Beruflich Dokumente

Kultur Dokumente

Intercambiador Comercial

Hochgeladen von

Gabriel GómezCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Intercambiador Comercial

Hochgeladen von

Gabriel GómezCopyright:

Verfügbare Formate

Heat Exchangers

Details

• SX2000U utilizes compact 3⁄8” OD tubes for

compact selections. Pre-engineered units

SX2000U/B300

4” thru 12” shell diameters.

• B300 utilizes larger 3⁄4“ OD tubes to handle

wide range of fluids. Shell diameters from

4” to 30” OD.

• Available in 2, 4 or 6 pass arrangements

to optimize performance requirements.

• ASME Section VIII Div. 1 “U” Stamp

as standard.

Exchanger Type:

U-Tube

Removable Floating Bundle

Advantages:

Allows for differential thermal

expansion between shell and tubes

as well as between individual tubes.

Capable of withstanding MATERIALS

thermal shock.

Shell Fabricated Carbon Steel with Stainless options

All welded rugged carbon steel

shell side construction provides Tubes Fabricated Carbon Steel with Stainless,

maximum durability. Sheets 90/10 CuNi and Brass options

Provides maximum heat transfer Copper with option for Stainless Steel,

Tubes 90/10 or 70/30 CuNi

surface area per given

shell and tube size. Cast Iron with Cast Stainless Steel 316

Bonnets and Cast Bronze options

Easily interchangeable with designs

of various manufacturers. Feet & Carbon Steel

Bolting

Limitations:

Individual tube replacement

not always possible. sX2000U/B300

Cannot be made single-pass Standard Design Capabilities

on tube side, so true counter

current flow not possible.

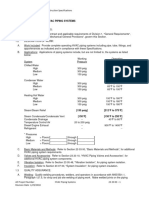

Design Design

Tube side can be cleaned Pressure Temperature

by chemical means only.

4” thru 8” Dia.–150 10”

375 ºF

Tube Side Dia. and up–150 psi

190.6 ºC

(10.5 kg/cm2)

150 psi 375 ºF

Shell Side

10.5 kg/cm2 190.6 ºC

The New Standard in Shell & Tube Heat Exchangers 7

Das könnte Ihnen auch gefallen

- Bell & Gossett Su Wu Shell and Tube Heat Exchanger BrochureDokument2 SeitenBell & Gossett Su Wu Shell and Tube Heat Exchanger BrochureThomas GuerreroNoch keine Bewertungen

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopVon EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Choke Technical Handbook PDFDokument13 SeitenChoke Technical Handbook PDFCesar GouroNoch keine Bewertungen

- HeatExchangers WebDokument4 SeitenHeatExchangers WebAdityaNoch keine Bewertungen

- New Copper - Tube Technologies For CO Heat Exchangers:: CO2 Gas Cooler and DX CoilDokument12 SeitenNew Copper - Tube Technologies For CO Heat Exchangers:: CO2 Gas Cooler and DX CoilRodrigo GonçalvesNoch keine Bewertungen

- ConstructionDokument38 SeitenConstructionChakravarthi NagaNoch keine Bewertungen

- 500mwboilermahagenco 140115124304 Phpapp02Dokument38 Seiten500mwboilermahagenco 140115124304 Phpapp02Lakshmi NarayanNoch keine Bewertungen

- BakerSPD Choke Tech Handbook 5-9-06 PDFDokument14 SeitenBakerSPD Choke Tech Handbook 5-9-06 PDFTg TarroNoch keine Bewertungen

- Spiral Tube Heat Exchanger: Optimize Heat Transfer Efficiency and SpaceDokument2 SeitenSpiral Tube Heat Exchanger: Optimize Heat Transfer Efficiency and SpaceTeuku Husein FahsyaNoch keine Bewertungen

- Sample Cooler Catalogue-SeplDokument2 SeitenSample Cooler Catalogue-SeplHANIF AKBARNoch keine Bewertungen

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDokument2 Seiten200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNoch keine Bewertungen

- Tube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Dokument5 SeitenTube Fittings: Size From 1/16" Thru 2" (2mm Thru 50mm)Jit BNoch keine Bewertungen

- 4-1. Hy-Lok Tube Fittings (2020)Dokument76 Seiten4-1. Hy-Lok Tube Fittings (2020)Jit BNoch keine Bewertungen

- Boiler Pressure PartsDokument3 SeitenBoiler Pressure PartsBedabyas DehuryNoch keine Bewertungen

