Beruflich Dokumente

Kultur Dokumente

Ijet13 05 05 155

Hochgeladen von

Mohd ShahnawazOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ijet13 05 05 155

Hochgeladen von

Mohd ShahnawazCopyright:

Verfügbare Formate

M.J.Gopinathan et.

al / International Journal of Engineering and Technology (IJET)

High Performance and Efficiency of Joints

in Precast Members

M.J.Gopinathan #1, K.Subramanian#2,

#1

Research Scholar, Anna University, Chennai, India

#2

Professor and Head,

Dept of Civil Engineering Coimbatore Institute of Technology, Coimbatore, India

1

mjgopi2009t@gmail.com

2

smjgopi2009t@gmail.com

Abstract— The use of precast element enables the possibility of developing and simplifying the

construction and facilitates the introduction of new technological methods. The usage of precast concrete

began about 70 years ago. Till now the technology has maintained its status in the construction industry

as “The Least Understood form of Construction”. The advantages of the pre-cast construction are not

explored by most part of the world especially by the developing countries. In the competition between

precast and monolithic structures, prefabrication gains an ever increasing prominence because it is

accompanied by the improvement of quality, while the requirement in materials, working time and cost

shows a decreased tendency. This paper presents the results of a two dimensional 3-bay G+5 storeyed

prefabricated frame subjected to lateral loading. The joints in beam column junction and joints in beam

to beam connection were strengthened by specially designed steel bolts and L-angles by welding and

bolting. The frame was subjected to lateral cyclic load until failure. The results are compared with

ANSYS model. The efficiency and performance of beam-column joints and beam-beam joints were

studied and the behaviour of prefabricated frame is compared with monolithic frame.

Key words- Precast Concrete- GFRP Fibers-High Strength Concrete-Beam-Column Joints.

I. INTRODUCTION

Prefabrication is an advanced and up to date method of reinforced concrete construction. In the

comparison between precast and monolithic structures, prefabrication gains an ever increasing prominence,

because it is accompanied by the improvement of quality, while the requirement in materials, working time and

cost show a decreased tendency. The cost of monolithic reinforced concrete structures is distributed into three

nearly equal parts: cost of concreting, of reinforcement, shuttering and scaffolding. For halls of great height the

cost of shuttering might even reach 60 percent of the total cost. Therefore solution should be sought to diminish

the considerable costs of the form work, due to chiefly to the great consumption of shuttering. The

prefabrication of reinforced concrete structure is a solution appropriate for the mentioned purpose. In order to

assess and evaluate the earlier work done on precast concrete frames and to identify the effective load resisting

structure, a detailing review of literature has been undertaken.

Reference [1] studied the seismic response of precast concrete frames with hybrid connections. The

enhanced and versatile model was developed to represent the inelastic behaviour of hybrid precast connection

region. Reference [2] studied Simulated Seismic loading of a two-story precast reinforced concrete building. In

that behaviour of precast building subjected to seismic loading. The performance of a precast concrete beam-to-

beam connection subject to reversed cyclic loading was studied by [3]. The test results of four types of ductile,

moment-resisting precast concrete frame connections and one monolithic concrete connection, all designed for

use in high seismic zones was presented by [4]. The performance of the precast concrete connections subject to

displacement control reversed cyclic loading is compared with that of the monolithic connection.Reference [5]

evaluated about Seismic assessment of existing precast industrial buildings using static and dynamic nonlinear

analyses. The presented research study shows that existing industrial precast buildings can be affected by severe

damages under medium seismic intensity seismic forces because of beam–column connection failure The

advantages and construction methods in precast concrete construction, precast concrete technology in high rise

and long span construction was briefly analysed by [6]. Reference [7] carried out a nonlinear finite element (FE)

analysis of ductile concrete connections.

This research paper focuses on the study of performance and efficiency of connections in members of a

3-bay G+5 storeyed precast frame with various connections subjected to lateral cyclic loading and to compare

the results with that of a control frame.

