Beruflich Dokumente

Kultur Dokumente

4139M06017 Default 000

Hochgeladen von

gopi krishnaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4139M06017 Default 000

Hochgeladen von

gopi krishnaCopyright:

Verfügbare Formate

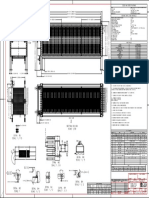

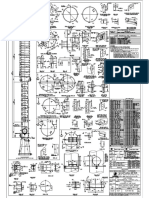

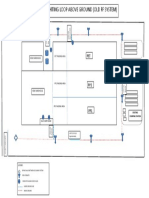

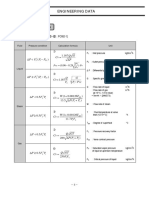

2700 HALF PIPE NPS 1• 32- { 48 HOLES FOR DESIGN DATA

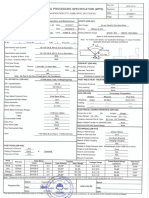

43 46 NPS4 WNRF M36 ANCHOR BOLTS AM AV CLIENT: GULF FARABI PETROCHEMICAL CO. LTD. PURCHASE ORDER NO. IK-5110-01A

33

1. DESIGN CODE: ASME VIII DIV. 1 ED. 2001 A03

EL.+25000 ID. 2423

200

0°

7.

2. STAMPING REQUIREMENT: NO U-STAMP U2-STAMP R-STAMP

5°

2-LIFTING TRUNNIONS 150 3. NATIONAL BOARD REGISTRATION: REQUIRED NOT REQUIRED

NPS 1•x2

AV 42 82 6THK.

200

1

180° APART 4. INSPECTION BY: ASME AI (ABS) CLIENT ODECO

CONC. REDUCER

VESSEL DAVIT DETAIL

81 OPERATING CONDITIONS

28 TYP. 8 NORMAL: -

AM 34 TO 39 PIPE NPS 2 5. INTERNAL PRESSURE (NORMAL) psig (Kg/Cm G):

2

MAXIMUM: -

AI 290

8 ° REF. PLANT NORTH 6. TEMPERATURE °F(°C): TOP/BOTTOM 132.8(56)/469.4(243) 7. SERVICE: -

21 9

8. SP. GRAVITY OF FLUID: (OPER./DESIGN) 0.702/1 9. LETHAL SERVICE: NO

400 150 77 10. CYCLIC SERVICE: NO 11. WET SOUR SERVICE: NO

12

V2

270° 90° 12. HYDROGEN SERVICE: NO 13. AMINE SERVICE: NO

40 TO 41A AO NOZZLE DETAIL 'FL1'NPS1½ NOZZLES DETAIL

14. NOMINAL CAPACITY: 34.43 CuM 15. NET CAPACITY 1.41 CuM

7 AL#1

(TYP.) DESIGN CONDITIONS

1

05° 16. DESIGN PRESSURE @ DESIGN TEMP.:psig (Kg/Cm2G) *INTERNAL: 50.07 (3.5204) @ 527 (275) °F (°C)

ID. 2150 psig (Kg/Cm2G) EXTERNAL: 15 (1.054) @ 469 (243) °F (°C)

17. MAX. ALLOWABLE WORKING PRESSURE: psig (Kg/Cm2G)

1040

HOT & CORRODED: 156.03 (10.97) @ 527 (275) °F (°C)

SKIRT ID. 2455

840

VESSEL DAVIT 18. D E L E T E D

V1 V1 2:1 ELLIPTICAL HEAD

B.C.D. 2620 SUPPORT

9 THK. MIN. & S.F. 10THK. MIN. (A.F.)

1 19. MDMT: 32 (0) °F(°C) 20. LPFT: -

OD. 2750 21. CORROSION ALLOWANCE: INCH (mm) SHELL/HEADS/NOZZLES/INTERNALS: 0.118 (3.0)

NOM. HEAD THK. = 12 mm

400

15

T.L. SKIRT: 0.063(1.6)

W.L. BASE & TOP COMP. RING

BC#1

7.

SHELL/HEAD 0.85/1

EL.+21700 22. JOINT EFFICIENCY:

5°

F. ANCHOR CHAIR DETAIL SHELL TO HEAD 1

50 S.

AI 30 TO 33 180°

AO 23. IMPACT TEST: REQD. NOT REQD. ITEM NO.

1200

RADIOGRAPHY RT4 (HEAD TO SHELL JOINT FULL)

10 100 10

40

EL.+21200 24. NDT: ULTRASONIC TESTING SEE NOTE 8b.1 PT VT

VIEW V1-V1

COURSE #9)

PNEUMATIC TEST FOR REINF. PADS (SEE NOTE 7b.2) PMI WFMT

VRD DISTRIBUTOR 2-LIFTING TRUNNIONS SCALE 1:30

25 27 30° CU 25. HYDROSTATIC TEST PRESSURE psig (Kg/Cm2G) SHOP (HORZ.): 236.12 (16.601) @ 69.8 (21) °F (°C)

(BY OTHERS) 180° APART

FIELD (VER.): 202.84 (14.261) @ 69.8 (21) °F (°C)

EL.+20700

40° 26. PNEUMATIC TEST PRESSURE psig (Kg/Cm G) 2

SHOP (HORZ.): N/A

4 AL

DM

9 0° 27. POSTWELD HEAT TREATMENT: NO 28.MANUFACTURING TOLERANCES: 16940-00-SP-832 Rev.01

300

215

2450 (

BED LIMITER #2

TYP. ,4 29. HARDNESS TESTING: NO PLATE MATERIAL PROD. WELD COUPON

12 DAVIT

PACKED BED #1 30 ,5 DESIGN CODE: UBC-1997 ZONE: 1

5° A

(BY OTHERS) 30. SEISMIC LOADING:SOIL PROFILE TYPE: SD

AL#1

45

DESIGN CODE: ASCE 7-98 DESIGN WIND SPEED: (43m/sec)154.8 Km/Hr

31. WIND LOADING:

DI EXPOSURE FACTOR: C IMP. FACTOR: 1.15

3000 PAKED BED #1

32. BASE WIND SHEAR (Kgf): 8800 33. WIND BENDING MOMENT (Kgf-m) 135000

VACUUM STIFF. RING FOUNDATION LOADINGS

80x10 THK.

23 270° 90° 34. BASE SIESMIC SHEAR (Kgf): 5300 35. SIESMIC BENDING MOMENT (Kgf-m) 97000

BC#2 { 54 SLOT HOLE BO BL1 FOR SKIRT BASE RING 36. FOUNDATION COMPRESSIVE STRENGTH (MPa): 5.17

IN BASE RING DESIGN 37. CONCRETE ULTIMATE TENSILE STRENGTH (MPa):

(28 DAYS) 20.684

EL.+19100 38. PAINTING: SEE NOTE 11 39. SURFACE AREA Sq.M (Sq.Ft.): 126 (1362)

S1 S1

VIEW - V2 0° BL2

25

AL#2

40. INSULATION: 70mm THK. FROM BOTTOM T/L TO 10450-REST 25mm TILL TOP

A 41 FIRE PROOFING (BY OTHERS): (OUTSIDE) 50mm THK.

BI ° L

60°+5°

3

0 13 #6 WEIGHT SUMMARY

COURSE #8)

2 ,3 0

° 42. FABRICATED WT. (WITHOUT PACKED BEDS, FIREPROOFING, INSULATION, REBOILER, LADDERS & PLATFORMS): ~16400 KGS.

0~4 5

GIS SUPPORT #

180°

0~4

L 43 COLUMN LIFT WT. (EXCLUDING FIREPROOFING WT.): ~49000 KGS.

TOP A

(BY OTHERS) DAVIT 44. EMPTY WT. (INSTALLED WITH REBOILER) : ~55820 KGS.

T

45. OPERATING WT. (WITH WORKING FLUID) : ~58661 KGS.

4 PACKED BED SUPPORT RING 160°

T/3

24 BOTTOM

2450 (

(BY ODECO)

BM 46. HYDROTESTING WT. (WATER FILLED) : ~77765 KGS.

