Beruflich Dokumente

Kultur Dokumente

Xarr 2015 en PDF

Hochgeladen von

Hendra AwanOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Xarr 2015 en PDF

Hochgeladen von

Hendra AwanCopyright:

Verfügbare Formate

XAR® wear-resistant steels

Solution to your wear problems

ThyssenKrupp Steel Europe

Thinking the future of steel

XAR® steels –

ThyssenKrupp Steel Europe’s solution to your wear problems

XAR

ThyssenKrupp ®

high hard

XAR® (eXtra Abrasion Resistant) steels

are ThyssenKrupp Steel Europe’s solution

for applications where problems and cost

increases are the results of wear and abra-

sion. Thanks to the high level of hardness

achieved through the special chemical

composition of the XAR® steels and their

quenching and tempering heat treatment,

abrasion can be minimized and product

service life extended. XAR® steels were

developed in the Heavy Plate Unit of

ThyssenKrupp Steel Europe, one of the

world’s leading producers of flat steel

products. The first XAR® plates were pro-

duced more than 40 years ago in Duisburg.

Since then, remarkable developments

have been made with grades now avail-

able in plate thicknesses ranging from 4 to

100 mm, tailored for all applications, e.g.

in mining technology, earth moving equip-

ment, steel mills, cement works and agri-

cultural machinery.

Different XAR® grades

for different applications

The standard wear-resistant steel grade is

XAR® 400, which can increase product

service life to five times that of conventional Some applications are only subject to low XAR® 500 steel, which is formable and

structural steel. XAR® 400 combines high or moderate wear. XAR® 300 was developed weldable, is available for even higher

wear resistance with good cold formability for these applications. This steel is produced abrasive wear. For extreme abrasive wear

and weldability. It is the most frequently via normalizing rolling without any heat applications (without impulsive load)

used wear-resistant steel worldwide for treatment and therefore has a very good ThyssenKrupp Steel Europe offers its XAR®

many different applications. A heat-resistant price/performance ratio, combined with 600 grade. Due to its exceptional hardness,

XAR® 400 W variant is also available where excellent surface quality. cold-forming of this steel is not recom-

hardness and wear resistance at higher mended.

temperatures up to 400°C are required, XAR® 450 is the best choice where require-

for instance in cement works. ments call for higher wear resistance com- For applications placing increased tough-

bined with virtually the same processing ness requirements on the wear plate,

characteristics as the standard XAR® 400 XAR® HT is the right choice with its com

grade. XAR® 450 is expected to increasingly bination of wear resistance and extremely

replace the standard XAR® 400 steel grade high notch impact strength.

in the future.

Wear-resistant XAR® steels

for different applications

Balanced alloying concepts for simple

processing and wear resistance

The recently published expert opinion of

the Institute of Tribology at the Mannheim

University of Applied Sciences confirms that

“within the range of low-alloyed, wear-resis-

tant special structural steels with good pro-

cessing characteristics, ThyssenKrupp Steel

Europe’s XAR® steels with hardness values

from 300 to 600 HB represent an optimum

concept with regard to steel composition,

manufacturing process and microstructure”.

Extensive wear investigations carried out on

our XAR® steels have shown that optimum

abrasion resistance is achieved through

their high hardness and in particular the

specific alloying with Cr and Nb. Toughness

and cold-forming behavior as well as resist-

ance to impact wear are increased through

the Nb-microalloying. Cr-alloying improves

wear resistance, especially in aggressively

corrosive media.

The lean analysis concepts and low carbon

equivalent of our XAR® steels make cutting

and welding easier and provide better cold

forming properties with tight bending radii.

For instance MAG welding without preheat-

ing is possible up to a thickness of 20 mm

(40 mm combined thickness) for XAR® 400

plates and up to 15 mm (30 mm combined

thickness) for XAR® 450 plates. 10 mm thick

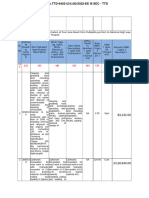

Hardness and chemical composition XAR® 400 plates can be bent with radii as

Steel grade Delivery Thickness Hardness Alloying small as r/t ≥ 4.0 (10 mm thick XAR® 450

condition range [mm] [HBW] plates with r/t ≥ 5.0).

