Beruflich Dokumente

Kultur Dokumente

SMP For Vacuum Pump

Hochgeladen von

SonratOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SMP For Vacuum Pump

Hochgeladen von

SonratCopyright:

Verfügbare Formate

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 1 of 9

STANDARD MAINTANENCE PROCEDURE

FOR

VACCUM PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 2 of 9

OBJECTIVE

The purpose of this work instruction is to explain the procedure for carrying out Overhaul of

VACCUM PUMP.

1. VACCUM PUMP

The details of the VACCUM PUMP are as follows :

Make: GARDNER DENVER NASH MACHINERY LTD.; MODEL-F-68, TYPE-2BE4 400-2BY3,

Q=3751.8 kg/h, H=-45.06 kPa MOTOR TYPE Y2 315L1-4, 160kW, 415V.

DETAILED INSTRUCTION

Sr. Activity

No.

I Overhaul to be done as per Checklist

1 Before commencing dismantling operations, ensure that the

following tools and tackles are available:

A crane / chain pulley block suitable for handling the weight of

pumping unit.

A selection of ring and open-ended spanners in Metric sizes.

Eyebolts in Metric sizes.

Hardwood and metal packing blocks.

Miscellaneous tools including a set of Allen keys, drills, pin drivers,

files etc.

Extractor / puller for bearing and coupling.

.

After a long service, wear will occur in parts of the pump necessitating

the renewal of the parts. Those most likely to be affected are impeller,

Wear Rings, Bearings, and Sleeves.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 3 of 9

2 Dismantling

1. Before dismantling, make sure the motor is disconnected.

2. The suction and discharge shutoff valves must be closed.

3. The pump casing must have cooled down to ambient

temperature.

4. The pump casing must be empty and not under pressure.

5. Detach all auxiliary supply pipe lines.

6. Remove belt guard.

7. Remove belts & pulley from the pump shaft.

8. Pull out bearing bracket with discharge cover and complete rotor

(assembled unit).

9. If the pump has been in operation for a long time some parts

may be difficult to remove.

In this case use a penetrating oil or suitable pull-off device.

10.Loosen & remove impeller Lock nut.

11.Remove impeller from pump shaft.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 4 of 9

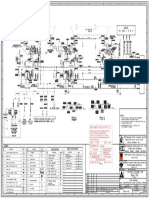

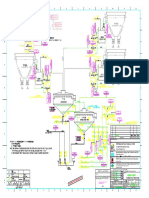

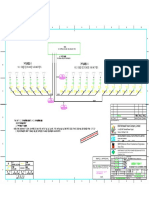

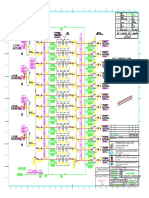

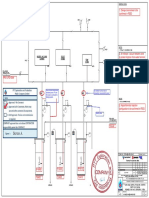

BLOW-UP DRAWING FOR VACCUM PUMP

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 5 of 9

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 6 of 9

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 7 of 9

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 8 of 9

REVIEW DATE:-

SMP WILL BE REVIEWED IN EVERY SIX MONTH FROM THE DATE OF ISSUE BASED ON

ACTUAL PROBLEM FACED AND SHALL BE UPDATED ACCORDINGLY.

MECHANICAL MAINTANENCE TEAM WILL VISIT THE EQUIPMENT TWICE IN A WEEK & IF

ANY ABNORMALITY NAMELY (VIBRATION, ABNORMAL SOUND, TEMPERATURE RISE, BELT

TIGHTNESS ETC) OF EQUIPMENT IS OBSERVED AND THEN THE SAME WILL BE RECTIFIED

WITHIN PRESCRIBED TIME PERIOD.

DO’s & DONT’s :

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Power from knowledge

KSK Mahanadi Power Company Ltd.

6 X 600 MW Power Plant KMPCL/MAINT/VP/01

SMP FOR BA HP PUMP

Issue No: 1 Issue Date: Revision: 1 Revision Date: 29.07.13 File no: Page 9 of 9

DO’s :

1. Ensure relevant equipment/system PTW is available before starting the work.

2. Ensure relevant equipment/system is electrically isolated before starting the work, if applicable.

3. Ensure relevant air/water valves are fully closed for the equipment/system before starting the work.

4. Provide Danger Boards before starting the work involving dismantling of any equipment/system.

5. Ensure proper follow-up of all statutory requirements & hazard norms.

6. Ensure proper follow-up of all plant practices, existing regulations, prescribed procedures & general

safety prior to carry out any work.