- 112 09 Heat Exchangers BrochureDokument4 Seiten112 09 Heat Exchangers BrochureLe Quang SonNoch keine Bewertungen

- PF Cfhe Coils enDokument2 SeitenPF Cfhe Coils enfeyza cebiNoch keine Bewertungen

- 06 Ey PDFDokument1 Seite06 Ey PDFJavier Caamaño VillafañeNoch keine Bewertungen

- Spiral Tube Heat ExchangerDokument2 SeitenSpiral Tube Heat ExchangerM AhmadNoch keine Bewertungen

- Pipeline Strainer - SpecsDokument6 SeitenPipeline Strainer - SpecsCristhian AyanomeNoch keine Bewertungen

- SpiralHE12 1 1 PDFDokument2 SeitenSpiralHE12 1 1 PDFaqibazizkhanNoch keine Bewertungen

- Annexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3Dokument3 SeitenAnnexure Specification Dsil Requirement Quad Body 1200M2: Page 1 of 3kallappa naikNoch keine Bewertungen

- Basco Type 500Dokument12 SeitenBasco Type 500Sebastian OviedoNoch keine Bewertungen

- Evaporators: Dry-ExpansionDokument4 SeitenEvaporators: Dry-ExpansionghilesNoch keine Bewertungen

- Co Nfigurati O N Gu Ide: JMG Magnetic Level Gauge & JXC External ChamberDokument16 SeitenCo Nfigurati O N Gu Ide: JMG Magnetic Level Gauge & JXC External ChamberBaoLCNoch keine Bewertungen

- Get Profile 1 PDFDokument24 SeitenGet Profile 1 PDFحمودي معزNoch keine Bewertungen

- Alfa Laval M10-BW: Gasketed Plate-And-Frame Heat ExchangerDokument4 SeitenAlfa Laval M10-BW: Gasketed Plate-And-Frame Heat Exchangersandor terceroNoch keine Bewertungen

- Reflex Level GaugesDokument5 SeitenReflex Level GaugesKarthikeyanNoch keine Bewertungen

- 4-1. Hy-Lok Tube Fittings (2020)Dokument76 Seiten4-1. Hy-Lok Tube Fittings (2020)bernaNoch keine Bewertungen

- 23 20 00 Hvac Piping SystemsDokument14 Seiten23 20 00 Hvac Piping Systemsamirshahi2019Noch keine Bewertungen

- Flanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsDokument2 SeitenFlanged Spherical Pipe Joints: - Elastomeric Expansion Joints / Flexible ConnectorsKhaled Al AkhdarNoch keine Bewertungen

- Benefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksDokument17 SeitenBenefits of Extruded Heat Sinks: Plate Fin Heat Sinks Cross Cut Heat SinksFebri AndriyudaNoch keine Bewertungen

- Final Multi Rifled TubesDokument8 SeitenFinal Multi Rifled TubesböhmitNoch keine Bewertungen

- Heat Ex Changer Model Selection TypeDokument10 SeitenHeat Ex Changer Model Selection TypenoxleekNoch keine Bewertungen

- Datasheet Hydraulic Radiator AOCHMDokument5 SeitenDatasheet Hydraulic Radiator AOCHMLauraNoch keine Bewertungen

- Domestic Cat S 944MDokument8 SeitenDomestic Cat S 944MAnonymous 7xHNgoKE6eNoch keine Bewertungen

- Ball Valves 3,000 Psi To 10,000 PsiDokument15 SeitenBall Valves 3,000 Psi To 10,000 PsisitaNoch keine Bewertungen

- Asme Sa 210 Grade C TubesDokument1 SeiteAsme Sa 210 Grade C TubesFerroPipENoch keine Bewertungen

- 104-32 HTDokument8 Seiten104-32 HTLuis BassoNoch keine Bewertungen

- LNG Applications of Diffusion Bonded HEXDokument9 SeitenLNG Applications of Diffusion Bonded HEXrowanlimNoch keine Bewertungen

- PIPE SpecificationDokument5 SeitenPIPE SpecificationNilesh GohelNoch keine Bewertungen

- Shell and Tube Heat Exchanger Design 2Dokument29 SeitenShell and Tube Heat Exchanger Design 2Jonelou Cusipag100% (3)

- Severn 3000 Series V1.1Dokument8 SeitenSevern 3000 Series V1.1Thắng Trần QuangNoch keine Bewertungen

