Beruflich Dokumente

Kultur Dokumente

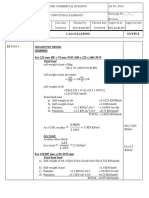

Design of Purlin Calculation

Hochgeladen von

Win Than0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

237 Ansichten1 SeiteDesign Purlin

Originaltitel

Purlin__Design

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDesign Purlin

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

237 Ansichten1 SeiteDesign of Purlin Calculation

Hochgeladen von

Win ThanDesign Purlin

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

PROJECT

KYAW THAR ENGINEERING &

CALC BY CHECK BY DATE

CONSTRUCTION CO. LTD.

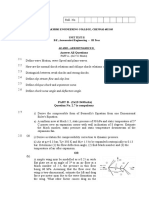

DESIGN OF PURLIN CALCULATION

1. GEOMETRY DATA 1.1 MATERIAL PROPERTIES

Simple Span Length 4.57 m. 15 ft Steel Modulus of Elasticity Es 2.10E+06 ksc.

Purlin Spacing ,S (@) 0.91 m. 3 ft Yield Strength Fy 4500 ksc.

Dead load ,DL 24 Kg./m2 5.00 psf Allowable Tensile Stress Fb=0.6Fy 2700 ksc.

Live load ,LL 24 Kg./m2 5.00 psf Allowable Shear Stress Fv=0.4Fy 1800 ksc.

Presure of Wind Load ,Pn 50 Kg./m2 10.24 psf

Angle of Roof 20.0 Deg.

2. CALCULATION GRAVITY LOADS ON PURLIN

2.1 Summaries Load (DL+LL)xS = 45 Kg./m

2.2 Wind Load ,S.2Pn.sin/(1+sin2), Wd = 28.0 Kg./m

Wy = 44.6159707406279 cos20 = 69.9 Kg./m Vy = 159.8 Kg.

Wx = 44.6159707406279 sin20 = 15.3 Kg./m Vx = 17.4 Kg.

Mx = Wy.L2/8 = 182.7 Kg.-m

My = Wx.L2/8 = - Kg.-m

Wx.L2/32 = 10.0 Kg.-m ( For Design Sag Rod at Mid Span)

Required Sx = Mx/Fb = 6.8 cm3

3. PROVIDE PURLIN MEMBER

Use C 100x50x20x2.3 1 33

width, bf= 5.0 cm moment of inertia, Ix = 80.7 cm4

depth, d = 10.0 cm Iy = 19.0 cm4

3

thick of web, tw= 0.23 cm section modulus, Sx = 16.0 cm OK

3

thick of flange, tf= 0.23 cm Sx = 6.1 cm

section area, Ax = 5.17 cm2 radius of gyration, rx = 4.0 cm

weight , w = 4.06 kg/m

4. DETERMINE TENSILE & SHEARING STRESS

4.1 fb= Mx/Sx + 2My/Sy = 1,470.4 Kg./m fb <Fb, OK.

4.2 fv= Vx/Af + Vy/Aw = 89.53 Kg. fv <Fv, OK.

5. DEFLECTION CHECK

Allowable Deflection allow = L/360 = 1.27 cm.

Actural Deflecton max = WyL4/145.EIx = 1.24 cm. OK. <Cont. Span>

*** PROVIDE, Purlin C 100x50x20x2.3mm.Thk, 4.06 kg/m ****

6. DESIGN SAG RODesign

Axial Force in Sag Rog = 10 Vx = 174.3 Kg.

Sag Rod Length, L = 91 cm.

Tiral Rod, RB 14 mm. (Min 15 mm.)

Ax = 1.54 cm2

rx = 0.35 cm , rx = (Ix/Ax)^0.5 = d/4 ,for round bar

Tensile Stress ,fa =P/Ax = 113.3 ksc. OK.

