Beruflich Dokumente

Kultur Dokumente

Ultra Daf

Hochgeladen von

MD SHARIQUECopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultra Daf

Hochgeladen von

MD SHARIQUECopyright:

Verfügbare Formate

ULTRADAF®

1. TECHNICAL CHARACTERISTICS

Dissolved air flotation (DAF) is one of the processes applied for the treatment of water with a low content of solids in suspension,

floc concentrations between 5 and 50 mg/l, e.g.:

• Production of potable water

• Pre-treatment in the desalination of seawater

• Treatments for the re-use of treated water

It is also applied to water with a high solid content, provided its hygroscopic characteristics allow its floatability (algae, biological

sludge, etc.).

Through the accumulation of micro-bubbles (<100 μm) to discrete particles and floc, this material can be dragged to the surface

due to the difference in density vis-à-vis the water. It means that particles or material that have almost the same density as water

can be separated.

Elements that have a tendency to float, being less dense than water, are hydrocarbons, oils, fats, algae, etc. Also, elements that

can float with the help of air bubbles, because their overall density is less than that of water (this way it is possible to eliminate

colloidal material, color, and a part of organic material), activated charcoal, etc.

2. OPERATION

To achieve optimal operation of flotation on the water line, coagulation must take place previously, due to the fact that:

• The micro-bubbles have a negative surface load, as well as being hydrophobic

• Optimal coagulation produces flocs without loads. This means that electrostatic forces can be ignored, cancel out repulsive

forces and achieve good aggregation conditions.

The objective of flocculation is to increase particle size (25-50 μm) to increase the efficiency of their collection by the bubbles.

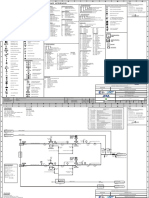

The air input is done by saturating a certain flow of water under pressure (recirculation flow). The saturation is done in a

pressurization tank with a certain hold time.

The mix of water saturated with air, oxygen and nitrogen is dosed in the DAF through injectors that produce a sudden loss of load

(cavitation).

This water current rises in the DAF, dragging the flocs up to the surface. They are then removed from the surface by mechanical

means (scrapers).

3. COMPETITIVE ADVANTAGES

ACCIONA Agua has developed a DAF called ULTRADAF®. It provides better hydraulic conditions than existing equipment and

has an injection system based on a series of optimized nozzles that allow work at high speeds and with high performance in the

removal of the contaminating material.

4. OTHER INFORMATION

In later developments, ACCIONA Agua had completed the DAF range with the ULTRADAF® Evo, an apparatus in which the diffusion

of air at the size of a micro-bubble is done directly, without the help of a water flow and, therefore, without a saturator.

The design of the diffusion system represents a clear advance in this type of equipment, with specific applications. .

Das könnte Ihnen auch gefallen

- Siemens Forty X Disc Filters Tech. Specs.Dokument25 SeitenSiemens Forty X Disc Filters Tech. Specs.Alfonso José García LagunaNoch keine Bewertungen

- Water Desalination MatrixDokument37 SeitenWater Desalination MatrixShehreyar KhanNoch keine Bewertungen

- Stocks ControllerDokument2 SeitenStocks ControllerO'dumont Consulting Ltd.Noch keine Bewertungen

- 2015 DELWP-commissioned ReportDokument98 Seiten2015 DELWP-commissioned ReportJoe HinchliffeNoch keine Bewertungen

- LGP32-13PL1 Power SpecificationDokument73 SeitenLGP32-13PL1 Power SpecificationClaudio Hector Arrosa100% (1)

- Discharge Calculator - Flowrates, Jet Properties and Outfall DesignDokument35 SeitenDischarge Calculator - Flowrates, Jet Properties and Outfall DesignjnmanivannanmechNoch keine Bewertungen

- QC10-H-149 - C09 - Rev5 MASTER BUILDER'S AND FINISHING WORKSDokument43 SeitenQC10-H-149 - C09 - Rev5 MASTER BUILDER'S AND FINISHING WORKSVijith29Noch keine Bewertungen