XAR® 300 normalized 4 – 50 ≥ 270* ~ 0.20 % C**, Cr(Mo)-alloyed

XAR HT

®

40 – 100 310 – 370 ~ 0.25 % C**, CrMo(Ni)-alloyed

XAR 400

®

4 – 100 370 – 430 ~ 0.15 % C**, Cr(Mo)-alloyed

XAR 400

®

40 – 100 370 – 430 ~ 0.16 % C**, CrNiMo-alloyed

PREMIUM

XAR® 400 W 4 – 40 360 – 440 ~ 0.25 % C**, Cr(Mo)-alloyed

XAR 450

®

quenched 4 – 100 420 – 480 ~ 0.19 % C**, Cr(Mo)-alloyed

XAR 450

® (+ tempered)

40 – 100 420 – 480 ~ 0.21 % C**, CrNiMo-alloyed

PREMIUM

XAR® 500 4 – 100 470 – 530 ~ 0.25 % C**, CrMo(Ni)-alloyed

XAR 500

®

40 – 100 470 – 530 ~ 0.26 % C**, CrNiMo-alloyed

PREMIUM

XAR® 600 4 – 50 > 550 ~ 0.35 % C**, CrNiMo-alloyed

* plate thickness ≤ 20 mm ** plate thickness 15 mm

Toughness improvement by Nb-microalloying Improvement of wear resistance with 1% Cr

Typical Charpy-V-energy values at –40ºC, longitudinal [J] XAR® 400 – Gravel friction, grain 6 – 8 mm

30 25%

no no

Nb Nb Nb Nb

0 0%

XAR® 400 XAR® 450 basic neutral acid

Hot strip plates for extremely uniform plate thickness of XAR® applied with an even coat 12–18 µm thick.

weight optimized structures plates cut from hot strip also offers advan- Investigations have shown that plates with

tages with regard to cold forming. this primer can be cut by laser without any

Weight plays an important role in many problems. The inorganic content means

structures. Therefore, restricted thickness that the primer can be welded over, making

tolerances are often required. ThyssenKrupp removal of the primer before welding gener-

Steel Europe can produce XAR® steels via Modern shot blasting and priming line ally unnecessary.

two different routes. Hot strip mill production offers high surface quality

offers the advantage of very close thickness

tolerances of ± 0.2 mm which are lower Plates are delivered shot blasted and primed

than the usual thickness tolerances of four- to meet the highest surface quality require-

high mill plates and also lower than the ments. Shot blasting and priming is carried

tolerances usually required by customers. out on a modern line at ThyssenKrupp Steel

In addition to weight-saving potential, the Europe. A low-zinc silicate primer is usually

Statistical thickness tolerance distribution for hot strip plates

Crane

specs.

Relative frequency

Hot strip

plates EN 10029

0.2 0.7 1.5

Total thickness tolerance [mm]

ThyssenKrupp Steel Europe – The online world of ThyssenKrupp

more than just a plate supplier Steel Europe’s special structural steels

ThyssenKrupp Steel Europe is more than a Optimized processing and application of

reliable plate supplier. The expansion of the XAR® steels require a close cooperation

worldwide distribution network is aimed not between supplier and customer. A com-

just to guarantee the availability and just-in- prehensive technical customer service

time delivery of XAR® steels to customers. has therefore been established to provide

The close cooperation with first-class steel support in terms of all material processing

service centers also makes it possible to of- and design questions.

fer components which are prefabricated by

means of cutting, cold forming or welding. Visit our website at www.thyssenkrupp-

In this way ThyssenKrupp Steel Europe steel-europe.com/plate for further infor-

meets the steadily growing demands of its

customers for quality, service and deli-

very performance.

mation about our special structural steels,

including data sheets and processing recom-

mendations. In addition, you can find your

personal sales or technical customer service

contact. ProWeld, a computer software

developed by ThyssenKrupp Steel Europe for

calculating welding parameters, can also be

ordered via our internet homepage.

General note

All statements as to the properties or

utilization of the materials and products

mentioned in this brochure are for the

purpose of description only. Guarantees in

respect of the existence of certain proper-

ties or utilization of the material mentioned

are only valid if agreed upon in writing.

Subject to technical changes without notice.