Check Slenderness ratio

K = 1.0 , KL/rx = 261 < 300 ,OK

*** PROVIDE, RB 14 mm. Sag Rod ****

Das könnte Ihnen auch gefallen

- Minimum Thickness of Solid Slab According To ACIDokument1 SeiteMinimum Thickness of Solid Slab According To ACImuhanned100% (1)

- Annexure-1 Wind Load ReportDokument4 SeitenAnnexure-1 Wind Load ReportPrabartak DasNoch keine Bewertungen

- Project by Location: Girting Design ADokument10 SeitenProject by Location: Girting Design AJurie_sk3608Noch keine Bewertungen

- PUMP SIZING SPREADSHEET FOR KEROSENE TRANSFERDokument30 SeitenPUMP SIZING SPREADSHEET FOR KEROSENE TRANSFEREbby Onyekwe100% (1)

- Purlin & GirtDokument96 SeitenPurlin & GirtudayvadapalliNoch keine Bewertungen

- Wind Load CalculationDokument17 SeitenWind Load CalculationNIHARIKA JAINNoch keine Bewertungen

- Max Purlin Girt Spacing Dead Load CalculationsDokument1 SeiteMax Purlin Girt Spacing Dead Load Calculationsspsingh_jmdNoch keine Bewertungen

- Base Plate INDIA CODEDokument4 SeitenBase Plate INDIA CODEbama sankari100% (1)

- Design of PurlinDokument24 SeitenDesign of PurlinD SRINIVAS67% (3)

- FROM IS 875-Part 3Dokument2 SeitenFROM IS 875-Part 3Santosh Bapu100% (1)

- Purlin Design PDFDokument3 SeitenPurlin Design PDFUday Udmale100% (1)

- Anchor Bolt Design, IS Code LSDDokument33 SeitenAnchor Bolt Design, IS Code LSDamlan jyoti ChakravortyNoch keine Bewertungen

- Design Information: 1. Type of Structure 3. Reference CodesDokument8 SeitenDesign Information: 1. Type of Structure 3. Reference CodesWin ThanNoch keine Bewertungen

- RC Stair Design (EN1992)Dokument7 SeitenRC Stair Design (EN1992)Win ThanNoch keine Bewertungen

- MS PurliDokument4 SeitenMS PurliJennifer PearsonNoch keine Bewertungen

- Portal Frame AnalysisDokument2 SeitenPortal Frame AnalysismaheshbandhamNoch keine Bewertungen

- Design of Beams - BS 8110Dokument3 SeitenDesign of Beams - BS 8110thanigai veluNoch keine Bewertungen

- Basement Wall CalculationDokument3 SeitenBasement Wall CalculationSaurav Silwal100% (1)

- Car ShelterDokument29 SeitenCar ShelterMochammad Shokeh100% (1)

- Input Data Materials: Double Pile CapDokument10 SeitenInput Data Materials: Double Pile CapBilal Al-MuhtasebNoch keine Bewertungen

- Engineering Calculation Sheet Consulting EngineersDokument27 SeitenEngineering Calculation Sheet Consulting Engineersazhar ahmadNoch keine Bewertungen

- Sepakat Setia Perunding SDN BHD: Design InformationDokument6 SeitenSepakat Setia Perunding SDN BHD: Design InformationAfiq SyahmiNoch keine Bewertungen

- Wind Load Calculation 29-08-2018Dokument4 SeitenWind Load Calculation 29-08-2018mbhanusagar.keynesNoch keine Bewertungen

- Check of Z Section On Principle Axes: Data InputDokument3 SeitenCheck of Z Section On Principle Axes: Data InputAlden CayagaNoch keine Bewertungen

- Concrete Pier Design SummaryDokument6 SeitenConcrete Pier Design SummaryMatiur Rahman BasumNoch keine Bewertungen

- Shear Wall Sample Design CalculationsDokument2 SeitenShear Wall Sample Design CalculationsRohan DharmadhikariNoch keine Bewertungen

- Knee ConnectionsDokument13 SeitenKnee ConnectionsNag RajNoch keine Bewertungen

- Composite Beam Simply Supported DesignDokument12 SeitenComposite Beam Simply Supported DesignMario FeghaliNoch keine Bewertungen

- Design of Underground Water TankDokument6 SeitenDesign of Underground Water TankAlfred PatrickNoch keine Bewertungen

- Purlin Design ReportDokument12 SeitenPurlin Design Reportarif_rubin100% (1)

- Purlin DesignDokument9 SeitenPurlin DesignAjayvidyanand SharmaNoch keine Bewertungen

- Corbel BS8110Dokument3 SeitenCorbel BS8110Nugraha BintangNoch keine Bewertungen

