Beruflich Dokumente

Kultur Dokumente

Turbimachines

Hochgeladen von

Arun BeniwalOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Turbimachines

Hochgeladen von

Arun BeniwalCopyright:

Verfügbare Formate

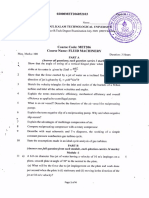

TURBO-MACHINES (7ME4A) - Tutorial Sheet-3 (UNIT-3)

(Hydraulic Pumps: Centrifugal, Axial and Reciprocating type)

1. Explain slip and slip factor for a centrifugal pump. (RTU2018, 6marks)

2. Derive an expression for the workdone by impeller of a centrifugal pump. (RTU2018, 10marks)

3. The impeller of a centrifugal pump having an external and internal diameter 400mm and 200mm, width of outlet 40mm and running at

1000 rpm work against a head of 45mm. The velocity of flow through the impeller is constant and equal to 3 m/s. The vanes are set

back at an angle of 40° at outlet. Determine : (i) inlet vane angle (ii) work done by the impeller on water per second and (iii)

manometric efficiency (RTU2018, 10marks)

4. Briefly explain about indicator diagram of a reciprocating pump. (RTU2018, 6marks)

5. Explain for a centrifugal pump why there should be a minimum speed for discharge to start. (RTU2017, 8marks)

6. A centrifugal pump having outer diameter equal to two times the inner diameter and running at 1200 rpm, works against a total head of

75m.The velocity of flow through the impeller is constant and equal to 3m/s. The vanes are set back at an angle of 30° at outlet. If the

outlet diameter of the impeller is 60cm and width at outlet is 5cm, determine-(i) vane angle at inlet (ii) workdone per second by

impeller (iii) manometric efficiency. (RTU2017,2009, 8marks)-Valan Arasu

7. Define slip, percentage slip and negative slip of reciprocating pump. Explain the function of air vessels in a reciprocating pump.

(RTU2017, 4+4=8marks)

8. Discuss the typical characteristics of an axial flow pump. Also explain regulation by adjustable impeller blades of an axial flow pump.

(RTU2017,2009, 4+4=8marks)

9. State the main components of a centrifugal pump and describe the function of each. (RTU2016,2013,2009, 8marks)

10. A centrifugal pump has to deliver 20 litres/sec of water when running at 1200 rpm. The inlet vane angle is 30° and exit vane angle is

45°. If the velocity of flow is constant in the impeller, the power supplied to run the pump by motor is 40kW. Assuming the

mechanical efficiency 90%, find the inlet and outlet diameters of the impeller. Take D2 = 2D1. (RTU2016, 8marks)

11. Define cavitations and explain causes for creating the cavitations. Mention the effects of cavitations. (RTU2016,2013,2009, 8marks)

12. The piston area of a single acting reciprocating pump 0.15m2 and stroke is 30cm. The water is lifted through a total head of 15m.The

area of delivery pipe is 0.03 m2. If the pump is running at 50 rpm, find the percentage slip, coefficient of discharge and the power

required to drive the pump. The actual discharge is 350L/sec. Take mechanical efficiency 85%. (RTU2016, 8marks)

13. What do you understand by characteristic curves of a pump? What is the significance of the characteristic curve?(RTU2015, 8marks)

14. An impeller of a centrifugal pump having internal and external are 150mm and 300mm respectively. The vane angle of the impeller at

inlet and outlet are 20o and 30o respectively. The pump is running at 1300 rpm. The water enters the impeller radially and velocity of

flow is constant. Determine the work done by the impeller per unit weight of water. (RTU2015, 8marks)

15. The stroke and bore of a cylinder reciprocally engine running at 70 rpm are 500mm and 250mm respectively. The 20m long delivery

pipe has a diameter of 80mm. Determine the power saved by installing in an vessel in the delivery pipe , if pipe friction factor is 0.008.