7. While replacing any spares/oil, ensure that the same must be as per OEM recommendation.

8. After overhauling of any equipment, ensure proper preservation of spares/oil.

9. Always use the special tools as recommended by OEM for certain equipments like HCSD Pump.

DONT’s :

1. Don’t start the work without presence of Safety Personnel in case fire / other hazards are involved.

2. Don’t use hammer / heating for removing bearings / gears.

3. Don’t use tools & tackles which are not calibrated / certified by relevant authority.

4. Don’t start the work in Pressure Vessels/Pressure Line/Water Line, unless it is completely de-

pressurised.

5. Don’t start the work, especially at height, without proper PPE’s.

6. Don’t start the work, without presence of skilled personnel/expert.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

Das könnte Ihnen auch gefallen

- SMP For Sealing Water Pump Multi Stage.Dokument13 SeitenSMP For Sealing Water Pump Multi Stage.SonratNoch keine Bewertungen

- CCCWDokument7 SeitenCCCWSonratNoch keine Bewertungen

- SMP For Agitator (Slurry Sump)Dokument9 SeitenSMP For Agitator (Slurry Sump)SonratNoch keine Bewertungen

- PM WORK For Fluidizing Blower of Fly Ash SiloDokument4 SeitenPM WORK For Fluidizing Blower of Fly Ash SiloSonratNoch keine Bewertungen

- PM Work For Bag Filters of Fly Ash SiloDokument4 SeitenPM Work For Bag Filters of Fly Ash SiloSonrat0% (1)

- Sop For Concentrator (r1)Dokument5 SeitenSop For Concentrator (r1)Sonrat100% (1)

- SMP For Supply Water PumpDokument13 SeitenSMP For Supply Water PumpSonratNoch keine Bewertungen

- Sop For Vent FilterDokument6 SeitenSop For Vent FilterSonratNoch keine Bewertungen

- OCCW Pump SOP-1Dokument7 SeitenOCCW Pump SOP-1SonratNoch keine Bewertungen

- Sop For Ba-Hp Pump (r1)Dokument6 SeitenSop For Ba-Hp Pump (r1)SonratNoch keine Bewertungen

- Sop For HCSD PumpDokument6 SeitenSop For HCSD PumpSonrat100% (2)

- PM FOR FLY ASH Dry SystemDokument30 SeitenPM FOR FLY ASH Dry SystemSonratNoch keine Bewertungen

- Condenser Ball Cleaning SystemDokument6 SeitenCondenser Ball Cleaning SystemSonratNoch keine Bewertungen

- PM For Bottom Ash Wet System SystemDokument7 SeitenPM For Bottom Ash Wet System SystemSonratNoch keine Bewertungen

- Standard Operating Instruction: Sop For Condenser Ball CleaningDokument6 SeitenStandard Operating Instruction: Sop For Condenser Ball CleaningSonratNoch keine Bewertungen

- Sop For Ta CompressorDokument8 SeitenSop For Ta CompressorSonratNoch keine Bewertungen

- Turbine Drains SOPDokument6 SeitenTurbine Drains SOPSonratNoch keine Bewertungen

- Sop For Ash Slurry Pump (r1)Dokument6 SeitenSop For Ash Slurry Pump (r1)SonratNoch keine Bewertungen

- SMP For Dry Ash UnloaderDokument8 SeitenSMP For Dry Ash UnloaderSonratNoch keine Bewertungen

- MDBFP Sop KSK-1Dokument12 SeitenMDBFP Sop KSK-1SonratNoch keine Bewertungen

- Standard Operating Instruction: Turbine Lube Oil SystemDokument34 SeitenStandard Operating Instruction: Turbine Lube Oil SystemSonratNoch keine Bewertungen

- PM Work For Dry Ash UnloaderDokument4 SeitenPM Work For Dry Ash UnloaderSonratNoch keine Bewertungen

- 057 - SOP of Boiler Circulating Pump FlushingDokument6 Seiten057 - SOP of Boiler Circulating Pump FlushingsambhuNoch keine Bewertungen

- Sop For Eco SystemDokument6 SeitenSop For Eco SystemSonratNoch keine Bewertungen