60°+5°

ODECO REFERENCE DRAWINGS

SECTION S1-S1

DRAWING No. DESCRIPTION DRAWING No. DESCRIPTION

GROUND FLUSH LOCALLY

SCALE 1:30 4139-M06-02 MISCELLANEOUS DETAILS 4139-M06-07 BASE PLATE TEMPLATE DETAIL

AT GUSSET

550

4139-M06-03 MANWAY WITH HINGE DETAIL & DAVIT DETAILS 4139-M06-08 PLATFORMS & LADDERS DETAIL

4139-M06-04 DETAILS OF PIPE SUPPORT CLIPS 4139-M06-09 INSULATION SUPPORTS & FIRE PROOFING CLIPS DETAIL

4139-M06-05 PACKED BED & INTERNALS DETAILS 4139-M06-10 DETAIL OF HYDROTEST & TRANSPORTATION SADDLES

EL.+17150

)BY OTHER

BL1 43 46 BUTT JOINT IN COMPRESSION RING ET FL1 FL2 4139-M06-06 NAME PLATE & BRACKET DETAIL 4139-CS-M06 DESIGN CALCULATIONS

BC#3 CLIENT REFERENCE SPEC./DRAWINGS

SEE NOTE 8b.1 FS

345

DRAWINGS/SPECS. No. REV. DESCRIPTION

1900

0°

°

CHIMENEY TRAY VACUUM STIFF. RING GROUND FLUSH LOCALLY 3-11-4 30-DEC-99 PRESSURE VESSEL CORBON STEEL

30

23

INSULATION 25 THK.

WELD DETAIL 3-273-1 30-APR-99 REBOILER TUB FOR INTERMEDIATE STABBED-IN REBOILER

°

80x10 THK. AT GUSSET

(BY OTHERS)

AL#3

3-312-4 26-FEB-99 DISTRIBUTORS

60°+5° REF. DWG. 4146-M11-01 16940-00-SP-401 REV. 01 WIND & EARTH QUAKE LOADING

0~4 AL WO# 4146 PO# 1K-5310-01 16940-00-SP-800 REV. 01 GENERAL REQT'S FOR WELDED UNFIRED PRESSURE VESSELS

BL2 43 46 FU #7

0~4

COURSE #7)

TOP 16940-00-SP-832 REV. 01 FABRICATION DIMENSIONAL TOLERANCES

EL.+16100 30 ,9 16940-00-SP-837 REV. 01 PROTECTIVE PAINTS & COATINGS

5°

T

015559-000-SP-45-0002 REV. 01 EXTERNAL NOZZLE LOADS

EL.+15880 600-SP-45-0021 REV. 02 ADDITIONAL NOTES TO UOP PROJECT SPEC.

FD1 285

T/3

BOTTOM 917859-301 REV. 01 DATA SHEET FOR FINISHING COLUMN

CHIMENEY TRAY SUPPORT °

4 80 EL.+15650 60°+5° UN-2000-06, PART2 - VESSEL CLIPS FOR LADDER & PLATFORMS

(BY ODECO)

2450 (

59B50 - PIPING CLIPS

(

BO 53 TO 55

GROUND FLUSH FD2 270° 90° GENERAL NOTES:

11450

EL.+15260 FR 1. ALL DIMENSIONS ARE IN MM UNLESS OTHER WISE STATED.

BI 2. FINISH OF FLANGE FACES SHALL BE SMOOTH FINISH BETWEEN 125-250 AARH.

EL.+15060 DAVIT

BUTT JOINT IN BASE RING

1580

3. FLANGES UPTO NPS 24 ARE ACCORDING TO ASME B16.5. & ABOVE NPS 24 ACCORDING TO ASME B16.47 SERIES 'A'.

BM 47 TO 52 21 4. GASKET 4.5mm THK. SPIRAL WOUND GRAPHITE FILLED WITH SS-304 INNER RING AND C.S OUTER CENTERING RING.

82 45 44 SEE NOTE 8b.1

)

5. NOZZLE PROJECTIONS ARE FROM C.L. OF VESSEL TO FLANGE RAISED FACE, UNLESS OTHERWISE SPECIFIED.

10 THK.

6. FABRICATION:

VSI COLLECTOR/DISTR. 60°+5° 6.1. FABRICATION TOLERANCES PER ASME SEC. VIII DIV. 1 AND 16940-00-SP-832 REV. 01.

25 SHELL NAME PLATE A

L.

BC#4 (BY OTHERS) L 6.2. FLANGE BOLT HOLES SHALL STRADDLE THE NORMAL HORIZONTAL AND VERTICAL CENTERLINES OF COLUMN.

13 #8

T.

14700 (

& BRACKET ° 6.3. ANCHOR BOLTS SHALL STRADDLE COLUMN CENTERLINES ON NORTH-SOUTH, EAST-WEST AXIS.

COURSE #4A)

0 0

180°

INLET PIPE 3 ° 6.4. ALL EXTERNAL REINFORCEMENT PADS TO BE PROVIDED WITH MIN. OF ONE 1/4" NPS VENT HOLE. PADS FOR NOZZLES GREATER

26 2 THEN 16 INCH NPS HAVE A MIN. OF 2 VENT HOLES. AND NOZZLES IN EXECSS OF NPS 36 HAVE A MIN. OF 4 VENT HOLES.

(BY OTHERS)

AL#4

VENT HOLES SHALL BE TAPPED.

FM 6.5. INTERNAL AND EXTERNAL WELDED ATTACHMENT PADS SHALL HAVE THEIR CORNERS ROUNDED TO A MINIMUM RADIUS OF

INSIDE

VSI DISTRIBUTOR SUPPORT 50 mm RADIUS (UNLESS OTHERWISE STATED)

1~2

4A 0~4

6.6. REINF. PADS INSTALLED IN SECTIONS SHALL HAVE ATLEAST ONE HOLE PER SECTION.

(BY ODECO)

SECTION S2-S2

1225 (

6.7. THE INSIDE EDGE OF NOZZLE NECK BE RADUISED TO 6mm MIN.

HEAD TO SHELL WELD DETAIL 6.8. BOLTING BE UNC UPTO 1" AND 8 THREAD SERIES ABOVE 1".

6.9. MANWAY, NOZZLE, REINFORCE PADS, EXTERNAL & INTERNAL ATTACHMENT WELDS SHALL NOT BE LOCATED WITH IN 40mm.

VACUUM STIFF. RING 4-EARTHING LUGS

BC#5

80x10 THK.

23 0° OF ANY OTHER WELD.

AT 0°, 120°, 180° & 270° 7. INSPECTION & PRESSURE TEST:(PER ASME SEC VIII. 1, & U.O.P STD. SPECIFICATION 3-11-4 DATED 30 DEC. 99)

EL.+13100 11.25°

60°+5° 1

1.25° SV1 7a. INSPECTION

AL#12 = = 7a.1. PRIOR TO FINAL INSPECTION AND PRESSURE TESTING, THE INSIDE AND OUTSIDE OF THE VESSEL SHALL BE THOROUGHLY

TYP.

°

PACKED BED #2 CLEANED OF ALL SLAG, SCALE, DIRT, GRIT, WELD SPATTER, PAINT, OIL, ETC.

30

(BY OTHERS) 338.5° 7b. PRESSURE TESTING

11

7b.1. VESSEL SHALL BE PRESSURE TESTED USING WATER AS THE TESTING MEDIA IN ACCORDANCE WITH ASME SEC VIII DIV. 1 &

#

L

PARA 6 OF U.O.P STD. SPEC. 3-11-4 AFTER COMPLETION OF ALL EXTERNAL AND INTERNAL WELDING, NONDESTRUCTIVE

4410 PACKED BED #2

°

COURSE #6)

A

5 SKIRT BRACING EXAMINATION, REPAIRS AND PRIOR TO PAINTING. HYDROSTATIC TEST PRESSURE SHALL BE HELD FOR A MINIMUM OF ONE HOUR

INSIDE 4 PER 25 mm OF VESSEL THICKNESS AND IN NO CASE LESS THAN ONE HOUR.

