through Orifices and Mouthpieces: TheorySri E.Maheswar Reddy Assistant ProfessorNoch keine Bewertungen

- Civil FormulaDokument80 SeitenCivil FormulaBharat SharmaNoch keine Bewertungen

- Calibration of Venturi MeterDokument9 SeitenCalibration of Venturi Meterseminarproject40% (5)

- OutletsDokument107 SeitenOutletsHassan 62Noch keine Bewertungen

- AHEC Hydaulic Design of Small Hydro 2011Dokument116 SeitenAHEC Hydaulic Design of Small Hydro 2011dunlcaaNoch keine Bewertungen

- Lab Manual 2 Rectangular and Triangular NotchesDokument8 SeitenLab Manual 2 Rectangular and Triangular NotchesLeo KhanNoch keine Bewertungen

- OutletsDokument107 SeitenOutletsNumair Ahmad FarjanNoch keine Bewertungen

- Venturimeter 28Dokument10 SeitenVenturimeter 28Agyeman EmmanuelNoch keine Bewertungen

- Civil Engineering Lab Manual Hydraulics Engineering Department of Civil EngineeringDokument26 SeitenCivil Engineering Lab Manual Hydraulics Engineering Department of Civil EngineeringAbdul WahabNoch keine Bewertungen

- VENTURIMETERDokument10 SeitenVENTURIMETERKrishan PrajapatiNoch keine Bewertungen

- V NotchDokument2 SeitenV NotchUstaziyatul AlamNoch keine Bewertungen

- Cross Flow 5Dokument8 SeitenCross Flow 5Abd Rahman HidayatNoch keine Bewertungen

- Btech4th-CE-Hydraulics & Hydraulic Machine LabDokument26 SeitenBtech4th-CE-Hydraulics & Hydraulic Machine LabSri E.Maheswar Reddy Assistant ProfessorNoch keine Bewertungen

- Study The Working of Hydraulic Ram: GoalsDokument2 SeitenStudy The Working of Hydraulic Ram: GoalsNah Sr AdNoch keine Bewertungen

- Fluid Mechanics Manual 067 PDFDokument63 SeitenFluid Mechanics Manual 067 PDFHarshita SharmaNoch keine Bewertungen

- Fluid Report 2 1Dokument10 SeitenFluid Report 2 1Jin AhmedNoch keine Bewertungen

- Lab Manual of Hydraulics PDFDokument40 SeitenLab Manual of Hydraulics PDFJULIUS CESAR G. CADAONoch keine Bewertungen

- Centrifugal Pump Design - Rev 2Dokument11 SeitenCentrifugal Pump Design - Rev 2jehadyam100% (1)

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicDokument12 SeitenHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicSyafiq Roslan75% (4)

- Design Cal - 2300PEDokument47 SeitenDesign Cal - 2300PEEmily Chay88% (24)

- LabDokument4 SeitenLabnidhalsaadaNoch keine Bewertungen

- Drainahe SystemDokument11 SeitenDrainahe SystemJanissaries NivercaNoch keine Bewertungen

- Fliud Mechanics Exxperiment 1Dokument2 SeitenFliud Mechanics Exxperiment 1Nah Sr AdNoch keine Bewertungen

- Hydrologic AnalysisDokument5 SeitenHydrologic AnalysisGoldy GalamitonNoch keine Bewertungen

- Coefficient of Discharge Test.Dokument9 SeitenCoefficient of Discharge Test.AhmadGhanemNoch keine Bewertungen

- Venturi MeterDokument4 SeitenVenturi Meterprince.patelNoch keine Bewertungen

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Dokument1 SeiteGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNoch keine Bewertungen

- Detail "A" Barrel Details: Ext Ext Ext Ext ExtDokument1 SeiteDetail "A" Barrel Details: Ext Ext Ext Ext Extton carolinoNoch keine Bewertungen

- General Notes & Specifications Section "A-A": Flow FlowDokument1 SeiteGeneral Notes & Specifications Section "A-A": Flow Flowton carolinoNoch keine Bewertungen

