Beruflich Dokumente

Kultur Dokumente

Comparison Pe4710 Pe3608

Hochgeladen von

Rene CALLIRI MAQUERA0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

139 Ansichten1 SeiteComparacion de tuberias PE4710 vs PE3608

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenComparacion de tuberias PE4710 vs PE3608

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

139 Ansichten1 SeiteComparison Pe4710 Pe3608

Hochgeladen von

Rene CALLIRI MAQUERAComparacion de tuberias PE4710 vs PE3608

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

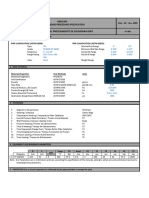

Sample Comparison between PE 4710 and PE 3608

Properties & Standards PE 4710 PE 3608 PE 3408

Tensile yield strength (psi, min) @ 73⁰F 3,500 3,000

Allowable compressive stress (psi) @ 73⁰F 1,150 1,000

Hydrostatic Design Stress (psi) @ 73⁰F 1,000 800

Pressure Class, DR 11 (psi) @ 73⁰F 200 160

Allowable total pressure during recurring surge, DR 11 (psi) @ 73⁰F 300 240

Allowable total pressure during occasional surge, DR11 (psi) @ 73⁰F 400 320

Bend raduis, DR 11 (min.) 25 x Pipe OD

Design deflection limit, pressure pipe, DR 11 (AWWA M55) 5%

Pipe ID 12" DIPS, PC 200 (inches, nominal) 10.66 10.09

Fracture Toughness, PENT (hrs, min.) 500 100

Safe Pull Tensile Stress, 12 hrs (psi) @ 73⁰F 1,300 1,150

Apparent Elastic Modulus, 100 years (psi) @ 73⁰F 28,000 27,000

No longer available

Fatigue life, PPI PACE (years) ≥ 100

ANSI/AWWA C906-15 sizes 4" - 65"

Allowable leakage, M55 zero

Hazen-Williams C Factor 150

ASTM fusion standard ASTM F2620

ASTM Electrofusion standard ASTM F1055

ASTM HDD standard ASTM F1962

ASTM Fittings Standards ASTM D3261 / F2206

NSF standard NSF/ANSI 61

© 2015 Plastics Pipe Institute

AWWA Design Factor 0.63 0.5

AWWA Safety Factor (against burst) >2

AWWA Manual AWWA M55

ANSI/AWWA Standards AWWA C901-08 and C906-15

July 2015

Das könnte Ihnen auch gefallen

- Soldaduras Varios PDFDokument54 SeitenSoldaduras Varios PDFCristhian AndresNoch keine Bewertungen

- Content of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesDokument24 SeitenContent of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesJuan Ayala ValdebenitoNoch keine Bewertungen

- Hdpe Bps Sab355Dokument1 SeiteHdpe Bps Sab355Benjamin Enmanuel Mango DNoch keine Bewertungen

- Guía de Evaluación AWS G1.10MDokument45 SeitenGuía de Evaluación AWS G1.10MDaniel Jimenez100% (1)

- Split Tee CatalogoDokument3 SeitenSplit Tee Catalogobotella berNoch keine Bewertungen

- Astm F2947-14Dokument7 SeitenAstm F2947-14Augusto MedeirosNoch keine Bewertungen

- Gasket Paking ListDokument1 SeiteGasket Paking ListIrwansyah MuchtarNoch keine Bewertungen

- F 876 - 01 - Rjg3ni0wmuuyDokument6 SeitenF 876 - 01 - Rjg3ni0wmuuyPrakash MakadiaNoch keine Bewertungen

- Astm A 335Dokument8 SeitenAstm A 335Ruben Dario Espinoza Vasquez100% (1)

- TR 33 Generic Butt Fusion Joining Gas PipeDokument40 SeitenTR 33 Generic Butt Fusion Joining Gas PipeRamonezeNoch keine Bewertungen

- ASTM C1147-14 CodeDokument4 SeitenASTM C1147-14 CodeGene DiJoseph100% (1)

- Astm-F 2164Dokument5 SeitenAstm-F 2164damithNoch keine Bewertungen

- PCR PCRH Full lit-SP PDFDokument18 SeitenPCR PCRH Full lit-SP PDFjuanfco1965100% (1)