1~2

2

0~4 SV4 3 7b.2. ALL WELDED ATTACHMENTS PROVIDED WITH TELL TALE HOLES SHALL BE PNEUMATICALLY TESTED AT MINIMUM 1 KG/CM

0

AL#5

0° PRIOR TO VESSEL PRESSURE TESTING. TELL TALE HOLES MUST NOT BE PLUGGED DURING THE VESSEL PRESSURE TEST.

EL.+12060

CU 56 TO 58 .5° G 7b.3. NO PAINT OR PRIMER SHALL BE APPLIED TO A VESSEL PRIOR TO HYDROSTATIC TESTING.

4 67 LU

ALL LONGI. & CIRC. NG

7b.4. AFTER TESTING, THE VESSEL SHALL BE COMPLETELY DRAINED AND THOROUGHLY DRIED INCLUDING AROUND INTERNAL.

2450 (

ILI 7b.5. MANWAY HINGES SHALL BE IN PLACE BEFORE COLUMN IS TESTED.

TA

SHELL WELD SEAMS DETAIL 8. NDT: (PER ASME SEC V & U.O.P STD. SPEC. 3-11-4 DATED 30 DEC. 99)

SKIRT NAME PLATE 8a. RADIOGRAPHIC EXAMINATION

21900 TAN.TO TAN.

& BRACKET 8a.1. SEGMENTS OF REINFORCING PADS SHALL BE JOINT WITH FULL PENETRATION BUTT WELDS. SUCH WELDS SHALL BE

SUBJECT TO 100% RADIOGRAPHY.

@270°

8a.2. NOZZLE NECKS FABRICATED FROM PLATE SHALL BE 100% RADIOGRAPHED.

NOZZLE NECK

270° 90° 8b. ULTRASONIC EXAMINATION

SA 8b.1. BUTT WELDS IN COMPRESSION & BASE RING TO BE 100% ULTRASONICALLY TESTED.

BC#5A VACUUM STIFF. RING

80x10 THK.

23 8b.2. REGION OF LIFTING TRUNION & TAILING LUG JUNCTION WITH VESSEL TO BE EXAMINED BY U.T AFTER WELDING TO CHECK FOR

LAMELLAR TEARING AND WELD DEFECTS.

45°+5° ° 8c. MAGNETIC PARTICLE EXAMINATION

TSB SUPPORT 255 8c.1. "MPI" OR "PT" TO BE DONE FOR ALL TEMPORARY ATTACHMENT REMOVAL AREAS AFTER GRINDING.

9

(BY OTHERS) "VT" TO BE DONE FOR THE FULL JOB.

GO

8c.2. WELDS JOINING NON-PREESSURE RETAINING COMPONENTS TO PRESSURE RETAINING COMPONENTS SHALL BE 100% DYE PENETRANT OR MPI.

EL.+10100 9. SUPPLEMENTARY MATERIAL REQUIREMENT:

12

COURSE # 5)

70

0~2 0° 9.1. CARBON STEEL MATERIAL FOR PRESSURE RETAINING COMPONENTS SHALL BE FULLY-KILLED CONFORMING TO MATERIAL

32-ANCHOR CHAIRS

INLET PIPE SPEC. OF ASME SEC. II, PART A. ADDITIONALY CARBON EQUIVALENT SHALL NOT EXCEED 0.45%, BY FULL CHEMICAL ANALYSIS

26

0~3

Mn Cr.+MO+V Ni+Cu

4 (BY OTHERS) R1

2

SV2 AS CALCULATED BELOW WITH CE =

6 +[ 5 ]+[ 5 ]

10

10. ERECTION:

M AX.

302

#

° 10.1. SHACKLE LENGTH (FOR TAILING LUG) = 302MM MAX.

L

2450 (

59 TO 62 EL.+9360 5 GRIND FLUSH SKIRT BUTT

A

2

0°

DM 47 TO 52 21 WELD DETAIL OF 2 WELD BEFORE ANCHOR CHAIR 10.2. BEFORE LIFTING THE EQUIPMENT REMOVE THE BOLTED PLATFORM CLEAT (PC/E-3). LIFT THE EQUIPMENT & ERECT FOR

21

EL.+9130 RIB INSTALLATIOIN SAME IN THE POSITION. BOLT THE PLATFORM CLEATS AGAIN. (BY LIFTING CONTRACTOR) .

DI NOZZLE- AV AL#13

TSB SUPPORT RING 180°

11. SURFACE PREPARATION & PAINTING (16940-00-SP-837 REV. 01)

1800

24 177.5° BASE RING & COMPRESSION 11.1. SHELL, HEAD & EXTERNAL ATTACHMENT (CODE SYSTEM 1C) "UPTO TOP OF INSULATION RING ON SKIRT"

(BY ODECO)

AL#5A

NOZZLE NECK SV3 RING WELD SEAMS TO AVOID SURFACE PREPARATION : SA 2.5 (SP 10)

SECTION S3-S3 INTERFERECE WITH SKIRT PRIMER : FP 101, DFT 75 u (2 PACK SELF CURING ZINC SILICATE ETHYL SILICATE BASED)

TOP COAT : TC 303, DFT 20 u (HEAT RESISTANT SILICONE ALUMINIUM)

TYP. LONGI. WELD SEAM. TOP COLOUR : ALUMINIUM

C.O.G EL. +8359

100

BC#6 TOTAL DFT : 95 u

45

COURSE #4A)

°+5 tc 83 PIPE NPS2", SCH.160, ~171 LG. 3 SA 106 GR.B 7.6 FD1, FD2, FS 11.2. SKIRT OUTSIDE (CODE SYSTEM 5A) "BELOW INSULATION RING ON SKIRT"

°

SURFACE PREPARATION : SA 2.5 (SP 10)

82 FLANGE NPS2", WNRF, CL. 300, SCH.160 5 SA 105 20 AV, BI, FD1, FD2, FS

VSI COLLECTOR/DISTR. PRIMER : TC 304, DFT 150 u (TWO PACK EPOXY PHENOLIC)

25 81 SKIRT BRACING DETAIL 1 - 88.1 DWG. 4139-M06-02 FINISHING COAT : TC 304, DFT 150 u (TWO PACK EPOXY PHENOLIC)

(BY OTHERS)

TOP COLOUR : MUNSELL COLOUR NO. N4.5 (NEAREST EQU. RAL #7031)

4A 80 ACCUMULATOR TRAY SUPPORT 1 SA 516 GR.70N 46.2 DWG. 4139-M06-05 TOTAL DFT : 300 u

EL.+7600

1225 (

11.3. SKIRT INSIDE (CODE SYSTEM 5B)

79 VACUUM RING 10 THK. ID. 1424, OD. 1554 1 SA 516 GR.70N 28 DWG. 4139-M06-02

R6 INSIDE SURFACE PREPARATION : SA 2.5 (SP 10)

AL#6

VACUUM STIFF. RING

PRIMER : FP 102, DFT 75 u (TWO PACK ZINC RICH EPOXY PRIMER)

79 78 COLLECTOR TRAY & STABBED-ON REBOILER TUB 1 - 663 DWG. 4139-M06-05

1~2

65x10 THK. UNDER COAT : UC 201, DFT 125 u (TWO PACK MICACEOUS IRON OXIDE PIGMENTED EPOXY)

NECK OD+3 77 HALF PIPE NPS 4", SCH.40, 400 LG. 1 SA 106 GR.B 3.2 NOZZLE 'FL1' FINISHING COAT : TC 301, DFT 50 u (TWO PACK ACRYLIC MODIFIED POLYURETHANE)

BC#7

TOP COLOUR : MUNSELL COLOUR NO. N4.5 (NEAREST EQU. RAL #7031)

REF. DWG. 4146-M11-01

76 FLANGE (BY ODECO) 1 SA 105N 366.6 WO# 4146 PO# 1K-5310-01 TOTAL DFT : 250 u

NECK TO SHELL WELD DETAIL 75 ELBOW NPS 4", L.R., 90°, SCH.120 1 SA 234 GR.WPB 6 NOZZLE 'GO' 11.4. ORIENTATION MARK "0°" SHALL BE MARKED BY A VERTICAL YELLOW LINE 50mm MIN. WIDE ABOVE THE BASE.