- Section "B-B" Barrel Details Detail "A": Hydraulic ElementsDokument1 SeiteSection "B-B" Barrel Details Detail "A": Hydraulic Elementston carolinoNoch keine Bewertungen

- Series of Drop-2Dokument1 SeiteSeries of Drop-2ton carolinoNoch keine Bewertungen

- General Notes & Specifications Detail "A" Barrel Details Section "B-B"Dokument1 SeiteGeneral Notes & Specifications Detail "A" Barrel Details Section "B-B"ton carolinoNoch keine Bewertungen

- Detail "A" Section "B-B": Sadle Clamp DetailsDokument1 SeiteDetail "A" Section "B-B": Sadle Clamp Detailston carolinoNoch keine Bewertungen

- Notation: Engineering With The SpreadsheetDokument8 SeitenNotation: Engineering With The Spreadsheetton carolinoNoch keine Bewertungen

- Section "B-B" Section "A-A": Proposed Road CrossingDokument1 SeiteSection "B-B" Section "A-A": Proposed Road Crossington carolinoNoch keine Bewertungen

- Celerity: Wave Action: Tank SupportDokument10 SeitenCelerity: Wave Action: Tank Supportton carolinoNoch keine Bewertungen

- AsasDokument10 SeitenAsaston carolinoNoch keine Bewertungen

- Transition SignalsDokument10 SeitenTransition Signalshana nixmaNoch keine Bewertungen

- Corona ConcernsDokument5 SeitenCorona ConcernsIvanNoch keine Bewertungen

- Stockholm Metro Case Study 2 PDFDokument3 SeitenStockholm Metro Case Study 2 PDFJenelle SandersNoch keine Bewertungen

- Introduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008Dokument20 SeitenIntroduction To Ada Solo Project: Robert Rostkowski CS 460 Computer Security Fall 2008anilkumar18Noch keine Bewertungen

- A330 Tire Inspn PDFDokument21 SeitenA330 Tire Inspn PDFRithesh Ram NambiarNoch keine Bewertungen

- Fault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDokument27 SeitenFault and Alarm Indicators: Planning and Installation Guide For Trident v2 SystemsDeepikaNoch keine Bewertungen

- Grade 7 and 8 November NewsletterDokument1 SeiteGrade 7 and 8 November Newsletterapi-296332562Noch keine Bewertungen

- Compressor Service ProcedureDokument22 SeitenCompressor Service ProcedureFriget Rusianto100% (2)

- ITS Quick Ref GuideDokument6 SeitenITS Quick Ref GuidedhanahbalNoch keine Bewertungen

- Kobelco 30SR Service ManualDokument6 SeitenKobelco 30SR Service ManualG NEELAKANDANNoch keine Bewertungen

- 2501 Solid Drawn Copper Tubes For General Engineering PurposesDokument8 Seiten2501 Solid Drawn Copper Tubes For General Engineering PurposesKaushik SenguptaNoch keine Bewertungen

- Norma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Dokument42 SeitenNorma para Tuercas Hexagonales y Cuadradas (Inch Series) ASME-ANSI B18.2.2-1987Jorge Roman SantosNoch keine Bewertungen

- 7th Sem PPT FinalDokument28 Seiten7th Sem PPT FinalDeepa JethvaNoch keine Bewertungen

- Wireless Body Area Networks: A SurveyDokument29 SeitenWireless Body Area Networks: A Surveyabdul hananNoch keine Bewertungen

- Basement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryDokument2 SeitenBasement Masonry Wall Design Based On TMS 402-16/13: Input Data & Design SummaryRidho ZiskaNoch keine Bewertungen

- Solucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edDokument8 SeitenSolucionario Statistics For Business and Economics - David R. Anderson, Dennis J. Sweeney - 8edTukumaneriko Filiponditoniko0% (1)