- Standard Operating Instruction: Sop For CT FanDokument5 SeitenStandard Operating Instruction: Sop For CT FanSonratNoch keine Bewertungen

- Gland Sealing Systeam011Dokument6 SeitenGland Sealing Systeam011SonratNoch keine Bewertungen

- Sop For Eco-Hp Pump (r1)Dokument6 SeitenSop For Eco-Hp Pump (r1)SonratNoch keine Bewertungen

- Final KSK Sop Instrument CompressorDokument10 SeitenFinal KSK Sop Instrument CompressorSonratNoch keine Bewertungen

- Sop For LP PumpDokument5 SeitenSop For LP PumpSonratNoch keine Bewertungen

- My Latest CV - EngineerDokument3 SeitenMy Latest CV - EngineersasibhushanNoch keine Bewertungen

- KSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpDokument6 SeitenKSK Mahanadi Power Company Ltd. 6 X 600 MW Power Plant Sop For Vacuume PumpSonratNoch keine Bewertungen

- Sop For Oil Purification SystemDokument8 SeitenSop For Oil Purification SystemSonrat100% (1)

- Sop For LP Pump (R1)Dokument6 SeitenSop For LP Pump (R1)SonratNoch keine Bewertungen

- Chapter 15 Condensate SystemDokument11 SeitenChapter 15 Condensate SystemsambhuNoch keine Bewertungen

- Sop For LP PumpDokument5 SeitenSop For LP PumpSonratNoch keine Bewertungen

- Standard Operating InstructionDokument8 SeitenStandard Operating InstructionSonratNoch keine Bewertungen

- Sop For Dry Ash Pressure Conveying SystemDokument7 SeitenSop For Dry Ash Pressure Conveying SystemSonratNoch keine Bewertungen

- First Fill Bed Material Calculation For Bed Plate W DDokument3 SeitenFirst Fill Bed Material Calculation For Bed Plate W DRAJKUMARNoch keine Bewertungen

- Condensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDokument8 SeitenCondensate Extraction Pump (CEP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNoch keine Bewertungen

- Cep Sop KSKDokument11 SeitenCep Sop KSKSonratNoch keine Bewertungen

- Sop For Vacuum PumpDokument7 SeitenSop For Vacuum PumpSonratNoch keine Bewertungen

- Commissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaDokument21 SeitenCommissioning Measures Form For Approval: Phase I of 2×330MW Project of Tengda Coal-Fired Power Plant in IndiaParthiban KarunaNoch keine Bewertungen

- Cold Start Up Check ListDokument6 SeitenCold Start Up Check ListSreekanthMylavarapuNoch keine Bewertungen

- Maintenance BFPDokument28 SeitenMaintenance BFPYulianto Kartono100% (1)

- EH Oil Pump SOPDokument8 SeitenEH Oil Pump SOPSonratNoch keine Bewertungen

- CCW Pump First Trial Run Check ListDokument8 SeitenCCW Pump First Trial Run Check ListA.PRABHAKARANNoch keine Bewertungen

- Steam Circulation SystemDokument36 SeitenSteam Circulation Systemnavdeeplakhera100% (1)

- CC Pump Manual-Full (Original)Dokument109 SeitenCC Pump Manual-Full (Original)friendbce100% (1)

- List of BHEL TOP File Handed Over To DocumentationDokument578 SeitenList of BHEL TOP File Handed Over To DocumentationNaresh PattanaikNoch keine Bewertungen

- Standard Operation ProcedureDokument66 SeitenStandard Operation Procedureved847100% (2)

- MDBFP Oil FlushingDokument13 SeitenMDBFP Oil Flushingsrigirisetty208Noch keine Bewertungen

- LR Soot Blow PDFDokument35 SeitenLR Soot Blow PDFvtbk100% (1)

- Sop For Recovery Water Pump (r1) IncompleteDokument6 SeitenSop For Recovery Water Pump (r1) IncompleteSonratNoch keine Bewertungen

- Steam Turbine Jacking Oil SystemDokument6 SeitenSteam Turbine Jacking Oil SystemAli Hegaig100% (1)

- ACWDokument9 SeitenACWrohit_me083Noch keine Bewertungen

- 11V02 Acc SPC M 0001 V2 Part ADokument182 Seiten11V02 Acc SPC M 0001 V2 Part Asuparnabhose100% (1)