(RTU2015, 8marks) -R K Bansal

16. Derive an expression to obtain the work done by axial flow pump on fluid. (RTU2015, 8marks)

17. A centrifugal pump has inlet diameter of 350 mm and outlet diameter of 650 mm. The velocity of flow is 2 m/s. The vanes are curved

backward and make an angle of 450 to the tangent at the outlet tip. Determine minimum starting speed of the pump. Take manometric

efficiency as 75%. (RTU2014, 8marks)

18. Define the following terms as applied to centrifugal pumps: (i) Manometric head (ii) Static head (iii) Overall efficiency (iv) Net

positive suction head (RTU2015, 2x4=8marks)

19. Distinguish between centrifugal pump and axial flow pump. Compare the performance of both pumps with reference to following

charcterictics: (i) discharge and head (ii) discharge and power (iii) discharge and efficiency. (RTU2014, 8marks)

20. Develop an expression for cavitation number for axial flow pump. What are the causes of cavitation ang how will you prevent

cavitation? (RTU2014, 8marks)

21. Explain the concept of slip in case of centrifugal pump. Define slip factor. (RTU 2013)

22. With the help of neat sketches, explain all the component of centrifugal pump. Also explain NPSH & priming in a pump.

(RTU 2012,2009, 8marks)

23. Draw the velocity triangle at the inlet and outlet tips of the vane fixed to an impeller and derive an expression for minimum starting

speed of a centrifugal pump. (RTU 2012, 8marks)

24. Explain the various pump losses and efficiencies in a centrifugal pump. (RTU 2012,8marks)

25. The impeller of the centrifugal pump is 30 cm at the outlet of 15 cm at the inlet. Impeller vane angles are 300 and 250 at the inner and

outer peripheries, respectively and the speed is 1450 rpm. The velocity of the flow through impeller is constant. Find the work done

per unit weight per unit second. (RTU 2013)

26. The outer diameter of an impeller of a centrifugal pump is 40 cm and outlet width is 5 cm. the pump is running at 800 rpm and

working against a head of 16m the vane angle at outlet is 40o. Assuming the manometric efficiency to be 75%, determine the

discharge. (RTU 2012, 8marks)-Valan Arasu

Arun Beniwal Page of 2

27. Give the complete description of an axial flow pump and find out an expression for workdone on the fluid and energy transfer.

(RTU 2012,2009, 8marks)

28. Explain the characteristics of an axial flow pump and the phenomenon of cavitation. (RTU 2012, 8marks)

29. An axial flow pump has an impeller of outlet diameter 1.0m. The diameter of boss is 0.5m. If the specific speed of the pump is 38 and

velocity of flow is 2m/s, suggest a suitable speed of pump to give a head of 6m. Also determine vane angle at the entry of the pump if

the flow is axial at inlet. (RTU 2012, 8marks)-Valan Arasu

30. An axial flow pump has particulars as its discharge is 180 l/s, head developed 2m, specific speed 250, speed ratio 2.4, flow ratio 0.5,

Calculate: (i)speed of pump (ii)runner diameter (iii)boss diameter (RTU 2012, 8marks)-Valan Arasu

31. A centrifugal pump delivers salt water against a net head of 15m at a speed of 1000rpm. The vanes are curved backward at 30° with

the periphery. Obtain the discharge for an impeller diameter of 30cm and outlet width of 5cm at a manometric efficiency of 90%.

(RTU 2012, 8marks)-K L Kumar

32. What are the characteristics curves of a centrifugal pump? What is the use of these curves? (RTU 2012, 8marks)

33. Define manometric and impeller efficiency for centrifugal pump. Derive the expression for the minimum speed for starting a

centrifugal pump. (RTU 2012, 8marks)

34. A centrifugal pump with 1.2 m diameter runs at 200 rpm and pumps 1880 l/s, the average lift being 6m. The angle which the vane

makes at the exit with the tangent to the impeller is 26° and the radial velocity of flow is 2.5 m/s. Determine the manometric efficiency

and the least speed to start pumping against a head of 6m, the inlet diameter of the impeller being 0.6m.

