Beruflich Dokumente

Kultur Dokumente

HPU Material Data Sheet

Hochgeladen von

flasher_for_nokia0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten1 SeiteThis material data sheet provides information about a hydrolysis resistant polyurethane called HPU. HPU is composed of polyoxytetramethylene glycol and diphenylmethane diisocyanate polymers that produce a hardness of 95 Shore A. It has good physical properties and resistance to common hydraulic fluids and oil-water emulsions, making it suitable for seal applications. The data sheet lists the material's physical properties, chemical resistance, main applications, and notes that the listed properties relate to fundamental material values tested under laboratory conditions.

Originalbeschreibung:

Hpu doc

Originaltitel

Hpu

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis material data sheet provides information about a hydrolysis resistant polyurethane called HPU. HPU is composed of polyoxytetramethylene glycol and diphenylmethane diisocyanate polymers that produce a hardness of 95 Shore A. It has good physical properties and resistance to common hydraulic fluids and oil-water emulsions, making it suitable for seal applications. The data sheet lists the material's physical properties, chemical resistance, main applications, and notes that the listed properties relate to fundamental material values tested under laboratory conditions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

60 Ansichten1 SeiteHPU Material Data Sheet

Hochgeladen von

flasher_for_nokiaThis material data sheet provides information about a hydrolysis resistant polyurethane called HPU. HPU is composed of polyoxytetramethylene glycol and diphenylmethane diisocyanate polymers that produce a hardness of 95 Shore A. It has good physical properties and resistance to common hydraulic fluids and oil-water emulsions, making it suitable for seal applications. The data sheet lists the material's physical properties, chemical resistance, main applications, and notes that the listed properties relate to fundamental material values tested under laboratory conditions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

Material Data Sheet HPU

Hydrolysis Resistant Polyurethane - Red

GENERAL DETAILS

DMR HPU is composed of prepolymers based on Polyoxytetramethylene glycol (PTMEG) and Diphenylmethane Diisocynate (MDI) processed with

catalysts and chain extenders, producing a hardness of 95 +/- 2 shore A with very good physical properties. The resistance to the most common

hydraulic fluids and oil-water emulsions make HPU a very universal material for seal applications.

PHYSICAL PROPERTIES STANDARD UNIT VALUE CHEMICAL RESISTANCE

Specific Gravity DIN 53479 g/cm³ 1.10 Water up to 70°C R

Hardness at 20°C DIN 53505 Shore A 95 +/- 2 Water up to 90°C R

100% Modulus DIN 53504 N/mm² >12 HFA Fluids R

Tensile Strength DIN 53504 N/mm² 38 HFB Fluids R

Elongation at break DIN 53504 % 520 HFC Fluids S

Tear Strength DIN 53515 KN/m 158 HFD Fluids U

Resilience DIN 53512 % 40 Mineral Oils R

Compression Set * DIN 53517 % 31 Vegetable Oils R

Hardness at -5°C DIN 53505 Shore A 95 Fuels S

Hardness at +80°C DIN 53505 Shore A 93 Ozone R

Min Service Temperature °C -30 Air up to 100°C R

Max Service Temperature °C +105 Air up to 150°C U

* Compression set: 25% deflection 22 hours at 70°C

MAIN APPLICATIONS KEY TO CHEMICAL RESISTANCE

U-Cup seals (Piston & Rod working) R = Resistance

Wiper seals S = Suitable

Rotary seals U = Unsuitable

O-Rings ANALYSIS AND EVALUATION

Flange seals The properties mentioned relate to fundamental values for

Polyurethane products. Values mentioned correspond to ASTM or DIN

Anti-Extrusion rings norm and have been tested on standardised plates in laboratory

conditions and can not be carried over to the finished product.

Tel: 0114 243 2777

Fax: 0114 242 2300 Email: sales@dmrseals.co.uk Web: www.dmrseals.co.uk

Das könnte Ihnen auch gefallen

- Stone Cladding Fixings Technical StandardsDokument6 SeitenStone Cladding Fixings Technical StandardsvtalexNoch keine Bewertungen

- Catalogo Bepco Tractor PartsDokument266 SeitenCatalogo Bepco Tractor PartsGabriel Escarcena Robles100% (5)

- Mud Pump Consumables - enDokument24 SeitenMud Pump Consumables - enflasher_for_nokia100% (1)

- Stickmate 235 AC & 235 AC/DC Owner's ManualDokument40 SeitenStickmate 235 AC & 235 AC/DC Owner's ManualHobart Welding Products100% (1)

- Volvo EW145B Wheeled ExcavatorDokument48 SeitenVolvo EW145B Wheeled ExcavatorHai Van100% (9)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Choke and Kill Manifold Brochure PDFDokument12 SeitenChoke and Kill Manifold Brochure PDFtaloslamomia9417100% (1)

- USDA Engineering Classification of Rock MaterialsDokument61 SeitenUSDA Engineering Classification of Rock MaterialsTanNoch keine Bewertungen

- Gas Sweetening and Processing Field ManualVon EverandGas Sweetening and Processing Field ManualBewertung: 4 von 5 Sternen4/5 (7)

- ANSI Flanges Dimensions Specs Grades ClassesDokument23 SeitenANSI Flanges Dimensions Specs Grades ClassesVenkatesh GangadharNoch keine Bewertungen

- Ifi 115Dokument1 SeiteIfi 115Vinay PawarNoch keine Bewertungen

- Motor Spec - IPOWER Rev01Dokument4 SeitenMotor Spec - IPOWER Rev01GAGANNoch keine Bewertungen

- Duraflo Composite Oemduea Mongoose PsDokument2 SeitenDuraflo Composite Oemduea Mongoose Psflasher_for_nokiaNoch keine Bewertungen

- Palm Kernel Oil Mill ProjectDokument8 SeitenPalm Kernel Oil Mill Projectsjr141071100% (2)

- H1 SteeringDokument225 SeitenH1 SteeringVinay Kumar NeelamNoch keine Bewertungen

- Hydril Annular BOP1Dokument2 SeitenHydril Annular BOP1Abde EsselamNoch keine Bewertungen

- Hydril Annular BOP1Dokument2 SeitenHydril Annular BOP1Abde EsselamNoch keine Bewertungen

- Operation & Maintenance Manual: For Vahterus Plate & Shell Heat ExchangersDokument32 SeitenOperation & Maintenance Manual: For Vahterus Plate & Shell Heat ExchangersMarkNoch keine Bewertungen

- Ch04Dokument20 SeitenCh04nilesh0074313Noch keine Bewertungen

- Manual Bomba de LodosDokument37 SeitenManual Bomba de LodosJuan RuizNoch keine Bewertungen

- Humidity Sensor SelectionDokument10 SeitenHumidity Sensor Selectionmythri100% (1)

- PU, Slicone, NBR SealDokument28 SeitenPU, Slicone, NBR SealJirakom LimmongkolkulNoch keine Bewertungen

- NBR Data SheetDokument1 SeiteNBR Data SheetArdiansyah Oktavianus WahyudiNoch keine Bewertungen

- ECORUBBER1Dokument1 SeiteECORUBBER1Zoran BadurinaNoch keine Bewertungen

- Brochure PT. Total Prime EngineeringDokument16 SeitenBrochure PT. Total Prime EngineeringAnonymous H9Qg1iNoch keine Bewertungen

- Fluteck P7500 CA v01.19Dokument2 SeitenFluteck P7500 CA v01.19fprovitaliNoch keine Bewertungen

- POM Diet: Polyacetale, Copolymer, Standard Colour: WhiteDokument1 SeitePOM Diet: Polyacetale, Copolymer, Standard Colour: WhitemorchedtounsiNoch keine Bewertungen

- Quadriga Flyer Pu 80 Stand 07 2015 enDokument2 SeitenQuadriga Flyer Pu 80 Stand 07 2015 enKV CAD/CAM/CAENoch keine Bewertungen

- EPDM Standard - enDokument1 SeiteEPDM Standard - enEmmanuel Jiménez EcheverríaNoch keine Bewertungen

- NBR Data SheetDokument1 SeiteNBR Data SheetrjueiNoch keine Bewertungen

- Material 72 NBR 872: Black Cross Linking: SulfurDokument3 SeitenMaterial 72 NBR 872: Black Cross Linking: SulfurPhong DuongNoch keine Bewertungen

- P000232 Fully Synthetic Gear Oil (GL5) SAE 75W 90 30 en GBDokument1 SeiteP000232 Fully Synthetic Gear Oil (GL5) SAE 75W 90 30 en GBFarhan MalekNoch keine Bewertungen

- AB Seals Product Identification Guide Ver 150715Dokument48 SeitenAB Seals Product Identification Guide Ver 150715Storm RiderNoch keine Bewertungen

- 72 NBR 902-En - 1Dokument3 Seiten72 NBR 902-En - 1Pierre PescayNoch keine Bewertungen

- Ravenol Getriebeol CLP 100 1Dokument1 SeiteRavenol Getriebeol CLP 100 1norbertoNoch keine Bewertungen

- Total Altis SH 2 Grease TDSDokument1 SeiteTotal Altis SH 2 Grease TDSANoch keine Bewertungen

- Tinorethane Anti-Rust PrimersDokument4 SeitenTinorethane Anti-Rust PrimersAbed samadsureyft7vewyrNoch keine Bewertungen

- NBR NB702717-en - 1Dokument4 SeitenNBR NB702717-en - 1Pierre PescayNoch keine Bewertungen

- Aceite MR520Dokument4 SeitenAceite MR520capc.asesoriasNoch keine Bewertungen

- Technical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantDokument3 SeitenTechnical Data (Spec Qualified) Perma-Slik G: Air Dry, Mos Solid Film LubricantSantaj TechnologiesNoch keine Bewertungen

- Material Data Sheet N107-B85: NBR N107 - Black (Sulphur Cross Linked)Dokument1 SeiteMaterial Data Sheet N107-B85: NBR N107 - Black (Sulphur Cross Linked)zarul lurazNoch keine Bewertungen

- Reinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Dokument3 SeitenReinz AFM 37 가스켓 TDS (BFP 기본 가스켓) 1Geonung Park (Fall For 2)Noch keine Bewertungen

- AGIP Arnica SDokument2 SeitenAGIP Arnica SRZW RNoch keine Bewertungen

- PVDF PipeDokument4 SeitenPVDF PipeIbhar Santos MumentheyNoch keine Bewertungen

- Tds 1332210 enDokument3 SeitenTds 1332210 envladatanNoch keine Bewertungen

- Manual Tecnico de Tuberias de PVC y CPVC-GFDokument48 SeitenManual Tecnico de Tuberias de PVC y CPVC-GFluis claudio c, vieiraNoch keine Bewertungen

- Agip Arnica S: Characteristics (Typical Figures)Dokument2 SeitenAgip Arnica S: Characteristics (Typical Figures)AMAZING AGNoch keine Bewertungen

- 트렐레 fkm - xplor - V9T22 - gb - enDokument2 Seiten트렐레 fkm - xplor - V9T22 - gb - enhouk sukNoch keine Bewertungen

- TDS Altis SH 2Dokument1 SeiteTDS Altis SH 2Daniel CaviedesNoch keine Bewertungen

- Materialdatasheet 80 NBR 709 6Dokument3 SeitenMaterialdatasheet 80 NBR 709 6Miguel ContrerasNoch keine Bewertungen

- Manual Z Long Life 75W80 TDSDokument2 SeitenManual Z Long Life 75W80 TDSVusal HasanovNoch keine Bewertungen

- Data SheetDokument2 SeitenData SheetSreesanth SaruvilNoch keine Bewertungen

- MolykoteDokument2 SeitenMolykoteRafael FrançaNoch keine Bewertungen

- Tds Renolin CLP enDokument7 SeitenTds Renolin CLP enrytNoch keine Bewertungen

- RAVENOL Turbo Oil T32Dokument2 SeitenRAVENOL Turbo Oil T32HANIF AKBARNoch keine Bewertungen

- PR 1750 Class ADokument2 SeitenPR 1750 Class AMeed Bin HameedNoch keine Bewertungen

- Shell Fire-Resistant Hydraulic Fluid S3 DU 100 Technical Data SheetDokument2 SeitenShell Fire-Resistant Hydraulic Fluid S3 DU 100 Technical Data SheetJorge Arrieta TorresNoch keine Bewertungen

- NBR 60.10-01Dokument1 SeiteNBR 60.10-01UcokNoch keine Bewertungen

- Technical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDokument2 SeitenTechnical Datasheet: Properties Unit Value Test Method Value Test Method Test Specimen O-RingDacetIronForceNoch keine Bewertungen

- GENERAL Properties of PTFEDokument1 SeiteGENERAL Properties of PTFEIvan GhidiniNoch keine Bewertungen

- 3144 - 1111 Hydrauliköl HLP 46 - ENDokument1 Seite3144 - 1111 Hydrauliköl HLP 46 - ENGuntara WigunaNoch keine Bewertungen

- 90 NBR 109-En - 1Dokument3 Seiten90 NBR 109-En - 1Pierre PescayNoch keine Bewertungen