II. MATERIALS USED

The details of materials used in this research work are as given below.

A. Materials used

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4002

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

The materials used are Ordinary Portland Cement of 53grade conforming IS-12269, and the properties

of fine aggregate and coarse aggregate are given in Tables I and Table II. The aggregates used were maximum

of 12.5mm and confirming to BIS 383-1970. Potable water is used for casting of concrete and Fe415 grade steel

is adopted.

TABLE I

Properties of fine aggregate

Properties Test Results

Fineness Modulus 2.2

Specific Gravity 2.7

Zone III

TABLE III

Properties of coarse aggregate

Properties Test Results

Specific Gravity 2.72

Water Absorption 0.15%

B. Mix Proportion

Two types of concrete mixes M20 and M60 were adopted. The properties adopted are as follows in

weight basis.

For M20 Grade of concrete design based on IS 10262 - 2009

Cement: FA : CA : W/C

1 : 1.48 : 3.33 : 0.5

For M60 Grade of concrete design based on ACI code

Cement: FA : CA : W/C

1 : 1.36 : 2.2 : 0.28

III. EXPERIMENTAL INVESTIGATION

A. Methodology

In this precast frame model various types of joints were designed and the following two types of joints

were studied experimentally.

1. Joints in beam column junction

2. Joints in beam to beam connection

In above mentioned, the connection is strengthened by the help of Steel bolts and L- Angles by welding

and bolting. Then both are bonded to the reinforced concrete beam using welding and bolting, such that the steel

materials tied with all around the beam as well as beam column joint. The two different types of models were

cast and tested by applying lateral cyclic load. The load deflection behaviour as well as the modes of failure was

studied. The results are compared with the model cast by monolithic construction.

B. Proportioning of Concrete

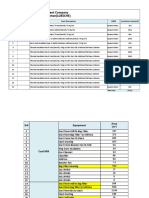

The details of the types of frames cast for testing are given in Table III.

TABLE IIIII

Types of frames cast for testing

Sl. No Frame ID Type of Specimen Prefabricated Pattern

Control frame

1 CF -

3bay x 5 storey

Prefabricated frame

2 PS-I Beam column joint connection

3bay x 5storey

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4003

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

C. Dimensions of the model prefabricated frame

To study the behaviour of prefabricated frame under lateral loading, a series of two frames were cast.

Out of two frames, one of the frames is control frame and the other one is prefabricated frame. The raft footing

is of size 1600 mm x 800 mm having a thickness of 150 mm and with four numbers of columns. The size of the

columns is 150 mm x 100 mm and that of beams is 100 mm x 100 mm.

D. Reinforcement details of control frame

The longitudinal reinforcement adopted for the columns and beams were HYSD bars of different sizes.

For the first and second columns, six numbers of 10 mm dia bars were provided. The reinforcement was

curtailed in the upper stores due to reduction in axial forces and bending moments. For the third, fourth and fifth

storey columns, four numbers of 10mm dia bars were provided. For all the beams, four number of 8 mm dia bars

were provided as the beams have same strength. The transverse reinforcement, in the form of closed rectangular

two legged stirrups of 6 mm dia rods were provided at 30 mm c/c near the end of the beams, whereas in the

middle portion of the beams the spacing was adopted as 60 mm c/c. similarly, for the columns, the spacing for

lateral ties near the beam-column junction was 40 mm c/c and 80 mm for the remaining portion.

E. Types of joints adopted for the Prefabricated frame

For the prefabricated frame various types of Beam-column joints like L-joint, T-joint and

Crossed – joint were adopted and the Figures 1(a), (b) and (c) shows the joints in the frames. The reinforcement

for entire prefabricated frame is shown in Figure 2.

