Beruflich Dokumente

Kultur Dokumente

Pse CHP

Hochgeladen von

Debraj Dutta0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten9 SeitenPower systems

Originaltitel

PSE_CHP

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenPower systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

14 Ansichten9 SeitenPse CHP

Hochgeladen von

Debraj DuttaPower systems

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 9

POWER STATION ENGINEERING

Lecture: Thermal Power Plant - Coal Handling

Prof. Swagat Das

School of Electrical Engineering

COAL

• Coal is a combustible black or brownish-black sedimentary rock usually occurring in rock strata in layers or

veins called coal beds or coal seams.

• Coal is composed primarily of carbon, along with variable quantities of other elements, chiefly hydrogen,

sulfur, oxygen, and nitrogen.

• Coal is a fossil fuel that forms when dead plant matter is converted into peat, which in turn is converted into

lignite, then sub-bituminous coal, after that bituminous coal, and lastly anthracite.

• Coal is extracted from the ground by coal mining. Since 1983, the world's top coal producer has been China. In

2015 China produced 3.747 billion tonnes of coal – 48% of 7.861 billion tonnes world coal production. In 2015

other large producers were United States (813 million tonnes), India (678), European Union (539) and Australia

(503).

TYPES OF COAL - FORMATION

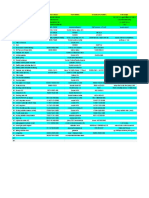

2018 Coal Mining data by

Global Energy Stats. (in Mt)

TYPES OF COAL - CALORIFIC VALUE

Types of coal Moisture content Carbon content Calorific value

Peat 60-90% 5-10% 2,600 kcal/kg

Lignite 30-50% 20-40% 4,000kcal/kg

Bituminous 10-20% 60-80% 5,800 to 8,000 kcal/kg

Anthracite 5-10% 90% 8,000kcal/kg

• The ash content in bituminous is 6-10%

• Semi-bituminous has properties in between those of bituminous and anthracite coal and is widely used in

power plants.

• Indian thermal power plants use bituminous/ Sub bituminous coal with gross calorific value ranging in between

3000 kcal to 5000 kcal.

• Further to clarify, each and every coal based thermal power plant in India is designed to burn a specific range of

coal. Mostly coal of GCV in between 3000 to 3500 which is abundantly available in Indian mines. However in

view to reduce the menace of high ash produced out of ash enriched Indian coal, Indian thermal plants use

blended coal.

COAL HANDLING PLANT

FUNCTIONS OF CHP

• The function of coal handling plant is automatic feeding of coal to the boiler furnace.

• A thermal power plant burns enormous amounts of coal.

• A 200 MW plant may require around 2000 tons of coal daily.

• Coal is weighed and led to hopper and then it is fed to the grate through some form of stoker mechanism which

are overfeed stoker or underfeed stoker depending on whether the coal entry is above or below the air entry.

The coal input to the boiler of the power plant passes through three different phases before combustion in the

boiler.

ü Receiving, storing, and transporting the coal to the boiler. This is bulk storage and bulk handling

ü Preparing the coal for firing or pulverizing. This is what is special in a coal fired power plant, especially large

thermal power plants

ü Burning the coal in the combustion process to release the energy in the fuel

• CHP is divided into 3 sections:

ü Uploading plant: wagon tipper

ü Conveying plant: for conveying coal from unloading to the coal yard or directly to the bunkers

ü Crushing plant: for crushing the coal to the required size

SCHEMATIC OF CHP

UPLOADING, CONVEYING & CRUSHING PLANT

Uploading plant:

ü Coal is brought to power station through rail wagons; 6-8 shunted wagons

ü Each wagon adjusted on the tipper platform in proper position

ü The tipper tilts the wagon and unloads the coal into the hopper

ü Then from hopper coal is fed to conveyer belt A and B by means of electrically vibrating feeders

Conveying plant:

ü Consisits of belt conveyors 1A, 1B, 2, 3, 4, 5, 6.

ü Belt no. 4 can be rotated in either direction while all others have one direction only

ü Vibrating screens & Crushers

ü The crushed coal from crusher and small size coals from screens fall on conveyer belt 4

ü Direct bunkering coal on belt no. 5

ü Stocking coal falls on belt no. 3, leads to Coal yard for stocking

ü Tippers control the feeding of coal to bunkers

ü Magnetic separators are present to remove any magnetic material such as bolts, iron scrap, etc which may

be in the coal

Crushing plant:

ü Screens are provided to reduce the load on the crusher

ü Coal size >19mm are crushed in the crusher

PULVERISING PLANT

Pulverising plant:

In modern thermal power plant, coal is pulverised, i.e., ground to dust like size and carried to the furnace in a

stream of hot air. Pulverising is a means of exposing a large surface area to the action of oxygen and consequently

helping combustion.