- AECOM Handbook 2023Dokument122 SeitenAECOM Handbook 2023vividsurveyorNoch keine Bewertungen

- Desalination Report-2018Dokument56 SeitenDesalination Report-2018Remya RanjithNoch keine Bewertungen

- CERC Capital Cost Benchmarks Thermal Power PlantsDokument222 SeitenCERC Capital Cost Benchmarks Thermal Power PlantsUzair Ahmad SiddiquiNoch keine Bewertungen

- Kuwait Five Year PlanDokument26 SeitenKuwait Five Year PlanbdmintlNoch keine Bewertungen

- EN Folder Watersupply ILF PDFDokument12 SeitenEN Folder Watersupply ILF PDFMishealNoch keine Bewertungen

- Purification of Brackish Water Using Hybrid CDI-EDI TechnologyDokument30 SeitenPurification of Brackish Water Using Hybrid CDI-EDI TechnologyamtNoch keine Bewertungen

- CSG Water Management PlanDokument83 SeitenCSG Water Management PlanABC News OnlineNoch keine Bewertungen

- QP10-U-705 Rev0 Typical Crossing of Foreign Cabels or PipesDokument1 SeiteQP10-U-705 Rev0 Typical Crossing of Foreign Cabels or PipesnawajhaNoch keine Bewertungen

- Kinew K DD SFSB 000 I Tds 3005 Rev 0Dokument73 SeitenKinew K DD SFSB 000 I Tds 3005 Rev 0muhammad nazmi100% (1)

- Planning For Desalination ReportDokument54 SeitenPlanning For Desalination Reportaagrawal3Noch keine Bewertungen

- Effluent Treatment Plant (ETP) - Process Flow DiagramDokument4 SeitenEffluent Treatment Plant (ETP) - Process Flow DiagramshimanthNoch keine Bewertungen

- r0 Proposal of Gree Tophill Lars - Ehi Rev1Dokument45 Seitenr0 Proposal of Gree Tophill Lars - Ehi Rev1Anonymous fS6Znc9Noch keine Bewertungen

- QP10-U-704 Rev0 Typical Major Road Cross Section Concrete CADokument1 SeiteQP10-U-704 Rev0 Typical Major Road Cross Section Concrete CAnawajhaNoch keine Bewertungen

- QP10-U-703 Rev0 Typical Line MarkerDokument1 SeiteQP10-U-703 Rev0 Typical Line MarkernawajhaNoch keine Bewertungen

- Water Treatment Plant Equipment and ComponentsDokument2 SeitenWater Treatment Plant Equipment and ComponentsJepri SihombingNoch keine Bewertungen

- Deputy City Engineer InterviewDokument2 SeitenDeputy City Engineer Interviewtanatsa piki100% (1)

- Saudi Wastewater Reuse Standards For AgriculturalDokument8 SeitenSaudi Wastewater Reuse Standards For AgriculturalShamma DamaniNoch keine Bewertungen

- Best Rotary Kiln Incinerator Manufacturers in India - BL EngineeringDokument2 SeitenBest Rotary Kiln Incinerator Manufacturers in India - BL Engineeringbl engineeringNoch keine Bewertungen

- Water Treatment Cost Curves 08-28-06Dokument10 SeitenWater Treatment Cost Curves 08-28-06ganeshNoch keine Bewertungen

- Design Report For Chikwina Service LinesDokument50 SeitenDesign Report For Chikwina Service LinesEddiemtongaNoch keine Bewertungen

- Integrated Plan For Chad's Water Development and Management (SDEA) - (Avril 2003)Dokument256 SeitenIntegrated Plan For Chad's Water Development and Management (SDEA) - (Avril 2003)Kendra MasseyNoch keine Bewertungen

- QW223601 03 MCT 4500004013 PR D156 00001 - 02Dokument16 SeitenQW223601 03 MCT 4500004013 PR D156 00001 - 02eladawyemadNoch keine Bewertungen

- Kimberley Pipeline Project ReviewDokument20 SeitenKimberley Pipeline Project ReviewhopexanddreamxNoch keine Bewertungen

