Beruflich Dokumente

Kultur Dokumente

Asdasd

Hochgeladen von

Ricardo NapitupuluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Asdasd

Hochgeladen von

Ricardo NapitupuluCopyright:

Verfügbare Formate

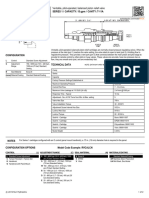

BWB Controls

Telephone (985)-876-4117

info@bwbcontrols.com

ISO 9001 Certified

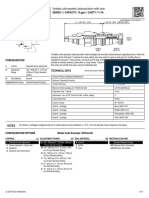

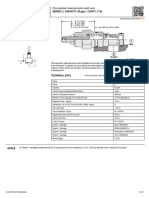

"RH2" PILOT

“PNEUMATIC or HYDRAULIC”

OPERATION

The BWB "RH2" is a 3 way, normally closed or normally open, automatic, pressure sensing device. By

choosing the appropriate inlet, the sensor can detect pressure above (PSH) or below (PSL) any desired

pressure setting. By selecting the correct piston assembly & spring combination (See Pressure Chart), and

either loosening or tightening the adjustment bolt, the sensor may be set between 3 and 10,000 PSI. It is

normally installed on a process vessel, process flow line, or in a control panel. The sensor receives sensing

pressure (Port P) from the component which it is monitoring and supply pressure (Port A or B) from the

safety system which it will shutdown.

FEATURES

316 STAINLESS STEEL MATERIALS

1/4” FNPT CONTROL PORTS

DEAD BAND +/- 5% TO 20% OF SET PRESSURE

SET POINT REPEATABILITY +/- 1% OF SET PRESSURE

SERVICE CLASSIFICATION

Standard service: Viton O-rings

Temperature Range: -15 to 250° F (-26 to 121° C)

Special service: O Ring compounds and materials to Customer Requirements

BWB Controls ‘RH2’ Pilots can be configured to meet the needs of the customer by changing the

Sensing Sleeves, Sensing Pistons and Springs. Please review the charts below to determine your

configuration.

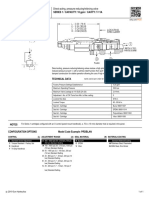

ORDERING INFORMATION PART # PISTON/SPRING ADJUSTABLE RANGE

RH2LP LP PLAIN 3 - 10 PSI .21 – .69 bar

EXAMPLE RH2 X / X X RH21/2P #1/2 - PLAIN 5 - 15 PSI .34 – 1.02 bar

RH21/2R #1/2 RED 15 - 50 PSI 1.02 – 3.45 bar

SPRING COLOR RH21/2G #1/2 – GREEN 50 - 200 PSI 3.45 – 13 bar

BASE SERIES ‘SEE TABLE’ RH21/2Y #1/2 - YELLOW 150 - 325 PSI 10 – 22 bar

‘P’ – PLAIN RH22/1G #2/1 - GREEN 150 - 500 PSI 10 – 34 bar

‘R’ – RED RH22/1Y #2/1 - YELLOW 300 - 900 PSI 20 – 62 bar

PISTON ASSEMBLY ‘G’ – GREEN RH22/3G #2/3 - GREEN 150 - 500 PSI 10 – 34 bar

‘SEE TABLE’ ‘Y’ – YELLOW

RH22/3Y #2/3 - YELLOW 300 - 900 PSI 20 – 62 bar

RH23/2G #3/2 - GREEN 500-1500 PSI 34 – 103 bar

WEIGHTS RH23/2Y #3/2 - YELLOW 750 - 2000 PSI 52 – 138 bar

RH24/5G #4/5 - GREEN 1000 - 3000 PSI 69 – 207 bar

RH2 5 POUNDS RH2 (PSHL)12.00 POUNDS RH24/5Y #4/5 - YELLOW 1500 - 4000 PSI 103 – 275 bar

RH2LP 5 POUNDS RH2DIF 8.00 POUNDS RH25/4G #5/4 - GREEN 2000 - 6000 PSI 138 – 413 bar

RH25/4Y #5/4 - YELLOW 3500 - 10000 PSI 241 – 689 bar

PANEL MOUNT

1 – 9/16" Diameter Hole (39 mm)

Maximum Panel Thickness, 0.25 Inches (6 mm)

Panel Nut Thickness; 0.25 inches (6 mm)

