Beruflich Dokumente

Kultur Dokumente

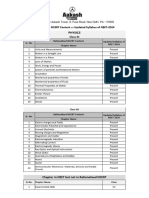

Prima Epoxy Zinc Phosphate Primer 2184

Hochgeladen von

fransiska_ogaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Prima Epoxy Zinc Phosphate Primer 2184

Hochgeladen von

fransiska_ogaCopyright:

Verfügbare Formate

PRIMA EPOXY ZINC PHOSPHATE PRIMER

2184

DESCRIPTION

PRIMA EPOXY ZINC PHOSPHATE ( 2184-series ) is two components polyamide catalyzed

epoxy containing zinc phosphate as corrosion inhibitive pigment.

As a general purpose steel primer which is to be top-coated with epoxies system or other system as

recommended.

FEATURES

Excellent chemical resistance

Excellent solvent resistance

Excellent bonding strength

Excellent water resistance

Very good abrasion resistance

Good flexibility

PHYSICAL DATA

Color : Grey / Cream / Red / Brown

Gloss : Flat

Specific Gravity : Approx 1.4 kg / L (mixed)

Volume Solids : Approx 52 %

Theoretical Coverage : Approx 7 m² / L at 75 micron d.f.t.

Drying Time : Touch dry : 3 – 4 hours at 30°C

Final cured : 1 week

APPLICATION DATA

No of Component : 2 (two packs)

Curing Agent : CA.8 – 0424

Recommended Film Thickness : 50 – 75 micron d.f.t / coat

Flash Point : 26° C Close cup

Thinner : Thinner 0124

Tool Cleaning : Tool Cleaner 0100

PD/2184-series June, 2011

MIXING AND THINNING

Mixing Ratio by volume : Component Base 2184 – series : 4

Curing Agent CA.8-0424 : 1

Mixing direction : Mix the individual component separately till uniformity of liquid

is obtained; combine both components then stir those combined

component (base and curing agent) with powered mixer for at

least 60 seconds before putting into application tool.

Thinning : Thinner 0124, usable when necessary.

Pot Life : 7 hours at 30°C

Induction Time : 2 – 3 minute

APPLICATION

Application tool : Airless spray or conventional spray, brush or roller.

Spray : Guiding data airless spray :

Pressure at nozzle 15 MPa ( 150 kp/cm2 ,2100 psi )

Nozzle tip 0.53 – 0.79 mm

Spray Angle 40° - 80°

Guiding data conventional spray :

Pressure at nozzle 3 - 4 Bar ( 43 - 57 psi )

Nozzle tip 1.5 – 2 mm

Spray Angle ± 70o

Application direction : Use a 50 % overlap with each pass of the gun.

Brush or roller : Recommended for small areas and touch up only. Care must be

taken to achieve the specified dry film thickness.

Application conditions : As dictated by normal good painting practice

Apply only on a dry and clean surface with a temperature above

dew point to avoid condensation.

Subsequent coat : Epoxies, urethane coatings, or consult the manufacturer.

Work Stoppages : Do not allow mixed material to remain in hoses, gun or spray

equipment.

Recoat interval at 30° C : Min : 6 hours

Max : 7 days at 30°C

Clean Up : Clean all equipment immediately after use with Tool Cleaner 0100.

It is good working practice to periodically flush out spray

equipment during the course of the working day.

SURFACE PREPARATION

Remove any oil, grease, or dirt from the surface to be coated with clean rags soaked in Tool Cleaner

0100.

New Steel : Abrasive blast cleaning to SIS Sa 2 ½ (SSPC SP 10). Lower

grade of surface preparation is also tolerable – please consult

with manufacturer.

Recoating : - Remove oil and grease etc, with Tool Cleaner 0100.

- All rust and other loose material by power tool cleaning. Hose

down sound and intact coating with fresh water and then allow

to dry.

PD/2184-series June, 2011

PRECAUTIONS

The product can be stored for at least 2 year in their original packs.

This product is flammable material. Keep away from sparks, open flames, and smokers. Take

precautions to avoid skin and eyes contact always uses goggles, face masks for protection. Provide

adequate ventilation during application is a mandatory.

For detailed information on health and safety hazards and precautions for use of this product, we

refer to the Material Safety Data Sheet

PACKING

5 L set, 20 L set

PD/2184-series June, 2011

Das könnte Ihnen auch gefallen

- Soldering electronic circuits: Beginner's guideVon EverandSoldering electronic circuits: Beginner's guideBewertung: 4.5 von 5 Sternen4.5/5 (9)

- Optigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLEVon EverandOptigal’s Q & A for the CLRE: Contact Lens Registry Exam Questions Basic Certification - NCLENoch keine Bewertungen

- EPD 100 Plascotuff Epoxy Coal TarDokument2 SeitenEPD 100 Plascotuff Epoxy Coal TarAdhil RamsurupNoch keine Bewertungen

- Technical Data Propan - Gemini SyntheticDokument2 SeitenTechnical Data Propan - Gemini SyntheticErwin MalmsteinNoch keine Bewertungen

- Apcothane CF 678Dokument1 SeiteApcothane CF 678Santaj TechnologiesNoch keine Bewertungen

- Zinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial ManualDokument1 SeiteZinc Anode 304 NPC Coating Zinc Anode 304 NPC Coating: Berger Industrial Manual Berger Industrial Manualআফজাল -উল ইসলাম নূর0% (1)

- 6424 Redoxide Primer 424 June-12Dokument2 Seiten6424 Redoxide Primer 424 June-12محمد عزتNoch keine Bewertungen

- 6440 SIPKYD ALUMINIUM 440 June-12Dokument2 Seiten6440 SIPKYD ALUMINIUM 440 June-12محمد عزتNoch keine Bewertungen

- PDS Hempadur Multi-Strength 45753 en-GBDokument2 SeitenPDS Hempadur Multi-Strength 45753 en-GBJosip LasanNoch keine Bewertungen

- MS GF 35870 en-GBDokument2 SeitenMS GF 35870 en-GBLinnie McleodNoch keine Bewertungen

- Nippon Road Line Paint TDSDokument2 SeitenNippon Road Line Paint TDSfaridanurro100% (1)

- Pds Simathane Gloss 9-1Dokument2 SeitenPds Simathane Gloss 9-1Aulia RahmahNoch keine Bewertungen

- DS - 752-Rev01 - Epilux 485 HB IntermediateDokument2 SeitenDS - 752-Rev01 - Epilux 485 HB IntermediatePammy JainNoch keine Bewertungen

- Pzi 233 Plascozinc 1 PrimerDokument2 SeitenPzi 233 Plascozinc 1 Primersarcozy922Noch keine Bewertungen

- Epilux 200 Polyamide Cured Coaltar EpoxyDokument3 SeitenEpilux 200 Polyamide Cured Coaltar EpoxyIqra AngelsNoch keine Bewertungen

- 6430 SIPKYD FINISH 430 June-12Dokument2 Seiten6430 SIPKYD FINISH 430 June-12محمد عزتNoch keine Bewertungen

- 805 Steelkote Ep ZN Hs Datasheet enDokument3 Seiten805 Steelkote Ep ZN Hs Datasheet enprasanth cp100% (1)

- NP ArocoatDokument4 SeitenNP ArocoatJohn HaNoch keine Bewertungen

- Aluminium Paint HR NipponDokument2 SeitenAluminium Paint HR Nipponyarth88Noch keine Bewertungen

- DS 428 LuxathaneFDFinishDokument2 SeitenDS 428 LuxathaneFDFinishRatish NairNoch keine Bewertungen

- EA9 Red Oxide PrimerDokument3 SeitenEA9 Red Oxide PrimernkhhhNoch keine Bewertungen

- Mon Chassis - Coat A4 - GB 0822Dokument2 SeitenMon Chassis - Coat A4 - GB 0822Matthew ZahraNoch keine Bewertungen

- Apcodur Epoxy Zinc Rich PrimerDokument2 SeitenApcodur Epoxy Zinc Rich PrimerMd. Sahabul IslamNoch keine Bewertungen

- TDS PU Primer 2K.Dokument2 SeitenTDS PU Primer 2K.Akshay KshirsagarNoch keine Bewertungen

- Technical Data: No. TD: PT-001 Revision: 04 Effective Date: 17 Juli 2020Dokument2 SeitenTechnical Data: No. TD: PT-001 Revision: 04 Effective Date: 17 Juli 2020MorenoNoch keine Bewertungen

- Nerothane 1000Dokument1 SeiteNerothane 1000nimish.aquamarine0% (1)

- 802 SteelKote EP Datasheet enDokument3 Seiten802 SteelKote EP Datasheet enGianiNoch keine Bewertungen

- Rust O Cap PDFDokument1 SeiteRust O Cap PDFTitus PraveenNoch keine Bewertungen

- PC 1262 - Asian Epoxy HB CoatingDokument3 SeitenPC 1262 - Asian Epoxy HB CoatingHithayathulla KhanNoch keine Bewertungen

- Unibar Shopprimer LV: BarilDokument2 SeitenUnibar Shopprimer LV: BarilFlori SmăduNoch keine Bewertungen

- SteelkobeDokument3 SeitenSteelkobealexamaigutNoch keine Bewertungen

- Zinc Chromate Primer PDFDokument2 SeitenZinc Chromate Primer PDFWanda WibisanaNoch keine Bewertungen

- Nerothane PU Topcoat: Scope Application DetailsDokument1 SeiteNerothane PU Topcoat: Scope Application DetailsTanvir Ahmed KhanNoch keine Bewertungen

- Neromastic 4000Dokument2 SeitenNeromastic 4000m pallonjiNoch keine Bewertungen

- Nippon HB Epoxy LinerDokument3 SeitenNippon HB Epoxy LinerRai Hasnain Ahmad DahaNoch keine Bewertungen

- Bergerthane PU Glossy Finish: Product Data Resistance GuideDokument2 SeitenBergerthane PU Glossy Finish: Product Data Resistance Guidesangram keshari pattanaikNoch keine Bewertungen

- DS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Dokument2 SeitenDS 165 Rev01 Bergerthane PU Glossy Finish (Berger)Ranjan Kumar SahuNoch keine Bewertungen

- Zinc Phosphate PrimerDokument2 SeitenZinc Phosphate PrimertrinityallianceconsultancyNoch keine Bewertungen

- Epilux 44 Enamel: Product Data Resistance GuideDokument2 SeitenEpilux 44 Enamel: Product Data Resistance GuideKishore Nayak kNoch keine Bewertungen

- TDS 41048 Hardtop WF Euk GBDokument6 SeitenTDS 41048 Hardtop WF Euk GBKingsman 86Noch keine Bewertungen

- Vinilex 120 Active Primer - Spec - enDokument3 SeitenVinilex 120 Active Primer - Spec - enDonzt Dontz FaujiNoch keine Bewertungen

- Hempadur Multi-Strength GF 35870 PDFDokument3 SeitenHempadur Multi-Strength GF 35870 PDFAnuar SalehNoch keine Bewertungen

- TDS PU Paint 2K.ffsDokument2 SeitenTDS PU Paint 2K.ffsAkshay KshirsagarNoch keine Bewertungen

- Interplate 11: Zinc SilicateDokument4 SeitenInterplate 11: Zinc SilicateMohamed NouzerNoch keine Bewertungen

- 3500-00 Simathane Gloss (Finish Coat)Dokument3 Seiten3500-00 Simathane Gloss (Finish Coat)Hendri Dwi cahyonoNoch keine Bewertungen

- Cathacoat 302 Zinc Silicate PrimerDokument4 SeitenCathacoat 302 Zinc Silicate PrimerAhmed IbrahimNoch keine Bewertungen

- Asian Paints Apcothane CF 674 PDFDokument1 SeiteAsian Paints Apcothane CF 674 PDFANUP KUMAR MITRANoch keine Bewertungen

- Red Gray Oxide Data SheetDokument2 SeitenRed Gray Oxide Data Sheetmahesh mahadkarNoch keine Bewertungen

- Apcodur Epoxy Mio Paint: Technical DataDokument1 SeiteApcodur Epoxy Mio Paint: Technical DataSagar BhosaleNoch keine Bewertungen

- Hi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicDokument4 SeitenHi-Acryl 1901 Acrylic Top Coat Is A One-Pack, Fast-Drying AcrylicEvonne LeeNoch keine Bewertungen

- Chem ClearDokument5 SeitenChem ClearBiju_PottayilNoch keine Bewertungen

- Apcodur 220Dokument3 SeitenApcodur 220JOSEPH GRAHAMSENGGNoch keine Bewertungen

- H. V. NC: High Gloss - WhiteDokument1 SeiteH. V. NC: High Gloss - Whiteمحمد عزتNoch keine Bewertungen

- EA4 Finish MetalDokument3 SeitenEA4 Finish MetalAzmeer YusufNoch keine Bewertungen

- Penguard Clear SealerDokument4 SeitenPenguard Clear SealerInaam Ullah MughalNoch keine Bewertungen

- Pds Topaz WB Primer 283me En-GbDokument2 SeitenPds Topaz WB Primer 283me En-GbDipin Nediya ParambathNoch keine Bewertungen

- Analisys and application of dry cleaning materials on unvarnished pain surfacesVon EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNoch keine Bewertungen

- The Nail technician’s Career Guide - The blueprint to a successful nail salon businessVon EverandThe Nail technician’s Career Guide - The blueprint to a successful nail salon businessNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

- Thermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Dokument8 SeitenThermocouples Experiment: To Determine The Time Constant of A Typical Iron-Constantan Thermocouple.Hafiz Tanveer50% (2)

