Beruflich Dokumente

Kultur Dokumente

199 DPU Section

Hochgeladen von

Anonymous 5qRTOZ0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten1 Seiteinternal detail of dpu

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldeninternal detail of dpu

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

39 Ansichten1 Seite199 DPU Section

Hochgeladen von

Anonymous 5qRTOZinternal detail of dpu

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

MEASUREMENT SYSTEMS

B A RT O N ®

Differential Pressure Units

Models 199 & 199N

Barton® Differential Pressure Units (DPUs) serve as actuating

units for a wide variety of instruments. All models feature

Barton’s® rupture-proof bellows.

Description

Each DPU consists of a Bellows Unit Assembly (BUA) and

removable pressure housings. Within the BUA, flexible bellows

are secured to a centerplate. In dual-bellows models, the movable

bellows are rigidly connected by a dual valve stem that passes

through the centerplate. Valve seats, in the centerplate passage,

form a seal with the valves. Contacting the valve stem in the

centerplate is a drive arm pivoted on the end of a sealed torque

tube. The bellows is filled with a clean, noncorrosive, low-freezing

point liquid. A range spring assembly provides tension against

applied pressures.

In operation, pressure is applied to both sides of the bellows.

Any difference in pressure causes the bellows to move until the

• Torque tube: Eliminates the possibility of leakage and need

spring effect (range springs) balances out the force. The linear

for lubrication. The needle bearing (inboard end) and ball

motion of the bellows (proportional to the DP) is transmitted as

bearing (on follower drive arm) operate with a minimum of

a rotary motion through the torque tube.

friction – resulting in high sensitivity over the life of the unit.

In dual-bellows units, if the bellows are subjected to a DP greater • The torque tube assembly consists of a tube, shaft, and

than the unit’s DP rating, a valve closes and “traps” the fill liquid supporting members. The outboard end of the torque tube

in the bellows — fully supporting the bellows and preventing is attached to the centerplate. The shaft passes through the

rupture. Since opposing valves are used, full protection is provided center of the tube and is welded to the inboard end.

in either direction. Since its outer end is attached to the centerplate, the

tube must twist when subjected to torque. The shaft,

Common Components freely supported at its outer end and attached to the tube

• Bellows Construction: Individual diaphragms, stamped and drive arm at its inner end, rotates through the same

and formed from selected materials (see individual DPU angle as the drive arm – the mechanical output of the DPU.

specifications), are assembled using highly specialized • Range springs: Determine the DP range of the unit, based

techniques, the results – exacting linearity characteristics, upon their number and strength. They have extremely low

a long cycle life, and freedom from effects of work hysteresis and exceptional temperature stability.

hardening commonly encountered with the hydraulically The M199 has an external range spring assembly that is

formed or mechanically rolled types. field replaceable.

Das könnte Ihnen auch gefallen

- Barton 199 DPU Data SheetDokument4 SeitenBarton 199 DPU Data Sheetmfg_serviciosNoch keine Bewertungen

- Boiler Feed PumpDokument22 SeitenBoiler Feed PumpnksatnamiNoch keine Bewertungen

- Articulo Bom 3 TornilloDokument4 SeitenArticulo Bom 3 TornilloJosé Olivier RománNoch keine Bewertungen

- 4, ACT TurbineDokument23 Seiten4, ACT TurbineMeet ZinzuvadiyaNoch keine Bewertungen

- Features of Metallic Expansion JointsDokument22 SeitenFeatures of Metallic Expansion JointsCepi Sindang KamulanNoch keine Bewertungen

- SnubbingDokument52 SeitenSnubbinggoodeel setyana100% (2)

- Springs: Functions, Types and DesignDokument16 SeitenSprings: Functions, Types and DesignSufiyan MohammedNoch keine Bewertungen

- PDFenDokument31 SeitenPDFenLurking RogueNoch keine Bewertungen

- Chapter 4Dokument29 SeitenChapter 4Engineers GalleryNoch keine Bewertungen

- Experiment 1Dokument22 SeitenExperiment 1dhruvmistry300Noch keine Bewertungen

- National Machinery - Cold Forming Glossary of TermsDokument17 SeitenNational Machinery - Cold Forming Glossary of Termssergio_daqNoch keine Bewertungen