Designed and Manufactured using Safe Engineering Practices

13 APRIL 2016

BWB Controls

Telephone (985)-876-4117

info@bwbcontrols.com

ISO 9001 Certified

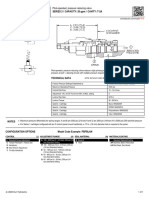

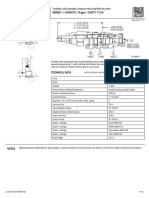

INSTALLATION ITEM DESCRIPTION

PORT ‘A’ 1 BODY

PSH – Supply Inlet (N.O.) 2 BASE

PSL – Exhaust (N.C.) 3 ADJUSTMENT BOLT

Pneumatic 30 to 1500 PSI (2.06 to 103.42 bar) 4 SPRING GUIDE

5 SLEEVE

Hydraulic 30 to 2200 PSI (2.06 to 151.68 bar)

6 INNER PISTON

1/4” FNPT - Orifice - . 109” (2.77 mm) 7 LOCKRING

PORT ‘B’ 8 PANEL NUT

PSL – Supply Inlet (N.C.) 9 SENSING PISTON ***

PSH – Exhaust (N.O.) 10 SENSING SLEEVE ***

Pneumatic 30 to 1500 PSI (2.06 to 103.42 bar) 11 SPRING

12 O-RING AND BACKUP

Hydraulic 30 to 2200 PSI (2.06 to 151.68 bar)

(QTY 4)

1/4” FNPT - Orifice - . 109” (2.77 mm) 13 O-RING (QTY 3)

PORT ‘C’

Supply Pressure Outlet *** SENSING PISTON AND

1/4" FNPT SLEEVE DATA IS FOUND BELOW

Orifice Size - .109” (2.77 mm)

REPAIR KIT(S):

PORT ‘P’

Sensing Pressure Inlet CONTAINS ALL SEALS

3 to 10000 PSI (0.21 to 689.48 bar)

1/4” FNPT and 1/2" MNPT

Orifice Size - . 109” (2.77 mm)

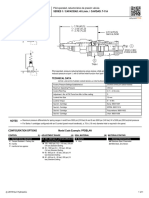

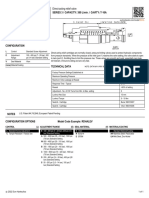

Please see the diagrams below of the Sleeve and Piston configurations.

1/2 PISTON ASSEMBLY DIMENSIONS

1/2 PISTON & SLEEVE 2/1 PISTON & SLEEVE

2/3 PISTON ASSEMBLY

2/3 PISTON & SLEEVE 3/2 PISTON & SLEEVE

4/5 PISTON ASSEMBLY

4/5 PISTON & SLEEVE 5/4 PISTON & SLEEVE

Designed and Manufactured using Safe Engineering Practices

13 APRIL 2016

Das könnte Ihnen auch gefallen

- R-Pilot 040417Dokument2 SeitenR-Pilot 040417Bobby SetiawanNoch keine Bewertungen

- Products - Instrumentation - Hydraulic Pnuematic Controls - Pressure Sensors - BWB Controller R-PilotDokument2 SeitenProducts - Instrumentation - Hydraulic Pnuematic Controls - Pressure Sensors - BWB Controller R-Pilotalan minayaNoch keine Bewertungen

- R Pilot - BWBPSHLDokument2 SeitenR Pilot - BWBPSHLalvipin0010% (1)

- PPDB en Us A4Dokument1 SeitePPDB en Us A4Felipe DiazNoch keine Bewertungen

- SVSW-007002-G04-0001 Rev C Bill of Material - Code 1Dokument7 SeitenSVSW-007002-G04-0001 Rev C Bill of Material - Code 1chuminhNoch keine Bewertungen

- Relief Valve VENTABLE RVCALAN - T11A RV1Dokument1 SeiteRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNoch keine Bewertungen

- 2.875 P110 8.70ppf PH6-TS6Dokument1 Seite2.875 P110 8.70ppf PH6-TS6Giana KoesoemahNoch keine Bewertungen

- Controls: "AUHP1" Automatic Relay "Pneumatic and Hydraulic"Dokument2 SeitenControls: "AUHP1" Automatic Relay "Pneumatic and Hydraulic"Carlos OrtizNoch keine Bewertungen

- Modelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Dokument1 SeiteModelo 3-Vías, Acción-Directa, Direccional Válvula Con Drenaje Interno Al Puerto 3 (1 Bloqueado, 2 A 3 Abierto)Erasmo LimaNoch keine Bewertungen