Fig. 1(a). L-Joint Fig. 1(b).T-Joint

Fig. 1(c). Crossed Joint

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4004

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

Fig. 2. Reinforcement for Prefabricated frame

F. Casting of Precast multi-storey precast frame

A 1/4th scale three bay five storey precast reinforced concrete frame representing multistorey system is

analysed and designed for gravity loads. The beam, column and the foundation block were cast separately and

assembled together by means of connections made of steel flats, bolts and welds. The beams and columns of the

precast model frame during casting is shown in Figure 3(a) to Figure 3(c). The frame during assembling is

shown in figure 4.

Fig. 3(a). Mould and reinforcements for preparation of precast beam and column specimens

Fig. 3(b). Concreting of precast column and completed beam specimens

G. Assembling the test set up

The various connections were strengthened by the help of steel bolts and L-angles by welding and

bolting. The column is bonded to the reinforced concrete beam by welding and bolting, such that the steel

materials tied with all around the beam as well as beam column joint. The bolts and L-angles used for

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4005

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

assembling the members of the precast frame are shown in Figure 4. The precast beams, with both side sleeves,

column complete with corbel and beam to column connection with the help of L- angle and bolts is shown in

Figure 5 and the assembling of members is shown in Figure 6.

Fig. 4. Steel bolts and L-angles used for connection of joints

Fig. 5. Connections of Beam-column joint Fig.6. Assembling of Prefabricated model frame

using Steel bolts and L-angles

H. Test set up

The model frames were tested as vertical cantilevers under a cyclic loading programme. The schematic

diagram of test set-up is presented in Figure 7. The reaction frame, which is used for loading arrangements, is

rigidly fixed to the test floor. A common console controlled all the jacks. Pressure gauges are used to measure

the applied load. Lateral cyclic loading is applied at first and second storey levels in line with the beams using

hydraulic jacks of capacity 500 kN. The lateral movement of the frames at the ultimate load stages is avoided by

providing suitable guides using mild steel pipes. LVDT (Linear Variable Differential Transducer) of least count

0.01mm are used for measuring deflections at top and bottom storey levels as shown in Figure 7.

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4006

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

Fig. 7. Schematic diagram of test set up

An additional LVDT is placed at the top level of partial infill to identify the behaviour of column

portion adjacent to the partial infill. The rigid body rotation of the frame with respect to foundation block is

avoided by providing mild steel channels and horizontal rods on both edges of the specimen at the top of the

foundation block. However the displacement due to rigid body rotation, if any, is measured by providing

deflectometers on the sides of the footings. For measuring strain in steel, steel studs are welded to main

reinforcement before casting the frame. DEMEC (Demountable Mechanical strain gauges) points are pasted for

measuring strain in steel. For measuring surface strain on concrete and infill material, DEMEC points (pellets)

were pasted to beam and columns faces of the RC frame and also on the surface of infill. Also DEMEC points

are pasted on column-brick joints to measure the strain at the bond between column and the masonry.

IV. RESULTS AND DISCUSSION

A. Initial cracking and ultimate load of frames

The frames were subjected to lateral cyclic load and tested up to failure. Both the frames showed an

increase in the initial cracking and ultimate load. The deflected precast frame is shown in Figure 8.

Fig. 8. Precast model frame after testing

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4007

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

Both the frames showed an increase in the initial cracking and ultimate load .The Table IV shows the

details of initial crack load, ultimate load and ultimate deflection given below.

TABLE IVV

Experimental Results of Control frames, Prefabricate frame-I, Prefabricate frame-II

Experimental Observations Deflection at

Frame ID Ultimate Load

Initial Crack Load (kN) Ultimate Load (kN) (mm)

CF 32.8 189.9 33

PS-I 76 210 43.2

B. Load deflection behaviour of frames

From the experimental results, Load vs Deflection graphs are plotted for all the frames. The load

deflection curve plotted for deflection at various heights of the column like bottom, middle and top of the

column. Load deflection curve for three frames are compared given below:

1. Load deflection curve for control frame

2. Load deflection curve for Prefabricated frame-I

C. Load – Deflection Behaviour Based on Type of Connection

The initial crack load, ultimate load and deflection at ultimate load observed for the control frame are

32.8 kN, 189.9 kN and 33 mm respectively. Whereas the initial crack load, ultimate load and deflection at

ultimate load observed for the precast frame are 76 kN, 210 kN and 43.2 mm respectively. The graph indicating

base shear and deflection at various positions of the precast frame is shown in the Figure 9. The Load – Cycle

number graph for bare frame is shown in Figure 10.

Fig. 9. Load deflection curve for control frame

Fig. 10. Load deflection curve for Prefabricated model

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4008

M.J.Gopinathan et.al / International Journal of Engineering and Technology (IJET)

V. CONCLUSION

The following conclusions were drawn for prefabricated frame specimen subjected to lateral cyclic

loading based on experimental results.

• For the conventional frame, the ultimate base shear of 189.9 kN was reached in th 14th load cycle whereas

for the prefabricated frame specimen it was 210 kN in the 14th cycle of loading.

• The storey deflection for the conventional frame, was 33 mm in the 16th cycle of loading and that for the

prefabricated frame specimen it was 43.2 mm in the 16th cycle of loading.

• From the above results, it is concluded that among the two frames, PS-I nearly reaches the ultimate load

of control frame, and the variation in deflection is also small. Hence, the prefabricated model performs

somewhat efficiently compared to the conventional models.

ACKNOWLEDGEMENT

The author is thankful to the authority of Coimbatore Institute of Technology and faculty members of

Civil Engineering Department for extending their help in carrying out in work.

REFERENCES

[1] Cheok.G.S, Stone.W.C (1998), “Seismic response of precast concrete frames with hybrid connection” ACI structural journal , Vol.

95(5),Oct 1998.

[2] Mario Rodriguez, John J Blandon, “Simulated Seismic loading of a two-story precast reinforced concrete building” university of

illnois-Urbna, paper (INCLUDE PAPER No, pages, Month). 2002.

[3] Hasan Husnu Korkmaza, (2005), “Performance of a precast concrete beam-to-beam connection subject to reversed cyclic loading”.

Elsevier, Engineering structures, Vol. 27, pp. 1392-1407(INCLUDE MONTH), 2005.

[4] Onur ertas, “Ductile connection in precast concrete moment resisting frames” PCI journal, Page 1-11, May-June 2006.

[5] Gennaro Magliulo, Giovanni Fabbrocinob, Gaetano Manfredia, “Seismic assessment of existing precast industrial buildings using

static and dynamic nonlinear analyses, Elsevier, Engineering structures, Vol. 30 , pp. 2580-2588, 2008

[6] Nagaraja, Thontalapura.M., “Precast concrete technology in high rise and long span construction” Proceedings of Advances in

concrete, structural, and geotechnical engineering - ACSGE, (INCLUDE PAPER No, pages, Month), 2009.

[7] Hassan Jafarian, Khosrow Barji, “Nonlinear Seismic Behavior Evaluation of Ductile Beam – Column Connections in Precast

Concrete”, International journal of civil and structural engineering, Vol. 2(2), pp. 445-453, Nov 2011.

ISSN : 0975-4024 Vol 5 No 5 Oct-Nov 2013 4009

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Monotop 412 NFG PdsDokument4 SeitenMonotop 412 NFG PdsJames MizziNoch keine Bewertungen

- Paint CoatingDokument43 SeitenPaint Coatingtuan mai van100% (1)

- Datasheet Hdpe 1-1.5-2-2.5Dokument1 SeiteDatasheet Hdpe 1-1.5-2-2.5மதன் குமார் முனியசாமிNoch keine Bewertungen

- Report On Bridge Development in PakistanDokument8 SeitenReport On Bridge Development in Pakistankhawaja Ali100% (1)

- DQS258 20232 A1 - Part A - FinaleDokument26 SeitenDQS258 20232 A1 - Part A - Finalenur asyiqinNoch keine Bewertungen