S2 S2 74 PIPE NPS4", SCH.120, 784 LG. 1 SA 106 GR.B 22.1 NOZZLE 'GO'

11.5. THE VESSEL ITEM NUMBER, PURCHASE ORDER NUMBER AND SUITABLE WARNINGS ABOUT LIFTING LIMITATIONS SHALL

FOR NOZZLES WITHOUT PAD (TYP.) SHALL BE CLEARLY MARKED ON VESSEL.

PACKED BED #3

COURSE #3)

73 PIPE NPS4", SCH.120, 201 LG. 1 SA 106 GR.B 5.69 NOZZLE 'GO' 12. SHIPPING: (U.O.P STD. SPEC. 3-11-4 DATED 30 DEC. 99)

(BY OTHERS) 12.1. PRIOR TO SHIPPING, COLUMN TO BE COMPLETELY AND THOROUGHLY DRIED AND CLEANED FROM ALL LOOSE SCALES,

4410 PACKED BED #3

NOZZLE NECK 72 FLANGE NPS4", WNRF, CL. 150, SCH.120 1 SA 105 7 NOZZLE 'GO' WELD SLAGS, DIRT AND DEBRIS. NOZZLE EO TO BE ADEQUATELY SUPPORTED TO PREVENT DAMAGE DURING SHIPMENT.

)BY OTHER

12.2. ALL UNPAINTED MACHINED SURFACE BOTH EXTERNAL & INTERNAL SHALL BE COATED WITH A RUST PRESENTATIVE AGENT.

71 PLATE 12 THK. ID. 117, OD. 230 1 SA 516 GR.70N 2.9 NOZZLE 'GO'

{1/4" NPT. HOLE 12.3. FLANGED OPENINGS SHALL BE PROTECETED WIHT BOLTED-ON WOODEN OUTDOOR PLYWOOD (MIN. 12 mm THK.) OR

3

AL#7

70 NECK PLATE 18 THK. x 339 x 2975 1 SA 516 GR.70N 143 NOZZLE 'FR' METAL COVERS, USING ATLEAST THREE BOLTS.

2200 (

45 SEE NOTE 6.4 12.4. ALL VENT HOLES IN REINFORCING PADS AND SADDLES, ETC. SHALL BE PLUGGED WITH STIFF GREASE.

EL.+5760 °+5 tc

° 69 PLATE 18 THK. ID. 968, OD. 1665 1 SA 516 GR.70N 204 NOZZLE 'FR'

ET 56 TO 58 TYP. 12.5. THE INTERIOR SURFACE OF COLUMN, INCLUDING INTERNALS, SHALL BE PROTECTED FROM CORROSION BY USE OF A

INSULATION 70 THK.

INSULATION t SA 193-B7 NONTOXIC VAPOR PHASE CORROSION INHIBITOR SUCH AS COTEC VCI-309 OR 307. OR EQUIVALENT @ 0.1 kg/m

3

18 20 68 STUD BOLTS W/NUTS (FULL TRH'D) {1„" x 160 LG. 20+3 SA 194-2H

24.6 NOZZLE 'FM'

SUPPORT

1~2

GASKET NPS20", CL. 150, 4.5THK. * PARTIAL PRESSURE ( P=15mmHg) HAVE BEEN INCLUDED IN DESIGN PRESSURE.

VACUUM STIFF. RING 67 1+2 SEE NOTE 4 - NOZZLE 'FM'

65x10 THK.

22 EXTERNAL ALLOWABLE NOZZLE LOADS

66 BLIND FLANGE NPS20", RF, CL. 150 1 SA 105 123 NOZZLE 'FM' SPARE PARTS (PER JOINT)

EL.+5100 COMMISSIONING & ERECTION Fa Fb,Fc Ma Mb,Mc

65 NECK PLATE 12 THK. x 194 x 1554 1 SA 516 GR.70N 28.3 NOZZLE 'FM' MARK NO

(N) (N) (N,m) (N,m)

BC#8 GASKET : 200%

FS,BI 1,000 1,220 350 250

64 FLANGE NPS20", WNRF, CL. 150, XS 1 SA 105 77 NOZZLE 'FM' BOLT/NUT : 10% (MIN. 3 SETS)

AI 1,510 1,850 830 580

R6

63 PLATE 14 THK. ID. 510, OD. 745 1 SA 516 GR.70N 51.4 NOZZLE 'FM' AO,DI,GO 2,160 2,620 1,540 1,090

°

10450 (

BO 3,780 4,630 4,070 2,880

NECK OD+3 45 SHELL 62 FLANGE NPS 4", SORF, CL. 150, 1 SA 105 5.9 NOZZLE 'DI'

FR - 47,563/- - 14,269/-

61 PIPE NPS4", SCH.120, 301 LG. 1 SA 106 GR.B 8.5 NOZZLE 'DI' SV1~4 4 4" SCH.40 - - - - - SKIRT VENT SEE DWG.

COURSE #2)

NECK TO SHELL WELD DETAIL 60 FLANGE NPS4", WNRF, CL. 150, SCH.120 1 SA 105 7 NOZZLE 'DI' SA 1 OD 500 16THK. - - - - 1000 ACCESS OPENING SEE DWG.

TSB SUPPORT 59 PLATE 10 THK. ID. 117, OD. 230 1 SA 516 GR.70N 43 NOZZLE 'DI' GO 1 4" SCH.120 150 WNRF SCH.120 12 230 OUTLET SEE DWG.

FOR NOZZLES WITH PAD

)

58 CONC. REDUCER NPS 2"x1•", SCH.160 (ASME 16.9) 3 SA 234 GR.WPB 4 NOZZLES CU/ET/FU

12 THK.

(BY OTHERS) FU 1 1•" SCH.160 150 WNRF SCH.160 - - TEMP 940

2

7100

10 57 PIPE NPS2", SCH.160, ~104 LG. 3 SA 106 GR.B 3.5 NOZZLES CU/ET/FU FS 1 2" SCH.160 300 WNRF SCH.160 - - STEAMOUT 940

2450 (

REF. DWG. 4146-M11-01

NOZZLE NECK 56 FLANGE NPS1•", WNRF, CL. 150, SCH.160 3 SA 105 5.4 NOZZLES CU/ET/FU FR 1 ID 929 18THK. 18 1665 REBOILER 1012

TSB SUPPORT RING WO# 4146 PO# 1K-5310-01

(

ID 1400 (MIN) 45

24 °

70

+5 45° FM 1 20" 12THK. 150 WNRF MANWAY WITH DAVIT 990

(BY ODECO) ° 55 PIPE NPS6", SCH.80, ~156 LG. 1 SA 106 GR.B 6.7 NOZZLE 'BO' XS 14 745

1~2

AL#8

8

54 FLANGE NPS6", WNRF, CL. 150, SCH.80 1 SA 105 10.8 NOZZLE 'BO' FL1/FL2 2 2" SCH.160 150 WNRF SCH.160 - - LEVEL 940

1200

COLLECTOR TRAY & VACUUM STIFF. RING

78 65x10 THK.