- 2 Insert Valves 2012-07Dokument30 Seiten2 Insert Valves 2012-07JairoHernanLoperaNoch keine Bewertungen

- PBFB en Us A4Dokument1 SeitePBFB en Us A4operacion hydratekNoch keine Bewertungen

- Modelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADokument1 SeiteModelo Pilot-Operated, Reductor/alivio de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AJonathanDavidDeLosSantosAdornoNoch keine Bewertungen

- M-45 OwsDokument194 SeitenM-45 OwsMehmet AGAGÜNDÜZ100% (1)

- 09 - Domino Junior Logic (Sept 07)Dokument6 Seiten09 - Domino Junior Logic (Sept 07)Peter RhoadsNoch keine Bewertungen

- 059006XYZ RE18310-13rextonDokument2 Seiten059006XYZ RE18310-13rextonBryan Edu Curay ZavalaNoch keine Bewertungen

- Model Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4Dokument1 SeiteModel Direct-Acting, Pressure Reducing/relieving Valve With Drain To Port 4mhasansharifiNoch keine Bewertungen

- Oily Water SeparatorDokument154 SeitenOily Water SeparatorПетко Петков100% (1)

- DRBCLBN Full Es Us A4Dokument2 SeitenDRBCLBN Full Es Us A4Erasmo LimaNoch keine Bewertungen

- RPGC Full en Us A4Dokument2 SeitenRPGC Full en Us A4zapchasty29Noch keine Bewertungen

- Tender NoticeDokument2 SeitenTender Notice4D EngineeringNoch keine Bewertungen

- Atlasco ManualDokument248 SeitenAtlasco ManualAyoade Lanre BexNoch keine Bewertungen

- Specs SheetDokument15 SeitenSpecs SheetFathan KarimanNoch keine Bewertungen

- Specs Sheet Duplicate 9655021-3-4 & AD993180Dokument8 SeitenSpecs Sheet Duplicate 9655021-3-4 & AD993180Fathan KarimanNoch keine Bewertungen

- SUN RPGC-JCN (Relief Valve)Dokument3 SeitenSUN RPGC-JCN (Relief Valve)ful islamNoch keine Bewertungen

- Control Valves Modulating: Customer: Contractor: Plant: LocationDokument64 SeitenControl Valves Modulating: Customer: Contractor: Plant: LocationJorge GonzalezNoch keine Bewertungen

- RPCCLAN Full en Us LetterDokument2 SeitenRPCCLAN Full en Us Lettera safaieNoch keine Bewertungen

- PRDBOEN Full en Us LetterDokument3 SeitenPRDBOEN Full en Us LetterPartagon PowNoch keine Bewertungen

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADokument2 SeitenModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNoch keine Bewertungen

- Model Free Flow Nose To Side Check Valve With Bypass OrificeDokument2 SeitenModel Free Flow Nose To Side Check Valve With Bypass OrificeRenjithSivaNoch keine Bewertungen

- Regulador Fisher 1era Etapa r622hDokument2 SeitenRegulador Fisher 1era Etapa r622hBrayan CJNoch keine Bewertungen

- Pressure Switch POPREN - Rv00Dokument1 SeitePressure Switch POPREN - Rv00Lý Thái ThuầnNoch keine Bewertungen

- Model Ventable, Pilot Operated, Balanced Piston Relief ValveDokument2 SeitenModel Ventable, Pilot Operated, Balanced Piston Relief ValveErasmo LimaNoch keine Bewertungen

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2ADokument1 SeiteModel Direct-Acting, Pressure Reducing/relieving Valve: Series 2 / Capacity: 20 GPM / Cavity: T-2AleosignareNoch keine Bewertungen

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADokument1 SeiteModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNoch keine Bewertungen

- TRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596Dokument3 SeitenTRSV SP-ENH 5.5 20 Vamtop - 4.562in Sealbore MN 102951596alejandromarinch7Noch keine Bewertungen

- Brochure R 102323Dokument5 SeitenBrochure R 102323alan minayaNoch keine Bewertungen

- Mug Pump Technical InfoDokument5 SeitenMug Pump Technical InfoEmmanuel Soberano HernandezNoch keine Bewertungen

- HBB - Fuel Train - RA - Prebuild Option 3Dokument4 SeitenHBB - Fuel Train - RA - Prebuild Option 3AlvaroJavierReyesNoch keine Bewertungen