- BFP TDDokument22 SeitenBFP TDArvind ShuklaNoch keine Bewertungen

- SMP For Fluidizing Air BlowerDokument20 SeitenSMP For Fluidizing Air BlowerSonrat100% (1)

- SMP For Slurry PumpDokument14 SeitenSMP For Slurry PumpSonrat100% (1)

- SMP For Electric Air LockerDokument9 SeitenSMP For Electric Air LockerSonratNoch keine Bewertungen

- Bah Side ViewDokument1 SeiteBah Side ViewSonratNoch keine Bewertungen

- Part List - BEL0800 PDFDokument1 SeitePart List - BEL0800 PDFSonratNoch keine Bewertungen

- SMP For Dry Ash UnloaderDokument8 SeitenSMP For Dry Ash UnloaderSonratNoch keine Bewertungen

- SMP For Ba Overflow PumpDokument14 SeitenSMP For Ba Overflow PumpSonratNoch keine Bewertungen

- Control Write Up HCSDDokument10 SeitenControl Write Up HCSDSonratNoch keine Bewertungen

- Bah ElevationDokument1 SeiteBah ElevationSonratNoch keine Bewertungen

- SMP For Fluidizing Air BlowerDokument20 SeitenSMP For Fluidizing Air BlowerSonrat100% (1)

- Sop For Vent FilterDokument6 SeitenSop For Vent FilterSonratNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- SMP For Slurry PumpDokument14 SeitenSMP For Slurry PumpSonrat100% (1)

- HCSD PDFDokument1 SeiteHCSD PDFSonratNoch keine Bewertungen

- SMP For Supply Water PumpDokument13 SeitenSMP For Supply Water PumpSonratNoch keine Bewertungen

- FluidizingDokument13 SeitenFluidizingSonratNoch keine Bewertungen

- Over Flow Pump Concentrator Buffer Tank ModelDokument1 SeiteOver Flow Pump Concentrator Buffer Tank ModelSonratNoch keine Bewertungen

- ASH WATER PUMP HOUSE-Model PDFDokument1 SeiteASH WATER PUMP HOUSE-Model PDFSonratNoch keine Bewertungen

- BAH JET PUMP DISCHAGE PIPE LINE-Model PDFDokument1 SeiteBAH JET PUMP DISCHAGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- Pdi EspDokument1 SeitePdi EspSonratNoch keine Bewertungen

- PM For Fly Ash Dry SystemDokument31 SeitenPM For Fly Ash Dry SystemSonratNoch keine Bewertungen

- StructureDokument1 SeiteStructureSonratNoch keine Bewertungen

- Water & Slurry BalanceDokument1 SeiteWater & Slurry BalanceSonratNoch keine Bewertungen

- ECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFDokument1 SeiteECO-JET PUMP-DISCHARGE PIPE LINE-Model PDFSonratNoch keine Bewertungen

- Compressor House ModelDokument1 SeiteCompressor House ModelSonratNoch keine Bewertungen

- Silo Blower Compressor ModelDokument1 SeiteSilo Blower Compressor ModelSonratNoch keine Bewertungen

- VP To Buffr Hopper-ModelDokument1 SeiteVP To Buffr Hopper-ModelSonratNoch keine Bewertungen

- Silo Unloading ModelDokument1 SeiteSilo Unloading ModelSonratNoch keine Bewertungen

- ESP-FLD. BLOWER-Model PDFDokument1 SeiteESP-FLD. BLOWER-Model PDFSonratNoch keine Bewertungen

- Buffer Hopper & Air Lock Tank-ModelDokument1 SeiteBuffer Hopper & Air Lock Tank-ModelSonratNoch keine Bewertungen

- Unidades Interiores Ductos MHBDokument32 SeitenUnidades Interiores Ductos MHBjuanNoch keine Bewertungen

- Emergency Stop & Idle Timer System Liebh 9400Dokument2 SeitenEmergency Stop & Idle Timer System Liebh 9400Nova kurniawan 34Noch keine Bewertungen

- Chem-Feed Diaphragm Metering Pump: FeaturesDokument4 SeitenChem-Feed Diaphragm Metering Pump: FeaturesAlejandro MoralesNoch keine Bewertungen