Reprints, even extracts, only with permission

of ThyssenKrupp Steel Europe AG, Heavy

Plate Unit.

Please contact:

The latest information can be found on the internet

www.thyssenkrupp-steel-europe.com/plate

ThyssenKrupp Steel Europe AG

Kaiser-Wilhelm-Strasse 100 · 47166 Duisburg · Germany

Edition 08/2015

Order No. 1095

Postal address: 47161 Duisburg · Germany

Telephone +49 (0)203 52-0 · Telefax +49 (0)203 52-25102

www.thyssenkrupp-steel-europe.com · info.steel-europe@thyssenkrupp.com

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- FQP For Civil WorkDokument15 SeitenFQP For Civil WorkManoj ShahNoch keine Bewertungen

- Fine-Scale Precipitation and Mechanical Properties of Thin Slab Processed Titanium-Niobium Bearing High Strength SteelsDokument9 SeitenFine-Scale Precipitation and Mechanical Properties of Thin Slab Processed Titanium-Niobium Bearing High Strength SteelsHendra AwanNoch keine Bewertungen

- Preheat and PWHT Procedure: GlobalDokument12 SeitenPreheat and PWHT Procedure: GlobalHendra AwanNoch keine Bewertungen

- Traksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelDokument9 SeitenTraksi: Pengaruh Post Weld Heat Treatment (PWHT) Terhadap Struktur Mikro Dan Kekerasan Sambungan Las Stainless SteelHendra AwanNoch keine Bewertungen

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 004.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Dokument2 SeitenTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 004.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNoch keine Bewertungen

- Material Receiving Report: 1 Inch X 6M 60mm X 500Dokument3 SeitenMaterial Receiving Report: 1 Inch X 6M 60mm X 500Hendra AwanNoch keine Bewertungen

- PDS - NA - PRP Repair Data SheetDokument2 SeitenPDS - NA - PRP Repair Data SheetHendra AwanNoch keine Bewertungen

- Timor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Dokument2 SeitenTimor-1 CFSPP Project Supporting Dokumen: Doc No.: 003.SD/ENC-UBE/TIMOR1/III/2021 Ref No. 0Hendra AwanNoch keine Bewertungen

- BRT-PPGJ-Q-006 (Nde Shop1) 1Dokument22 SeitenBRT-PPGJ-Q-006 (Nde Shop1) 1Hendra AwanNoch keine Bewertungen

- Polyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerDokument2 SeitenPolyethylene Repair Products: Repair Patch, Melt Stick, Liquid Epoxy and Mastic FillerHendra AwanNoch keine Bewertungen

- Wrapidcoat PVC: Superior Mechanical ProtectionDokument2 SeitenWrapidcoat PVC: Superior Mechanical ProtectionHendra AwanNoch keine Bewertungen

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDokument2 SeitenWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanNoch keine Bewertungen

- Wrapidtape: Primerless Crosslinked Protective TapeDokument2 SeitenWrapidtape: Primerless Crosslinked Protective TapeHendra AwanNoch keine Bewertungen

- Wrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionDokument2 SeitenWrapidbond: A Visco-Elastic Adhesive Based System For Pipeline Corrosion ProtectionHendra AwanNoch keine Bewertungen

- Harmony K - K1F003MLHDokument9 SeitenHarmony K - K1F003MLHHendra AwanNoch keine Bewertungen

- Timer Controllers: With Universal Power For Both 120 and 220 VACDokument1 SeiteTimer Controllers: With Universal Power For Both 120 and 220 VACHendra AwanNoch keine Bewertungen

- Cylindrical Fuse Base Detail86Dokument3 SeitenCylindrical Fuse Base Detail86Hendra AwanNoch keine Bewertungen

- Certificate - of - Conformance MagnehelicDokument1 SeiteCertificate - of - Conformance MagnehelicHendra AwanNoch keine Bewertungen

- SITE BOOK Quantity Take Off Details PDFDokument20 SeitenSITE BOOK Quantity Take Off Details PDFkumaravajiraNoch keine Bewertungen

- Powder Metallurgy: Introduction ToDokument268 SeitenPowder Metallurgy: Introduction ToBhavya SumaNoch keine Bewertungen