22 53 PLATE 10 THK. ID. 172, OD. 340 1 SA 516 GR.70N 6 NOZZLE 'BO' FD1/FD2 2 2" SCH.160 300 WNRF SCH.160 - - DRIAN 940

STABBED-ON REBOILER TUB

SA 193-B7 ET 1 1•" SCH.160 150 WNRF SCH.160 - - TEMP 940

52 STUD BOLTS W/NUTS (FULL TRH'D) {1„" x 160 LG. 40+4 SA 194-2H

49.2 NOZZLE 'BM' & 'DM'

EL.+2600

BC#9 DM 1 20" 12THK. 150 WNRF XS 14 745 MANWAY WITH DAVIT 990

51 GASKET NPS20", CL. 150, 4.5THK. 2+4 SEE NOTE 4 - NOZZLE 'BM' & 'DM'

SHELL

DI 1 4" SCH.120 150 WNRF SCH.120 10 230 INLET 940

NECK OD+4 50 BLIND FLANGE NPS20", RF, CL. 150 2 SA 105 246 NOZZLE 'BM' & 'DM'

77

EL.+2180 CU 1 1•" SCH.160 150 WNRF SCH.160 - - TEMP 940

EL.+1800 FU 56 TO 58 49 NECK PLATE 12 THK. x 204 x 1554 2 SA 516 GR.70N 50.1 NOZZLE 'BM' & 'DM'

tc

43 46 FL1 BO 1 6" SCH.80 150 WNRF SCH.80 10 340 OUTLET 940

45° 48 FLANGE NPS20", WNRF, CL. 150, XS 2 SA 105 154 NOZZLE 'BM' & 'DM'

BM 1 20" 12THK. 150 WNRF XS 14 745 MANWAY WITH DAVIT 990

47 PLATE 14 THK. ID. 507, OD. 745 2 SA 516 GR.70N 51 NOZZLE 'BM' & 'DM'

1400

9

COURSE #1)

NAME PLALTE EL.+1630 92 EL.+1630 NOZZLE NECK

BL1/BL2 2 2" SCH.160 150 WNRF SCH.160 - - LEVEL 940

46 PIPE NPS2", SCH.160, ~177 LG. 4 SA 106 GR.B 7.9 BL1,BL2,FL1,FL2

19 D

I. FR 69 70 76 45° {1/4" NPT. HOLE BI 1 2" SCH.160 300 WNRF SCH.160 - - INLET 940

& BRACKET

tc SEE NOTE 6.4 45 FLANGE NPS 2", SORF, CL. 150, 1 SA 105 2.7 NOZZLE 'BI'

INTER. LADDER AV 1 2" SCH.160 300 WNRF SCH.160 - - VENT SEE DWG.

45 44 PIPE NPS2", SCH.160, 309 LG. 1 SA 106 GR.B 3.3 NOZZLE 'BI'

2 20 & GRAB RUNG

°+5

° AO 1 4" SCH.120 150 WNRF SCH.120 12 230 OUTLET SEE DWG.

2450 (

EL.+1030 20 43 FLANGE NPS2", WNRF, CL. 150, SCH.160 4 SA 105 10.8 BL1,BL2,FL1,FL2

1~2

AM 1 20" 12THK. 150 WNRF XS 14 710 MANWAY WITH HINGE SEE DWG.

DAVIT

FD1 82 83

42 PIPE NPS2", SCH.160, 83 LG. 1 SA 106 GR.B 0.87 NOZZLE 'AV'

21 HLL=800

t

AI 1 3" SCH.160 150 WNRF SCH.160 10 178 INLET 940

41A PLATE 12 THK. ID. 117, OD. 230 1 SA 516 GR.70N 2.9 NOZZLE 'AO' PAD MARK NPS SCH./THK. CLASS TYPE/FACE SCH./THK. THK. OD. PROJECTION

EL.+600

FL2 43 46

F.

NLL=560 EL.+550 QTY. SERVICE

FM

1000

41 PIPE NPS4", SCH.120, 501 LG. 1 SA 106 GR.B 14.1 NOZZLE 'AO' NO. PIPE/NECK DATA FLANGE DATA REINF. PAD FROM CL/TL.

50 S.

FD2 82 83

AL#9

40 FLANGE NPS4", WNRF, CL. 150, SCH.120 1 SA 105 7 NOZZLE 'AO' NOZZLE DATA

EL.+150

63 TO 68 FS 82 83 SHELL 39 PLATE 14 THK. ID. 506, OD. 710 1 SA 516 GR.70N 21 NOZZLE 'AM' PAD

°

W.L. BC#10 °+5 SA 193-B7

T.L. REF. EL. 0.00 NECK OD+4 45 38 STUD BOLTS W/NUTS (FULL TRH'D) {1„" x 160 LG. 20+3 24.6 NOZZLE 'AM'

SA 194-2H VENDOR DOCUMENT CONTROL VENDOR DOCUMENT REVIEW

BC#11

2:1 ELLIPTICAL HEAD 37 GASKET NPS20", CL. 150, 4.5THK. 1+2 SEE NOTE 4 - NOZZLE 'AM' SNC-LAVALIN SNC-LAVALIN

9 THK. MIN. & S.F. 12THK. MIN. (A.F.)

1A NECK TO SHELL WELD DETAIL FOR FOR CONFORMITY WITH SPECIFICATIONS AND DESIGN DRAWINGS.

EL. -430 36 BLIND FLANGE NPS20", RF, CL. 150 1 SA 105 123 NOZZLE 'AM' CONTRACT RECEIVED BY DATE

S3 NOM. HEAD THK. = 14 mm S3 A NOT SUITABLE, RESUBMIT BEFORE FABRICATION.

35 NECK PLATE 12 THK. x 415 x 1554 1 SA 516 GR.70N 50.3 NOZZLE 'AM'

SKIRT VENT

DISTRIBUTOR & PREDISTRIBUTOR 015559 B MODIFY AS NOTED, RESUBMIT BEFORE FABRICATION.

EL.-700

15 GO 71 TO 75 34 FLANGE NPS20", WNRF, CL. 150, XS 1 SA 105 77 NOZZLE 'AM' C MODIFY AS NOTED, COMMENCE FABRICATION AND RESUBMIT.

MARK tc t 33 FLANGE NPS 3", SORF, CL. 150, 1 SA 105 4.2 NOZZLE 'AI'

PURCHASE ORDER SERIAL SUBMISSION D SUITABLE, COMMENCE FABRICATION AND RESUBMIT CERTIFIED

AS-BUILT DOCUMENTS.

975 OTHER, AS INDICATED ON THE TRANSMITTAL.

BI, BL1/2, E

VORTEX BREAKER 32 PLATE 10 THK. ID. 92, OD. 178 1 SA 516 GR.70N 1.5 NOZZLE 'AI'

PIPE SLEEVE IK-5110-01A 0082 09 F FINAL OR CERTIFIED AS-BUILT DOCUMENTS. NO FURTHER

17 12 TO 14 FD1/2, FL1/2 9 - RESUBMITTAL (UNLESS REVISED BY VENDOR).

31 PIPE NPS3", SCH.160, ~306 LG. 1 SA 106 GR.B 6.5 NOZZLE 'AI'

FS, AV THIS REVIEW DOES NOT RELIEVE THE FABRICATOR OF HIS RESPONSIBLITY FOR

ITEM TAG V.D.B INDEX NO.

30 FLANGE NPS3", WNRF, CL. 150, SCH.160 1 SA 105 4.5 NOZZLE 'AI' ERRORS IN THE DESIGN AND DETAILING OF CONNECTIONS,DIMENSIONS,SIZES.