- Design of Multi-Cell Box Culvert (Side Walls & Bottom Slab)Dokument4 SeitenDesign of Multi-Cell Box Culvert (Side Walls & Bottom Slab)Berry Umpola100% (2)

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDokument1 SeiteChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNoch keine Bewertungen

- Hollow Pot Design WorksheetDokument7 SeitenHollow Pot Design Worksheetpatrick chegeNoch keine Bewertungen

- Purlin DesignDokument6 SeitenPurlin DesignAnonymous mcHqIfbnV1Noch keine Bewertungen

- Drop Panel CalculationDokument2 SeitenDrop Panel Calculationsandiok86Noch keine Bewertungen

- Z Purlin CalculationDokument1 SeiteZ Purlin CalculationTharmalingam VijayNoch keine Bewertungen

- Repport Steel Structure PDFDokument111 SeitenRepport Steel Structure PDFAnonymous fxqnhfKNoch keine Bewertungen

- Designing Integral Bridges Without Movement JointsDokument32 SeitenDesigning Integral Bridges Without Movement Jointspmullins_11100% (5)

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Dokument7 Seiten1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNoch keine Bewertungen

- RC Corbel Design EC2Dokument3 SeitenRC Corbel Design EC2Tommaso PasconNoch keine Bewertungen

- ZPurlin R1Dokument15 SeitenZPurlin R1vkgoud82Noch keine Bewertungen

- Purlin DesignDokument9 SeitenPurlin DesignMungkorn SattNoch keine Bewertungen

- Check For Requirement of Boundary ElementDokument9 SeitenCheck For Requirement of Boundary ElementJai ThakkarNoch keine Bewertungen

- Design of Purlin PinnedDokument11 SeitenDesign of Purlin PinnedbalaNoch keine Bewertungen

- Design of DomeDokument5 SeitenDesign of DomeAmarjeet SinghNoch keine Bewertungen

- 1 Design ដៃរណែងមុំ 35Dokument1 Seite1 Design ដៃរណែងមុំ 35Ce Win100% (1)

- Clean Copy Metal Building Foundation Rev 2.1Dokument14 SeitenClean Copy Metal Building Foundation Rev 2.1jurieskNoch keine Bewertungen

- Pad Footing Analysis and Design (Bs8110-1:1997)Dokument6 SeitenPad Footing Analysis and Design (Bs8110-1:1997)ikanyu79Noch keine Bewertungen

- Design of Z Purlins ReportDokument18 SeitenDesign of Z Purlins ReportAgarwal MittalNoch keine Bewertungen

- RCC14 Crack WidthDokument1 SeiteRCC14 Crack WidthKha Phuc100% (1)

- Roof load calculations for 91.15m x 40m buildingDokument19 SeitenRoof load calculations for 91.15m x 40m buildingVikram Soni100% (1)

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokument56 SeitenSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNoch keine Bewertungen

- 4.0 Design of Purlin: Kvaerner PowergasDokument4 Seiten4.0 Design of Purlin: Kvaerner PowergasKanchan Raja SinghNoch keine Bewertungen

- Calculation NoteDokument10 SeitenCalculation NoteJay EvansNoch keine Bewertungen

- TR.28.2.1 Soft Story CheckingDokument2 SeitenTR.28.2.1 Soft Story CheckingsvnNoch keine Bewertungen

- JPPJ Calcs for Raft Foundation DesignDokument1 SeiteJPPJ Calcs for Raft Foundation DesignHimura_100% (1)

- Cold Form Lipped C Purlin Design Calculations and ChecksDokument8 SeitenCold Form Lipped C Purlin Design Calculations and ChecksKTMONoch keine Bewertungen

- Structural Design Criteria: Load Type Type of OccupancyDokument8 SeitenStructural Design Criteria: Load Type Type of OccupancyJoseph TuzonNoch keine Bewertungen

- Design of Purlin No : Project : Design byDokument7 SeitenDesign of Purlin No : Project : Design byFakhira Alya SabrinaMzNoch keine Bewertungen

- PurlinDokument2 SeitenPurlinSURIYANoch keine Bewertungen

- Perhitungan Bekisting & ScaffoldingDokument16 SeitenPerhitungan Bekisting & Scaffoldingfahrur huzainiNoch keine Bewertungen