(RTU2009, 8marks)-Valan Arasu

35. A centrifugal pump of 1.3m diameter delivers 3.5m3/min. of water at a tip speed of 10m/s and a flow velocity of 1.6m/s. The outlet

blade angle is at 30° to the tangent at the impeller periphery. Assuming zero whirl at inlet and zero slip, calculate the torque delivered

by the impeller. –Valan Arasu

36. The impeller of a centrifugal pump bas backward facing blades inclined at 30° to the tangent at impeller outlet. The blades are 20 mm

in depth at the outlet, the impeller is 250 mm in diameter and it rotates at 1450 rpm. The flow rate through the pump is 0.028 m3/s and

a slip factor of 0.77 may be assumed. Determine the theoretical head developed by the impeller and the number of impeller blades.

–Valan Arasu

37. During a test on the centrifugal pump, lhe following reading were obtained: vaccum gauge reading=25 cm of Hg, pressure gauge

reading=1.5 bar, effective height between gauges=0.5 m, power of electric motor=22 kW, discharge of pump=100 l/s, diameter of

suction and delivery pipes is each 15 cm. Determine manometric head and overall efficiency of the pump. –Valan Arasu

38. A centrifugal pump having external and internal diameters of respectively 1.25 m and 0.5 m is discharging water at the rate of 2000

lit/s against a head of 16m when running at 300 rpm . The vanes are curved back at an angle of 30° with the tangent at the outlet and

the velocity of flow is constant at 2.5 m/s. Find (a) hydraulic efficiency of the pump (b) power required and (c) least speed at which the

pump commences to work –Valan Arasu

39. A three stage centrifugal pump has impellers 40 cm in diameter and 2 cm wide at outlet. The vanes are curved back at the outlet at 45°

and they reduce the circumferential area by 10%. The manometric efficiency is 90% and the overall efficiency is 80%. Determine the

head generated by the pump, when running at 1000 rpm delivering 50 litres per second. What should be the shaft power?

–Valan Arasu

40. A single acting reciprocating pump running at 50 rpm delivers 0.01m3/s of water. The diameter of the piston is 200mm and stroke

length 400mm. Determine: (i)theoretical discharge of the pump (ii)coefficient of discharge (iii) slip and the percentage slip of the

pump. – R. K. Bansal

41. A centrifugal pump has an overall efficiency of 70 percent, supplies 25 l/s of water to a height of 20 m through a pipe of 10cm

diameter and length of 100 m. Assume friction co-efficient, f = 0.012, Estimate the power required to drive the pump.

–Valan Arasu

SOLUTIONS:-

Q. No. Answers

3

6 β1= 9.043o, W=346.42 kW, ηmano.=60.04 %

10 D1=0.4m, D2=0.8m

12 %slip=7 %, Cd=0.93, Pm=6.4 kW

14 W/mg=27.08 J/N

15 Psaving=17.14 kW

17 N=112.6 rpm

25 W/mg=20.1 J/N

26 Q=0.2262 m3/s

29 N=134.22 rpm, β1= 29.67o

30 N=991 rpm, D=0.29 m, Dh=0.11 m

31 Q=0.144 m3/s

34 ηmano.=63.3 %, N=199.4 rpm

35 T=273.7 N-m

36 E=23.74 m, Z=8.15

37 Hm=19.19 m, ηo=85.6 %

38 ηmano.= ηhyd.=52.2 %, P=601.38 kW, N=295.4 rpm

39 Total head for three stages=107.97 m, Ps=66.199 kW

40 Qth=0.01047 m3/s, Cd=0.955, Slip=0.00047, %slip=4.489 %

41 P=15.86 kW

Arun Beniwal Page of 2

Das könnte Ihnen auch gefallen

- Design and Analysis of Centrifugal CompressorsVon EverandDesign and Analysis of Centrifugal CompressorsNoch keine Bewertungen

- ME Fluid Mechanics Question BankDokument3 SeitenME Fluid Mechanics Question BankcbeprabhugmailNoch keine Bewertungen

- BE 2019 TurbomachinaryDokument5 SeitenBE 2019 TurbomachinarySuyash Shinde.Noch keine Bewertungen