- 30RB 21siDokument76 Seiten30RB 21sixavierxo50% (2)

- 6,8dk-28 Instruction Manual (Maintenance)Dokument189 Seiten6,8dk-28 Instruction Manual (Maintenance)Ira Paschenko100% (1)

- KAT NX KSA 2020 EN WebDokument220 SeitenKAT NX KSA 2020 EN WebSULISTYOWATINoch keine Bewertungen

- M04 Read and Interpret PlansDokument113 SeitenM04 Read and Interpret Plansmustied mohammed100% (1)

- Manholes Asme VIII 1 2010Dokument1 SeiteManholes Asme VIII 1 2010zopitaNoch keine Bewertungen

- Basic Laboratory Design For Biosafety Level 3 Laboratories - Finance and Administration - Oregon State UniversityDokument16 SeitenBasic Laboratory Design For Biosafety Level 3 Laboratories - Finance and Administration - Oregon State UniversityChristineNoch keine Bewertungen

- Rural Road DesignDokument86 SeitenRural Road DesignMilenka Uceda PuiconNoch keine Bewertungen

- BROCHURE Ruby & EmeraldDokument2 SeitenBROCHURE Ruby & EmeraldStevan S Delon MalondaNoch keine Bewertungen

- A Comparison Between Slurry and Earth Pressure Balanced SheildsDokument6 SeitenA Comparison Between Slurry and Earth Pressure Balanced SheildsAnthony FuNoch keine Bewertungen

- Bridge TypesDokument7 SeitenBridge TypesAbdo AboretaNoch keine Bewertungen

- ASME B16: Standardization of Valves, Flanges, Fittings, and Gaskets # Standard DesignationDokument6 SeitenASME B16: Standardization of Valves, Flanges, Fittings, and Gaskets # Standard DesignationNicolás MerinoNoch keine Bewertungen

- Quantity Surveyor Resumes SamplesDokument11 SeitenQuantity Surveyor Resumes Samplesnaresh4mrktgNoch keine Bewertungen

- Construction Materials BrochureDokument12 SeitenConstruction Materials BrochurejanakarajNoch keine Bewertungen

- High Strength ConcreteDokument13 SeitenHigh Strength ConcreteEkky CecilNoch keine Bewertungen

- DVS Technical Codes On Plastics Joining Technologies: Selected TranslationsDokument7 SeitenDVS Technical Codes On Plastics Joining Technologies: Selected TranslationsAndrei SimionNoch keine Bewertungen

- 8 - House BigDokument32 Seiten8 - House Biggiovanni100% (1)

- Conbextra EP10Dokument4 SeitenConbextra EP10Venkata Raju KalidindiNoch keine Bewertungen

- Moment of ResistanceDokument10 SeitenMoment of ResistanceBabaYakeNoch keine Bewertungen

- Design of Shells (Example Problem)Dokument5 SeitenDesign of Shells (Example Problem)AkarshGowdaNoch keine Bewertungen

- Unit 2 QB Construction PracticesDokument24 SeitenUnit 2 QB Construction PracticesRajha RajeswaranNoch keine Bewertungen

- Poliuretano Inyección Hidrofobico 10L Catalizador FichaDokument5 SeitenPoliuretano Inyección Hidrofobico 10L Catalizador FichaVictor Hugo Opazo CarreñoNoch keine Bewertungen

- Rubber BellowDokument20 SeitenRubber BellowPrateek100% (1)

- Design of Composite Steel DeckDokument1 SeiteDesign of Composite Steel DeckAndro Rebuyas0% (1)

- Ahu ControlDokument13 SeitenAhu ControleslamNoch keine Bewertungen

- Insulation BOQ Area Wise (Square MTR.)Dokument11 SeitenInsulation BOQ Area Wise (Square MTR.)Atiq Ur RehmanNoch keine Bewertungen