- Bab3.1. Perhitungan Atap.... OkDokument15 SeitenBab3.1. Perhitungan Atap.... OkDeki SugiantoNoch keine Bewertungen

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Dokument1 SeiteBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNoch keine Bewertungen

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Dokument1 SeiteBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNoch keine Bewertungen

- First Floor PlanDokument1 SeiteFirst Floor PlanWin ThanNoch keine Bewertungen

- ST 21Dokument9 SeitenST 21amarnath_jbbNoch keine Bewertungen

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Dokument1 SeiteBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNoch keine Bewertungen

- Septic Tank Design Computation PDFDokument4 SeitenSeptic Tank Design Computation PDFWin ThanNoch keine Bewertungen

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Dokument1 SeiteBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNoch keine Bewertungen

- Boq Summary: No. Material Unit Quantity Rate $ Cost $Dokument1 SeiteBoq Summary: No. Material Unit Quantity Rate $ Cost $Win ThanNoch keine Bewertungen

- TTDL PDFDokument1 SeiteTTDL PDFWin ThanNoch keine Bewertungen

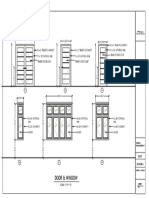

- Archi DWG - 2 ST Residential Buld - Hlaing TWP A-Xxx PL (A4)Dokument1 SeiteArchi DWG - 2 ST Residential Buld - Hlaing TWP A-Xxx PL (A4)Win ThanNoch keine Bewertungen

- 2ND To 12TH Floor Plan PDFDokument1 Seite2ND To 12TH Floor Plan PDFWin ThanNoch keine Bewertungen

- Mdy Glass CanopyDokument10 SeitenMdy Glass CanopyWin ThanNoch keine Bewertungen

- 09 ParkingDokument47 Seiten09 ParkingHarun SabljakovićNoch keine Bewertungen

- Bolt Nut Connection DesignDokument12 SeitenBolt Nut Connection DesignWin ThanNoch keine Bewertungen

- L90X90X10 PropertyDokument1 SeiteL90X90X10 PropertyWin ThanNoch keine Bewertungen

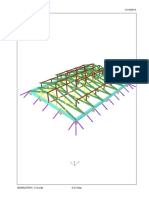

- Glass Canopy 3D PDFDokument1 SeiteGlass Canopy 3D PDFWin ThanNoch keine Bewertungen

- 19 PDFDokument1 Seite19 PDFWin ThanNoch keine Bewertungen

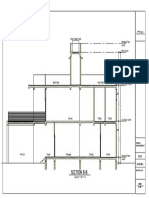

- NPT Residence Naypyitaw, Myanmar: Date 2019-08-5Dokument1 SeiteNPT Residence Naypyitaw, Myanmar: Date 2019-08-5Win ThanNoch keine Bewertungen

- Gfl-1fl Plan UpdatedDokument1 SeiteGfl-1fl Plan UpdatedWin ThanNoch keine Bewertungen

- 10 PDFDokument1 Seite10 PDFWin ThanNoch keine Bewertungen

- ETABS 2016 16.2.0 3D View SoftwareDokument1 SeiteETABS 2016 16.2.0 3D View SoftwareWin ThanNoch keine Bewertungen

- 18 PDFDokument1 Seite18 PDFWin ThanNoch keine Bewertungen

- Strap Footing Design: ASDIP Foundation 2.6.1Dokument4 SeitenStrap Footing Design: ASDIP Foundation 2.6.1Win ThanNoch keine Bewertungen

- Owner's Roof Framing PlanDokument3 SeitenOwner's Roof Framing PlanWin ThanNoch keine Bewertungen

- NPT Residence Naypyitaw, Myanmar: Date 2019-08-5Dokument1 SeiteNPT Residence Naypyitaw, Myanmar: Date 2019-08-5Win ThanNoch keine Bewertungen

- Calcs for Combined FootingDokument6 SeitenCalcs for Combined FootingWin ThanNoch keine Bewertungen

- Drawing1 Layout1Dokument1 SeiteDrawing1 Layout1Win ThanNoch keine Bewertungen

- L4 - Application of Momentum Integral Theorem and Boundary Layer SeparationDokument25 SeitenL4 - Application of Momentum Integral Theorem and Boundary Layer SeparationKar AbhishekNoch keine Bewertungen