- Images - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFDokument8 SeitenImages - MEQP - 08 - R05310302 HYDRAULIC MACHINERY AND SYSTEMS PDFvishnu chaudharyNoch keine Bewertungen

- Mechanical Engineering Turbo AssignmentDokument2 SeitenMechanical Engineering Turbo AssignmentRoha EngineeringNoch keine Bewertungen

- FM 15 MarksDokument5 SeitenFM 15 MarksPriyanka PrakashNoch keine Bewertungen

- Assignment #3Dokument2 SeitenAssignment #3Choa Pei ShuangNoch keine Bewertungen

- Sheet5-Centrifugal PumpDokument5 SeitenSheet5-Centrifugal Pumpyousef mohamedNoch keine Bewertungen

- ME2135E Fluid Mechanics II Tutorial 1Dokument3 SeitenME2135E Fluid Mechanics II Tutorial 1Law Zhan Hong0% (1)

- Muzeyin FocusDokument3 SeitenMuzeyin FocuseyobNoch keine Bewertungen

- 9A01308 Fluid Mechanics and Hydraulic MachineryDokument4 Seiten9A01308 Fluid Mechanics and Hydraulic MachinerysivabharathamurthyNoch keine Bewertungen

- Assignment 1 2 PumpDokument2 SeitenAssignment 1 2 PumpAnkit0% (1)

- Mechanical Engineering Faculty Turbomachinery DocumentDokument3 SeitenMechanical Engineering Faculty Turbomachinery DocumentLove StrikeNoch keine Bewertungen

- Mechanical Engineering Turbomachinery Assignment QuestionsDokument2 SeitenMechanical Engineering Turbomachinery Assignment QuestionsAbebe AyingdaNoch keine Bewertungen

- Problem Set ADokument3 SeitenProblem Set AAldrich BaldonadoNoch keine Bewertungen

- 9A01308 Fluid Mechanics & Hydraulic MachineryDokument4 Seiten9A01308 Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNoch keine Bewertungen

- Assignment IVDokument2 SeitenAssignment IVMANOJ MNoch keine Bewertungen

- Ajay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringDokument3 SeitenAjay Kumar Garg Engineering College, Ghaziabad: Department of Mechanical EngineeringMradul GuptaNoch keine Bewertungen

- Turbo Machinery Tutorial - Jan-Feb 2012Dokument3 SeitenTurbo Machinery Tutorial - Jan-Feb 2012Suchithra RamanNoch keine Bewertungen

- Fluid Machinery II Seme2 2006Dokument2 SeitenFluid Machinery II Seme2 2006Arindam MisraNoch keine Bewertungen

- HMDokument2 SeitenHMapi-279049687Noch keine Bewertungen

- Sheet (5) Moment of MomentumDokument8 SeitenSheet (5) Moment of MomentumABDELRHMAN ALINoch keine Bewertungen

- 2135 Tutorial 1Dokument4 Seiten2135 Tutorial 1Eezhar JumadiNoch keine Bewertungen

- Hydraulic Machinery Systems Exam QuestionsDokument4 SeitenHydraulic Machinery Systems Exam QuestionswirelessandlessNoch keine Bewertungen

- Hydraulic Machinery and Systems Jntu Model Paper WWW Student Yogi Com 100113195214 Phpapp01Dokument8 SeitenHydraulic Machinery and Systems Jntu Model Paper WWW Student Yogi Com 100113195214 Phpapp01Nitish ShresthaNoch keine Bewertungen

- Hydraulic Pumps Lec NotesDokument30 SeitenHydraulic Pumps Lec NotesDarsh MenonNoch keine Bewertungen

- UNIT 5 HydraulicsDokument31 SeitenUNIT 5 Hydraulicsnandu20Noch keine Bewertungen

- Fpe DBC 5th Sem AssignmentDokument10 SeitenFpe DBC 5th Sem AssignmentJain shahilkumarNoch keine Bewertungen

- Ktu Students: For More Study Materials WWW - Ktustudents.inDokument2 SeitenKtu Students: For More Study Materials WWW - Ktustudents.inAnonymous 2lKdNfxNoch keine Bewertungen