- Drawn Checked: ApprovedDokument3 SeitenDrawn Checked: ApprovedchethanNoch keine Bewertungen

- ITP - Plaster WorkDokument1 SeiteITP - Plaster Workmahmoud ghanemNoch keine Bewertungen

- SECTION 05730 Ornamental Formed Metal Rev 0Dokument25 SeitenSECTION 05730 Ornamental Formed Metal Rev 0Abdalrahman AntariNoch keine Bewertungen

- DEKMaster Fast CatDokument20 SeitenDEKMaster Fast CatmangeshshingoteNoch keine Bewertungen

- PageDokument5 SeitenPagebaroNoch keine Bewertungen

- Leporello Aluminium Casting Alloys RHEINFELDEN ALLOYS 2018Dokument10 SeitenLeporello Aluminium Casting Alloys RHEINFELDEN ALLOYS 2018luisA1923Noch keine Bewertungen

- EVACHMACriteriaFinal For2012Dokument10 SeitenEVACHMACriteriaFinal For2012Assane LeyeNoch keine Bewertungen

- Construction Technology MCQDokument16 SeitenConstruction Technology MCQvignesh rulzNoch keine Bewertungen

- Indal Steel PipeDokument9 SeitenIndal Steel Pipemailmaverick8167Noch keine Bewertungen

- OPC Cement 43 GradeDokument1 SeiteOPC Cement 43 Gradegiant pandaNoch keine Bewertungen

- Continuity TestingDokument107 SeitenContinuity TestingJohn Benedict MauricioNoch keine Bewertungen

- FP 450-60Dokument4 SeitenFP 450-60Supakanit LimsowanNoch keine Bewertungen

- E - Crosby Chain Grade 80 AlloyDokument1 SeiteE - Crosby Chain Grade 80 Alloyrony 2222Noch keine Bewertungen

- Alloy: Live GraphDokument13 SeitenAlloy: Live GraphKasia MazurNoch keine Bewertungen

- Cherlopalli Vakulamatha Temple RoadDokument39 SeitenCherlopalli Vakulamatha Temple Roadharsha vickyNoch keine Bewertungen

- Niels Schrodinger: Curso: Química Profesor (A) :gleddy Diaz Toro Alumno (A) :manuel Omar H.PDokument39 SeitenNiels Schrodinger: Curso: Química Profesor (A) :gleddy Diaz Toro Alumno (A) :manuel Omar H.Pomar PeñaNoch keine Bewertungen

- 5 - Performance Data Sheet SAMPLE - Drill Pipe 5.5 PDFDokument1 Seite5 - Performance Data Sheet SAMPLE - Drill Pipe 5.5 PDFTesturo KubotaNoch keine Bewertungen

- Infogramm: Remanium StarDokument2 SeitenInfogramm: Remanium StarPiNoch keine Bewertungen

- Catalogo MarlowDokument56 SeitenCatalogo MarlowZhi ShuNoch keine Bewertungen

- 3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Dokument3 Seiten3.balindong District Hospital-Completion of Ward, Pharmacy and Laboratory 6,970,000Rexter UnabiaNoch keine Bewertungen

- SCI C Vitaulic Snap-Let Outlet Snap 11.04Dokument2 SeitenSCI C Vitaulic Snap-Let Outlet Snap 11.04jplutodNoch keine Bewertungen

- Attachment 5 - Valve Design Table PDFDokument8 SeitenAttachment 5 - Valve Design Table PDFbisworupmNoch keine Bewertungen

- Bladder Accumulators Standard Model: 1. DescriptionDokument8 SeitenBladder Accumulators Standard Model: 1. DescriptionbarryNoch keine Bewertungen

- Corrosion-Guide 1 Stainless Steel CategoriesDokument8 SeitenCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéNoch keine Bewertungen

- Whiting Hinged Truss II: Dry Freight Roll-Up DoorDokument1 SeiteWhiting Hinged Truss II: Dry Freight Roll-Up DoorDesign RCFNoch keine Bewertungen

- 5-Aci 8855Dokument10 Seiten5-Aci 8855aliNoch keine Bewertungen

- CCUG P91 Fabrication Guidelines Dave Buzza-1Dokument22 SeitenCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarNoch keine Bewertungen