- Work N EnergyDokument6 SeitenWork N EnergyAnurag SharmaNoch keine Bewertungen

- Ch-8 Motion: Difference Between Uniform and Non Uniform MotionDokument4 SeitenCh-8 Motion: Difference Between Uniform and Non Uniform MotionBdbdhrhrjruhrhrNoch keine Bewertungen

- Heat transfer through plane walls and cylindrical pipesDokument37 SeitenHeat transfer through plane walls and cylindrical pipesHamza ShahidNoch keine Bewertungen

- 3.electric Charges Forces and FieldstheoryDokument25 Seiten3.electric Charges Forces and FieldstheoryGomes Ribeiro100% (1)

- Mass Transfer Operations Question BankDokument2 SeitenMass Transfer Operations Question BankSivamani Selvaraju100% (2)

- Analysis of Heat Transfer EquationsDokument13 SeitenAnalysis of Heat Transfer EquationsPejalan KakiNoch keine Bewertungen

- 02-Lignos EtAl-11NCEE ATC PaperRev1Dokument12 Seiten02-Lignos EtAl-11NCEE ATC PaperRev1faisaladeNoch keine Bewertungen

- Rearranging Formulae To Change The SubjectDokument12 SeitenRearranging Formulae To Change The SubjectAnderson AlfredNoch keine Bewertungen

- Topic 22 - ElectromagnetismDokument5 SeitenTopic 22 - ElectromagnetismMauriceNoch keine Bewertungen

- Portal RuangDokument17 SeitenPortal Ruangade azimaNoch keine Bewertungen

- Engr 2900 Mech of Materials Exam 2 KeysDokument8 SeitenEngr 2900 Mech of Materials Exam 2 KeysAshleyHeldNoch keine Bewertungen

- Assignment 1 2Dokument2 SeitenAssignment 1 2Jeevan GNoch keine Bewertungen

- Fluid Dynamics - 1Dokument69 SeitenFluid Dynamics - 1eschoolindiaNoch keine Bewertungen

- ASE 445 Hypersonic Flow Part 1 OutlineDokument40 SeitenASE 445 Hypersonic Flow Part 1 OutlineAtes Deniz PugarNoch keine Bewertungen

- Convection in Internal FlowsDokument7 SeitenConvection in Internal Flowsmsnaghavi100% (1)

- Artículo Expansion MultipolarDokument5 SeitenArtículo Expansion Multipolarjose luis rodriguez amadoNoch keine Bewertungen

- 1 ConductionDokument89 Seiten1 Conductionrahul prakashNoch keine Bewertungen

- FeCo-based BMG deformation and indentationDokument22 SeitenFeCo-based BMG deformation and indentationFAIQNoch keine Bewertungen

- 2016 Updated Objectives With Answer Key & Topic Wise Numericals With Formulae Physics XI PDFDokument95 Seiten2016 Updated Objectives With Answer Key & Topic Wise Numericals With Formulae Physics XI PDFSameer AhmedNoch keine Bewertungen

- Ad II (Ae6503)Dokument2 SeitenAd II (Ae6503)Raahini IzanaNoch keine Bewertungen

- Vibration of Multi Degree-Of-Freedom Systems: Unit 22Dokument23 SeitenVibration of Multi Degree-Of-Freedom Systems: Unit 22dfelias2219Noch keine Bewertungen

- Letter of Transmittal Report SubmissionDokument28 SeitenLetter of Transmittal Report SubmissionHeart BeatsNoch keine Bewertungen

- Tut 6Dokument3 SeitenTut 6Jesús Alejandro SantillánNoch keine Bewertungen

- CHAPTER 2 Motion Along A Straight Line: 2.1 Position, Displacement, and Average VelocityDokument8 SeitenCHAPTER 2 Motion Along A Straight Line: 2.1 Position, Displacement, and Average VelocitymikeNoch keine Bewertungen

- THICK CYLINDERS-Lectures New PDFDokument17 SeitenTHICK CYLINDERS-Lectures New PDFManoj Hepde100% (1)

- Torsion Design of BeamDokument14 SeitenTorsion Design of Beamyyanan_11180% (1)

- Elder 1967Dokument15 SeitenElder 1967ALEJANDRO GANCEDO TORALNoch keine Bewertungen