- Assignment TMDokument3 SeitenAssignment TMBeesam Ramesh KumarNoch keine Bewertungen

- c4 Tutorial TurbineDokument2 Seitenc4 Tutorial TurbinehahahaNoch keine Bewertungen

- FMMDokument2 SeitenFMMMadhan rNoch keine Bewertungen

- Fluid Power EngineeringDokument4 SeitenFluid Power EngineeringrameshsagapariyaNoch keine Bewertungen

- Question Paper Code:: (10×2 20 Marks)Dokument3 SeitenQuestion Paper Code:: (10×2 20 Marks)Keesanth Geetha ChandrasekaranNoch keine Bewertungen

- Met206 Fluid Machinery, July 2021Dokument4 SeitenMet206 Fluid Machinery, July 2021AkashNoch keine Bewertungen

- AQ Fluid Machinery-1Dokument3 SeitenAQ Fluid Machinery-1Sourabh BelladNoch keine Bewertungen

- Jntuworld: R09 Set No. 2Dokument9 SeitenJntuworld: R09 Set No. 2saiteja1234Noch keine Bewertungen

- Tutorial 4 Turbomachinery v2Dokument4 SeitenTutorial 4 Turbomachinery v2Nik JaffNoch keine Bewertungen

- FLUID MACHINERY TURBINE CHARACTERISTIC CURVESDokument2 SeitenFLUID MACHINERY TURBINE CHARACTERISTIC CURVESsarathkumararasu007Noch keine Bewertungen

- sheet no2Dokument7 Seitensheet no2Ismail SakrNoch keine Bewertungen

- Hydraulic Machines Question BankDokument11 SeitenHydraulic Machines Question BankAdit Gaur100% (3)

- Ce 6403 AheDokument1 SeiteCe 6403 AheManikandan SelvamNoch keine Bewertungen

- Practice ProblemsDokument2 SeitenPractice Problemsk2kkhanna105Noch keine Bewertungen

- FMM Mod-IDokument2 SeitenFMM Mod-ItagoreboopathyNoch keine Bewertungen

- Centrifugal and Reciprocating Pump GuideDokument2 SeitenCentrifugal and Reciprocating Pump GuideashutoshNoch keine Bewertungen

- r5310302 Hydraulic Machinery and SystemsDokument1 Seiter5310302 Hydraulic Machinery and SystemssivabharathamurthyNoch keine Bewertungen

- PUMPSDokument9 SeitenPUMPSYash GuptaNoch keine Bewertungen

- Propulsion 1 Unit-V Question Bank (Compressors)Dokument4 SeitenPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- Assignment 4-1Dokument2 SeitenAssignment 4-1ashutoshNoch keine Bewertungen

- Hydraulic Machines & Systems Exam QuestionsDokument3 SeitenHydraulic Machines & Systems Exam Questionskohli kingNoch keine Bewertungen

- Quetions Turbo.................Dokument4 SeitenQuetions Turbo.................DICKSON SIMUTAMINoch keine Bewertungen

- Guyana University Mechanical Engineering pump tutorialsDokument6 SeitenGuyana University Mechanical Engineering pump tutorialsleitchNoch keine Bewertungen

- FLM3B0S Tutorial 2a TurbomachinesDokument3 SeitenFLM3B0S Tutorial 2a TurbomachinesFabrizio NEBESSENoch keine Bewertungen

- Roll No. B.E / B.Tech (Full Time) D E G R E E End S E M E S T E R Examinations, April / May 2014Dokument2 SeitenRoll No. B.E / B.Tech (Full Time) D E G R E E End S E M E S T E R Examinations, April / May 2014Anonymous dL8dsCncNoch keine Bewertungen

- Department of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationDokument1 SeiteDepartment of Mechanical and Industrial Engineering: MIN-304: Fluid Machines Mid-Term ExaminationSaifullah AhmadNoch keine Bewertungen