- 70-335 Nitrogen Actuator AssemblyDokument8 Seiten70-335 Nitrogen Actuator AssemblyBrandon AtzNoch keine Bewertungen

- SUN RPGC-LAN (Relief Valve)Dokument3 SeitenSUN RPGC-LAN (Relief Valve)ful islamNoch keine Bewertungen

- Pa Fe 117Dokument2 SeitenPa Fe 117milton1987Noch keine Bewertungen

- PVDB Full en Us LetterDokument2 SeitenPVDB Full en Us LetterIsrael RuizNoch keine Bewertungen

- 19-0699 SPDokument2 Seiten19-0699 SPOmar turco curiNoch keine Bewertungen

- Data Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoDokument7 SeitenData Sheet-Vacuum Stripper Tower 11-T-1102: Nombre Del ProyectoAARON HERRERANoch keine Bewertungen

- Single or Dual Setpoint, Internal or External Adjustment: PSW-700 SeriesDokument2 SeitenSingle or Dual Setpoint, Internal or External Adjustment: PSW-700 SeriesraulNoch keine Bewertungen

- Model Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16ADokument1 SeiteModel Direct-Acting Relief Valve: SERIES 3 / CAPACITY: 380 L/min. / CAVITY: T-16APRASHANT KANTENoch keine Bewertungen

- Model Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162ADokument1 SeiteModel Direct-Acting Relief Valve: CAPACITY: 12 GPM / CAVITY: T-162AmhasansharifiNoch keine Bewertungen

- Model Ventable, Pilot-Operated, Balanced Poppet Relief ValveDokument2 SeitenModel Ventable, Pilot-Operated, Balanced Poppet Relief ValveGamal El Deen KamalNoch keine Bewertungen

- Blowout PreventerDokument6 SeitenBlowout PreventerMoataz NazeemNoch keine Bewertungen

- Relife Valve Rpeclnn - Pilot OperatedDokument2 SeitenRelife Valve Rpeclnn - Pilot OperatedHassan KhattabNoch keine Bewertungen

- 700 Spec-1 PDFDokument2 Seiten700 Spec-1 PDFmarei mahgoobNoch keine Bewertungen

- RVCALCN Full en Us A4Dokument2 SeitenRVCALCN Full en Us A4Felipe DiazNoch keine Bewertungen

- Series 21: Bar Max Adjustable PDokument4 SeitenSeries 21: Bar Max Adjustable PSamira 1986Noch keine Bewertungen

- 2021 16.0 TST-2 Service PackerDokument15 Seiten2021 16.0 TST-2 Service PackerDhenny FarialNoch keine Bewertungen

- Pressure Switch Directional Valves: InstallationDokument2 SeitenPressure Switch Directional Valves: InstallationEliud Rodriguez100% (1)

- Model 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Dokument2 SeitenModel 3-Way, Direct-Acting, Directional Valve With Internal Drain To Port 3 (1 Blocked, 2 To 3 Open)Erasmo LimaNoch keine Bewertungen

- Brochure RPSDokument5 SeitenBrochure RPSalan minayaNoch keine Bewertungen

- 17-SP Spreader Valves CatalogDokument8 Seiten17-SP Spreader Valves CatalogFederico TomiNoch keine Bewertungen

- TTP - LNK 1437 001 SlsDokument1 SeiteTTP - LNK 1437 001 SlsCavandraNoch keine Bewertungen

- Daily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographDokument1 SeiteDaily Report: Various Pressure Vessel (Baru Gas Plant Project - Pltgu Tenayan) Daily PhotographRicardo NapitupuluNoch keine Bewertungen

- Leak Test Procedure of Atmospheric VesselDokument9 SeitenLeak Test Procedure of Atmospheric VesselRicardo NapitupuluNoch keine Bewertungen

- It - PT - Asme - 01 - Rev 00Dokument16 SeitenIt - PT - Asme - 01 - Rev 00Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Dokument2 SeitenVp-15-109-001-A01-P-237-004ab-Sk-018 Lube-Oil Schematic and Bill of Materials (Steam Turbine)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineDokument4 SeitenVp-15-109-001-A01-P-237-004abc-D-006 Data Sheet For Steam TurbineRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorDokument3 SeitenVp-15-109-001-A01-P-237-004abc-D-008 Data Sheet For Main MotorRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpDokument9 SeitenVp-15-109-001-A01-P-237-004abc-D-005 Data Sheet For Boiler Feed Water PumpRicardo NapitupuluNoch keine Bewertungen

- S Curve Instrument CepuDokument1 SeiteS Curve Instrument CepuRicardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpDokument3 SeitenVp-15-109-001-A01-P-237-004abc-C-010 Performance Curve For PumpRicardo NapitupuluNoch keine Bewertungen

- SN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Dokument4 SeitenSN0-1-05-009 - Instrument Data Sheet For Flow Transmitter DP Type - TA2021 - 3Ricardo NapitupuluNoch keine Bewertungen

- Topologi Jaringan 49 Sekolah Sman/Smkn Se DiyDokument2 SeitenTopologi Jaringan 49 Sekolah Sman/Smkn Se DiyRicardo NapitupuluNoch keine Bewertungen

- API 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Dokument7 SeitenAPI 614/ISO 10438-2 DATASHEET Scope and Attachments Si Units (Kpa)Ricardo NapitupuluNoch keine Bewertungen

- Vp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvDokument3 SeitenVp-15-109-001-A01-P-237-004abc-Sk-060 Sectional Drawing & Part Name List of ArvRicardo NapitupuluNoch keine Bewertungen

- PLD - Shelter - 30 11 2020Dokument3 SeitenPLD - Shelter - 30 11 2020Ricardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceDokument1.274 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2003, May 29-31, 2003, Vouliagmeni, Athens, GreeceRicardo NapitupuluNoch keine Bewertungen

- Support and Non Pressure Part Calculation of Foul ProductionDokument34 SeitenSupport and Non Pressure Part Calculation of Foul ProductionRicardo NapitupuluNoch keine Bewertungen

- Nm-Dairy Planning Data SheetDokument16 SeitenNm-Dairy Planning Data SheetRicardo NapitupuluNoch keine Bewertungen

- 6 BLP Spesifikasi Teknis 49 SMA 14920Dokument6 Seiten6 BLP Spesifikasi Teknis 49 SMA 14920Ricardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainDokument228 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2001, February 11-15, 2001, Puerto de La Cruz, Tenerife, SpainRicardo NapitupuluNoch keine Bewertungen

- Eng - M - Lifting Lug Cal - 2Dokument6 SeitenEng - M - Lifting Lug Cal - 2Ricardo NapitupuluNoch keine Bewertungen

- B-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantDokument3 SeitenB-Tech Valve ACP-30Oct19 Azymuth Citra Perkasa Ricardo Napitupulu Bukit Asam Power PlantRicardo NapitupuluNoch keine Bewertungen

- API Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsDokument5 SeitenAPI Standard 521 - Guide For Pressure-Relieving and Depressuring SystemsRicardo NapitupuluNoch keine Bewertungen

- Mto Instrument Condensate RecoveryDokument1 SeiteMto Instrument Condensate RecoveryRicardo NapitupuluNoch keine Bewertungen

- The Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandDokument295 SeitenThe Following Papers Belong To: WSEAS NNA-FSFS-EC 2002, February 11-15, 2002, Interlaken, SwitzerlandRicardo NapitupuluNoch keine Bewertungen

- Chapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeDokument6 SeitenChapter 9. Estimating Centerline Temperature of A Buoyant Fire PlumeRicardo NapitupuluNoch keine Bewertungen

- Chapter 13. Fire Severity Calculations: Input ParametersDokument20 SeitenChapter 13. Fire Severity Calculations: Input ParametersRicardo NapitupuluNoch keine Bewertungen

- Mastil PDFDokument84 SeitenMastil PDFPepe AlNoch keine Bewertungen

- Genie Genuine Service Tools CatalogDokument12 SeitenGenie Genuine Service Tools CatalogAgus ImagineNoch keine Bewertungen

- Phot SKF PDFDokument379 SeitenPhot SKF PDFLê Duy PhongNoch keine Bewertungen

- IMO G12 - 218 Despacho Guaduas PDFDokument21 SeitenIMO G12 - 218 Despacho Guaduas PDFCarlos Andres Arias LopezNoch keine Bewertungen

- Ecr88 - 20009002-D CHNDokument720 SeitenEcr88 - 20009002-D CHNDiego MontenegroNoch keine Bewertungen

- Pfeiffer: Butterfly Valve Series 14b / 14c / 74bDokument8 SeitenPfeiffer: Butterfly Valve Series 14b / 14c / 74btree_99Noch keine Bewertungen

- BP1800 D Extended Rock Spare Parts Manual Edition - Aug '08Dokument162 SeitenBP1800 D Extended Rock Spare Parts Manual Edition - Aug '08komalinternational5Noch keine Bewertungen

- Butterfly Norris Series 285Dokument12 SeitenButterfly Norris Series 285metasoniko2014Noch keine Bewertungen

- Model E2 Ve2 Manual Rev 2.3.13Dokument68 SeitenModel E2 Ve2 Manual Rev 2.3.13manoj tyagiNoch keine Bewertungen

- L-600 Parts ManualDokument64 SeitenL-600 Parts Manualheartofdixie71% (7)

- EN Stauff One G Flanges 2014 PDFDokument74 SeitenEN Stauff One G Flanges 2014 PDFcaballero_tigreNoch keine Bewertungen

- FP Diesel Varios MotoresDokument18 SeitenFP Diesel Varios MotoresValeddia Beatriz Gutierrez Nina50% (2)

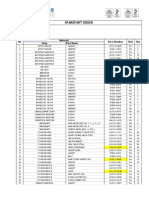

- Sparepart Order: Engine KOMATSU SAA12V140-P1150 Unit No. # 8 Grup Part Name No Material Parts Number Unit QtyDokument3 SeitenSparepart Order: Engine KOMATSU SAA12V140-P1150 Unit No. # 8 Grup Part Name No Material Parts Number Unit QtyAnom Harimurti100% (1)

- Mobile Division: Service Parts ListDokument20 SeitenMobile Division: Service Parts Listwag008Noch keine Bewertungen

- ZE4 APFS902571ASLv00Dokument217 SeitenZE4 APFS902571ASLv00MARKNoch keine Bewertungen

- 7785 A5Dokument13 Seiten7785 A5hmltdt9221100% (1)

- Catalog Lohan Hendra JANDokument78 SeitenCatalog Lohan Hendra JANKaiserNoch keine Bewertungen

- RPU80 160 300 Manual EN PDFDokument38 SeitenRPU80 160 300 Manual EN PDFandreaNoch keine Bewertungen

- Astm D 5084Dokument23 SeitenAstm D 5084Andrés Moreno100% (3)

- Howo Sinotruk 371 2021 3.0 Transmission-传动系 CAFK20100294Dokument72 SeitenHowo Sinotruk 371 2021 3.0 Transmission-传动系 CAFK20100294Karsten JaneckeNoch keine Bewertungen

- DNV Approval Porg.5-778.93Dokument8 SeitenDNV Approval Porg.5-778.93Daniel Cringus0% (1)

- 37P Running PartsDokument4 Seiten37P Running PartsSachin BanwalaNoch keine Bewertungen

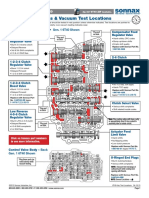

- 6T40-Vac Test LocationsDokument4 Seiten6T40-Vac Test LocationsMauricio Exequiel ChavezNoch keine Bewertungen

- Karcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRDokument17 SeitenKarcher Pressure Washer Parts and Basic Repair Service Manual Pump 785 HD2500G HD2500MTD HD2600DK HD2700DH HD2701DRt_zonne855750% (2)

- Extended Weld Socket Block Connector, Pipe Deep Weld Socket, Pipe / Code 61 or 62 Block Flange or PadDokument4 SeitenExtended Weld Socket Block Connector, Pipe Deep Weld Socket, Pipe / Code 61 or 62 Block Flange or PadHuy NguyễnNoch keine Bewertungen

- 200 Series ManualDokument38 Seiten200 Series ManualGleison PrateadoNoch keine Bewertungen

- PARTS BREAKDOWN FOR HD 1090 (1.951-681.0) : Location PN Description QTY From TO PIECE PARTS - Parts List Serial #Dokument15 SeitenPARTS BREAKDOWN FOR HD 1090 (1.951-681.0) : Location PN Description QTY From TO PIECE PARTS - Parts List Serial #PawełOsadaNoch keine Bewertungen

- Compresor MYCOMDokument8 SeitenCompresor MYCOMPEDRONoch keine Bewertungen

- RADLEYS Reactor-Ready-Lab-ReactorsDokument16 SeitenRADLEYS Reactor-Ready-Lab-ReactorsRenato BottiniNoch keine Bewertungen