Beruflich Dokumente

Kultur Dokumente

MCOM Commissioning Manual PDF

Hochgeladen von

jigyeshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MCOM Commissioning Manual PDF

Hochgeladen von

jigyeshCopyright:

Verfügbare Formate

Complete Solution for Motor Protection

INSTRUCTION MANUAL

Complete Solution for Motor Protection

The content of this publication is subject to change

without notice. Larsen & Toubro Limited reserves the

right to make product-improvement changes which

may or may not be re ected in this publication. Larsen

& Toubro Limited is not responsible for any inadvertent

admissions, omissions, or errors. Larsen & Toubro

Limited assumes no liability for damages arising out of,

or in connection with, the application or use of any

product or application described herein.

Rev. C

Released Date - September, 2016

L&T Electrical & Automation

Electrical Systems & Equipment

Head of ce

7C, TC II, Tower B, L&T Business Park,

L&T Gate No. 5, Saki Vihar Road, Powai,

Mumbai 400 072, India

© 2016 Larsen & Toubro Limited. All rights reserved.

MCOMP User Manual - REV. C

CONTENTS

1.0 PREFACE 01

Manual Overview 02

Version 02

Purpose of This Manual 02

Safety and General Information 02

Conventions and Nomenclature 02

Conventions 02

Nomenclatures 03

2.0 INTRODUCTION 05

About the Relay 06

Reasons for Motor Protections 06

Product Overview 07

Relay Main unit 07

Status of LED Indication 07

Current Module (CM) 08

Display unit 08

DIO Expansion unit 08

LED Indication on expansion unit 09

MCOMP Order Codes 09

Getting Started 11

3.0 SPECIFICATIONS 12

General 13

Dimensions 14

Type Tests 15

Certi cations 15

Environmental Conditions 15

Relay Elements 16

Metering 18

Monitoring 18

4.0 INSTALLATION 19

Overview 20

Mechanical Installation 20

Dimensions 20

Main unit Dimensions 20

CM 1 Dimensions 20

CM 2-5 Dimensions 21

DIO Expansion Module Dimensions 21

Display Dimensions 21

Product Identi cation Label 22

Mounting 22

Relay Mounting 22

CM Mounting 22

Display Mounting 23

DIO Expansion Module Mounting 23

MCOMP User Manual - REV. C

CONTENTS

Electrical Installation 24

Relay Main Unit Wiring 25

3 Phase Voltage Connections 26

3-Phase Current Connections 26

Con guration Port Connection 27

RTD/PTC and Analog O/P Connections 28

Communication Port Connection 28

Auxiliary Power Supply Connection 30

Digital Input Connections 30

Digital Output Connections 31

Current Module (CM) Wiring 31

Display Wiring 33

Expansion Unit Wiring 35

5.0 METERING AND MONITORING 37

Overview 38

Metering 38

Current Based Metering 38

RMS Line Current 38

Earth Fault Current 38

Average RMS Current 38

Thermal Capacity 38

Current Unbalance 38

Voltage Based Metering 38

RMS Line Voltage 38

RMS Phase Voltage 38

Average RMS Voltage 38

Frequency 38

Power and Energy Based Metering 39

Power 39

Energy 39

Power Factor 39

Miscellaneous Parameter 39

Temperature 39

Digital Input/Output Status 39

COMPlogic output Status 39

Monitoring 39

Motor Speci c Data Monitoring 39

Phase Sequence 39

Motor Starting Time 39

CM Type 40

Number of Starts 40

Number of Stops 40

Motor Run Hours 40

Total Motor Run Hours 40

Starting Peak Current 40

Annunciations 40

MCOMP User Manual - REV. C

CONTENTS

6.0 PROTECTIONS 41

Overview 42

Thermal Protection 43

Overload (49) 43

Current Based Protection 46

Over current Protection (50P) 46

Under current Protection (37) 46

Current unbalance Protection (46) 47

Earth Fault Protection (50N or 50SG) 47

Locked Rotor Protection (50LR) 48

IDMT Overcurrent (51P/51N) 48

Phase Loss Protection (47A) 49

Voltage Based Protection 49

Over voltage Protection (59) 49

Under voltage Protection (27) 50

Voltage unbalance Protection (47) 50

Phase reversal Protection (47B) 51

Frequency Based Protection 51

Under frequency Protection (81L) 51

Over frequency Protection (81H) 51

Advanced Features 51

Re-acceleration (27LV) 51

Temperature Monitoring 53

Maximum Number of Starts Protection (66) 54

Fail to Stop Protection 54

Interlock 1 to 12 54

Communication Failure Monitoring 54

Excessive Start Time Protection 54

Analog Input Monitoring 54

7.0 COMMUNICATION 56

Overview 57

Communication Interface 57

Communication Protocol 57

Modbus RTU 57

Supported Modbus Function Codes 58

Modbus RTU Settings 58

Modbus memory map 58

Pro bus DP 58

Pro bus Settings 59

Pro bus memory map 59

Modbus TCP/IP 59

Modbus TCP/IP Settings 59

Modbus TCP/IP Memory Map 60

Parameter Mapping 60

Status Word 62

Communication Architecture 62

Modbus Architecture 62

Pro bus Architecture 62

MCOMP User Manual - REV. C

CONTENTS

8.0 SETTINGS 64

Overview 65

Setting Parameters 65

System Setting Parameters 65

Protection Setting Parameters 69

Digital Input Output Setting Parameters 69

Basic Digital Input/Output 69

DIO Expansion Module 69

Digital Input Settings 70

Digital Output Settings 72

Analog Output Settings 73

Communication Setting Parameters 74

COMPlogic Setting Parameters 74

COMPlogic Modules 74

Truth Table 74

Signal Conditioner 74

Counters 75

Timers 76

List of logical Inputs 77

Relay Con guration 78

Relay Con guration through the Display 78

Relay Con guration through MCOMP suite 80

Relay Con guration through Communication 82

Examples of Relay Selection and Basic Settings using

Motor data 82

Case 1: 82

Solution: 82

Case 2: 83

Solution: 83

Setting Sheet 85

System Settings 85

Protection Settings 87

Communication Settings 91

DIO Settings (Digital Input/Output) 91

Parameter Mapping Settings 115

COMPlogic Settings 115

9.0 USER INTERFACE 119

Overview 120

MCOMP Suite Interface 120

Installation Guide 120

.NET Framework 3.5 Service Pack installation 120

Multi-version MCOMP Suite Installation 122

MCOMP Suite Installation 123

Operation Guide 124

MCOMP Suite Con guration 124

Monitoring Mode 125

Con guration Mode 132

Display Interface 144

Operation Guide 144

Metering 145

MCOMP User Manual - REV. C

CONTENTS

Settings 146

View Records 147

Commands 148

Display Settings 148

Connect to PC 149

10.0 TESTING AND TROUBLESHOOTING 150

Overview 151

Testing 151

Connection Setup Requirement 151

Metering testing 151

Phase current and voltage: 151

Power, Energy & Power factor: 151

Protection Testing 151

Troubleshooting 152

Special Commands 153

Inhibit Status 154

Motor Stop Cause 154

Memory Maps 156

Overview 157

A] Modbus RTU Memory Map 157

Trip Record Table 169

Event Record Table 172

Table A-3. Event Record Cause Table 172

B] Pro bus memory map 176

Cyclic Data 176

Data Representation 180

Data Modules available in GSD le 189

Acyclic Data 190

C] Modbus TCP/IP Memory Map 192

Application Notes 218

Overview 218

A] Starter Application 218

DOL Starter 218

RDOL Starter 219

STAR/DELTA Starter 220

B] Non Motor Load Application 221

C] Re-acceleration Application 221

D] 3P-3W, 3P-4W Application 222

E] Two Phase Voltage Inputs (R and Y phase input)

Application 223

F] Winding Heating Application 223

G] Analog Output Application 223

H] Pro bus Communication Application 224

I] Protection Function Application 227

Thermal Overload Case Study 227

Locked Rotor Protection 229

J] Watchdog Application 229

K] Single Phase Motor Application 231

MCOMP User Manual - REV. C

PREFACE

MCOMP User Manual - REV. C 1

PREFACE

Manual Overview Safety and General Information

The MCOMP Instruction Manual provides complete information This manual uses following safety statements:

necessary to install, operate, and maintain the MCOMP Relay and

its accessory components. Immediate Hazard.

An overview of each section of this manual is as follows: SEVERE personal injury or death WILL result.

DANGER

Preface: Describes the manual organization, Safety & General

Hazards or unsafe practices.

Information and conventions & nomenclatures used in this

SEVERE personal injury or death MAY result.

manual. WARNING

Introduction: Provides a brief overview of the product and the

Hazards or unsafe practices.

manual.

MINOR personal injury or damage to products or

Speci cations: Lists the Relay technical speci cations. CAUTION property MAY result.

Installation: Describes mechanical installation and electrical

IMPORTANT Essential advisory information.

wiring of the Relay.

Metering and Monitoring: Describes the operation and NOTE Additional or explanatory information.

calculation of each metering functions.

Protection: Describes the operating characteristics of each

protection element provided in the Relay.

Conventions and Nomenclature

Communication: Describes communication interface and

Conventions

protocols supported by the Relay.

In this manual,

Settings: Describes the different setting parameters meaning

with its use and how to enter settings into the relay. It also de nes Relay refers to MCOMP Main Unit

the setting sheet describing all the settings available in the relay. Display Unit refers to MCOMP Display Unit

User Interface: Describes how to con gure the Relay through CM refers to MCOMP Current Module

local interface using MCOMP Suite and the Display.

Expansion unit refers to add-on DIO/AI unit

Testing and Troubleshooting: Describes the common problems

encountered during the Relay testing and various troubleshooting

techniques.

Version

This is revision C release of the manual by Larsen & Toubro Ltd.

Purpose of This Manual

This manual intends to help the users of the MCOMP Relay, to

operate, maintain and troubleshoot the device. It may be used by

following users:

Design and Planning Engineers

System Integrators

Maintenance Engineers

MCOMP User Manual - REV. C 2

PREFACE

Nomenclatures

Following are the different Nomenclature and their descriptions

used in this Manual.

Nomenclatures Descriptions

CAT Category

CBCT Core Balance Current Transformer

CM Current Module

CRC Cyclic Redundancy Check

DCS Distributed Control System

DHCP Dynamic Host Configuration Protocol

DI Digital Input

DIN German Institute for Standardization

DIO Digital Input/Output

DO Digital Output

DOL Direct On Line

DP Decentralized Peripherals

DTE Data Terminal Equipment

EEPROM Electrically Erasable and Programmable Read Only Memory

EWS Engineering Work Station

FS System Frequency

GSD General Station Description

GMT Greenwich Mean Time

IEF Set Value for Earth Fault Current

IFLC Full Load Current

IOC Instantaneous Over Current

IR Running Current

ISET Set Value for Over load curve

LCS Local Control System

LED Light Emitting Diode

LRC Longitudinal Redundancy Check

LSB Least Significant Bit

MFLA Multiple of Full Load Current

MSB Most Significant Bit

OLED Organic Light Emitting Diode

PTC Positive Temperature Coefficient

PWR/COMM Power/Communication

RDOL Reverse Direct On Line

RMS Root Mean Square

Table 1-1: Nomenclature and Description

MCOMP User Manual - REV. C 3

PREFACE

RTD Resistance Temperature Detector

RTU Remote Terminal Unit

SCADA Supervisory Control and Data Acquisition

SNTP Simple Network Time Protocol

TCC Trip Curve Characteristics

TCP/IP Transfer Control Protocol/Internet Protocol

TM Thermal Memory

Table 1-1: Nomenclature and Description

Suggestions for Improving this Manual

For any feedback to improve this manual and its contents, kindly contact at ESE-CMT@LNTEBG.com.

MCOMP User Manual - REV. C 4

INTRODUCTION

MCOMP User Manual - REV. C 5

INTRODUCTION

About the Relay

MCOMP is designed as a reliable building block for Motor Control are designed to monitor key parameters of the motor to alert

Centres (MCCs) and a product designed to provide complete the operator of a condition of outage or damage.

motor protection. It covers conventional & advanced motor

protection, metering and annunciation in MCC feeders into

single, easy to con gure, compact communicating module with a Varying Starting Condition

optional OLED Display. The MCOMP is used as a protection The protection controller must be able to differentiate

controller for Low Voltage Contactor Controlled Motor Starter between starting condition and running condition.

Feeders.

During starting condition, a LV motor (up to 300 KW) has

starting current of about 550-700 % of its full load current,

Reasons for Motor Protections with a starting time usually ranging from 1 to 10 seconds.

Electric motors are the major operands of any industry. These It should be able to monitor pre-start conditions of the motor

motors come in with a wide variety of ratings, types and to prevent starting of motor under unfavorable conditions like

applications. Depending on the criticality of the process or inadequate thermal capacity available and voltage

application, the motor protection is selected. unhealthiness.

Motor Protection is required for the following reasons: It should check the pre-start, starting and running conditions

of the motor completely for safe operation of the motor.

MCOMP as a Microprocessor Equipped Intelligent Controller,

Varying Input Voltages and Load Currents

allows a user to set parameters of the motor according to the

Motor is a rotating equipment and its performance is application and process requirements.

dependent on the availability of tolerable levels of input

Based on the instantaneous measurement of the parameters,

voltages and variable loads. Faults occur when either of these

MCOMP monitors different conditions of the motor as shown in

parameters uctuates. Therefore, motor protection controllers

Table 2-1.

Condition of Motor Possible Irregularities Action by MCOMP

Under-voltage on the supply side. Prevents starting of the motor on under-voltage lockout.

Not cooled enough for next start. Prevents starting of the motor until the thermal memory

(thermal capacity) falls below a certain value.

Pre-start: Before the

motor starts (inhibit Frequent starting / Number of starts per defined time Prevents starting of the motor until a inhibit period is elapsed.

conditions)

Not reset after Trip Prevents starting of the motor until it is reset.

Any of the Digital Input is selected as Stop Input, Prevents starting of the motor until Stop Input is high.

and is low.

Starting: After START Exceed set starting time Relay trips the motor due to Excessive Start Time protection.

input is given or is

sensed till the motor Contactor feedback is not available even after START Relay stops the motor due to contactor feedback fault when

picks up speed command is given for a specified amount of time. one of the DI is configured as feedback.

Over-heating of the winding and insulation (Overload).

Jamming (Locked Rotor). Relay indicates an alarm and trips the motor if the

Running: Motor runs irregularity continues for an amount of time due to

in a stable manner Current is considerably lower than the running current. the corresponding protection.

Supply voltage goes low.

Leakage current flows in the motor (Earth Fault).

Supply frequency is not proper (under and over-frequency).

Relay indicates alarm and trips the motor if the irregularity

One of the supply phases is disconnected (Phase Loss). continues for set amount of time (or instantaneous) due to

Starting and running the corresponding protection.

conditions Number of starts exceeds permitted number within a

certain period.

Sequence of the 3-phase supply is changed (Phase Reversal).

Table 2-1: Motor Conditions

MCOMP User Manual - REV. C 6

INTRODUCTION

Product Overview processor, input/output board, voltage sensing module and

communication module in a single modular enclosure. The

The MCOMP facilitates following bene ts to users:

current module gets connected to the Relay unit for current

Flexible protection, control and communication options to sensing. The Relay is further provided with bi/tri color LED

suit any Low Voltage (LV) contactor controlled motor starter indicators. There is also a reset push button available for local trip

application. reset.

Integrated push button and LED indicators reduce external There are mainly three variants of the Relay main unit depending

components and wiring. on selection of communication protocol:

Flexibility to choose from various standard communication 1. Modbus RTU

protocols allow affordable integration to larger and complex

2. Pro bus

Substation monitoring & control systems.

3. Modbus TCP/IP

The Relay comes with its own high accuracy current module

eliminating the three conventional CTs required for each Refer MCOMP order codes section for all possible variants of

phase. The built in 4-20 mA Analog Output eliminates the MCOMP relay.

Table 2-2 shows the LED status description.

need of transducer for remote metering. This reduces the

overall module size making it more compact and cost

effective. LED Indications on Main unit

Reset push button is available on the Relay and the Display One LED for Fault:

thereby reducing the need for one DI to be con gured as Glows Red when the Relay senses Trip condition.

Reset (Auto reset option is available for thermal overload and

One Tri-color LED for Motor status RUN/STOP/INHIBIT

under-voltage protection).

Glows Green when the Relay senses the motor is OFF and

The optional OLED Display is provided with the Relay for

ready to START.

display of all metering, protection and setting parameters.

Glows Red when the Relay senses the motor is ON.

Conformal coating on the PCB inside the Relay resists the

corrosive environment, hazardous chemicals, dust, etc,. and Glows Amber when the Relay senses the motor is in INHIBIT

increases the life & reliability of the product. mode.

One Bi-color LED for Alarm/Pickup

Relay Main unit Glows Amber when Alarm condition is sensed by the Relay.

This is a self-contained and fully functional unit housing the main Glows Red when Pickup condition is sensed by the Relay.

Relay Main Unit

Display Unit

FRC Cable

Expansion DIO Unit

CM Unit

Display Cable

Expansion Unit Cable

Figure 2.1 Product overview

MCOMP User Manual - REV. C 7

INTRODUCTION

Reset Button

Resets the Trip condition of the Relay.

Resets the Relay to default settings when pressed for 3

seconds and released.

Drive LED s

Status of the Drive Drive Status Alarm/Pick up Trip

Running RED X OFF

Alarm X AMBER OFF

Pickup X RED OFF

Trip AMBER OFF RED

Inhibit AMBER X X

Ready to Start GREEN X OFF

Table 2-2: LED Status Description

Note: X Does not matter

Current Module (CM) Display unit

CM, provided with MCOMP, is used for 3-phase current sensing in The OLED Display is a detachable optional unit provided with the

motor starters ranging from 0.375 kW. Requisite connecting MCOMP for display of metering, protection and motor-speci c

cable for connection of CM to the Relay is supplied along with the parameters. The Display can additionally be used to con gure the

CM. Only one CM is required (up to 45 kW) for metering and Relay. The OLED Display is also provided with micro-USB front

protection, reducing the space which is required for conventional port to enable local parameterization through laptop using

CTs in the module. MCOMP Suite provided with the Relay.

There are two different sizes of CM, covering ve different current

ranges as shown in Table 2 3. DIO Expansion unit

Note: *When MCOMP is used with external conventional CT, it is The DIO Expansion unit is detachable optional unit provided with

required to enable the external CT ratio setting. In this case the MCOMP for increasing the count of Digital/Analog input and

starting range for IFLC is 50% of the primary current value set in the digital output as per application requirement. The expansion unit

external CT ratio setting. 50A mentioned in Table 2-3 is considering

comes in three types as 4DI/2DO module having 4 digital inputs &

the by default primary current as 100A in external CT ratio setting. If

primary current value changes, starting IFLC value changes accordingly. 2 digital outputs, 5DI/2AI module having 5 digital inputs & 2

analog inputs and 8DI module having 8 digital inputs. Depending

While selecting CM, it is strictly recommended to match the IFLC of the on the requirement of number of DI/DO or AI, suitable expansion

motor speci ed by motor manufacturer with CM IFLC range. module can be selected. The requisite connection cable of 0.4m

length comes along with expansion module. Maximum three

Motor rating in kW speci ed above is with considering approximate expansion modules can be connected to a single relay main unit.

scale factor of 1.8 between motor rating and IFLC. For IFLC range higher Refer table 8-10 in chapter Settings for details of all possible

than 80A, conventional CTs are required along with MCOMP CM. CM1

combination of DIO expansion unit connection to relay main unit.

and CM2 is used when secondary of conventional CT is 1 A and 5 A

respectively.

CM Type IFLC Range Motor Rating for 415V System

CM - 1 0.6 to 2.0 A 0.375 to 1.125 kW

CM - 2 1.8 to 5.4 A 1 to 3 kW

CM 3 4.5 to 13.5 A 2.5 to 7.5 kW

CM 4 12.6 to 37.8 A 7 to 21 kW

CM - 5 36 to 80 A 20 to 45 kW

With external conventional CT 50* to 600 A Up to 333 kW

Table 2-3: CM Type and Range

MCOMP User Manual - REV. C 8

INTRODUCTION

LED Indications on Expansion unit LED s for DI/DO status:

One LED for Power (PWR): Glows Red when corresponding DI/DO status is high / energized

state.

Glows Green when the expansion unit gets power from relay

main unit.

Test Button (T):

One LED for Communication status (COMM): Tests the DI/DO circuitry and corresponding LEDs by switching

it ON and OFF. It is recommended to use this button only when

Glows Red when communication between the Relay main unit

drive is in stop condition and 3 phase voltage is not available to

and expansion module is healthy.

the drive/motor.

MCOMP Order Codes

Part number selection MCOMP MAIN UNIT PART NUMBER

MAIN UNIT

U P YI R MCOMP_MAIN_UNIT_U_P_YI_R

O Universal (80 230 V AC/DC)

Auxiliary Voltage

D 24 V DC

R Modbus RTU

Communication T Modbus TCP/IP

P Profibus DP

UI Universal (80 230 V AC/DC)

Voltage sensing for YI 230 V AC/DC

Digital Input Card ZI 110 V AC/DC

DI 24 V DC

R RTD Input Port

Temperature Input

P PTC Input Port

Table 2-4: Main unit order code

Part number selection MCOMP CURRNET MODULE PART NUMBER

CURRENT MODULE

C1 H MCOMP_CURRENT_MODULE_C1_H

CM Type C1 CM Type 1 ( Iflc : 0.6 2 A)

C2 CM Type 2 ( Iflc : 1.8 5.4 A)

C3 CM Type 3 ( Iflc : 4.5 13.5 A)

C4 CM Type 4 ( Iflc : 12.6 37.8 A)

C5 CM Type 5 ( Iflc : 36 80 A)

S Cable of 0.3 m

H Cable of 0.5 m

CM Main unit Cable

M Cable of 0.75 m

1 cable of 1 m

Table 2-5: Current Module order code

MCOMP User Manual - REV. C 9

INTRODUCTION

DISPLAY UNIT Part number selection MCOMP DISPLAY UNIT PART NUMBER

D1 1 MCOMP_DISPLAY_UNIT_D1_1

Auxiliary Voltage D1 Universal (80 230 V AC/DC)

D2 24 V DC

H Cable of 0.5 m

Display Main unit Cable 1 Cable of 1 m

2 Cable of 2 m

Table 2-6: Display Unit order code

EXPANSION UNIT Part number selection MCOMP MAIN UNIT PART NUMBER

A YI H MCOMP_EXPANSION_UNIT_A_YI_H

A 4DI/2DO Expansion Unit

Module Type B 8DI Expansion Unit

C 5DI/2AI Expansion Unit

UI Universal (80 230 V AC/DC)

Voltage sensing for YI 230 V AC/DC

Digital Input Card

ZI 110 V AC/DC

DI 24 V DC

Expansion Main H Cable of 0.4 m

unit cable

Table 2-7: Expansion Unit order code

ACCESSORIES/ Part number selection MCOMP LOOSE CABLE PART NUMBER

LOOSE CABLES B MCOMP_LOOSE_CABLE_B

Cable Type A Display Main unit cable of 0.5 m

B Display Main unit cable of 1.0 m

C Display Main unit cable of 2.0 m

D CM Main unit cable of 0.5 m

E CM Main unit cable of 1.0 m

F Expansion Main unit cable of 0.4 m

G CM - Main unit cable of 0.3 m

H CM - Main unit cable of 0.75 m

Table 2-8: Accessories order code

Note: While selecting CM, it is strictly recommended to match the IFLC Above selection of MCOMP units and accessories is applicable for at

of the motor speci ed by motor manufacturer with CM IFLC range. For lid (ZX8* series CAT numbers) MCOMP relays. Ordering information of

IFLC range higher than 81A, conventional CTs are required along with earlier version of MCOMP units and CM units with dimensions 67 x

MCOMP CM. CM1 and CM2 is used when secondary of conventional 59.3 x 55 (D x W x H) for CM-1 module & 109.2 x 107.8 x 60 for CM 2-5

CT is 1 A and 5 A respectively. modules is available upon request.

While selecting main unit, 24 VDC voltage digital input card can be

selected only if auxiliary voltage is selected as 24 VDC.

MCOMP User Manual - REV. C 10

INTRODUCTION

Getting Started

For understanding the full functionality of the Relay a basic 3. Once powered on, the motor status LED on the Relay and

knowledge is required. It includes powering-up the Relay, setting PWR/COMM LED on the Display glows.

date & time for recording of events/trips records. 4. If Display is present in the system, ensure a proper connection

The steps to be followed are shown below: is established between the Relay and the Display. After

connection, the Display shows L&T logo screen followed by

1. For powering-up the Relay, check for the power supply

metering screen within 3 seconds. This ensures healthy

requirement mentioned on the side label: 80-240 V AC/DC or

communication between the Relay and the Display.

24 V DC.

5. Set date and time of the Relay from Display Menu (Refer

2. Check for polarity of power supply as L/+ (Relay terminal

System Settings in chapter User Interface) or from special

72/Display terminal 75) and N/- (Relay terminal 71/Display

commands in MCOMP Suite (Refer Special Commands in

terminal 76) on the Relay/ Display.

chapter User Interface).

MCOMP User Manual - REV. C 11

SPECIFICATIONS

MCOMP User Manual - REV. C 12

SPECIFICATIONS

General

Full Load Current Setting (IFLC)

Setting Range 0.6 - 600 A

Rated Voltage Setting (VL-L)

Setting Range 380 800 V

Power Supply

Aux Supply Voltage For universal Aux supply:

AC: 110 - 240V

DC: 110 - 220V

For 24 VDC Aux supply:

24 VDC

Operational Aux Supply Voltage For universal Aux supply:

AC: 70-265 VAC,

DC: 93-265 VDC

For 24 VDC Aux supply:

18-28 VDC

Power Consumption Main unit:

For universal Aux supply : ~ 20VA or 20W

For 24 VDC Aux supply : ~ 18W

(Above power consumption values are including two expansion units connected to main unit)

Display unit:

For universal Aux supply : ~ 5VA or 5W

For 24 VDC Aux supply : ~ 5W

Frequency and Phase Sequence (settable)

System Frequency 50 or 60 Hz

Phase Sequence RYB or RBY

Digital Inputs

Inputs Optically Isolated

Sensing Range (current consumption and Sure On voltages (AC): Sure Off voltages (AC):

sure-ON voltage of DI channel)

1] 60-240 V AC/DC card = 63VAC (3mA) 1] 60-240 V AC/DC card = 53VAC

2] 110 V AC/DC card = 73VAC (3mA) 2] 110 V AC/DC card = 61VAC

3] 240V AC/DC card = 144VAC (2.5mA) 3] 240V AC/DC card = 122VAC

Sure On voltages (DC): Sure Off voltages (DC):

1] 60-240 V AC/DC card = 75VDC (3mA) 1] 60-240 V AC/DC card = 65VDC

2] 110 V AC/DC = 80VDC (3.1mA) 2] 110 V AC/DC = 71VDC

3] 240V AC/DC = 184VDC (2.6mA) 3] 240V AC/DC = 168VDC

4] 24V DC = 18VDC (2.2mA) 4] 24V DC = 16VDC

Table 3-1 (1): General Speci cations

MCOMP User Manual - REV. C 13

SPECIFICATIONS

Digital Output Contacts

Base unit have all Form C contacts

Expansion unit have all Form A contacts

Rated Current 10 A on 240 V AC

10 A on 24 V DC

Maximum Breaking Capacity AC 2400 VA

Life expectancy Mechanical: 10,000,000 operations min. (at 18,000 operations/hr under no load)

Electrical: 100,000 operations average. (at 1,800 operations/hr under rated load)

Digital output operating time Pickup time - 4.8 ms

Drop off time - 4.4 ms

Analog Output

Current Output 4 20 mA

Accuracy ±5 %

Max. Load 200 Ohms

Isolation 2500 V

Assignable Parameters Voltage, Current, Power, Temperature, Frequency

Analog Input

Input Range 4 20 mA/0 20 mA (user selectable)

Accuracy ±1 % of full scale value

Resolution 12 bits

Input shunt resistance 50 Ohms

Max Input Current (Destructive) 24 mA

Conversion time 600 ms

Temperature Input

Input Type RTD (PT-100) or PTC Thermistor

Communication Ports

Micro-USB 1 on display front

RJ 11 (RS 485 support) 1 for MCOMP suite/display communication

4 Terminal Screw Type (RS 485 support) 1 in case of Modbus serial communication

DB9 Connector 1 in case of Profibus communication

RJ 45 port 1 in case of Modbus TCP/IP communication

Protocol Modbus or Profibus-DP or Modbus TCP/IP

Table 3-1 (2): General Speci cations

Dimensions

Component Depth (mm) Width (mm) Height (mm)

Relay 103.95 92 120

Display 35 96 51

CM 1 67 59.3 55

CM 2 to CM 5 109.2 107.8 60

Expansion Unit 102 83 70

Table 3-2: Dimensions

MCOMP User Manual - REV. C 14

SPECIFICATIONS

Type Tests

Tests Standard Test Level

Cold IEC 60068-2-1 -20oC, 72 Hours

Temperature Cycling IEC 60068-2-14 -20oC to 70oC, 3 hrs, 2 cycles

Vibration IEC 60068-2-6 10 to 150 Hz, 1G

Dry Heat IEC 60068-2-2 -20oC to 70oC, 3hrs

Damp Heat IEC 60068-2-30 55oC, 6 cycles, 24 hrs/cycle, 95% relative humidity

Shock Resistance IEC 60255-21-2 30G, 18 shocks

Bump 25G, 6000 bumps

Enclosure Protection IP 41 enclosed in a panel

Dielectric IEC 60255-5:2000(Cl. No 6.1.4) 2kV, 1 min

Impulse IEC 60255-5:2000(Cl. No 6.1.3) 4kV

Voltage Dip and Interruption IEC 61000-4-11 Class A

Insulation Resistance IEC 60255-5:2000(Cl. No 6.2.2) 500 VDC, 5 sec

Electrostatic Discharge Immunity IEC 61000-4-2, edition 1.2, 2001-04 8kV air discharge 6kV contact discharge

Radiated RF Immunity IEC 61000-4-3 Severity Level 3 Field Strength 10 V/m

Fast Transient, Burst Immunity IEC 61000-4-4 4kV @ 5kHz

Surge Immunity IEC 61000-4-5 4kV line-to-earth

Conducted RF Immunity IEC 61000-4-6 Severity Level 3 Voltage level: 10 Vrms

High Frequency Disturbance Immunity IEC 61000-4-18 1kV, 3 pulses

Conducted Emission CISPR 22 @ IEC : 2005

Radiated Emission CISPR 22 @ IEC : 2005

Table 3-3: Type Tests

Certifications

Certification

ISO: Relay is designed and manufactured using ISO 9001 certified quality program.

CE: CE Mark- Low Voltage Directive, EMC Directive.

PNO: Relay is certified with PNO certificate from Profibus International for Profibus variant of the Relay.

Table 3-4: Certi cations

Environmental Conditions

Environmental Conditions

Typical conditions under which the Relay is designed to operate:

Temperature -20 to 70 °C (operating)

-40 to 85 °C (storage) Since the equipment consist of Electrolytic

capacitors, it is advised to Power ON the relay continuously at least

for an hour in period of one year.

Supply Voltage Fluctuation 10 % of nominal voltage

Relative Humidity 5 to 95 %

Table 3-5: Environmental Conditions

MCOMP User Manual - REV. C 15

SPECIFICATIONS

Relay Elements

Relay Elements

Overload (49)

Setting Range 20 100 % IFLC

Thermal Memory Reset Value 5 30 %

Locked Rotor (50LR)

Setting Range 150 1000 % IFLC

Trip Delay 0.5 30 sec

Phase Reversal (47B)

Setting Range RYB or RBY

Trip Delay Instantaneous

Phase Loss (47A)

Trip Delay 0.1 30 sec

Earth Fault (50N or 50 SG)

Type Vector Sum or CBCT

Setting Range Vector Sum = 20-500% IFLC CBCT = 0.1-20 A Primary

Trip Delay 0.1 60 sec

Excessive Start Time

Setting Range 1 200 sec

Mode Enable/Disable

Max Number of Starts (66)

Setting Range 15 60 min

Number of permissive starts 1 30

Inhibit Period 1 120 min

Under Current (37)

Setting Range 30 85 % Ir

Trip Delay 1 120 sec

Over Current (50P)

Setting Range 50 1000 % IFLC

Trip Delay 0.1 10 sec

Under Voltage (27)

Setting Range 20 85 % VN

Trip Delay 0.2 25 sec

Current Unbalance (46)

Setting Range 5 100 % IFLC

Trip Delay 1 30 sec

Table 3-6 (1): Relay Elements

MCOMP User Manual - REV. C 16

SPECIFICATIONS

Voltage Unbalance (47)

Setting Range 5 50 % VN

Trip Delay 0.2 20 sec

Over Voltage (59)

Setting Range 101 130 % VN

Trip Delay 0.2 25 sec

Under Frequency (81L)

Setting Range 94 98 % FS

Trip Delay 1 30 sec

Over Frequency (81H)

Setting Range 101 105 % FS

Trip Delay 1 30 sec

Over Frequency (81H)

Type : RTD or PTC 1 Pt-100 RTD or max. 6 PTC in series

Reacceleration (27LV)

Voltage Dip 20 90 % VN

Voltage Restoration 65 95 % VN

Restart Time 0.2 60 sec

Restart Delay 4 1200 sec

Communication Failure

Setting Range 2 10 sec

Trip Delay 1 30 sec

Trip only in Remote Enable/Disable

Time Delayed Phase Over Current (51P) Stage 1 and Stage 2

Setting Range 20 1000 % IFLC

Time Constant 0.5 600 sec

IEC Curves Inverse, Very Inverse, Extremely Inverse

Time Delayed Neutral Over Current (51N) Stage 1 and Stage 2

Setting Range 20 1000 % IFLC

Time Constant 0.5 600 sec

IEC Curves Inverse, Very Inverse, Extremely Inverse

Analog Input (Trip/Alarm)

Setting Range 0/4 20mA

Trip Delay 1 30 sec

Mode of reset Local / Auto / Communication / Remote

Table 3-6 (2): Relay Elements

MCOMP User Manual - REV. C 17

SPECIFICATIONS

Metering

Metering Specifications

Line Currents Measurement Range 0 6000A with accuracy + 1% from 0.5 times IFLC to 1.5 times IFLC and beyond that + 5%

Earth fault current measurement range + 1% or + 50mA whichever is greater

Phase Voltages Measurement Range 0 600V with accuracy + 1% up to Nominal Voltage and + 5% after nominal voltage

Line Voltages Measurement Range 0 1000V with accuracy + 1% up to Nominal Voltage and + 5% after nominal voltage

Analog input measurement 0 / 4 20mA with ± 1% of full scale value up to 20mA and ±5% after 20mA till 24mA.

System Frequency + 1%

Active, Reactive, Apparent Power + 5%

Active, Reactive, Apparent Energy + 5%

Power Factor 0.9 to 1 with + 2%

0.707 to 0.9 with + 3%

0.5 to 0.707 with + 5%

Thermal Capacity + 2%

Temperature Measurement Range 0°C to +180°C in case of RTD, ±3o C

0 to 10K in case of PTC

Table 3-7: Metering Speci cations

Monitoring

Monitoring Specifications

Records Stores last five event records with date and time stamp.

Stores last five trip records with date and time stamp. Record gets stored with current, voltage, temperature,

frequency values present at the time of tripping.

Stores last stop cause

Hour Meter Records and stores last operational hours and total operation hours

Operation Counters Records and stores number of starts, stops and trips of the drive

Starting Curve Records and stores the starting characteristics of the drive

Starting Time Records and stores the start time taken

Starting Current Records the peak current taken during starting of the drive

DIO Status Shows real time status of digital input and output of the relay

Table 3-8: Monitoring Speci cations

Note: The Specifications are subject to change without notice.

MCOMP User Manual - REV. C 18

INSTALLATION

MCOMP User Manual - REV. C 19

INSTALLATION

Overview Installation of the Relay along with the dimensions and product

labels. These dimensions help in identifying proper installation

This section provides information about the installation of the

space for the Relay and its wiring connections.

Relay and the various connections attaching to the ports of the

Relay, CM, Display and DIO Expansion Module.

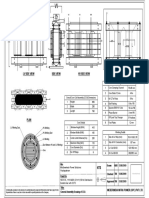

The user must be familiar with all con gurations and features in Dimensions

the Relay before installing, for safe installation and connection. The complete relay product package consists of the Relay, CM,

Expansion Module and the Display. The dimensions of all the units

are mentioned below. Some units may or may not be present

Mechanical Installation

depending on the ordering by the end user. Figure 4 1 to Figure

This section provides description about the Mechanical 4 5 shows the dimensions in diagrams.

Component Depth (mm) Width (mm) Height (mm)

Relay 103.95 92 120

Display 35 96 51

CM 1 67 59.3 35

CM 2 to CM 5 109.2 107.8 35

Expansion Unit 102 83 70

Main Unit Dimensions

92 103.95

103.95

120

LEGEND

MM

92

TOP VIEW FRONT VIEW SIDE VIEW

Figure 4-1: Main Unit Dimension

CM 1 Dimensions

59.3 35

67

LEGEND

35

MM

59.3

TOP VIEW FRONT VIEW SIDE VIEW

Figure 4-2: CM 1 Dimensions

MCOMP User Manual - REV. C 20

INSTALLATION

CM 2-5 Dimensions

107.8 35

109.2

35

LEGEND

MM

107.8

TOP VIEW FRONT VIEW SIDE VIEW

Figure 4-3: CM 2-5 Dimensions

DIO Expansion Module Dimensions

84 102

102

LEGEND

70

MM

TOP VIEW FRONT VIEW SIDE VIEW

Figure 4-4: DIO Expansion Module Dimensions

Display Dimensions

96 35

PWR/COMM

35

51

MOTOR STATUS

LEGEND ALARM/PICKUP

Mini USB Port

MM RST ENT

L

TRIP N

96

TOP VIEW FRONT VIEW SIDE VIEW

Figure 4-5: Display Dimensions

MCOMP User Manual - REV. C 21

INSTALLATION

Product Identification Label

The product identi cation label gives information about the Procedure:

product model, serial number, and revision number. It is located

1. Before mounting the Relay, ensure that power supply to

on the side of the units. Figure 4 6 shows format of the product

control panel is disconnected and the relay is free from all

identi cation label.

power connections.

2. Pull the DIN Clip.

3. Position the Relay on the DIN Rail properly.

4. Push the DIN Clip to x the Relay.

5. Follow the reverse procedure for removal of the Relay.

CM Mounting

CM is mounted on the 15mm DIN Rail provided in the motor

starter module. Figure 4 8 shows the mounting of CM.

Figure 4-6: Product Identi cation Label

2

Mounting

1

Relay Mounting

Din Rail

The Relay is mounted on 30 mm DIN Rail provided in the motor

starter module. Figure 4 7 shows the Relay mounting.

3 Din Clip

3

Din Rail

Figure 4-8: CM Mounting

2 Procedure:

1. Pull the DIN Clip.

2. Position the CM unit on the DIN Rail properly.

3. Push the DIN Clip to x the CM unit.

4. Follow the reverse procedure for removal of the CM.

Note: Note: Mounting of Current module with increased height as

Din Clip

compared to height mentioned in this manual requires 30mm DIN rail

4 instead of 15mm DIN rail.

Figure 4-7: Relay Mounting

MCOMP User Manual - REV. C 22

INSTALLATION

Display Mounting DIO Expansion Module Mounting

The Display can be mounted in a cut-out on the front door by The DIO Expansion Module is mounted on 30mm DIN Rail

using mounting clips provided. The cut out dimension required is provided in the motor starter module. Figure 4 10 shows the DIO

(W x H) : 92.5 x 45 mm. Figure 4 9 shows the Display Mounting. Expansion Module installation.

Panel

Frame Din Rail

2

Display

Cutout

Din Clip

4

Figure 4-10: DIO Expansion Module Mounting

Procedure:

Mounting 1. Before installation, ensure that power supply to control panel

Clip is disconnected and the DIO Expansion module is free from all

power connections.

2. Pull the DIN Clip.

Figure 4-9: Display Mounting 3. Position the DIO Expansion Module on the DIN Rail properly.

4. Push the DIN Clip to x the DIO Expansion Module.

Procedure: 5. Follow the reverse procedure for removal of the DIO

1. Before installation, ensure that power supply to control panel Expansion Module.

is disconnected and the relay is free from all power

connections.

2. Place the Display at the respective attaching place on the cut-

out of the control plate.

3. To install the Display use the mounting clips. Place the clip on

the slot provided and push it towards the control plate. Or it

can be directly place to the end of control plate and t it by

just pressing it on Display.

4. Follow the reverse procedure the removal of the Display.

MCOMP User Manual - REV. C 23

INSTALLATION

Electrical Installation

This section describes about the electrical installation of the Relay

main unit, CM, Display and DIO Expansion module. Figure 4 11

shows the typical relay wiring diagram.

R

Y

B

N

SFU / MCCB

FUSE L/+

N/-

1 2 3 4 71 72

N B Y R N/- L/+

3-PH.VOLTAGE AUX.VOLT

CONTACTOR

START

82

DIGITAL OUTPUT CONTACTS

61 Dl1

83

DIGITAL INPUTS

62 Dl2

STOP

63 Dl3 81

RESET 64 Dl4 85 CONTACTOR COIL

65 Dl5 86

66 Dl6 84

67 COM 88

89

R Y B 87

91 TRIP INDICATION

92

CBCT

CM UNIT 90

PWR/COMM

S1 MOTOR STATUS

S2 ALARM/PICKUP

R Y B RTD/PTC ANALOG O/P RS485

L

RST ENT

Tl1 Tl2 AO1 AO2 D+ D- TRIP Mini USB Port N

M MODBUS RS485 LOOPING

4-20mA OUTPUT

TO FIELD AMMETER

RTD/PTC

Figure 4-11: Typical wiring diagram

MCOMP User Manual - REV. C 24

INSTALLATION

Relay Main Unit Wiring

VR 4 Tl1 54

VY 1 3 Tl2 53

5 L/+ 72

VB 2 AO1 52

N/- 7 71

NEU 1 AO2 51

CM Connector

Pro bus

2 4 N/C4 92

COM4 91

N/04 90

Trip N/C3 89

Drive Status COM3 88

Alarm/Pick up COM 67 N/O3 87

Reset

8

l/P6 66 N/C2 86

l/P5 65 COM2 85

Display Port Expansion

3A l/P4 6 64 N/O2 84

Port

l/P3 63 N/C1 83

l/P2 62 COM1 82

3B l/P1 61 N/O1 81

Figure 4-12 (1): Overview of the Relay Main Unit Figure 4-12 (2): Main unit

Table 4-2 lists the terminal description for Relay main unit. The

relay main unit package consists of MCOMP main unit with its

mounting din clip and terminal connectors for wire termination.

Label Terminal Description Possible Wire Size

1 3-Phase Reference Voltage Connector (R,Y, B, N) 2.5 sq. mm *

(Screw Thread = M2.5, Tightening torque = 0.51 Nm)

2 Current Module Connector Prefabricated cable

3A Expansion Module Connector Prefabricated cable

3B Display/MCOMP Suite Connector Prefabricated cable

4 Communication Port (Modbus RTU/Profibus/Modbus TCP/IP) For Modbus 0.5 sq. mm

(Screw Thread = M2, Tightening torque = 0.2 Nm)

For Profibus, TCP/IP Respective cable with standard connector

5 Temperature Input (RTD or PTC) and Analog Output Connector 0.5 sq. mm *

(Screw Thread = M2, Tightening torque = 0.2 Nm)

6 Digital Input Connector 2.5 sq. mm *

(Screw Thread = M2.5, Tightening torque = 0.51 Nm)

7 Auxiliary Supply Connector 2.5 sq. mm *

(Screw Thread = M2.5, Tightening torque = 0.51 Nm)

8 Digital Output Connector 2.5 sq. mm *

(Screw Thread = M2.5, Tightening torque = 0.51 Nm)

Table 4-2: Relay main unit terminal description

Note: * In case terminals 3A and 3B is present on the Relay as a combined single terminal, refer MCOMP manual revision B for wiring of such type of a

relay. The wire size mentioned here may not be applicable in such case.

MCOMP User Manual - REV. C 25

INSTALLATION

3 Phase Voltage Connections 3-Phase Current Connections

Connection to this particular terminal depends on the application The connection to the current input port is from the CM. Figure

of the relay. Refer Application Notes for various types of 4 14 shows the 3-phase current cable connection.

connections as per application requirement. The typical

connection for this terminal in case of 3P-4W system is shown in

Figure 4 13. Procedure to wire the current connector:

1. Ensure that the Relay is free from all power connections.

Procedure to wire the voltage connector: 2. Check the CM cable for proper operation.

1. Ensure that the Relay is free from all power connections. 3. Press the notch and insert the CM cable connector in the

Relay current connector.

2. Check the connector cable for proper operation.

4. Release the notch.

3. Loosen the terminal screws of the connector.

4. Insert the RYBN wires (as per application requirement) in their

respective terminals. Procedure for removal of the current connector:

5. Tighten the terminal screws. 1. Ensure that the Relay is free from all power connections.

6. Anchor the connector by using two connector screws. 2. Press the notch and remove the CM cable connector from the

Relay current connector.

3. Release the notch.

Procedure for removal of the voltage connector:

1. Ensure that the Relay is free from all power connections.

2. Loosen the two connector screws.

3. Detach the connector from the Relay.

R

Y

B 61 Dl1

N

62 Dl2

DIGITAL INPUTS

63 Dl3

64 Dl4

FUSE

65 Dl5

66 Dl6

67 COM

NLK

1 2 3 4 71 72

N B Y R N/- L/+

3-PH.VOLTAGE AUX.VOLT

61 Dl1

DIGITAL INPUTS

62 Dl2

63 Dl3

64 Dl4

65 Dl5

CBCT

66 Dl6

67 COM

CM UNIT

Figure 4-13: 3 Phase Voltage Connections Figure 4-14: 3 Phase Current Connections

MCOMP User Manual - REV. C 26

INSTALLATION

Configuration Port Connection

The Relay con guration can be done in two ways by using: 3. Press the notch and insert the Display RS485 cable connector

in the Relay con guration port.

1. Display

4. Release the notch.

2. MCOMP Suite

Figure 4-16 shows the con guration port connection using

MCOMP Suite. Procedure for removal of the connector:

1. Ensure that the Relay is free from all power connections.

Procedure to wire the connector: 2. Press the notch and remove the Display RS485 cable

connector from the Relay con guration port.

1. Ensure that the Relay is free from all power connections.

3. Release the notch.

2. Check the Display RS485 connector cable for proper

operation.

61 Dl1

62 Dl2

DIGITAL INPUTS

63 Dl3

64 Dl4

65 Dl5

66 Dl6

67 COM

Figure 4-15: Con guration Port Connection

RS485

CONVERTER

Figure 4-16: Con guration Port connection using MCOMP suite

MCOMP User Manual - REV. C 27

INSTALLATION

RTD/PTC and Analog O/P Connections Communication Port Connection

Positive Temperature Coef cient (PTC) or RTD input is directly RS485 and RJ45 are available for communication. These ports are

connected to this port. PT100 is used as a temperature sensing used to communicate with the upper level systems such as

unit. The output of PT100 will act as RTD input in the Relay and EWS/DCS/SCADA on either Modbus RTU / Profibus / Modbus

the temperature range can be measured between 0 to 180 °C. TCP/IP protocol. Figure 4 18 to Figure 4 26 show the

communication connection with looping diagrams.

RTD or PTC inputs in the Relay are dependent on the ordering

code. For RTD/PTC input, the wire should get connected at

RS485 Port Connection for MODBUS RTU

terminal 53/TI2 and 54/TI1. If no RTD/PTC is connected, the

RTD/PTC Alarm and Trip setting must be disabled.

The analog output ranges from 4-20 mA. It can be mapped to any

of the parameters like 3-Phase Voltage, 3-Phase Current,

Frequency, Power, etc,. This output is given to an analog meter

like LCS meter (4 20 mA), DCS for monitoring, etc,. For analog

output the wire should get connected at terminals 52/AO1 (+ve)

and 51/AO2 (-ve). Figure 4 17 shows the cable connections.

Relay

Procedure to wire the connector:

RS485 MODBUS

1. Ensure that the Relay is free from all power connections. RTD/PTC ANALOG O/P D+ D+ D- D-

T1 TI2 AO1 AO2 41 42 43 44

2. Check the RTD/PTC/Analog connector cable for proper

operation.

MODBUS RS485

3. Loosen the terminal screws of the connector. LOOPING

4. Insert the cables in their respective terminals.

Figure 4-18: Modbus RS485 connection

5. Tighten the terminal screws.

6. Anchor the connector by using two connector screws.

RS485 Port Connection for PROFIBUS

Procedure for removal of the connector:

1. Ensure that the Relay is free from all power connections.

2. Loosen the two connector screws.

3. Detach the connector from the Relay.

Relay

RS485 PROFIBUS

RTD/PTC ANALOG O/P

T1 TI2 AO1 AO2

PROFIBUS RS485

LOOPING

Relay Figure 4-19: Pro bus RS485 port connection

RTD/PTC ANALOG O/P RS485

T1 TI2 AO1 AO2 D+ D-

MODBUS RS485

LOOPING

4-20mA OUTPUT

TO FIELD AMMETER

RTD/PTC

Figure 4-17: Temperature and Analog output connections

MCOMP User Manual - REV. C 28

INSTALLATION

EWS D+

SCADA EWS / SCADA / DCS

DCS

D-

Relay

41 D+

42 D+

43 D-

44 D- Relay

41 D+

42 D+ Relay

43 D-

44 D- Relay

41 D+

42 D+

43 D-

Relay

44 D- Relay

D+ D-

Figure 4-20: Modbus/Pro bus looping connections

RJ45 Port Connection for MODBUS TCP/IP

Procedure to wire the connector:

1. Ensure that the Relay is free from all power connections.

2. Check the communication cable for proper operation.

3. Press the notch and insert the communication cable in the

Relay communication port.

4. Release the notch.

Relay

Procedure for removal of the connector:

RJ45 PORT

1. Ensure that the Relay is free from all power connections. RTD/PTC ANALOG O/P

T1 TI2 AO1 AO2

2. Press the notch and remove the cable from the Relay

communication port. RJ45 MODBUS

TCP/IP PORT

3. Release the notch.

Figure 4-21: Modbus TCP/IP RJ 45 port connection

MCOMP User Manual - REV. C 29

INSTALLATION

Auxiliary Power Supply Connection Digital Input Connections

Auxiliary power supply is required to power up the Relay. The Relay main unit has six DIs and one common terminal

Universal power supply ranging from 80 to 240 V AC/DC or 24 V through which it senses the status of the motor and commands;

DC is used as an auxiliary supply. Figure 4 22 shows auxiliary and works accordingly. Six isolated digital inputs sense the

supply connection. voltage ranging from 60 V to 240 V AC/DC or 24 V DC and is

dependent on the selected voltage sensing range during ordering

of the relay. The six contact inputs can be programmed to any of

Procedure to wire the auxiliary supply connector: the input functions such as Stop, Start, Interlock, Reset, etc,.

1. Check the connector cable for proper operation.

Note: For proper sensing of Digital Inputs, the common terminal must

2. Loosen the terminal screws. be connected to neutral in case of AC, and to negative (-ve) in case

of DC.

3. Insert the supply wires in their respective terminals. Make sure

the power supply rating of the Relay before inserting the

supply wires into it. Figure 4 23 shows digital input connection.

4. Tighten the terminal screws.

5. Anchor the auxiliary supply connector by using two Procedure to wire the connector:

connector screws. 1. Check the connector cable for proper operation.

2. Loosen the terminal screws.

Procedure for removal of the connector: 3. Insert the wires in their respective terminals.

1. Ensure that the Relay is free from all the possible power 4. Tighten the terminal screws.

connections.

5. Anchor the DI connector cable by using two connector

2. Loosen the two connector screws. screws.

3. Remove the auxiliary supply connector from the Relay.

Procedure for removal of the connector:

1. Ensure that the Relay is free from all power connections.

N/- 2. Loosen the two connector screws.

3. Remove the DI connector cable from the Relay.

L/+

1 2 3 4 71 72

N/- L/+

N B Y R N/- L/+

3-PH.VOLTAGE AUX.VOLT

61 Dl1

DIGITAL INPUTS

62 Dl2

61 Dl1 63 Dl3

64 Dl4

DIGITAL INPUTS

62 Dl2

63 Dl3 65 Dl5

64 Dl4 66 Dl6

65 Dl5 67 COM

66 Dl6

67 COM

Figure 4-22: Auxiliary Supply connection Figure 4-23: Digital Input connections

MCOMP User Manual - REV. C 30

INSTALLATION

Digital Output Connections Current Module (CM) Wiring

The Relay main unit has four change-over potential free output Figure 4-25 shows overview of the Current Module Unit.

contacts. These DOs have the current carrying capacity of 10 A on

Table 4-3 lists the terminal description for Current module unit.

240 V AC. Each change-over contact has following terminals:

The current module unit package consists of MCOMP current

N/O (Normally Open) - It is normally not connected to the module unit with its mounting din clip and prefabricated FRC

common of the corresponding DO. When a DO is activated, the cable for connection with Relay main unit. The length of the cable

corresponding N/O contact is shorted to the common of that DO. is dependent on the ordered part number.

N/C (Normally Closed) - It is normally connected to the common

of the corresponding DO. When a DO is activated, the

corresponding N/C contact becomes open to the common of the

corresponding DO.

COM - It is the common terminal available to which NO and NC

terminals are connected alternately according to the activation of

the corresponding output.

These outputs can be programmed to any of the output functions

like alarm, trip, etc,. Figure 4 24 shows digital output connection.

Procedure to wire the connector:

1. Check the connector cable for proper operation.

2. Loosen the terminal screws.

3. Insert the wires in their respective terminals.

Figure 4-25: Current Module unit overview

4. Tighten the terminal screws.

5. Anchor the DO connector by using two connector screws.

Label Terminal Possible Wire Size/Diameter

Description

Procedure for removal of the connector: 3-Phase Current CM 1 pass through dia.: 4.5 mm

(R,Y,B)

Pass through Hole

1. Make sure that the Relay is free from all the power CM 2-5 pass through dia.: 16 mm

connections. 0.5 sq. mm*

2. Loosen the two connector screws. CBCT Input

1 (Screw Thread = M2,

Connector

3. Detach the DO connector from the Relay. Tightening torque = 0.2 Nm)

Current Module

2 Prefabricated cable

Connector

R

Y

B Table 4-3: Current Module terminal description

N

Note: * In case separate terminal for CBCT connection is not available

on CM unit, refer MCOMP manual revision B for wiring of such type of a

relay. The wire size mentioned here may not be applicable in such case.

SFU / MCCB

82 L/+

DIGITAL OUTPUT CONTACTS

83

CONTACTOR

81 N/-

85 CONTACTOR COIL

86

84

88 L/+

89

R Y B 87 N/-

91 TRIP INDICATION

92

CBCT

CM UNIT

90

S1

S2

R Y B

Figure 4-24: Digital Output connections

MCOMP User Manual - REV. C 31

INSTALLATION

The Relay is provided with its own CM. CM is available in 5 types. earth fault current under abnormal conditions. This is used as

an input by the Relay to measure earth fault current. Figure

CM has pass through arrangement, through which the motor

4 26 shows CM wiring.

supply wires (R, Y and B) enters (all three wires should enter

from same side) in to the CM before connecting to the motor. In case where external conventional CTs are required to sense

the current if the motor IFLC is greater than 80 A, the

The connecting wire from CM to the Relay is of two types

connection will be as shown in Figure 4 27. Based on the

based on its length (0.5 m and 1 m).

secondary of external CT, MCOMP current module is selected

In case of sensitive earth fault, CBCT is used. The 3-phase for the required application.

supply to the motor passes through CBCT which senses the

R Y B

CBCT

CM UNIT

S1

S2

R Y B

Figure 4-26: Current Module connections

MCOMP User Manual - REV. C 32

INSTALLATION

R

Y

B

N

SFU / MCCB

FUSE L/+

N/-

1 2 3 4 71 72

N B Y R N/- L/+

2 4 6 2 4 6

3-PH.VOLTAGE AUX.VOLT

1 3 5 1 3 5

START1 82

DIGITAL OUTPUT CONTACTS

61 Dl1

START2 83

DIGITAL INPUTS

62 Dl2

CONTACTOR A CONTACTOR B

63 Dl3 81

STOP

64 Dl4 85 CONTACTOR COIL

RESET 65 Dl5 86

66 Dl6 84

67 COM 88

89

87

91 TRIP INDICATION

92

EXTERNAL CT

90

PWR/COMM

B Y R

MOTOR STATUS

CBCT

ALARM/PICKUP

CM UNIT RTD/PTC ANALOG O/P RS485 L

RST ENT

Tl1 Tl2 AO1 AO2 D+ D- TRIP Mini USB Port N

S1

MODBUS RS485 LOOPING

S2

R Y B 4-20mA OUTPUT

TO FIELD AMMETER

RTD/PTC

Figure 4-27: External Conventional CT connections

Note: Ensure that all cables (RYB) enter from single side. The Relay auto detects the CM type. Ensure power recycle of the Relay after proper connection

with the CM.

Display Wiring

The OLED Display is an optional unit provided with the Relay to 4 28 shows the Display front and bottom view. The Display unit

display metering, protection and drive speci c parameters. Figure package consists of MCOMP

PWR/COMM

L/+ N/+

MOTOR STATUS D-

ALARM/PICKUP

Mini USB Port

L D+

RST ENT

TRIP N

Figure 4-28: Display front and bottom view

MCOMP User Manual - REV. C 33

INSTALLATION

Display unit along with its 4 mounting clips and Display-cable for 3. Front USB Port Connection.

connecting to relay main unit. The length of the Display-cable is

The OLED Display is provided with a USB port in the front. It

dependent on the ordered part number.

enables local con guration through computer/laptop using

MCOMP Suite. Mini USB cable is required for the connection.

Figure 4 31 shows the Display front port connection.

1. Con guration Port connection.

Con guration port (RJ-11) is provided to communicate with the

Relay. Figure 4 29 shows the con guration port available at

bottom side of the Display. A prefabricated cable comes along

with the display to connect to the relay main unit.

L/+ N/+

D-

D+

PWR/COMM

MOTOR STATUS

ALARM/PICKUP

Mini USB Port

L

RST ENT

TRIP N

Figure 4-29: Display con guration port connections Figure 4-31: Display front USB port connection

Note: * In case RJ11 port is not available on display unit, refer MCOMP

2. Auxiliary Supply Connection. manual revision B for wiring of such type of a relay.

An auxiliary supply is needed to power up the Display, which will

get connected to the port provided at the bottom side of the

Display. Figure 4 30 shows the Display auxiliary supply

connection. Possible wire size for termination is 0.5 sq. mm.

Auxiliary Supply

L/+ N/+

D-

D+

Figure 4-30: Display auxiliary supply connection

MCOMP User Manual - REV. C 34

INSTALLATION

Expansion Unit Wiring

The DIO Expansion unit is detachable optional unit used along Maximum number of 5DI/2AI or 3DI/2DO/2AI units allowed

with MCOMP main unit for increasing the count of Digital/Analog to be connected to main unit is 1. 5DI/2AI unit and

input and digital output as per application requirement. The 3DI/2DO/2AI unit cannot be connected together to main unit.

expansion unit comes in three types as 4DI/2DO module having 4

If 5DI/2AI or 3DI/2DO/2AI unit is connected along with

digital inputs & 2 digital outputs, 5DI/2AI module having 5 digital

4DI/2DO or 8DI expansion unit then it should be connected as

inputs & 2 analog inputs and 8DI module having 8 digital inputs.

last unit in the series.

The expansion unit package consists of MCOMP expansion unit

with its mounting din clip and expansion-cable of 0.4 meter for Table 4-4 lists the terminal description for various types of

connecting to relay main unit. Refer Digital input and Digital Expansion module units.

output wiring sections in Main unit wiring for expansion DIO Table 4-5 shows all possible combination of expansion units

wiring connections. which can be successfully connected together to the main unit.

Maximum three expansion modules can be connected to a single Figure 4-32 shows MCOMP main unit and expansion unit

relay main unit provided: connection representation:

Maximum number of 4DI/2DO units allowed to be connected

to main unit is 2.

Expansion Module Type Label, Terminal Description and possible wire size

DI1-DI8:

Field input connection points

Dl1 Dl2 Dl3 Dl4 COM COM

DO1(1-2),DO2(3-4):

1234 N/O Digital output connection points

Dip switches AI1+/-, AI2+/-:

T

Analog inputs connection points

1 2 3 4 COM:

DO1 DO2 4DI/2DO Module Wire neutral in case of AC digital inputs, -ve supply in

case of DC digital inputs

T:

Dl1 Dl2 Dl3 Dl4 Dl5 Dl6 COM COM Test push button

1,2,3,4 Dip switches:

1234

Select module ID for expansion module as per

Dip switches

T

configuration done in relay main unit

When 1000 => module id 1

Dl7 COM COM Dl8

When 0100 => module id 2

8Dl Module

When 1100 => module id 3

Dl1 Dl2 Dl3 COM Al1+ Al1- Al2+ Al2-

1234

Possible wire size for all termination points: 2.5 sq. mm.

Dip switches

T

(Screw Thread = M3, Tightening torque = 0.45-0.5 Nm)

Dl4 COM COM Dl5

5Dl/2Al Module

Table 4-4: Expansion Module terminal description

MCOMP User Manual - REV. C 35

INSTALLATION

VR 4 Tl1 54

VY 3 Tl2 53

L/+ 72

VB 2 AO1 52

N/- 71

NEU 1 AO2 51

CM Connector

Pro bus

N/C4 92

COM4 91

N/04 90

N/C3 89

Trip

Drive Status COM3 88 Expansion unit 1 Expansion unit 2 Expansion unit 3

Alarm/Pick up COM 67 N/O3 87

Reset l/P6 66 N/C2 86

l/P5 65 COM2 85

Display Port Expansion

Dl1 Dl2 Dl3 Dl4 Dl5 Dl6 COM COM Dl1 Dl2 Dl3 Dl4 Dl5 Dl6 COM COM Dl1 Dl2 Dl3 Dl4 Dl5 Dl6 COM COM

l/P4 64 N/O2 84 1234 1234 1234

Port

l/P3 63 N/C1 83 Dip switches Dip switches Dip switches

l/P2 62 COM1 82 T T T

l/P1 61 N/O1 81

Dl7 COM COM Dl8 Dl7 COM COM Dl8 Dl7 COM COM Dl8

8Dl Module 8Dl Module 8Dl Module

Relay main unit

Figure 4-32: Main unit and expansion unit connection

Single unit Combination Expansion unit 1 Expansion unit 2 Expansion unit 3

1 4DI/2DO X X

2 8DI X X

3 5DI/2AI X X

4 3DI/2DO/2AI X X

Two unit Combination Expansion unit 1 Expansion unit 2 Expansion unit 3

1 4DI/2DO 8DI X

2 4DI/2DO 4DI/2DO X

3 4DI/2DO 5DI/2AI X

4 4DI/2DO 3DI/2DO/2AI X

5 8DI 8DI X

6 8DI 5DI/2AI X

7 8DI 3DI/2DO/2AI X

Three unit Combination Expansion unit 1 Expansion unit 2 Expansion unit 3

1 4DI/2DO 4DI/2DO 8DI

2 4DI/2DO 8DI 8DI

3 8DI 8DI 8DI

4 8DI 8DI 5DI/2AI

5 8DI 8DI 3DI/2DO/2AI

6 8DI 4DI/2DO 5DI/2AI

7 8DI 4DI/2DO 3DI/2DO/2AI

Table 4-5: Expansion unit connection combinations

MCOMP User Manual - REV. C 36

METERING AND

MONITORING

MCOMP User Manual - REV. C 37

METERING AND MONITORING

Overview Average of True RMS Current

This chapter describes the various parameters available in the The average current is calculated using formula:

Relay for metering and monitoring. The Relay measures real-time Iavg = (Ir + Iy + Ib)/3

values of Current, Voltage, Power, Analog Output, Temperature

and monitors motor speci c data like number of starts, stops,

running hours, etc,. Thermal Capacity

All values measured by the Relay can be accessed using following The Thermal Capacity is the tolerable capacity that the motor can

interfaces: withstand under overload condition. It is calculated internally by

Display the Relay as per IEC 60255 curve. To calculate the Thermal

Capacity, the Relay uses the IFLC of the Motor, instantaneous

MCOMP Suite running current and trip class of the Motor.

Communication Port

Current Unbalance

Metering Current unbalance is calculated in percentage as explained in

Current Based Metering Protection Chapter under Current Unbalance Protection. It is

instantaneously available for monitoring in MCOMP suite &

True RMS Line Current

Display monitoring window.

The Relay measures RMS values of line currents (Ir, Iy and Ib)

through CM.

Voltage Based Metering

Ir: Current owing through R phase

True RMS Line Voltage

Iy: Current owing through Y phase

The Relay measures the RMS value of the line voltage (Vry, Vyb

Ib: Current owing through B phase

and Vbr).

Vry: Voltage of R phase with respect to Y phase

Earth Fault Current

Vyb: Voltage of Y phase with respect to B phase

Earth Fault Current is an unbalanced current which can be

Vbr: Voltage of B phase with respect to R phase

represented by vector summation. In case of 3-phase system,

under healthy conditions, Earth Fault current will be zero. It is

present only when Earth Fault occurs. The Relay measures the True RMS Phase Voltage

Earth Fault current in following ways.

The Relay measures phase to neutral voltages (Vr, Vy and Vb).

Vr: Voltage of R phase with respect to neutral

Vector Summation

Vy: Voltage of Y phase with respect to neutral

Earth Fault Current is equal to the vector sum of three line current

values. It is calculated using formula: Vb: Voltage of B phase with respect to neutral

Ie = Ir + Iy + Ib

Where Ie is Earth Fault Current. Average of True RMS Voltage

Average RMS voltage is calculated using formula:

CBCT (Core Balance Current Transformer) Vavg = (Vr + Vy + Vb)/3

CBCT is used for earth leakage and sensitive Earth Fault

conditions. The 3-phase supply to the motor passes through Frequency

CBCT which senses the Earth Fault current under abnormal

Relay measures the frequency of the 3-phase voltage supplied to

conditions. The output of CBCT is used as an input by the Relay to

the Motor.

measure Earth Fault current.

MCOMP User Manual - REV. C 38

METERING AND MONITORING

Power and Energy Based Metering Power Factor

Power Power Factor is the cosine of the angle between the phase

currents and phase voltages. It can also be represented as the

Active, Reactive, and Apparent Power are based on the following

absolute value of the ratio of Active Power to Apparent Power.

factors:

Power Factor is calculated using formula:

3-phase RMS phase voltage Vr, Vy, Vb

Power Factor = Active Power / Apparent Power

3-phase RMS line current Ir, Iy, Ib

Power factor (cos φ)

Active power is also known as real power which gives the RMS

Miscellaneous Parameter

value of power. It is calculated using formula: Temperature

Active Power (kW) = Vr x Ir x cos φ x Vy x Iy x cos φ + Vb x Ib x cos φ Relay measures the temperature of the Motor by using RTD or

PTC inputs. RTD measures temperature in terms of degree

Celsius, PTC measures temperature in terms of ohmic value.

Reactive Power is calculated using formula:

Reactive Power (kVAR) = Vr x Ir x sin φ x Vy x Iy x sin φ + Vb x Ib x sin

Digital Input/Output Status

φ

Relay shows Real time (activated or deactivated) status of Digital

Input/Output.

Apparent Power is calculated using formula:

Apparent Power (kVA) = (Total Active Power)² + (Total Reactive Power)²

COMPlogic output Status

Relay shows Real time (activated or deactivated) status of

Energy COMPlogic outputs (Truth tables, timer, counters etc)

The energy consumed by the load can be calculated using

formula:

Monitoring

Active Energy (kWh) = Total Active Power X Number of Hours Run

Motor Speci c Data Monitoring

Reactive Energy (kVARh) = Total Reactive Power x Number of Hours

Run Phase Sequence

Apparent Energy (kVAh) = Total Apparent Power x Number of Hours Relay detects the phase sequence (Voltage Phase Sequence) of

Run the 3-phase motor.

Motor Starting Time

Relay measures the actual time taken by the Motor to start. The

j(lm) S

motor starting time is measured as time taken by average current

to rise from 0 A to a value above IFLC and drop back below IFLC

value. Figure 5 2 illustrates the starting curve of the motor.

S

Q

Current (RMS)

Motor

O Curve

O P Re S

IFLC

Figure 5-1: Power Factor Ir

Pre Start Starting Time Running

Figure 5-2: Starting curve of the motor

MCOMP User Manual - REV. C 39

METERING AND MONITORING

CM Type Total Motor Run Hours

Relay auto detects the type of CM connected to the Main Unit. Relay measures the total number of hours the motor has run from

the time the Relay settings have been restored.

Number of Starts

Starting Peak Current

Relay measures the total number of times the motor has started

from the time factory settings of the Relay has been stored. It is the maximum current drawn by the motor during the starting

time as shown in Figure 5 2.

Number of Stops

Annunciations

Relay measures the total number of times the motor has stopped

from the time factory settings of the Relay has been restored. Relay indicates healthy/unhealthy status of the motor such as

Ready to start, Run, Trip, Alarm and Inhibit conditions using

annunciation LEDs.

Motor Run Hours

Relay measures the number of hours the motor has run from the

time it has last been started.

MCOMP User Manual - REV. C 40

PROTECTIONS

MCOMP User Manual - REV. C 41

PROTECTIONS

Overview Pickup Set: A setting limit for the monitored parameter that

triggers Pickup of a protection function. Pickup set is calculated

This section provides a detailed description about the various

using formula:

faults possible in the motor; their causes and the preventive

measures taken by the Relay to protect the motor. Alarm is an Pickup Set = Pickup Set in % of corresponding parameter

indication which requires immediate attention. It indicates a need = (Pickup Set in %) X (Parameter Value)/100

for corrective action to prevent fault occurrence. It may result into

serious implications if not noticed. The alarm-related parameters Example: For Locked Rotor protection, the corresponding

can be con gured for most of the protection functions. parameter is IFLC. If IFLC value is 10 A, then the corresponding

parameter value will be 10 A, for Pickup Set of 150 %:

Pickup Set Value (IOC) = (150 x 10) / 100 = 15 A

The Relay responds to an Alarm in following ways:

The alarm gets activated upon the occurrence of any fault.

Alarm Set: A limit in % for the monitored parameter that triggers

The cause and time for the Alarm/Pickup will be recorded. a protection function alarm. Alarm Set value is calculated using

Alarm/Pickup LED glows Amber. formula:

The Relay counts and records the number of Alarm/Pickup Alarm Set = Alarm Set in % of corresponding parameter

conditions. = (Alarm Set in %) X (Pickup Set)/100

Example: For Locked Rotor protection, the corresponding

The Relay responds to a fault in following ways: parameter is IOC (Pickup Set). If IOC value is 15 A, then the

corresponding parameter value will be 15 A and for Alarm set of

On the Relay, trip LED glows Red.

90 %:

On the Relay, motor status LED glows Amber.

Alarm Set value = (90 x 15) / 100 = 13.5

DO of the Relay used for starter will go LOW.

DO of the Relay used for tripping will go HIGH.

Hysteresis band: This setting de nes the reset value for the

The Relay stores the data for the cause of fault along with the alarm and pickup set values for respective protection. Hysteresis

parameters such as time of fault, source of fault and setting is categorized into three settings as current, voltage and

corresponding values of Current, Voltage, Earth Current, frequency to provide alarm/pickup reset values for all current

Temperature, Power Factor and Frequency. The Relay keeps a based, voltage based and frequency based protections

count for the number of faults occurred and stores ve events & respectively.

ve trip records which can be viewed by the user at any point of

time. Parameter Setting Range Step Increase Factory Setting

The Relay clears the alarm/pickup whenever the measured value Current 3 15 % 1% 3%

drops below the Alarm/Pickup Reset threshold.

Voltage 3 15 % 1% 3%

Figure 6 1 describes a typical motor protection function. This

diagram is expressed in terms of a measuring parameter. Frequency 1 15 % 1% 3%

Table 4-6: Hysteresis setting

Measuring parameter (X)

Pickup Reset: A setting limit for the monitored parameter that

X>=Xa resets (removes) the Pickup condition when the corresponding

X>=XP

monitored parameter resumes to a safe value, else the Pickup

condition persists. Pickup Reset is calculated using formula:

Instantaneous Pickup Reset = (Pickup Set)*(100 + Hysteresis band setting)/100

Trip Delay

Example: If pickup set value is 15 A for locked rotor protection,