- Bolt Torque Chart: ASTM A307Dokument5 SeitenBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- Anexo I - Típicos de Soportes Metálicos PDFDokument174 SeitenAnexo I - Típicos de Soportes Metálicos PDFAngely CanalesNoch keine Bewertungen

- Figure 323.2 Asme b31.3Dokument1 SeiteFigure 323.2 Asme b31.3Siddiqui Abdul KhaliqNoch keine Bewertungen

- F2788 PDFDokument11 SeitenF2788 PDFHernando Andrés Ramírez GilNoch keine Bewertungen

- gm19 - GEOMEMBRANASDokument13 Seitengm19 - GEOMEMBRANASIsaias Quispe RuizNoch keine Bewertungen

- Dimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97Dokument3 SeitenDimensions of Sockolets Pressure Class 3000 and 6000 Lbs - MSS-SP97konazoi100% (1)

- PQR For 32 MM PlateDokument1 SeitePQR For 32 MM PlateMuhammed MubeenNoch keine Bewertungen

- 1 5011739Dokument10 Seiten1 5011739rizky rodytullahNoch keine Bewertungen

- 4S-10.01 Simons FRP Structures PDFDokument27 Seiten4S-10.01 Simons FRP Structures PDFjdiaz87Noch keine Bewertungen

- Polyken 930: Product Data SheetDokument2 SeitenPolyken 930: Product Data SheetAgustina De Winne100% (1)

- GRI GM19aDokument13 SeitenGRI GM19aAllen EstelaNoch keine Bewertungen

- Pexgol Engineering GuideDokument88 SeitenPexgol Engineering GuideGiann CarlosNoch keine Bewertungen

- Astm E96.9061 PDFDokument8 SeitenAstm E96.9061 PDFgaso99Noch keine Bewertungen

- HDPE Pipes MichelangeloDokument58 SeitenHDPE Pipes MichelangeloAleksa CavicNoch keine Bewertungen

- Inconel 82 PDFDokument1 SeiteInconel 82 PDFMiguel MorenoNoch keine Bewertungen

- BN-DS-A000 Design Standards OverviewDokument2 SeitenBN-DS-A000 Design Standards Overviewyulianus_srNoch keine Bewertungen

- Astm D 3035 PDFDokument7 SeitenAstm D 3035 PDFSushil GambhirNoch keine Bewertungen

- F 1055 - 98 RjewntutotgDokument9 SeitenF 1055 - 98 RjewntutotgMMNoch keine Bewertungen

- Corrugated Single Wall PCPP BrochureDokument1 SeiteCorrugated Single Wall PCPP BrochurebcsmurthyNoch keine Bewertungen

- Astm F412-2009Dokument16 SeitenAstm F412-2009WalterNoch keine Bewertungen

- Astm d2444 21 落锤试验机标准Dokument10 SeitenAstm d2444 21 落锤试验机标准Avin WangNoch keine Bewertungen

- Normas DVS PDFDokument11 SeitenNormas DVS PDFrodrigo diaz poblete100% (1)

- ASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseDokument5 SeitenASTM-F844 Washers, Steel, Plain (Flat), Unhardened For General UseleandroschroederNoch keine Bewertungen

- f2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDokument21 Seitenf2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDeyvi Vasquez PittmanNoch keine Bewertungen

- E.13 - Tylok (SM) SS-12-DMC-12Dokument1 SeiteE.13 - Tylok (SM) SS-12-DMC-12PercyAlexanderNoch keine Bewertungen

- Tabla de DVS 2212-1Dokument9 SeitenTabla de DVS 2212-1percivalczNoch keine Bewertungen

- Obtaining Hydrostatic or Pressure Design Basis For "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and FittingsDokument11 SeitenObtaining Hydrostatic or Pressure Design Basis For "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe and FittingsDavid Luna MolinaNoch keine Bewertungen

- Nozzle CatalogueDokument53 SeitenNozzle CatalogueMike UpNoch keine Bewertungen

- Dic Pps Weld StrengthDokument1 SeiteDic Pps Weld StrengthWoong KimNoch keine Bewertungen