- Form I Exhibition Cum-Convention Centre Dwarka: February, 2017Dokument98 SeitenForm I Exhibition Cum-Convention Centre Dwarka: February, 2017sarvaryaNoch keine Bewertungen

- Terms of Reference For 2023 CED 3rd YearDokument10 SeitenTerms of Reference For 2023 CED 3rd YearEugene DamoahNoch keine Bewertungen

- 10 State Standards - Waste Water FacilitiesDokument178 Seiten10 State Standards - Waste Water Facilitiesblin254Noch keine Bewertungen

- Contract Change Order No. 13 RedactedDokument7 SeitenContract Change Order No. 13 RedactedL. A. PatersonNoch keine Bewertungen

- Using stainless steel for high pressure piping in SWRO plantsDokument6 SeitenUsing stainless steel for high pressure piping in SWRO plantsAndreea FieraruNoch keine Bewertungen

- ControlDokument15 SeitenControlmontie3Noch keine Bewertungen

- Financing Municipal WaterDokument83 SeitenFinancing Municipal WaterJohn SmithNoch keine Bewertungen

- 10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsDokument239 Seiten10 Beach Well Intakes For Small Seawater Reverse Osmosis PlantsAnonymous tqG0TJSAap100% (1)

- Basic Engg Package for Sewage Treatment PlantDokument29 SeitenBasic Engg Package for Sewage Treatment PlantRentu PhiliposeNoch keine Bewertungen

- Uaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileDokument20 SeitenUaq c1 w0 Eri 5010 MH WRF 001 Reva - Erd Technical FileABHIJITH M SNoch keine Bewertungen

- Facts About Fidic Blue Book Second EditionDokument4 SeitenFacts About Fidic Blue Book Second EditionSanchit SuriNoch keine Bewertungen

- Presentation FRP 06Dokument10 SeitenPresentation FRP 06Mohamed BouchouatNoch keine Bewertungen

- Solid Waste Incinerator ManufacturersDokument2 SeitenSolid Waste Incinerator Manufacturersbl engineeringNoch keine Bewertungen

- WDR 20160919 Water Desalination ReporTDokument4 SeitenWDR 20160919 Water Desalination ReporTPhilip Jay-ar DimailigNoch keine Bewertungen

- CQA Plan - Full PDFDokument75 SeitenCQA Plan - Full PDFYedid AmqNoch keine Bewertungen

- MEP QS Job OfferDokument1 SeiteMEP QS Job Offerمحمد إسلام عبابنهNoch keine Bewertungen

- Voutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Dokument12 SeitenVoutchkov (2010) CoinsiderationdForSelectionOfSeawaterFiltrationPretrementSystem Desalination (261 354-364Shamma DamaniNoch keine Bewertungen

- Operating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryDokument12 SeitenOperating A Water Treatment Plant Is Complex and Requires Knowledge of MachineryJoshua OmolewaNoch keine Bewertungen

- Interface Mangement: Formalize Contractor Collaboration To Mitigate Interface-Related Cost & Schedule RiskDokument2 SeitenInterface Mangement: Formalize Contractor Collaboration To Mitigate Interface-Related Cost & Schedule RiskJonathen Hormen100% (2)

- Expansion of Water Treatment PlantDokument20 SeitenExpansion of Water Treatment PlantRohail AfzalNoch keine Bewertungen

- Performance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExampleDokument6 SeitenPerformance of Reinforced Thermosetting Resin Pipe Systems in Desalination Applications: A Long-Term Solution To Corrosion - The Arabian Gulf ExamplejatecconsultNoch keine Bewertungen

- Strengthening 49 km of NH-2B in West BengalDokument102 SeitenStrengthening 49 km of NH-2B in West BengalOllie BhattNoch keine Bewertungen

- QIPP MPN013 M00 2203 - A - Status2Dokument5 SeitenQIPP MPN013 M00 2203 - A - Status2Ganesh R NairNoch keine Bewertungen