Pulverising mills are further classified as:

1. Contact mill

2. Ball mill

3. Impact mill

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Part Subtitusi Every 16 - 03 - 20Dokument1 SeitePart Subtitusi Every 16 - 03 - 20Nacz92Noch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- D105 With 42" Deck: Maintenance Reminder SheetDokument1 SeiteD105 With 42" Deck: Maintenance Reminder SheetJames HuntNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Purpose: The Product Which I Have Chosen Is "Toothbrush"Dokument3 SeitenPurpose: The Product Which I Have Chosen Is "Toothbrush"Zainab KashaniNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Kawasaki Vn1600 A1 A2 2003 Service ManualDokument20 SeitenKawasaki Vn1600 A1 A2 2003 Service Manualkevin100% (37)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Yuchai Yc6j125z-T20 PDFDokument99 SeitenYuchai Yc6j125z-T20 PDFjosephvanbac83% (12)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- STaSIS MTF Turbo Install LongitudialDokument55 SeitenSTaSIS MTF Turbo Install LongitudialLeptonNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Chevy High Performance - January 2020 USA PDFDokument76 SeitenChevy High Performance - January 2020 USA PDFErc3Noch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- FT Motor Volvo TAD750GEDokument2 SeitenFT Motor Volvo TAD750GEYael Reinoso AriasNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Parts Manual 777d SN FKR 200-UpDokument670 SeitenParts Manual 777d SN FKR 200-UpEghie Rahardi100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- wb97s 5e0 S N f30003 UpDokument924 Seitenwb97s 5e0 S N f30003 UpTamquadistu AlexNoch keine Bewertungen

- Reducing Atmospheric Pollution from Land TransportDokument8 SeitenReducing Atmospheric Pollution from Land TransportmirulNoch keine Bewertungen

- YTG30TLV 20 kVA Silent Type Genset Dimensions and SpecsDokument1 SeiteYTG30TLV 20 kVA Silent Type Genset Dimensions and Specseric287Noch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- English Series60Dokument1.685 SeitenEnglish Series60AzizeArif100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Sae 1726 MiliporeDokument2 SeitenSae 1726 Miliporeagvlogs5741Noch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Irs 1041 FormDokument4 SeitenIrs 1041 FormcaliechNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Loss Prevention Bulletin - Bunkering - The Cappuccino EffectDokument3 SeitenLoss Prevention Bulletin - Bunkering - The Cappuccino EffectPeter CotopoulisNoch keine Bewertungen

- NicoleDokument2 SeitenNicoleJennyAlfaroNoch keine Bewertungen

- Iveco Trakker AD260T38 Tipper SADokument19 SeitenIveco Trakker AD260T38 Tipper SACsibiErvinNoch keine Bewertungen

- Remote Operated Fork Lift Mechanism Work PDFDokument32 SeitenRemote Operated Fork Lift Mechanism Work PDFasdfrewNoch keine Bewertungen

- Diagrama de Motor DetroitDokument1 SeiteDiagrama de Motor Detroitstichi0911100% (18)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 4MATIC Automatic four-wheel drive controlDokument6 Seiten4MATIC Automatic four-wheel drive controlAnonymous qz5pEMh44Noch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- CNG Economics TrivandrumDokument7 SeitenCNG Economics TrivandrumUJJWALNoch keine Bewertungen

- Sundyne High Speed Pump (OH6)Dokument40 SeitenSundyne High Speed Pump (OH6)Angga Deri Saputra100% (2)

- SGT-500 Industrial Gas Turbine: Answers For EnergyDokument4 SeitenSGT-500 Industrial Gas Turbine: Answers For EnergySalim BenlahceneNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Not for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahiliDokument52 SeitenNot for Reproduction: en - English ar-es - Español et - Eesti keel fr - Français ru - Pусский sw - KiswahilifosterNoch keine Bewertungen

- AUTOMOTIVE POWERTRAIN COURSE OutlineDokument2 SeitenAUTOMOTIVE POWERTRAIN COURSE OutlineSelazinap LptNoch keine Bewertungen

- Socoteco 2 Therma Marine Decision,+ERC+Case+No.+2014-081+RCDokument28 SeitenSocoteco 2 Therma Marine Decision,+ERC+Case+No.+2014-081+RCSamMooreNoch keine Bewertungen

- The Understated Benefits of Trolley Assisted HaulageDokument49 SeitenThe Understated Benefits of Trolley Assisted HaulagewalterloliNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Reading Pump Curves: by James Mcdonald, Pe, CWT Originally Published CSTN - September/October 2004Dokument3 SeitenReading Pump Curves: by James Mcdonald, Pe, CWT Originally Published CSTN - September/October 2004kirmaniNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)