- 1 en H ECOPUR Material DatasheetDokument1 Seite1 en H ECOPUR Material DatasheetCarlos FiorilloNoch keine Bewertungen

- DMH 310 H-NBR: Mechanical, Physical and Thermal PropertiesDokument1 SeiteDMH 310 H-NBR: Mechanical, Physical and Thermal Propertiessetiadi pratondoNoch keine Bewertungen

- Gengear Series SPL-A Up To 320Dokument3 SeitenGengear Series SPL-A Up To 320Hakim AmmorNoch keine Bewertungen

- 72 NBR 902-EnDokument3 Seiten72 NBR 902-EnAyman RiyadhNoch keine Bewertungen

- Zurcon Z80 PDFDokument1 SeiteZurcon Z80 PDFLuz SmithNoch keine Bewertungen

- Daphne Alpha Screw 32: Lubricant Product InformationDokument2 SeitenDaphne Alpha Screw 32: Lubricant Product InformationSadid ShahzadNoch keine Bewertungen

- Hyspin ZZ Range: DescriptionDokument2 SeitenHyspin ZZ Range: DescriptionDaniel VuletaNoch keine Bewertungen

- Chemthane 2265Dokument1 SeiteChemthane 2265VICTOR RESENDIZNoch keine Bewertungen

- TD - Rhenus LKZ 2Dokument1 SeiteTD - Rhenus LKZ 2Teknik LasallefoodNoch keine Bewertungen

- TC30 IntlDokument1 SeiteTC30 IntlWilliam ContrerasNoch keine Bewertungen

- Arcanol Technical Datasheet Load LubricantDokument5 SeitenArcanol Technical Datasheet Load LubricantJoan HoyosNoch keine Bewertungen

- Material Properties FKM 75 FKM 585Dokument3 SeitenMaterial Properties FKM 75 FKM 585Victor CadilloNoch keine Bewertungen

- F T Poliuretano 24022020Dokument3 SeitenF T Poliuretano 24022020FedericoNoch keine Bewertungen

- FUCHS RENOLIN B SeriesDokument1 SeiteFUCHS RENOLIN B SeriesAnonymous srwHCpANoch keine Bewertungen

- Gear Compound Plus Iso - 68 - enDokument1 SeiteGear Compound Plus Iso - 68 - enSedin MurtićNoch keine Bewertungen

- Gear Compound Plus Iso - 68 - enDokument1 SeiteGear Compound Plus Iso - 68 - enSedin MurtićNoch keine Bewertungen

- LC1D115P7: Product Data SheetDokument3 SeitenLC1D115P7: Product Data Sheetflasher_for_nokiaNoch keine Bewertungen

- Thermowell For Thermometers ManualDokument40 SeitenThermowell For Thermometers Manualflasher_for_nokiaNoch keine Bewertungen

- Astm A479Dokument7 SeitenAstm A479Martin RomeroNoch keine Bewertungen

- HDLS Series Switches: Installation Instructions For TheDokument4 SeitenHDLS Series Switches: Installation Instructions For Theflasher_for_nokiaNoch keine Bewertungen

- Bimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55Dokument13 SeitenBimetal Thermometer For The Process Industry Per EN 13190, Premium Version Model 55flasher_for_nokiaNoch keine Bewertungen

- CX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxDokument2 SeitenCX1020 - Basic CPU Module: CX1020-0xxx CX1020-0xxx CX1020-0xxxflasher_for_nokiaNoch keine Bewertungen

- TD 670 676 680 8PG BW Oct2015Dokument8 SeitenTD 670 676 680 8PG BW Oct2015flasher_for_nokiaNoch keine Bewertungen

- Assessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density LogsDokument7 SeitenAssessing Rock Compressive Strength and Predicting Formation Drillability Using Sonic, Gamma & Density Logsflasher_for_nokiaNoch keine Bewertungen

- Laboport: Mini Diaphragm Vacuum Pumps and CompressorsDokument2 SeitenLaboport: Mini Diaphragm Vacuum Pumps and Compressorsflasher_for_nokiaNoch keine Bewertungen

- Astm A479Dokument7 SeitenAstm A479Martin RomeroNoch keine Bewertungen

- Bill of Materials for Gate ValveDokument6 SeitenBill of Materials for Gate Valveflasher_for_nokiaNoch keine Bewertungen

- Data Sheet P 550: Technical InformationDokument1 SeiteData Sheet P 550: Technical Informationflasher_for_nokiaNoch keine Bewertungen