- Two Screw Pumps: Reprint From Petromin October Issue 1994Dokument4 SeitenTwo Screw Pumps: Reprint From Petromin October Issue 1994Luis ReyesNoch keine Bewertungen

- Shaft 141118092812 Conversion Gate02Dokument14 SeitenShaft 141118092812 Conversion Gate02Aso SerwanNoch keine Bewertungen

- Horizontal Split Case LN TypeDokument38 SeitenHorizontal Split Case LN TypeprojashNoch keine Bewertungen

- Types of Springs and Their UsesDokument16 SeitenTypes of Springs and Their Usesaravindangokul687Noch keine Bewertungen

- Machine DesignDokument26 SeitenMachine Designrajasekar21Noch keine Bewertungen

- Sanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsDokument35 SeitenSanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsChaitanya YengeNoch keine Bewertungen

- Application of Bellows Expansion Joints in Piping SystemDokument5 SeitenApplication of Bellows Expansion Joints in Piping Systemjlcheefei9258Noch keine Bewertungen

- DLT Strand Jack Systems - 2.0 - 600 PDFDokument24 SeitenDLT Strand Jack Systems - 2.0 - 600 PDFganda liftindoNoch keine Bewertungen

- Single-Seat Straight-Way Valve With Exchangeable Seat RingDokument16 SeitenSingle-Seat Straight-Way Valve With Exchangeable Seat RingUgo MorelliNoch keine Bewertungen

- TC Manual Fluid PumpsDokument32 SeitenTC Manual Fluid Pumpsvickers100% (1)

- CH3 Ibl ADokument70 SeitenCH3 Ibl Anoorr66Noch keine Bewertungen

- Operating Instruction Underbody ClampDokument2 SeitenOperating Instruction Underbody ClampBe HappyNoch keine Bewertungen

- Single-Impeller Centrifugal Pumps for Civil, Agri & Industrial UseDokument2 SeitenSingle-Impeller Centrifugal Pumps for Civil, Agri & Industrial UseMisshell Tu GatitaNoch keine Bewertungen

- Term PaperDokument23 SeitenTerm PaperAman Goyal (B19ME004)Noch keine Bewertungen

- Butterfly Valve BrochureDokument6 SeitenButterfly Valve BrochureRohiNoch keine Bewertungen

- Bourdenpressuregauge 180227171311Dokument10 SeitenBourdenpressuregauge 180227171311Dimas NugrahaNoch keine Bewertungen

- Bellows Pressure SensorsDokument13 SeitenBellows Pressure Sensorspritesh deshmukhNoch keine Bewertungen

- Bombas Centífugas KSBDokument12 SeitenBombas Centífugas KSBkarmencitaconk4035Noch keine Bewertungen

- Vane Motors High Performance Hydraulic Series M5B - M5BS - M5BFDokument11 SeitenVane Motors High Performance Hydraulic Series M5B - M5BS - M5BFRidha AbbassiNoch keine Bewertungen

- Machine Elements Design of Couplings and BrakesDokument23 SeitenMachine Elements Design of Couplings and BrakesEyu KalebNoch keine Bewertungen

- Expansion JointsDokument15 SeitenExpansion Jointsaop10468Noch keine Bewertungen

- Hy Andritz High Pressure Pump Hp43 en DataDokument56 SeitenHy Andritz High Pressure Pump Hp43 en DataDaryl DelimanNoch keine Bewertungen

- GB SpringDokument69 SeitenGB Springshivkumar1587100% (1)

- Pressure Balanced Drilling Bumper Sub: Instruction Manual 4410Dokument17 SeitenPressure Balanced Drilling Bumper Sub: Instruction Manual 4410Foros IscNoch keine Bewertungen

- MEC 203 Lec 02Dokument15 SeitenMEC 203 Lec 02Prince RajNoch keine Bewertungen

- Dme Unit V (17.11.22)Dokument16 SeitenDme Unit V (17.11.22)sathiaNoch keine Bewertungen

- SENSORS AND TRANSDUCERS: LOAD CELLSDokument25 SeitenSENSORS AND TRANSDUCERS: LOAD CELLSSantanu SantraNoch keine Bewertungen