50 mm FIRE PROOFING CU, ET, FU 10 -

FIRE PROOFING CLIPS STATUS REVIEWED BY DATE

29 PLATE 10THK, x 50 x 106 LG. 4 SA 516 GR.70/SA36 1.6 EARTHING LUGS (GALV.) 600-V-07 B1, B2, F2

18 OUTSIDE ONLY(BY OTHERS) AI, BO, BM, DM, DI 10 8

AL#10

AL#11

(INSIDE & OUTSIDE)

AM, AO, FM, GO 10 10 28 VESSEL DAVIT 1 SA 516 GR.70/SA 106 GR.B 440.6 DWG. 4139-M06-02

SKIRT)

ABC ARM SSA

)

FR 12 10 27 LIFTING TRUNNION 2 - 292.0 DWG. 4139-M06-02

16 THK.

7 AS BUILT

4300

07.05.05 07.05.05 07.05.05

26 INLET PIPE (BY OTHERS) 2 - - BY OTHERS

4184 (

6 ABC SSA

VSI COLLECTOR DISTRIBUTOR

REVISED AS MARKED /

25 2 - - BY OTHERS

BC#12

(

6

ISSUED FOR CONSTRUCTION 09.04.05 09.04.05 09.04.05

24 TBS SUPPORT RING - SA 516 GR.70N 636.0 DWG. 4139-M06-05

5 REVISED AS MARKED / ABC SSA

23 VACUUM RING 10 THK. ID. 1424, OD. 1584 4 SA 516 GR.70N 119 DWG. 4139-M06-02

NOZZLE PROJECTION

SKIRT NAME PLATE & BRACKET 5

AL#13

19 ISSUED FOR CONSTRUCTION 12.03.05 12.03.05 12.03.05

22 VACUUM RING 10 THK. ID. 1428, OD. 1558 2 SA 516 GR.70N 56 DWG. 4139-M06-02

EL. -2800

4-EARTHING LUGS DRAWN/

0~4

21 MANWAY WITH HINGE & DAVIT 4 - 76.0 DWG. 4139-M06-03 REV. DESCRIPTION CHECKED APPROVED

FLANGE REVISED

29

75°+5°

ACCESS OPENING 7 20A INTERNAL RUNGS 22 x 22 x ~840 LG. 1 SA 516 GR.70N 3.2 DWG. 4139-M06-02

10 (500 I.D.x16 THK.) REVISIONS

7 20 INTERNAL RUNGS {22 x ~840 LG. (WITH REPADS) 2 SA-36 7.0 DWG. 4139-M06-02

AL#12

11 100 19 NAME PLATE WITH BRACKET 2 SS/SA516 GR.70N 12.0 DWG. 4139-M06-06

TAILING 1~2 COMPUTER REFERENCE DRAWING NUMBER : 4139M06017

1000

15 12

16 18 INSULATION SUPPORT RINGS / FIREPROOFING CLIPS - - 101.0 DWG. 4139-M06-09

800

LUG REMOVE GALV. OVER

{12 VORTEX BREAKER

BC#13 THIS AREA PRIOR NECK 17 1 SA 516 GR.70N 2.0 DWG. 4139-M06-02

TO WELDING

300

1:3 TAPER 16 TAILING LUG 1 SA 516 GR.70N 122.0 DWG. 4139-M06-02

=

BC#14

50

IF REQD.

15 PIPE NPS4", ERW, SCH.40 , 270 LG. 4 SA 516 GR.70N 17.0 SKIRT VENTS Olayan Descon Engineering Co.

=

BASE PL.

BASE RING ID. 2150 14 PLATE 6 THK. x 50 x 73 LG. 1 SA 516 GR.70 0.2 PIPE SLEEVE 'GO'

45 THK.

P.O.Box 10108, Jubail Industrial City, KSA

32-M36 ANCHORS(BY OTHER) ON B.C.D. 2620 29 NOZZLE FLANGE TO NECK 13 PIPE NPS 10", SCH.40, 252 LG. 1 SA 106 GR.B 15.8 PIPE SLEEVE 'GO'

6 DESIGNED: CLIENT:

12 PLATE 16 THK. ID. 278, OD. 550 1 SA 516 GR.70 22 PAD FOR PIPE SLEEVE

BASE & TOP COMP. RING OD. 2750 WELD DETAIL (TYP.)

EARTHING LUG DETAIL 11 PLATE 16 THK. x 230 x 1621 LG. 1 SA 516 GR.70 46.8 SKIRT ACCESS

GULF FARABI PETROCHEMICAL CO. LTD.

10 PLATE 16 THK. ID. 536, OD. 1000 1 SA 516 GR.70 70.0 PAD FOR SKIRT ACCESS MMD

E L E V A T I O N DISTRIBUTOR, BOLTS

9 PLATE 10 THK. x 159 x 215 64 SA 516 GR.70 172 ANCHOR CHAIRS RIBS DRAWN: PROJECT:

SEE SECTIONS FOR TRUE ORIENTATION ODECO SCOPE GASKET & NUTS

BY OTHERS 8 PLATE 40 THK. ID. 2423, OD. 2750 1 SA 516 GR.70 315 COMP. RING GULF FARABI

Fakher

M IN.

150

PLATE 45 THK. ID. 2150, OD. 2750

32

C2x45° 7 1 SA 516 GR.70 816 BASE RING N-PARAFFINS & LAB PLANT

13 FOR "AI & DI" (TYP.)

6 CONICAL SKIRT PLATE 16 THK. 1 SA 516 GR.70N 1598 DWG. 4139-M06-02

11 FOR "BI" SCALE: TITLE:

BOTTOM

5 CONICAL SKIRT PLATE 16 THK. 1 SA 516 GR.70N 1631 DWG. 4139-M06-02 GENERAL ARRANGEMENT OF

HEAD

SKIRT 4A PLATE 10 THK. x 1225 x 4430 2 SA 516 GR.70N 852 SHELL

OUTSIDE 1:40 FINISHING COLUMN (600-V-07)

4 PLATE 10 THK. x 2450 x 4430 5 SA 516 GR.70N 4260 SHELL

ID 1396 3 PLATE 12 THK. x 2200 x 4436 1 SA 516 GR.70N 919 SHELL DATE WORK ORDER DRAWING NO. REV.

6THK.

1

2 PLATE 12 THK. x 2450 x 4436 2 SA 516 GR.70N 2048 SHELL

1A 2:1 ELLIP. HEAD ID 1400, 9THK.(MIN.) S.F.=50x12THK. A.F. 1 SA 516 GR.70N 188 BOTTOM HEAD

10 (FOR AI & DI) "D1" 26.09.04 4139 4139-M06-01 7

1 2:1 ELLIP. HEAD ID 1400, 9THK.(MIN.) S.F.=50x10THK. A.F. 1 SA 516 GR.70N 188 TOP HEAD

8 (FOR BI)

HEAD TO SKIRT ITEM DESCRIPTION QTY. MATERIAL WT.KG. REF. DWG. & REMARKS

THIS DRAWING IS PRIVATE AND CONFIDENTIAL AND IS PROPERTY OF OLAYAN DESCON. IT MUST NOT BE COPIED OR

INTERNAL FLG. WELD DETAIL

WELD SEAM DETAIL LENT WITHOUT THE CONSENT OF OLAYAN DESCON. AND MUST BE RETURNED WITH THE TENDER AND/OR ON COMPLETION

TYP. SORF INTERNAL FLANGE TO NOZZLE NECK WELD DETAIL FOR NOZZLE 'AI' 'BI' & 'DI'

BILL OF MATERIAL (SEE NOTES 2,3 & 4)

OF THE ORDER TO OLAYAN DESCON ENGINEERING CO. JUBAIL K.S.A.