- Fluid MachinesDokument14 SeitenFluid MachinesNishankzattNoch keine Bewertungen

- HDM360S Tutorial 3 -2024 - TurbinesDokument6 SeitenHDM360S Tutorial 3 -2024 - TurbinesSimphiweNoch keine Bewertungen

- 14 MarksDokument4 Seiten14 MarksmohanNoch keine Bewertungen

- Term End Exam - Nov 2014 TurbomachinesDokument4 SeitenTerm End Exam - Nov 2014 TurbomachinesyashvantNoch keine Bewertungen

- Fluid Machinery Question Bank No.01Dokument5 SeitenFluid Machinery Question Bank No.01Sunil KumarNoch keine Bewertungen

- Syllabus ME RTUDokument15 SeitenSyllabus ME RTURaghvendra Singh ShaktawatNoch keine Bewertungen

- Steam Engineering Unit Test AnalysisDokument2 SeitenSteam Engineering Unit Test AnalysisArun BeniwalNoch keine Bewertungen

- MCQ 2018 Unit Test 1 Set-BDokument1 SeiteMCQ 2018 Unit Test 1 Set-BArun BeniwalNoch keine Bewertungen

- TurboDokument2 SeitenTurboArun BeniwalNoch keine Bewertungen

- Steam Engineering Unit TestDokument3 SeitenSteam Engineering Unit TestArun BeniwalNoch keine Bewertungen

- MCQ 2017 Unit Test 1 Set-ADokument24 SeitenMCQ 2017 Unit Test 1 Set-AArun BeniwalNoch keine Bewertungen

- TurboDokument2 SeitenTurboArun BeniwalNoch keine Bewertungen

- Steam Engineering Unit TestDokument3 SeitenSteam Engineering Unit TestArun BeniwalNoch keine Bewertungen

- Steam Engineering Unit TestDokument3 SeitenSteam Engineering Unit TestArun BeniwalNoch keine Bewertungen

- MCQ 2018 Unit Test 1 Set-BDokument1 SeiteMCQ 2018 Unit Test 1 Set-BArun BeniwalNoch keine Bewertungen

- AnovaDokument13 SeitenAnovaArun BeniwalNoch keine Bewertungen

- Steam Engineering Unit TestDokument3 SeitenSteam Engineering Unit TestArun BeniwalNoch keine Bewertungen

- Project Synopsys 1 2018Dokument2 SeitenProject Synopsys 1 2018Arun BeniwalNoch keine Bewertungen

- Meul703 TurbomachinesDokument2 SeitenMeul703 TurbomachinesArun BeniwalNoch keine Bewertungen

- Distance Learning 2016 Telecom AcademyDokument17 SeitenDistance Learning 2016 Telecom AcademyDyego FelixNoch keine Bewertungen

- Apostles CreedDokument141 SeitenApostles Creedjerome mecca0% (2)

- Test Unit 3Dokument2 SeitenTest Unit 3RAMONA SECUNoch keine Bewertungen

- Modern Mathematical Statistics With Applications (2nd Edition)Dokument13 SeitenModern Mathematical Statistics With Applications (2nd Edition)Alex Bond11% (28)

- Mock Exam 2Dokument33 SeitenMock Exam 2Althea Karmylle M. BonitaNoch keine Bewertungen

- Web Search - One People's Public Trust 1776 UCCDokument28 SeitenWeb Search - One People's Public Trust 1776 UCCVincent J. CataldiNoch keine Bewertungen

- The Human Element is Critical in Personal SellingDokument18 SeitenThe Human Element is Critical in Personal SellingArsalan AhmedNoch keine Bewertungen

- ASBMR 14 Onsite Program Book FINALDokument362 SeitenASBMR 14 Onsite Program Book FINALm419703Noch keine Bewertungen

- Lecture 15 (91 Slides)Dokument91 SeitenLecture 15 (91 Slides)Hasnain GoharNoch keine Bewertungen

- Psychology - A Separate PeaceDokument2 SeitenPsychology - A Separate PeacevasudhaaaaaNoch keine Bewertungen

- Goan Bread Tradition Questions AnsweredDokument2 SeitenGoan Bread Tradition Questions AnsweredPreeti SharmaNoch keine Bewertungen