- Structural Report of Proposed Fencing and ExtensionDokument21 SeitenStructural Report of Proposed Fencing and ExtensionLester LazoNoch keine Bewertungen

- Decreasing VOC Emissions at The Source With New Additive Technologies For Olefin CompositesDokument11 SeitenDecreasing VOC Emissions at The Source With New Additive Technologies For Olefin CompositesFERNANDO JOSE NOVAESNoch keine Bewertungen

- ASTM D6641 D6641M 16e2Dokument6 SeitenASTM D6641 D6641M 16e2saif ullahNoch keine Bewertungen

- Final Year Project Report: Micro RefrigeratorDokument40 SeitenFinal Year Project Report: Micro RefrigeratorWaseem Aulakh100% (1)

- Metal O-Ring PDFDokument8 SeitenMetal O-Ring PDFanon_481226617Noch keine Bewertungen

- Permeability of Concrete - tcm45-346751Dokument3 SeitenPermeability of Concrete - tcm45-346751abualamalNoch keine Bewertungen

- Atul 30,36-LoescheDokument16 SeitenAtul 30,36-LoescheSales ITANoch keine Bewertungen

- Liberty ShipsDokument37 SeitenLiberty Ships2K19/ME/041 ANSH JININoch keine Bewertungen

- Preca Catalog - Read ViewDokument9 SeitenPreca Catalog - Read ViewAnyaWestmorelandNoch keine Bewertungen

- Advanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434Dokument27 SeitenAdvanced Cast Products - Ductile Iron Specs-ASTM 897, ASTM A536, SAE J434George CharitouNoch keine Bewertungen

- BD - K - EXPANSION JOINTSDokument18 SeitenBD - K - EXPANSION JOINTSMuthusamy ArumugamNoch keine Bewertungen

- Building Materials Construction Planning PDFDokument252 SeitenBuilding Materials Construction Planning PDFTharun TejaNoch keine Bewertungen

- Design-Coordination-Checklist Architectural Verfeb252020Dokument5 SeitenDesign-Coordination-Checklist Architectural Verfeb252020KunnalNoch keine Bewertungen

- Lee Et Al (2007) PDFDokument11 SeitenLee Et Al (2007) PDFMarco F. GallegosNoch keine Bewertungen

- NCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - PhysicsDokument1 SeiteNCERT Rationalised Content Vs Updated Syllabus of NEET-2024 - Physicsmohduwais695Noch keine Bewertungen

- 4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFDokument5 Seiten4.13.5 - 6 Simple Formula For Heat Loss Calculation PDFSatria PurwantoNoch keine Bewertungen

- Gas Assisted Injection MoldingDokument32 SeitenGas Assisted Injection MoldingYuvaraj YuvarajNoch keine Bewertungen

- The Use of Post Tensioning in Marine StructuresDokument39 SeitenThe Use of Post Tensioning in Marine StructuresmonkeyDivanNoch keine Bewertungen

- Coriolis Flow MeterDokument4 SeitenCoriolis Flow MeterIsares PodkohNoch keine Bewertungen

- Thermo Assignment Exam 4Dokument3 SeitenThermo Assignment Exam 4Harley QuinnNoch keine Bewertungen

- 12NC 853001901100 GTIN (EAN) Code 8003437219146: Whirlpool Air Conditioner - SPIW 412LDokument2 Seiten12NC 853001901100 GTIN (EAN) Code 8003437219146: Whirlpool Air Conditioner - SPIW 412LffffgjNoch keine Bewertungen

- Unit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsDokument30 SeitenUnit 1 Steady & Variable Stresses in Machine Members: Design of Machine ElementsPrasanth YuviNoch keine Bewertungen

- TMS 302 Sound Standard Public Comment Version 2018-08-07Dokument19 SeitenTMS 302 Sound Standard Public Comment Version 2018-08-07gare1404Noch keine Bewertungen

- 4 - Bending of PlatesDokument14 Seiten4 - Bending of PlatesTushar Vinay MehtaNoch keine Bewertungen

- Cement Manufacturing Process: Step 1: Extraction of Raw MaterialsDokument3 SeitenCement Manufacturing Process: Step 1: Extraction of Raw MaterialsKamran LurkaNoch keine Bewertungen

- H GuruDokument4 SeitenH GuruAvneet MaanNoch keine Bewertungen

- 03 01 30mapDokument11 Seiten03 01 30mapmp4 ghad mp4Noch keine Bewertungen

- Core DesignDokument45 SeitenCore Designfaezah adnan100% (16)

- Analysis of Truss-Method of Sections and Joints PDFDokument6 SeitenAnalysis of Truss-Method of Sections and Joints PDFStruktur ArkoninNoch keine Bewertungen