- Seal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDokument5 SeitenSeal Supply Systems - Thermosiphon Systems: Rely On ExcellenceDikaAnindyajatiNoch keine Bewertungen

- Single Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - ZDokument2 SeitenSingle Counterbalance, Relief Compensated: A-VBSO-SE-CC-30-PL 08.45.17 - X - Y - Znemi90Noch keine Bewertungen

- Rac MCQDokument20 SeitenRac MCQAbhijit BiswasNoch keine Bewertungen

- Pressure Swing AdsorptionDokument2 SeitenPressure Swing AdsorptionaiensyafiqahNoch keine Bewertungen

- Pumps and Valves Watts Bar Nujclear Power Plant: Unit 1Dokument69 SeitenPumps and Valves Watts Bar Nujclear Power Plant: Unit 1Miloud BekhitiNoch keine Bewertungen

- 02 - AFT - Know Your Pump & System Curves - Part 2ADokument8 Seiten02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNoch keine Bewertungen

- ME2135E Fluid Mechanics Lab - 1 Centrifigual PumpDokument11 SeitenME2135E Fluid Mechanics Lab - 1 Centrifigual PumpLinShaodun86% (7)

- Everest Blowers M5125 Technical Specs GADrawingw FiltraDokument4 SeitenEverest Blowers M5125 Technical Specs GADrawingw FiltraKELVIN TECHNOLOGIESNoch keine Bewertungen

- Pneumatic PosisionerDokument10 SeitenPneumatic Posisionerwong_arifNoch keine Bewertungen

- SRP 003x PRESSURE TEST PROCEDUREDokument10 SeitenSRP 003x PRESSURE TEST PROCEDURECavid MAMMADOVNoch keine Bewertungen

- SAMSON ANTI CAVITATION 3 TrimsDokument8 SeitenSAMSON ANTI CAVITATION 3 TrimsShaheen HydrosNoch keine Bewertungen

- Tacmina Motor SXDA1Dokument12 SeitenTacmina Motor SXDA1arisqi wahyuNoch keine Bewertungen

- Hvac CH 3Dokument23 SeitenHvac CH 3Abduljalil AlabidiNoch keine Bewertungen

- Druckabschaltventil enDokument4 SeitenDruckabschaltventil enSakthi Sekar CbiNoch keine Bewertungen

- Blow Off Tank-HurstDokument2 SeitenBlow Off Tank-HurstChristhian Dany Q.C.Noch keine Bewertungen

- Ball Valves and Cylindrical Valves: Compact One PieceDokument12 SeitenBall Valves and Cylindrical Valves: Compact One PieceershanquneriNoch keine Bewertungen

- HydroVar HDPE - Xls FinalDokument14 SeitenHydroVar HDPE - Xls FinalADsupermanNoch keine Bewertungen

- Serie HPRDokument4 SeitenSerie HPREstebanRojasKrustofskyNoch keine Bewertungen

- Lab 2 Fluid Bernoulli's Theorem DemonstrationDokument8 SeitenLab 2 Fluid Bernoulli's Theorem DemonstrationNURUL AINA BINTI MOHAMAD FUAD STUDENTNoch keine Bewertungen

- PS-PKS-FK-PRO-28 Form Cheklist KebersihanDokument3 SeitenPS-PKS-FK-PRO-28 Form Cheklist Kebersihanmuhammad fadlyNoch keine Bewertungen

- SINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValveDokument2 SeitenSINGER MODEL 106/206-RPS: Pressure Relief or Sustaining ValvezaidNoch keine Bewertungen

- Control HidraulicoDokument4 SeitenControl HidraulicoCe BayonaNoch keine Bewertungen

- Variable Inlet Guide Vane System: GE Power SystemsDokument4 SeitenVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- Hydraulic Cylinder Side LoadDokument8 SeitenHydraulic Cylinder Side LoadsushilNoch keine Bewertungen

- Power Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Dokument46 SeitenPower Plant Lecture Notes - CHAPTER-3 STEAM GENERATOR: October 2014Kimeli KiptanuiNoch keine Bewertungen

- Sample Fire Water UFD For FloaterDokument1 SeiteSample Fire Water UFD For FloaterdoosraemailNoch keine Bewertungen

- Bulletin Bctb-302 Gas CompressibilityDokument3 SeitenBulletin Bctb-302 Gas Compressibilityjhchung111Noch keine Bewertungen