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationDokument5 SeitenTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelNoch keine Bewertungen

- Description Materials: Cast Iron For Horizontal InstallationDokument2 SeitenDescription Materials: Cast Iron For Horizontal InstallationParth GosaiNoch keine Bewertungen

- King 7470 Series DatasheetDokument2 SeitenKing 7470 Series DatasheetMacro MediciónNoch keine Bewertungen

- Reflex Type Guage GlassDokument6 SeitenReflex Type Guage Glasschamaras.engNoch keine Bewertungen

- Firetube or WatertubeDokument3 SeitenFiretube or WatertubeAdrian Soriaga LontocNoch keine Bewertungen

- Specification For Fire Pump - Part 10Dokument5 SeitenSpecification For Fire Pump - Part 10Melisa MackNoch keine Bewertungen

- Pressure Parts 500MW BoilerDokument34 SeitenPressure Parts 500MW Boilerdreamboy87Noch keine Bewertungen

- Copper TubesDokument10 SeitenCopper TubesJade Atkinson PhellaineNoch keine Bewertungen

- 501SHDokument2 Seiten501SHbhaskarbabaiNoch keine Bewertungen

- 2016 - 03 - 11 - 16 - 24 - Barton 202e 202n 242e J8a Tech DataDokument3 Seiten2016 - 03 - 11 - 16 - 24 - Barton 202e 202n 242e J8a Tech DataMounica PallaNoch keine Bewertungen

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDokument2 SeitenHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNoch keine Bewertungen

- 210 MW BoilerDokument25 Seiten210 MW BoilerAhemadNoch keine Bewertungen

- Product Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Dokument12 SeitenProduct Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Vilas m ChinkeNoch keine Bewertungen

- PF CFHE ClosedCircuitCoolers ENDokument2 SeitenPF CFHE ClosedCircuitCoolers ENLaurentiu ApostolNoch keine Bewertungen

- Materials of Construction: Conventional ConverterDokument2 SeitenMaterials of Construction: Conventional ConverterChrispine M BakulumaNoch keine Bewertungen

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDokument2 Seiten01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNoch keine Bewertungen

- C-J Catalog N - Cooker-CoolersDokument4 SeitenC-J Catalog N - Cooker-CoolersSky SpectreNoch keine Bewertungen

- Summary of MATLAB Onramp: Basic SyntaxDokument3 SeitenSummary of MATLAB Onramp: Basic SyntaxGabriel GómezNoch keine Bewertungen

- Tensile Test PLA 3D Print PDFDokument17 SeitenTensile Test PLA 3D Print PDFGabriel GómezNoch keine Bewertungen

- Artículo II ParcialDokument27 SeitenArtículo II ParcialGabriel GómezNoch keine Bewertungen

- Insights For Policy Makers: Biomass For Heat and Power Technology Brief 1Dokument22 SeitenInsights For Policy Makers: Biomass For Heat and Power Technology Brief 1Gabriel GómezNoch keine Bewertungen

- Combustibles LíquidosDokument21 SeitenCombustibles LíquidosGabriel GómezNoch keine Bewertungen

- Astm A 653Dokument13 SeitenAstm A 653Anonymous LQdcbfAEYNNoch keine Bewertungen

- Benchmade 2005 ConsumerDokument51 SeitenBenchmade 2005 ConsumerAdrian KozelNoch keine Bewertungen

- 210 Control Valve NewDokument4 Seiten210 Control Valve Newabdulhayee199811Noch keine Bewertungen

- Stainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicalDokument20 SeitenStainless Steel: Aerospace Paper Food Processing Metalworking Petrochemical ChemicaljjdNoch keine Bewertungen

- Material Science by S Montal Question PDFDokument54 SeitenMaterial Science by S Montal Question PDFÂvï JâísNoch keine Bewertungen

- EBK - LinepipeDokument2 SeitenEBK - Linepipeyrdna nawaiteosNoch keine Bewertungen

- Caution: Hemically Lackening RassDokument21 SeitenCaution: Hemically Lackening RassHarry Herdiana AgustianNoch keine Bewertungen

- Microstructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialDokument17 SeitenMicrostructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialEditor IJTSRDNoch keine Bewertungen

- What Is CRS Steel and Bar Bending Schedule - QuoraDokument5 SeitenWhat Is CRS Steel and Bar Bending Schedule - QuoraPritha DasNoch keine Bewertungen