Das könnte Ihnen auch gefallen

- Pressure Vessel Manual-M.asgaRZADEGANDokument79 SeitenPressure Vessel Manual-M.asgaRZADEGANH BNoch keine Bewertungen

- What Is Design Interpretation?Dokument17 SeitenWhat Is Design Interpretation?Qaisir MehmoodNoch keine Bewertungen

- Pressure VesselDokument7 SeitenPressure VesselTeuku Muhammad ArrahmanNoch keine Bewertungen

- Synopsis of Changes in Section VIII Div2 E2023Dokument140 SeitenSynopsis of Changes in Section VIII Div2 E2023yathi sNoch keine Bewertungen

- Bilge Keels PDFDokument3 SeitenBilge Keels PDFUtpalSahaNoch keine Bewertungen

- Salt Spray and Cyclic Corrosion Testing PDFDokument2 SeitenSalt Spray and Cyclic Corrosion Testing PDFJorge Enrique Salas RoblesNoch keine Bewertungen

- Training Manual For PVelite Basic LevelDokument41 SeitenTraining Manual For PVelite Basic LevelsudokuNoch keine Bewertungen

- PV Elite BrocDokument6 SeitenPV Elite BrocprasadgssNoch keine Bewertungen

- Requirements For Pressure Vessel Basic Engineering DesignDokument6 SeitenRequirements For Pressure Vessel Basic Engineering DesignLDM Man. e Mont. Ind. EIRELINoch keine Bewertungen

- FVCDokument0 SeitenFVCsmileya_vpNoch keine Bewertungen

- WPS PQR Checklist 2021 by WeldassistantDokument2 SeitenWPS PQR Checklist 2021 by WeldassistantŞhallaw R. QadirNoch keine Bewertungen

- Summary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTDokument11 SeitenSummary of ASME BPVC Section VIII Div 1 (Part 4) - Welding & NDTTin Aung KyiNoch keine Bewertungen

- Help For P-V Elite PDFDokument39 SeitenHelp For P-V Elite PDFTushar MangratiNoch keine Bewertungen

- Control Flownex SimulinkDokument8 SeitenControl Flownex SimulinkSrashmiNoch keine Bewertungen

- ASME UM Audit Preparation ListDokument2 SeitenASME UM Audit Preparation ListMd Anamul Hoque100% (1)

- Pressure Vessel RT TestDokument3 SeitenPressure Vessel RT TestAriq FauzanNoch keine Bewertungen

- PV Elite SyllabusDokument1 SeitePV Elite SyllabusJason Chong100% (1)

- Flange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Dokument2 SeitenFlange - Long Weld Neck, ANSI Class 600, ASME B16.5, 1 - 16 - Raised Face (In)Magin Idelfonso TorreblancaNoch keine Bewertungen

- Eco Solutions - Saving Resources, Creating ValueDokument17 SeitenEco Solutions - Saving Resources, Creating ValueChayon MondalNoch keine Bewertungen

- Oil Gas Construction Factory L.L.CDokument2 SeitenOil Gas Construction Factory L.L.CRenny DevassyNoch keine Bewertungen

- Pressure Vessel Design - ProceduresDokument62 SeitenPressure Vessel Design - ProceduresLê Phạm HoàngNoch keine Bewertungen

- TQ - Air Fin Cooler (CS) - ModificationDokument6 SeitenTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNoch keine Bewertungen

- 338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFDokument9 Seiten338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFjdgh1986Noch keine Bewertungen

- U1a - 735834Dokument2 SeitenU1a - 735834Alex SimonNoch keine Bewertungen

- Flange Data: Bolt Reference Charts For ASME B16.5 FlangesDokument4 SeitenFlange Data: Bolt Reference Charts For ASME B16.5 FlangesMilena Lemus FonsecaNoch keine Bewertungen

- Nozzle LoadDokument8 SeitenNozzle LoadDam VoNoch keine Bewertungen

- Api600 Valve Trim ChartDokument2 SeitenApi600 Valve Trim ChartBoankNoch keine Bewertungen

- Asme 9 DatosDokument47 SeitenAsme 9 Datosvichu_villamarNoch keine Bewertungen

- Thermowell Calculation Guide V1.3Dokument19 SeitenThermowell Calculation Guide V1.3AymanelorbanyNoch keine Bewertungen

- Mechanical Design For Pressure VesselDokument26 SeitenMechanical Design For Pressure VesselibicengNoch keine Bewertungen

- Welcome To: Training Program On GUIDED TOUR OF ASME CodesDokument120 SeitenWelcome To: Training Program On GUIDED TOUR OF ASME CodesAndri Konyoa KonyoaNoch keine Bewertungen

- Long Weld Necks 900 Rating DimensionDokument1 SeiteLong Weld Necks 900 Rating DimensionsriNoch keine Bewertungen

- Explomet PolandDokument6 SeitenExplomet PolandLucian CiprianNoch keine Bewertungen

- Compare Ansi Asme-FemDokument8 SeitenCompare Ansi Asme-FemMiftakhu ZaimNoch keine Bewertungen

- EGP3-01.16 Welding For Skids and Miscellaneous SteelDokument10 SeitenEGP3-01.16 Welding For Skids and Miscellaneous SteelMathias OnosemuodeNoch keine Bewertungen

- Process Industry Practices PipingDokument5 SeitenProcess Industry Practices Pipingabdo samadNoch keine Bewertungen

- Toaz - Info Lifting Lug Calculation On Dish End PRDokument156 SeitenToaz - Info Lifting Lug Calculation On Dish End PRandry4jcNoch keine Bewertungen

- Titan Flow Control, IncDokument178 SeitenTitan Flow Control, IncKemQueNoch keine Bewertungen

- Sample2 DrawingDokument1 SeiteSample2 DrawingSourav HaitNoch keine Bewertungen

- Stress Analysis and Design Optimization of A Pressure Vessel Using Ansys PackageDokument12 SeitenStress Analysis and Design Optimization of A Pressure Vessel Using Ansys Packageanthony zegarra ochoaNoch keine Bewertungen

- Pressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesDokument37 SeitenPressure Relief Device Inspection: Review of NBIC Part 2, Par. 2.5/ Jurisdictional IssuesPham LanphuongNoch keine Bewertungen

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDokument17 SeitenMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (1)

- Analysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodDokument4 SeitenAnalysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodIJSTENoch keine Bewertungen

- Welding of Pressure VesselsDokument2 SeitenWelding of Pressure VesselsDvida PleasureNoch keine Bewertungen

- Sample UDS DocumentDokument14 SeitenSample UDS Documentnilesh_raykarNoch keine Bewertungen

- How To Use Code Case in PV EliteDokument2 SeitenHow To Use Code Case in PV EliteMukeshChopraNoch keine Bewertungen

- Pap 2Dokument68 SeitenPap 2Aziz SyahrizalNoch keine Bewertungen

- Code Case 2695 in PV Elite - How To Use It PDFDokument2 SeitenCode Case 2695 in PV Elite - How To Use It PDFMukeshChopra100% (1)

- Pressure Vessel SpecificationDokument15 SeitenPressure Vessel Specificationmichael chiwuezeNoch keine Bewertungen

- 8-12 X 3000 M Spherical LPG Storage TankDokument1 Seite8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- FDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Dokument15 SeitenFDA and 1935 2004 DoC General Food Contact Regulations BU HFH Rev 008Gisela ViskaNoch keine Bewertungen

- Guide To Pressure Vessel CodesDokument61 SeitenGuide To Pressure Vessel Codespradeepbt100% (1)

- ProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFDokument37 SeitenProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFShaimaa SaadNoch keine Bewertungen

- Design and Analysis of Above-Ground Full Containment LNG Storage TanksDokument6 SeitenDesign and Analysis of Above-Ground Full Containment LNG Storage TanksrodrigoperezsimoneNoch keine Bewertungen

- 2 3A Lecture Fatigue PDFDokument39 Seiten2 3A Lecture Fatigue PDFKamel FedaouiNoch keine Bewertungen

- SecVIII Div1 UW40Dokument2 SeitenSecVIII Div1 UW40arianaseriNoch keine Bewertungen

- 11110d-2 Obround Nozzle Revised DesignDokument1 Seite11110d-2 Obround Nozzle Revised DesignSivateja NallamothuNoch keine Bewertungen

- 093 2018 0753 JCC JV TPPD F100Dokument1 Seite093 2018 0753 JCC JV TPPD F100陈耀Noch keine Bewertungen

- BB BB: Code and SpecificationsDokument1 SeiteBB BB: Code and SpecificationsandersonNoch keine Bewertungen

- RP-O501 Summary PDFDokument2 SeitenRP-O501 Summary PDFJorge PerdigonNoch keine Bewertungen

- DRWGDokument1 SeiteDRWGgopi krishnaNoch keine Bewertungen

- Se 1025Dokument7 SeitenSe 1025Roohian AliNoch keine Bewertungen

- Prohibited Articles PDFDokument1 SeiteProhibited Articles PDFgopi krishnaNoch keine Bewertungen

- CSWIP 3.2 Course Material 2016Dokument418 SeitenCSWIP 3.2 Course Material 2016skychurch97% (29)