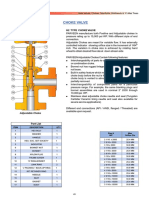

- Choke ParveenDokument3 SeitenChoke ParveenYM Edwin Gil BeltranNoch keine Bewertungen

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDokument1 Seite5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaNoch keine Bewertungen

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralDokument1 Seite5.000 HWDP With NC50 (4.5IF) (6.625 X 3.000 TJ) Integral SpiralFranklin Jose Almera AcostaNoch keine Bewertungen

- API 7K Certified Mud Pump Parts ListDokument23 SeitenAPI 7K Certified Mud Pump Parts Listflasher_for_nokiaNoch keine Bewertungen

- Doniflon 2010: Properties Appropriate Industries & ApplicationsDokument2 SeitenDoniflon 2010: Properties Appropriate Industries & Applicationsflasher_for_nokiaNoch keine Bewertungen

- rfb7 de en PDFDokument2 Seitenrfb7 de en PDFflasher_for_nokiaNoch keine Bewertungen

- 12 Point Flange Screws Technical SpecificationsDokument1 Seite12 Point Flange Screws Technical Specificationsflasher_for_nokiaNoch keine Bewertungen

- Rfb7 - de - en Triple Mas 6000Dokument2 SeitenRfb7 - de - en Triple Mas 6000Miguel GonzalezNoch keine Bewertungen

- Rfb7 - de - en Triple Mas 6000Dokument2 SeitenRfb7 - de - en Triple Mas 6000Miguel GonzalezNoch keine Bewertungen

- Correction of Service Manual Si-18 M-11011Dokument18 SeitenCorrection of Service Manual Si-18 M-11011Ahmed AzadNoch keine Bewertungen

- Dls 7 eDokument12 SeitenDls 7 eseaqu3stNoch keine Bewertungen

- Dye Bath LubricantsDokument6 SeitenDye Bath Lubricantsthedevil666100% (1)

- UK Gate Valves Brochure High Res 02 - 2017Dokument20 SeitenUK Gate Valves Brochure High Res 02 - 2017Sivasubramanian PalaniappanNoch keine Bewertungen

- Food Process EngineeringDokument9 SeitenFood Process Engineeringvineeth vipparthiNoch keine Bewertungen

- Dlab Ms-H280-ProDokument3 SeitenDlab Ms-H280-ProAntoNoch keine Bewertungen

- C267Dokument6 SeitenC267Rufo CascoNoch keine Bewertungen

- Basement ConstructionDokument12 SeitenBasement Constructionfgfghhffgh100% (2)

- Breviar de Calcul - Cos C.R.Dokument63 SeitenBreviar de Calcul - Cos C.R.tulvyNoch keine Bewertungen

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Dokument255 SeitenD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Technical Data Sheet for Zinc PrimerDokument4 SeitenTechnical Data Sheet for Zinc PrimerBiju_PottayilNoch keine Bewertungen

- A Review On Surface Treatment For Concrete - Part 2 - Performance OkeDokument10 SeitenA Review On Surface Treatment For Concrete - Part 2 - Performance Okealdi sophianNoch keine Bewertungen

- Plastic Mixed Reinforced Concrete - BehaviourDokument4 SeitenPlastic Mixed Reinforced Concrete - BehaviourThiaga RajanNoch keine Bewertungen

- KNOC - Surface Pre and Painting ProcedureDokument32 SeitenKNOC - Surface Pre and Painting Procedureminhhieu.qc100% (1)

- Vacuum InterruptersDokument17 SeitenVacuum InterruptersCARLOS LÓPEZNoch keine Bewertungen

- Properties of SteamDokument27 SeitenProperties of SteamVishal DhimanNoch keine Bewertungen

- Ruido Suspension Delantera cx-5 PDFDokument7 SeitenRuido Suspension Delantera cx-5 PDFAriel SerrateNoch keine Bewertungen

- M-DS31 Filcor Eps Data Sheet Cordek v1Dokument2 SeitenM-DS31 Filcor Eps Data Sheet Cordek v1ShamaNoch keine Bewertungen

- The Fortessa Collection 2010Dokument36 SeitenThe Fortessa Collection 2010monu6006Noch keine Bewertungen

- Blanco Ku 0099M 13094 DATA 1 PDFDokument96 SeitenBlanco Ku 0099M 13094 DATA 1 PDFCm EtcmNoch keine Bewertungen