- Standard Specification For Fiberglass, (Fibra de Vidrio)Dokument5 SeitenStandard Specification For Fiberglass, (Fibra de Vidrio)coltkidNoch keine Bewertungen

- Iso 15874-2-2013 - 2500Dokument26 SeitenIso 15874-2-2013 - 2500Udai SamiNoch keine Bewertungen

- Polyken 2036Dokument2 SeitenPolyken 2036nrd9771Noch keine Bewertungen

- Abrasion ResistanceDokument4 SeitenAbrasion ResistancerobigedNoch keine Bewertungen

- Astm F2634 2015Dokument13 SeitenAstm F2634 2015Ricardo PeraltaNoch keine Bewertungen

- Brochure UPI 2016Dokument24 SeitenBrochure UPI 2016ashishNoch keine Bewertungen

- Asme SB 862 Astm b862 PDFDokument14 SeitenAsme SB 862 Astm b862 PDFp v krishnakantNoch keine Bewertungen

- Astm E177Dokument13 SeitenAstm E177AlbertoNoch keine Bewertungen

- DVS 2207-12 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-UDokument7 SeitenDVS 2207-12 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-UEugenioNoch keine Bewertungen

- Simona-Catalogo Pipes & Fittings & ValvesDokument60 SeitenSimona-Catalogo Pipes & Fittings & ValvesMohamed MagdyNoch keine Bewertungen

- Perú Corp. S.A.: Piping Class Fire Fighting SystemDokument16 SeitenPerú Corp. S.A.: Piping Class Fire Fighting SystemRonny Estremadoiro ArteagaNoch keine Bewertungen

- Flat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PDokument2 SeitenFlat Washers, ASTM F436, Thru-Hardened, Plain: Page 1 of 2 REV-03 Date: November 17, 2015 FW.F436.PLuis CarlosNoch keine Bewertungen

- Anchor FlangeDokument4 SeitenAnchor FlangeHector MejiaNoch keine Bewertungen

- Hidrante Seco Mod F0733Dokument1 SeiteHidrante Seco Mod F0733Julio FloresNoch keine Bewertungen

- CRANE-Ficha Tecnica-Valvula CompuertaDokument1 SeiteCRANE-Ficha Tecnica-Valvula CompuertaWillyam JiménezNoch keine Bewertungen

- Distancia Mínima Entre SoldadurasDokument3 SeitenDistancia Mínima Entre SoldadurasMiguel Angel RebolloNoch keine Bewertungen

- Mechanical Specifications For Fiberbond ProductDokument8 SeitenMechanical Specifications For Fiberbond ProducthasnizaNoch keine Bewertungen

- Wear Plate BrochureDokument2 SeitenWear Plate Brochurec3512Noch keine Bewertungen

- Especificaciones Tecnicas Tee Hdpe FM Georg FisherDokument1 SeiteEspecificaciones Tecnicas Tee Hdpe FM Georg FisherRene CALLIRI MAQUERANoch keine Bewertungen

- Especificaciones Tecnicas Tee Hdpe FM Georg FisherDokument1 SeiteEspecificaciones Tecnicas Tee Hdpe FM Georg FisherRene CALLIRI MAQUERANoch keine Bewertungen

- Especificaciones Tecnicas Codo Hdpe FM Georg FischerDokument1 SeiteEspecificaciones Tecnicas Codo Hdpe FM Georg FischerRene CALLIRI MAQUERANoch keine Bewertungen

- Code: Student:: I Wish I Wasn't So Shy / I Was More ConfidentDokument2 SeitenCode: Student:: I Wish I Wasn't So Shy / I Was More ConfidentRene CALLIRI MAQUERANoch keine Bewertungen

- GEE ElectrodeDokument17 SeitenGEE ElectrodeSatyamEngNoch keine Bewertungen

- MSDS MEGAFLOC 515 Revisi OkDokument5 SeitenMSDS MEGAFLOC 515 Revisi OkYafie Al IslamiNoch keine Bewertungen

- Superoxide in Biology and MedicineDokument11 SeitenSuperoxide in Biology and MedicineNvo SpektarNoch keine Bewertungen