- 2012 04 Main Types of Paint Used With SteelDokument5 Seiten2012 04 Main Types of Paint Used With SteelWilda Sania MtNoch keine Bewertungen

- Package Name: Combo 70: Additions ExclusionsDokument1 SeitePackage Name: Combo 70: Additions Exclusionsgopi krishnaNoch keine Bewertungen

- MTC & Asme II Part-A Chart For Ref.Dokument3 SeitenMTC & Asme II Part-A Chart For Ref.gopi krishnaNoch keine Bewertungen

- Scope of Work For Fire LoopDokument1 SeiteScope of Work For Fire Loopgopi krishnaNoch keine Bewertungen

- Mega MTC - ElbowDokument2 SeitenMega MTC - Elbowgopi krishnaNoch keine Bewertungen

- Risk Based Inspection TestDokument16 SeitenRisk Based Inspection TestSameh Amin50% (2)

- Api-580, Rbi, QDokument5 SeitenApi-580, Rbi, Qimrankhan22100% (1)

- Platform DrawingDokument4 SeitenPlatform Drawinggopi krishnaNoch keine Bewertungen

- Firefighting Line Above GroundDokument1 SeiteFirefighting Line Above Groundgopi krishnaNoch keine Bewertungen

- Stainless SelectionDokument1 SeiteStainless Selectiongopi krishnaNoch keine Bewertungen

- Reactor TypesDokument81 SeitenReactor TypesLenin PrabhuNoch keine Bewertungen

- pressureProcedTest PDFDokument7 SeitenpressureProcedTest PDFfaizal azizNoch keine Bewertungen

- Nuclear Power Plant Information: Boiling Water Reactor (BWR)Dokument18 SeitenNuclear Power Plant Information: Boiling Water Reactor (BWR)cagertonNoch keine Bewertungen

- Reactor TypesDokument81 SeitenReactor TypesLenin PrabhuNoch keine Bewertungen

- Nuclear Power Plant Information: Boiling Water Reactor (BWR)Dokument18 SeitenNuclear Power Plant Information: Boiling Water Reactor (BWR)cagertonNoch keine Bewertungen

- AGA Purging.2001 PDFDokument157 SeitenAGA Purging.2001 PDFLeDzung100% (1)

- Westech InspectionDokument2 SeitenWestech Inspectiongopi krishnaNoch keine Bewertungen

- Westech InspectionDokument2 SeitenWestech Inspectiongopi krishnaNoch keine Bewertungen

- Work Completion Certificate Date Report No.: Project'S Name & NoDokument1 SeiteWork Completion Certificate Date Report No.: Project'S Name & Nogopi krishnaNoch keine Bewertungen

- Shell and Tube HX Basic CalculationDokument35 SeitenShell and Tube HX Basic Calculationวรศิษฐ์ อ๋องNoch keine Bewertungen

- WPS-2 inDokument1 SeiteWPS-2 ingopi krishnaNoch keine Bewertungen

- Qa/Qc Department: ICOM QC Inspector Client QC Inspector Name Signature DateDokument2 SeitenQa/Qc Department: ICOM QC Inspector Client QC Inspector Name Signature Dategopi krishnaNoch keine Bewertungen

- Heat InputDokument1 SeiteHeat Inputgopi krishnaNoch keine Bewertungen

- Hexagon Nut and Bolt SizesDokument2 SeitenHexagon Nut and Bolt Sizesgopi krishnaNoch keine Bewertungen

- Bridge Erection MachinesDokument73 SeitenBridge Erection Machinesstavros_sterg80% (5)

- Basic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYDokument17 SeitenBasic - Concepts - in - Pharmaceutical - Care CLINICAL PHARMACYPrincess RonsableNoch keine Bewertungen

- Bantilan Maureen Lhee RDokument8 SeitenBantilan Maureen Lhee RAlexa Anne Louise BercillaNoch keine Bewertungen

- Pro-Watch Ecosystem: The Power of TheDokument1 SeitePro-Watch Ecosystem: The Power of TheNik SiagNoch keine Bewertungen

- 67 - Es - Ut Republic Csalamade BooDokument47 Seiten67 - Es - Ut Republic Csalamade BooTyler LeeNoch keine Bewertungen

- Engineering Data: 2. CV CalculationDokument1 SeiteEngineering Data: 2. CV Calculationdj22500Noch keine Bewertungen

- AIMS Manual - 2021Dokument82 SeitenAIMS Manual - 2021Randyll TarlyNoch keine Bewertungen

- Grade 4 SYLLABUS Check Point 1Dokument2 SeitenGrade 4 SYLLABUS Check Point 1Muhammad HassaanNoch keine Bewertungen

- Qüestionari KPSI.: ActivitiesDokument2 SeitenQüestionari KPSI.: ActivitiesfrancisNoch keine Bewertungen

- Symposium's Platonic LoveDokument10 SeitenSymposium's Platonic LovezkottNoch keine Bewertungen

- L 1 Introduction To MorphologyDokument31 SeitenL 1 Introduction To MorphologyIftkhar GorsiNoch keine Bewertungen

- Service and Technology Marketing Service and Technology MarketingDokument27 SeitenService and Technology Marketing Service and Technology MarketingVinudeep MalalurNoch keine Bewertungen

- AquaMapPublic v202Dokument26 SeitenAquaMapPublic v202engfeupNoch keine Bewertungen

- 78-SAFETY - QUESTIO in PDFDokument21 Seiten78-SAFETY - QUESTIO in PDFIndermohan MehtaNoch keine Bewertungen

- PT2 Exam CLASS XI CS 2023Dokument2 SeitenPT2 Exam CLASS XI CS 2023Aditya AurangeNoch keine Bewertungen

- Applied-Signed Product Cordial Labeling and - Santhi.mDokument6 SeitenApplied-Signed Product Cordial Labeling and - Santhi.mImpact JournalsNoch keine Bewertungen

- GE 8 ETHICS Week2 9Dokument54 SeitenGE 8 ETHICS Week2 9Jay Ar OmbleroNoch keine Bewertungen

- Student Teacher InterviewDokument3 SeitenStudent Teacher InterviewLauren ColeNoch keine Bewertungen

- Pdpa CraDokument3 SeitenPdpa CraAdyrah RahmanNoch keine Bewertungen

- Reemergent Scientism, Postmodernism, and Dialogue Across DifferencesDokument7 SeitenReemergent Scientism, Postmodernism, and Dialogue Across DifferencesJose Luis Ramos CañonNoch keine Bewertungen

- When A Transformer Has Stomach Pain and Wants ToDokument4 SeitenWhen A Transformer Has Stomach Pain and Wants ToRobert GalarzaNoch keine Bewertungen

- Report - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222Dokument23 SeitenReport - Roche Pharmaceuticals LTD (Human Resource Planning & Development) 222jawwadraja100% (1)

- Intro To RMAN-10g-okDokument41 SeitenIntro To RMAN-10g-okAnbao ChengNoch keine Bewertungen

- Slab Culvert Irc 21 Irc 112Dokument5 SeitenSlab Culvert Irc 21 Irc 112Rupendra palNoch keine Bewertungen

- Healing GardensDokument7 SeitenHealing GardensElvaNoch keine Bewertungen

- Innoversant Solutions - Business Consulting Services IndiaDokument15 SeitenInnoversant Solutions - Business Consulting Services Indiaispl123Noch keine Bewertungen

- Sony HCD Dx8Dokument66 SeitenSony HCD Dx8videoson100% (1)

- SF DumpDokument17 SeitenSF DumpBeatríz YañezNoch keine Bewertungen

- STIGA - Vue Eclatée Moteur BRIGGS & STRATTONDokument32 SeitenSTIGA - Vue Eclatée Moteur BRIGGS & STRATTONregis.petitjeanNoch keine Bewertungen

- Crystal Gallery: AccountabilityDokument15 SeitenCrystal Gallery: AccountabilityJitesh ManwaniNoch keine Bewertungen