- Caution!: Portable Digital Color Doppler Ultrasound SystemDokument177 SeitenCaution!: Portable Digital Color Doppler Ultrasound SystemDaniel Galindo100% (1)

- Camsco Breaker PDFDokument12 SeitenCamsco Breaker PDFMichael MaiquemaNoch keine Bewertungen

- The Impact of Internet Use For StudentsDokument8 SeitenThe Impact of Internet Use For StudentsCharlesNoch keine Bewertungen

- Advanced English Communication Skills LaDokument5 SeitenAdvanced English Communication Skills LaMadjid MouffokiNoch keine Bewertungen

- A Neural Network Model For Electric PDFDokument6 SeitenA Neural Network Model For Electric PDFR Adhitya ArNoch keine Bewertungen

- Residential Solar System Proposal ExampleDokument13 SeitenResidential Solar System Proposal ExamplehernelandNoch keine Bewertungen

- Assessment of Reinforcement CorrosionDokument5 SeitenAssessment of Reinforcement CorrosionClethHirenNoch keine Bewertungen

- Super CatalogueDokument8 SeitenSuper CatalogueITL200_UNoch keine Bewertungen

- 01 SQL ErrorsDokument2.085 Seiten01 SQL ErrorsM. temNoch keine Bewertungen

- ERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaDokument9 SeitenERP and SCM Systems Integration: The Case of A Valve Manufacturer in ChinaiacikgozNoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument3 SeitenSaudi Aramco Inspection ChecklistManoj KumarNoch keine Bewertungen

- Power Network Telecommunication: Powerlink - Technical DataDokument10 SeitenPower Network Telecommunication: Powerlink - Technical Datawas00266Noch keine Bewertungen

- Mix Design PosterDokument1 SeiteMix Design PosterAbhilash KumarNoch keine Bewertungen

- Long+term+storage+procedure 1151enDokument2 SeitenLong+term+storage+procedure 1151enmohamadhakim.19789100% (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesVon EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesBewertung: 5 von 5 Sternen5/5 (1)

- Phase Equilibria in Chemical EngineeringVon EverandPhase Equilibria in Chemical EngineeringBewertung: 4 von 5 Sternen4/5 (11)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsVon EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsNoch keine Bewertungen

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- The Perfumed Pages of History: A Textbook on Fragrance CreationVon EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationBewertung: 4 von 5 Sternen4/5 (1)

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- Water-Based Paint Formulations, Vol. 3Von EverandWater-Based Paint Formulations, Vol. 3Bewertung: 4.5 von 5 Sternen4.5/5 (6)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Fundamentals of Risk Management for Process Industry EngineersVon EverandFundamentals of Risk Management for Process Industry EngineersNoch keine Bewertungen

- Fun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Hydrogen : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen

- Principles and Case Studies of Simultaneous DesignVon EverandPrinciples and Case Studies of Simultaneous DesignNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Distillation Design and Control Using Aspen SimulationVon EverandDistillation Design and Control Using Aspen SimulationBewertung: 5 von 5 Sternen5/5 (2)

- High Pressure Phase Behaviour of Multicomponent Fluid MixturesVon EverandHigh Pressure Phase Behaviour of Multicomponent Fluid MixturesNoch keine Bewertungen

- First U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Von EverandFirst U.K. National Conference on Heat Transfer: The Institution of Chemical Engineers Symposium Series, Volume 2.86Noch keine Bewertungen

- The Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringVon EverandThe Stress Analysis of Pressure Vessels and Pressure Vessel Components: International Series of Monographs in Mechanical EngineeringS. S. GillBewertung: 3.5 von 5 Sternen3.5/5 (3)

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Physical and Chemical Equilibrium for Chemical EngineersVon EverandPhysical and Chemical Equilibrium for Chemical EngineersBewertung: 5 von 5 Sternen5/5 (1)

- The Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookVon EverandThe Periodic Table of Elements - Halogens, Noble Gases and Lanthanides and Actinides | Children's Chemistry BookNoch keine Bewertungen