- Worksheet Cellular Respiration#2 - Ch9 PDFDokument6 SeitenWorksheet Cellular Respiration#2 - Ch9 PDFTaniaBarrios-ChongNoch keine Bewertungen

- General Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsDokument20 SeitenGeneral Chemistry 2: 2 Semester - Module 2 Types of Solids, Phase Changes and DiagramsKrisha Mae Oao Calumpit100% (2)

- Experiment 6: Determination of Ascorbic Acid Using Iodometric Titration MethodDokument7 SeitenExperiment 6: Determination of Ascorbic Acid Using Iodometric Titration MethodNurul AdNoch keine Bewertungen

- Stabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Dokument5 SeitenStabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Fadhil Muhammad AwaluddinNoch keine Bewertungen

- Agfa Cassettes Manual PDFDokument32 SeitenAgfa Cassettes Manual PDFcarlosNoch keine Bewertungen

- StereochemistryDokument52 SeitenStereochemistryTimmyNoch keine Bewertungen

- (William Jones, C. N. R. Rao) Supramolecular OrganDokument456 Seiten(William Jones, C. N. R. Rao) Supramolecular OrganJennifer Carolina Rosales NoriegaNoch keine Bewertungen

- LHB Coach (Mechnical Features)Dokument38 SeitenLHB Coach (Mechnical Features)gayathri12092002Noch keine Bewertungen

- Oring CatalogueDokument90 SeitenOring Cataloguedoan lucNoch keine Bewertungen

- RioBooster SDSDokument10 SeitenRioBooster SDSpepeNoch keine Bewertungen

- HY10 1630US 5 2012-Diaphragm AccumulatorsDokument6 SeitenHY10 1630US 5 2012-Diaphragm AccumulatorsAlejandro GilNoch keine Bewertungen

- International Journal of Mining, Reclamation and EnvironmentDokument17 SeitenInternational Journal of Mining, Reclamation and EnvironmentMargaritha Alexanderina FrancisNoch keine Bewertungen

- Phosphorus Removal On DewateringDokument39 SeitenPhosphorus Removal On DewateringAlberto SemillánNoch keine Bewertungen

- Alloy 276 Spec SheetDokument3 SeitenAlloy 276 Spec SheetermusatNoch keine Bewertungen

- Module 2: Infrared SpectrosDokument5 SeitenModule 2: Infrared SpectrosAngela ReyesNoch keine Bewertungen

- Radio-Analytical TechniquesDokument30 SeitenRadio-Analytical TechniquesMohammad Zamir TaqwaNoch keine Bewertungen

- ChemistryDokument9 SeitenChemistryAbhey GuptaNoch keine Bewertungen

- 44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTDokument8 Seiten44AC9100-000-V.02-0105-A4 - Rev B - GENERAL SPECIFICATION FOR WELDED TUBE TO TUBE SHEET JOINTAvinash ShuklaNoch keine Bewertungen

- Cls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12Dokument47 SeitenCls Jeead-18-19 Xii Che Target-7 Set-2 Chapter-12DxNoch keine Bewertungen

- Polymer Repair PDFDokument3 SeitenPolymer Repair PDFamirouche15Noch keine Bewertungen

- Neet Test Series 2022 Test Code: NT - 02: Biology Physics ChemistryDokument16 SeitenNeet Test Series 2022 Test Code: NT - 02: Biology Physics Chemistry6 months AgoNoch keine Bewertungen

- Design 2 MLDDokument9 SeitenDesign 2 MLDANIL KUMAR H CNoch keine Bewertungen

- 025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Dokument3 Seiten025welding Engineering An Introduction - (2.5 Plasma Arc Welding)Kamarul NizamNoch keine Bewertungen

- Contextualized Learners ModuleDokument23 SeitenContextualized Learners ModuleSou MeiNoch keine Bewertungen

- Fem Lab Quiz 2Dokument4 SeitenFem Lab Quiz 2srinis4777-1Noch keine Bewertungen

- GIZ Manual On IHWM Module 6bDokument8 SeitenGIZ Manual On IHWM Module 6bAlberto CamachoNoch keine Bewertungen

- D 3002 DesignDokument20 SeitenD 3002 DesignmargaretramosNoch keine Bewertungen