- Centrifugal & Axial Compressor - ConstructionDokument16 SeitenCentrifugal & Axial Compressor - ConstructionNikesh100% (3)

- Plunger Tips - Amp: PurposeDokument2 SeitenPlunger Tips - Amp: PurposeAlson LeeNoch keine Bewertungen

- Elastic Pressure TransducersDokument7 SeitenElastic Pressure TransducersKrypton HalideNoch keine Bewertungen

- Ajax General CatalogueDokument12 SeitenAjax General Catalogueabet_450% (2)

- Unit 2 Pressure Measurement Techniques 1. Explain Construction and Working of C-Type Bourdon TubeDokument6 SeitenUnit 2 Pressure Measurement Techniques 1. Explain Construction and Working of C-Type Bourdon TubeCheenuNoch keine Bewertungen

- Coupling NotesDokument28 SeitenCoupling NotesRose Mj80% (5)

- HPH BrochureDokument12 SeitenHPH BrochureCristhian Vilca SilvestreNoch keine Bewertungen

- Design of SpringsDokument128 SeitenDesign of SpringsYeshavanth Raj .S100% (4)

- Clutch DesignDokument33 SeitenClutch DesigneldrainyNoch keine Bewertungen

- Drill String Design PDFDokument12 SeitenDrill String Design PDFSurya AdhieNoch keine Bewertungen

- Springs NotesDokument9 SeitenSprings NotesP DargopatilNoch keine Bewertungen

- Definition For SpringDokument18 SeitenDefinition For SpringamanpurushothNoch keine Bewertungen

- Module-7 Thin and Thick CylinderDokument52 SeitenModule-7 Thin and Thick CylinderRahul SinghNoch keine Bewertungen

- Flange Joint and Flange ManagementDokument20 SeitenFlange Joint and Flange Managementsiraphat.bmNoch keine Bewertungen

- Unit-Iii Transmission System: ClutchDokument46 SeitenUnit-Iii Transmission System: ClutchRubalakshmi GovindarajNoch keine Bewertungen

- Screwed Joints Microproject MsbteDokument4 SeitenScrewed Joints Microproject MsbteSamarth PatilNoch keine Bewertungen

- Unit IV Energy Storing Elements and Engine ComponentsDokument55 SeitenUnit IV Energy Storing Elements and Engine ComponentsJayashree rajamuruganNoch keine Bewertungen

- 1 3 Rolling Contact Bearings RNR 25012021Dokument31 Seiten1 3 Rolling Contact Bearings RNR 25012021potnuru Jaivanth100% (1)

- Springs: Definition For SpringDokument20 SeitenSprings: Definition For Springmuna222Noch keine Bewertungen

- Cylindrical Compression Helix Springs For Suspension SystemsVon EverandCylindrical Compression Helix Springs For Suspension SystemsNoch keine Bewertungen

- Petroleum Course For PE RSEDokument5 SeitenPetroleum Course For PE RSEAnonymous 5qRTOZNoch keine Bewertungen

- Petroleum Course For PE RSEDokument5 SeitenPetroleum Course For PE RSEAnonymous 5qRTOZNoch keine Bewertungen

- PMT Myanmar's Rising StarDokument3 SeitenPMT Myanmar's Rising StarAnonymous 5qRTOZNoch keine Bewertungen

- C1 Controller StartupDokument1 SeiteC1 Controller StartupAnonymous 5qRTOZNoch keine Bewertungen

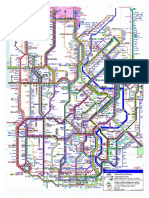

- Metro Map Yangon Bus Route PDFDokument1 SeiteMetro Map Yangon Bus Route PDFAnonymous 5qRTOZNoch keine Bewertungen

- 199 DPU SectionDokument1 Seite199 DPU SectionAnonymous 5qRTOZNoch keine Bewertungen

- UAK Control Valve 101Dokument4 SeitenUAK Control Valve 101Anonymous 5qRTOZNoch keine Bewertungen

- English Week3 PDFDokument4 SeitenEnglish Week3 PDFLucky GeminaNoch keine Bewertungen

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDokument61 SeitenBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriNoch keine Bewertungen