- Fractional GradingDokument7 SeitenFractional Gradingapi-355619062Noch keine Bewertungen

- ARCH1350 Solutions 6705Dokument16 SeitenARCH1350 Solutions 6705Glecy AdrianoNoch keine Bewertungen

- LumsDokument52 SeitenLumsUmar AliNoch keine Bewertungen

- Gcse English Literature Coursework Grade BoundariesDokument8 SeitenGcse English Literature Coursework Grade Boundariesafjwfealtsielb100% (1)

- Di OutlineDokument81 SeitenDi OutlineRobert E. BrannNoch keine Bewertungen

- Silvianita - LK 0.1 Modul 2 English For Personal CommunicationDokument3 SeitenSilvianita - LK 0.1 Modul 2 English For Personal CommunicationSilvianita RetnaningtyasNoch keine Bewertungen

- Technical Specifications For The: LAMBDA 950 UV/Vis/NIR and LAMBDA 850 UV/Vis SpectrophotometersDokument4 SeitenTechnical Specifications For The: LAMBDA 950 UV/Vis/NIR and LAMBDA 850 UV/Vis SpectrophotometersDiogo GálicoNoch keine Bewertungen

- Benefits and Risks of Dexamethasone in Noncardiac Surgery: Clinical Focus ReviewDokument9 SeitenBenefits and Risks of Dexamethasone in Noncardiac Surgery: Clinical Focus ReviewAlejandra VillaNoch keine Bewertungen

- Dwi Athaya Salsabila - Task 4&5Dokument4 SeitenDwi Athaya Salsabila - Task 4&521Dwi Athaya SalsabilaNoch keine Bewertungen

- Life and Works of Jose RizalDokument5 SeitenLife and Works of Jose Rizalnjdc1402Noch keine Bewertungen

- The Meaning of Al FatihaDokument11 SeitenThe Meaning of Al Fatihammhoward20Noch keine Bewertungen

- Summary Basis For Regulatory Action TemplateDokument23 SeitenSummary Basis For Regulatory Action TemplateAviseka AcharyaNoch keine Bewertungen

- Ns5e rw3 SB Ak HyeDokument24 SeitenNs5e rw3 SB Ak HyeKeys Shield JoshuaNoch keine Bewertungen

- 59-33 ATO Implementation Journal KSA 100Dokument18 Seiten59-33 ATO Implementation Journal KSA 100nicolas valentinNoch keine Bewertungen

- BCOM 302 BookDokument179 SeitenBCOM 302 BookHitanshi AgarwalNoch keine Bewertungen

- The Army Crew Team Case AnalysisDokument3 SeitenThe Army Crew Team Case Analysisarshdeep199075% (4)

- Semi-Detailed Lesson Plan Template: Pagsanjan Intergrated National High School 8Dokument3 SeitenSemi-Detailed Lesson Plan Template: Pagsanjan Intergrated National High School 8Mae Ganate RoblesNoch keine Bewertungen

- A Study On Inventory Management Towards Organizational Performance of Manufacturing Company in MelakaDokument12 SeitenA Study On Inventory Management Towards Organizational Performance of Manufacturing Company in MelakaOsama MazharNoch keine Bewertungen

- 3B Adverbial PhrasesDokument1 Seite3B Adverbial PhrasesSarah INoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyVon EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNoch keine Bewertungen

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationVon EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNoch keine Bewertungen

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Implementing an Integrated Management System (IMS): The strategic approachVon EverandImplementing an Integrated Management System (IMS): The strategic approachBewertung: 5 von 5 Sternen5/5 (2)

- Handbook on Battery Energy Storage SystemVon EverandHandbook on Battery Energy Storage SystemBewertung: 4.5 von 5 Sternen4.5/5 (2)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Rules of Thumb for Maintenance and Reliability EngineersVon EverandRules of Thumb for Maintenance and Reliability EngineersBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesVon EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertBewertung: 3 von 5 Sternen3/5 (2)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeVon EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeBewertung: 4 von 5 Sternen4/5 (130)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen