Beruflich Dokumente

Kultur Dokumente

Beam Web Capacity

Hochgeladen von

shantanu chowdhury0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten1 Seiteweb capacity

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenweb capacity

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

5 Ansichten1 SeiteBeam Web Capacity

Hochgeladen von

shantanu chowdhuryweb capacity

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

CONNECTIONS 241

where d2 is the mid-flange to mid-flange distance. As explained in Section 8.7.1.2 the

nominal butt weld capacity is then:

Nw = f y f A f

where fyf is the flange design yield stress and A f is the area of one flange. For final check

with φ = 0.9 for SP quality welds:

Nw* < φNw

It should be noted that if this inequality is not satisfied then a total member check should

be undertaken. Alternatively, if it is more than satisfied, then IPBW or continuous fillet

welds should be considered.

8.9.1.3 Beam web weld capacity

Again using simple theory, the two web fillet welds carry all the shear force but no moment:

Vw = 2vww d1 tt = 2 × (0.6fuw tt kr )d1tt

where

Vw = nominal capacity of the web fillet weld group

vww = nominal capacity of the web fillet weld per unit length

(Section 8.7.2)

fuw = nominal tensile strength of the weld metal

tt = design throat thickness of the fillet weld

kr = lap length reduction factor (taken as 1.0 in this instance)

d1 = clear web depth between flanges

Verify the web weld capacity with φ = 0.8 for SP quality welds:

V * < φVw

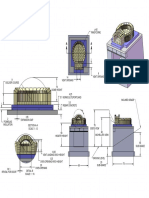

8.9.1.4 Column web capacity in bearing (crushing)

Load from the beam flange is dissipated through the column flange a distance of 2.5

times the depth of dissipation, which is equal to the sum of the column flange thickness

and the flange-web transition radius. This is distance kc shown in Figure 8.20(a). The

critical area of the column web is thus:

Ac w = (tf b + 5kc ) tw c

The bearing capacity of the web is thus:

Rbc = 1.25f y c Ac w (see Section 5.8.5.2)

The design beam flange force is conservatively:

M*

Rb* f

= }}

d2

Verify capacity with φ = 0.9:

R*bf < φR b c

If the web capacity is insufficient, it will be necessary to stiffen the web. A web stiffener

is in many ways similar to a beam bearing stiffener and should be designed to Clause 5.14

of AS 4100.

Das könnte Ihnen auch gefallen

- Sample: Project Editor AuthorDokument11 SeitenSample: Project Editor Authorshantanu chowdhury100% (1)

- Reading and Comprehension Workbook: Get The RDokument34 SeitenReading and Comprehension Workbook: Get The Rshantanu chowdhuryNoch keine Bewertungen

- Solved Example - Strength TransferDokument5 SeitenSolved Example - Strength Transfershantanu chowdhuryNoch keine Bewertungen

- Get The R: Esult S You Want!Dokument34 SeitenGet The R: Esult S You Want!shantanu chowdhuryNoch keine Bewertungen

- Basic Skills: English MathematicsDokument17 SeitenBasic Skills: English Mathematicsshantanu chowdhuryNoch keine Bewertungen

- Get The Re: SultsDokument22 SeitenGet The Re: Sultsshantanu chowdhuryNoch keine Bewertungen

- Get The Re: SultsDokument22 SeitenGet The Re: Sultsshantanu chowdhuryNoch keine Bewertungen

- Quiz 1 - ADokument3 SeitenQuiz 1 - Ashantanu chowdhuryNoch keine Bewertungen

- EQ Action LoadDokument1 SeiteEQ Action Loadshantanu chowdhuryNoch keine Bewertungen

- Moment AmplificationDokument1 SeiteMoment Amplificationshantanu chowdhuryNoch keine Bewertungen

- Ed18-0137 Fee-Help Booklet Acc-AwfDokument35 SeitenEd18-0137 Fee-Help Booklet Acc-Awfshantanu chowdhuryNoch keine Bewertungen

- Bolt in Plane ActionDokument1 SeiteBolt in Plane Actionshantanu chowdhuryNoch keine Bewertungen

- Other Action LoadDokument1 SeiteOther Action Loadshantanu chowdhuryNoch keine Bewertungen

- Butt WeldDokument1 SeiteButt Weldshantanu chowdhuryNoch keine Bewertungen

- D ConnectDokument2 SeitenD Connectshantanu chowdhuryNoch keine Bewertungen

- T JointDokument1 SeiteT Jointshantanu chowdhuryNoch keine Bewertungen

- Weld ExamplesDokument1 SeiteWeld Examplesshantanu chowdhuryNoch keine Bewertungen

- Weld SimbolsDokument1 SeiteWeld Simbolsshantanu chowdhuryNoch keine Bewertungen

- W ConnectionsDokument5 SeitenW Connectionsshantanu chowdhuryNoch keine Bewertungen

- Design of Simple WeldDokument1 SeiteDesign of Simple Weldshantanu chowdhuryNoch keine Bewertungen

- B Strength Limit StateDokument1 SeiteB Strength Limit Stateshantanu chowdhuryNoch keine Bewertungen