- MORTGAGE Short NotesDokument11 SeitenMORTGAGE Short Noteshamzatariq015Noch keine Bewertungen

- Lanegan (Greg Prato)Dokument254 SeitenLanegan (Greg Prato)Maria LuisaNoch keine Bewertungen

- Test Bank For Core Concepts of Accounting Information Systems 14th by SimkinDokument36 SeitenTest Bank For Core Concepts of Accounting Information Systems 14th by Simkinpufffalcated25x9ld100% (46)

- S2 Retake Practice Exam PDFDokument3 SeitenS2 Retake Practice Exam PDFWinnie MeiNoch keine Bewertungen

- DSE61xx Configuration Suite Software Manual PDFDokument60 SeitenDSE61xx Configuration Suite Software Manual PDFluisNoch keine Bewertungen

- Development of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993Dokument14 SeitenDevelopment of Rsto-01 For Designing The Asphalt Pavements in Usa and Compare With Aashto 1993pghasaeiNoch keine Bewertungen

- Ijimekko To Nakimushi-Kun (The Bully and The Crybaby) MangaDokument1 SeiteIjimekko To Nakimushi-Kun (The Bully and The Crybaby) MangaNguyễn Thị Mai Khanh - MĐC - 11A22Noch keine Bewertungen

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Dokument19 SeitenHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedeNoch keine Bewertungen

- Microsoft Word 2000 IntroductionDokument72 SeitenMicrosoft Word 2000 IntroductionYsmech SalazarNoch keine Bewertungen

- Common Size Analys3esDokument5 SeitenCommon Size Analys3esSaw Mee LowNoch keine Bewertungen

- Understanding Oscilloscope BasicsDokument29 SeitenUnderstanding Oscilloscope BasicsRidima AhmedNoch keine Bewertungen

- Cianura Pentru Un Suras de Rodica OjogDokument1 SeiteCianura Pentru Un Suras de Rodica OjogMaier MariaNoch keine Bewertungen

- IP68 Rating ExplainedDokument12 SeitenIP68 Rating ExplainedAdhi ErlanggaNoch keine Bewertungen

- APC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IDokument3 SeitenAPC Smart-UPS 1500VA LCD 230V: Part Number: SMT1500IDesigan SannasyNoch keine Bewertungen

- Modified Release Drug ProductsDokument58 SeitenModified Release Drug Productsmailtorubal2573100% (2)

- Roadmap For Digitalization in The MMO Industry - For SHARINGDokument77 SeitenRoadmap For Digitalization in The MMO Industry - For SHARINGBjarte Haugland100% (1)

- Chapter 2Dokument22 SeitenChapter 2Okorie Chinedu PNoch keine Bewertungen

- PWC Global Project Management Report SmallDokument40 SeitenPWC Global Project Management Report SmallDaniel MoraNoch keine Bewertungen

- Ryerson EthicsDokument20 SeitenRyerson EthicssinghbabaNoch keine Bewertungen

- Ks3 Science 2008 Level 5 7 Paper 1Dokument28 SeitenKs3 Science 2008 Level 5 7 Paper 1Saima Usman - 41700/TCHR/MGBNoch keine Bewertungen

- Diemberger CV 2015Dokument6 SeitenDiemberger CV 2015TimNoch keine Bewertungen

- Weir Stability Analysis Report PDFDokument47 SeitenWeir Stability Analysis Report PDFSubodh PoudelNoch keine Bewertungen

- Florence Walking Tour MapDokument14 SeitenFlorence Walking Tour MapNguyễn Tấn QuangNoch keine Bewertungen

- 14 15 XII Chem Organic ChaptDokument2 Seiten14 15 XII Chem Organic ChaptsubiNoch keine Bewertungen

- PW CDokument4 SeitenPW CAnonymous DduElf20ONoch keine Bewertungen

- April 2017 Jacksonville ReviewDokument40 SeitenApril 2017 Jacksonville ReviewThe Jacksonville ReviewNoch keine Bewertungen

- Symmetry (Planes Of)Dokument37 SeitenSymmetry (Planes Of)carolinethami13Noch keine Bewertungen

- Antiquity: Middle AgesDokument6 SeitenAntiquity: Middle AgesPABLO DIAZNoch keine Bewertungen