- (Davies, Michael Scott, P.J.B.) Guide To The UseDokument645 Seiten(Davies, Michael Scott, P.J.B.) Guide To The UseامينNoch keine Bewertungen

- Mech Engg Question Bank - I Sem For MechanicalDokument124 SeitenMech Engg Question Bank - I Sem For Mechanicalanon_102708056Noch keine Bewertungen

- NS-ES-0241 - WESTINGHOUSE Enhanced Replacement Pressurizer Heaters - PWRDokument2 SeitenNS-ES-0241 - WESTINGHOUSE Enhanced Replacement Pressurizer Heaters - PWRLuis OrtizNoch keine Bewertungen

- Iso 17637-2016Dokument14 SeitenIso 17637-2016Upul Eranda Abeyrathna83% (6)

- Compulsory StdsDokument9 SeitenCompulsory StdsthakrarhitsNoch keine Bewertungen

- ASSAB Tool Steel Performance Comparison Chart PDFDokument1 SeiteASSAB Tool Steel Performance Comparison Chart PDFSophian Hakim WirajayaNoch keine Bewertungen

- Metallographic Investigation On The Cladding FailureDokument18 SeitenMetallographic Investigation On The Cladding FailureAndres_Pastor1987Noch keine Bewertungen

- 2110 Eng AlloyDokument53 Seiten2110 Eng AlloyDennis LingNoch keine Bewertungen

- GJ Profile (11-Jan-2015)Dokument15 SeitenGJ Profile (11-Jan-2015)nirdoshkumarNoch keine Bewertungen

- 201172711456351Dokument9 Seiten201172711456351Ferlie IndrapatiNoch keine Bewertungen

- Welders Performance Qualification Record: Actual Values Range QualifiedDokument13 SeitenWelders Performance Qualification Record: Actual Values Range QualifiedErick AguadoNoch keine Bewertungen

- Welding DefectsDokument4 SeitenWelding Defectsrohini nilajkar0% (1)

- Dorman Long 1924 Handbook PDFDokument403 SeitenDorman Long 1924 Handbook PDFKen SmithNoch keine Bewertungen

- Steel Castings, General Requirements, For Pressure-Containing Parts'Dokument14 SeitenSteel Castings, General Requirements, For Pressure-Containing Parts'amerNoch keine Bewertungen

- CR Mo 4Dokument2 SeitenCR Mo 4Mohsen ParpinchiNoch keine Bewertungen

- Astm A325Dokument3 SeitenAstm A325Mohammed 3014Noch keine Bewertungen

- DR Engp I 1.1 Rev.7Dokument752 SeitenDR Engp I 1.1 Rev.7Vinícius Toni MartinsNoch keine Bewertungen

- DX51D en 2 PDFDokument2 SeitenDX51D en 2 PDFОливер АндовскиNoch keine Bewertungen

- High Conductive High Galvanized Round Steel WireDokument2 SeitenHigh Conductive High Galvanized Round Steel WireAMARENDRA SINoch keine Bewertungen

- Fabrication Erection and Installation Procedure For PipingDokument35 SeitenFabrication Erection and Installation Procedure For Pipingmohd as shahiddin jafri100% (1)

- Process Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuideDokument55 SeitenProcess Industry Practices Structural: PIP STE05121 Anchor Bolt Design GuidemithileshNoch keine Bewertungen

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tVon EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tBewertung: 4.5 von 5 Sternen4.5/5 (27)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneVon EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Laws of UX: Using Psychology to Design Better Products & ServicesVon EverandLaws of UX: Using Psychology to Design Better Products & ServicesBewertung: 5 von 5 Sternen5/5 (9)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsVon EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNoch keine Bewertungen

- Analog Design and Simulation Using OrCAD Capture and PSpiceVon EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceNoch keine Bewertungen

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- 507 Mechanical Movements: Mechanisms and DevicesVon Everand507 Mechanical Movements: Mechanisms and DevicesBewertung: 4 von 5 Sternen4/5 (28)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceVon EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceBewertung: 4 von 5 Sternen4/5 (19)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesVon EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNoch keine Bewertungen

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchVon EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchBewertung: 4 von 5 Sternen4/5 (10)

- Design for How People Think: Using Brain Science to Build Better ProductsVon EverandDesign for How People Think: Using Brain Science to Build Better ProductsBewertung: 4 von 5 Sternen4/5 (8)

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsVon EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsVon EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsNoch keine Bewertungen

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingVon EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNoch keine Bewertungen