- Simple WeldDokument7 SeitenSimple Weldshantanu chowdhuryNoch keine Bewertungen

- C SectionsDokument2 SeitenC Sectionsshantanu chowdhuryNoch keine Bewertungen

- F WeldDokument4 SeitenF Weldshantanu chowdhuryNoch keine Bewertungen

- R ConnectionsDokument2 SeitenR Connectionsshantanu chowdhuryNoch keine Bewertungen

- Equal End Moments PDFDokument2 SeitenEqual End Moments PDFshantanu chowdhuryNoch keine Bewertungen

- B ConnectionsDokument4 SeitenB Connectionsshantanu chowdhuryNoch keine Bewertungen

- Capacity B GroupDokument3 SeitenCapacity B Groupshantanu chowdhuryNoch keine Bewertungen

- Equal End Moments PDFDokument2 SeitenEqual End Moments PDFshantanu chowdhuryNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Pratt Truss Roof Design For Industrial Applications Using The IS 800 Code & Limit State ProcedureDokument5 SeitenPratt Truss Roof Design For Industrial Applications Using The IS 800 Code & Limit State ProcedureRuthwik SwaroopNoch keine Bewertungen

- Over Head ResevoirDokument8 SeitenOver Head ResevoirPoulomi BiswasNoch keine Bewertungen

- SAES-Q-005 (Concrete Foundations)Dokument1 SeiteSAES-Q-005 (Concrete Foundations)Nino Celso AstilleroNoch keine Bewertungen

- TSPSC Aee Civil SyllabusDokument4 SeitenTSPSC Aee Civil Syllabusapi-293926977Noch keine Bewertungen

- Beam 20x40Dokument3 SeitenBeam 20x40chhay longNoch keine Bewertungen

- Part2 - Exercise ChokeDokument4 SeitenPart2 - Exercise ChokeGustavo ChacónNoch keine Bewertungen

- Elated Worked ExamplesDokument24 SeitenElated Worked ExamplesNaturinda SarahNoch keine Bewertungen

- Mast MaterialDokument1 SeiteMast MaterialShankar SwaminathanNoch keine Bewertungen

- Pizza Oven SchematicDokument1 SeitePizza Oven Schematicsir.roy.keaneNoch keine Bewertungen

- Carbon Steel 1020Dokument1 SeiteCarbon Steel 1020Sreekar ParimiNoch keine Bewertungen

- Pushover AnalysisDokument12 SeitenPushover AnalysisabdulmananNoch keine Bewertungen

- Single: Made of ALAPLEN® CV30Dokument3 SeitenSingle: Made of ALAPLEN® CV30jay chitrodaNoch keine Bewertungen

- Galerkin MethodDokument12 SeitenGalerkin Methodahmed namaNoch keine Bewertungen

- Structures Module 3 Notes FullDokument273 SeitenStructures Module 3 Notes Fulljohnmunjuga50Noch keine Bewertungen

- (1903-7C1910) Air Handling Unit & Modular Air Handling Unit 10.25Dokument27 Seiten(1903-7C1910) Air Handling Unit & Modular Air Handling Unit 10.25d.gitaNoch keine Bewertungen

- First Prs EditedDokument38 SeitenFirst Prs EditedMathew SebastianNoch keine Bewertungen

- Reliability of Beams According To Eurocodes in Serviceability Limit StateDokument21 SeitenReliability of Beams According To Eurocodes in Serviceability Limit StateKetan BhoiNoch keine Bewertungen

- Gujarat Technological University Master of Engineering Subject Code: 3722018 Subject Name: 2 SemesterDokument3 SeitenGujarat Technological University Master of Engineering Subject Code: 3722018 Subject Name: 2 SemesterHardik JogranaNoch keine Bewertungen

- Abbygail Shane Oledan MBEAB AMT 3103 PRELIM TQDokument2 SeitenAbbygail Shane Oledan MBEAB AMT 3103 PRELIM TQEunice Vera C EspinaNoch keine Bewertungen

- Civil Engineering Reference BooksDokument2 SeitenCivil Engineering Reference Booksdevbrat boseNoch keine Bewertungen

- Top Down Construction MethodDokument1 SeiteTop Down Construction Methodtruenotesrakesh100% (3)

- EGL-Evergreen Line Cargo Worthy StandardDokument12 SeitenEGL-Evergreen Line Cargo Worthy StandardHoan VuNoch keine Bewertungen

- PA2020473 - Dwelling - 29B Foreshore Road KelsoDokument59 SeitenPA2020473 - Dwelling - 29B Foreshore Road KelsoimilnerNoch keine Bewertungen

- Structural Engineering PDFDokument22 SeitenStructural Engineering PDFrajaktraja_779727735Noch keine Bewertungen

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDokument112 SeitenCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- Formerly Naval State UniversityDokument1 SeiteFormerly Naval State Universityphilip arconNoch keine Bewertungen

- AISC Engineering Journal 2017 1Q PDFDokument69 SeitenAISC Engineering Journal 2017 1Q PDFaapennsylvania100% (1)

- Water Treatment EngineerDokument22 SeitenWater Treatment EngineernatarajNoch keine Bewertungen

- Flow Characteristics:: B. Pressure Loss (Head Loss, PressureDokument4 SeitenFlow Characteristics:: B. Pressure Loss (Head Loss, PressureLily NurdianaNoch keine Bewertungen

- Renovation of Onups Ward BuildingDokument37 SeitenRenovation of Onups Ward BuildingpaulomirabelNoch keine Bewertungen