- Ducts Acessaries 1Dokument15 SeitenDucts Acessaries 1KUMAARRR100% (1)

- Project Report PDFDokument26 SeitenProject Report PDFcaloycaloy2Noch keine Bewertungen

- 0D107Line ListDokument1 Seite0D107Line Listgeverett2765Noch keine Bewertungen

- Intelligent WaterDokument8 SeitenIntelligent WaterCristian SotoNoch keine Bewertungen

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsVon EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNoch keine Bewertungen

- Sanitary Engineer II: Passbooks Study GuideVon EverandSanitary Engineer II: Passbooks Study GuideNoch keine Bewertungen

- CBT Inspector Qualification Guideline PDFDokument9 SeitenCBT Inspector Qualification Guideline PDFhemant128467% (6)

- Plumbing Rfi Front SheetDokument14 SeitenPlumbing Rfi Front SheetMD SHARIQUENoch keine Bewertungen

- Equipment and Inspection Tools Log.Dokument2 SeitenEquipment and Inspection Tools Log.MD SHARIQUENoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilDokument4 SeitenSaudi Aramco Inspection Checklist: Geotechnical Field Works Inspection SAIC-A-1008 30-Nov-17 CivilMD SHARIQUENoch keine Bewertungen

- A Checklist For Writing Seo: Friendly PostsDokument5 SeitenA Checklist For Writing Seo: Friendly PostsMD SHARIQUENoch keine Bewertungen

- Saudi Aramco Inspection ChecklistDokument2 SeitenSaudi Aramco Inspection ChecklistMD SHARIQUENoch keine Bewertungen

- Profibus Pa: Profibus Pa Profibus PA Profibus PA Profibus PaDokument4 SeitenProfibus Pa: Profibus Pa Profibus PA Profibus PA Profibus PamandaremNoch keine Bewertungen

- Challenges in Running A Commercial Web Search Engine: Amit SinghalDokument50 SeitenChallenges in Running A Commercial Web Search Engine: Amit Singhalapi-25889104Noch keine Bewertungen

- Water Treatment PlantDokument13 SeitenWater Treatment PlantWater Next SolutionsNoch keine Bewertungen

- LUM Direct Accelerated Stability TestsDokument27 SeitenLUM Direct Accelerated Stability TestsMuhammad Erwin YamashitaNoch keine Bewertungen

- Wisconsin DNR Study Guide for Advanced Preliminary and Primary TreatmentDokument22 SeitenWisconsin DNR Study Guide for Advanced Preliminary and Primary TreatmentBuenaventura Jose Huamani TalaveranoNoch keine Bewertungen

- .. PDF SugarDokument34 Seiten.. PDF SugarSnehal Badwaik100% (1)

- Unit 1 - Water Technology: Engineering Chemistry Two Marks Question and AnswersDokument19 SeitenUnit 1 - Water Technology: Engineering Chemistry Two Marks Question and Answers14567Noch keine Bewertungen

- Existing and New Processes For Beneficiation of Indian Iron OresDokument10 SeitenExisting and New Processes For Beneficiation of Indian Iron OresGottumukkala Venkateswara RaoNoch keine Bewertungen

- Water Coagulation and Flocculation 1663749610Dokument53 SeitenWater Coagulation and Flocculation 1663749610salehNoch keine Bewertungen

- Coagulation and Flocculation Processes in Water TreatmentDokument9 SeitenCoagulation and Flocculation Processes in Water TreatmentMAHERNoch keine Bewertungen

- Disperse Systems: Reporters: #25 LEE, Sharmaine C. #26 LOTERTE, Edwin A. #27 LUMBAO, Jicah A. #28 MONSALUD, Miguel MDokument141 SeitenDisperse Systems: Reporters: #25 LEE, Sharmaine C. #26 LOTERTE, Edwin A. #27 LUMBAO, Jicah A. #28 MONSALUD, Miguel MSharmaine Margaret LeeNoch keine Bewertungen

- Samara University Environmental Health CourseDokument410 SeitenSamara University Environmental Health CourseErega AyeleNoch keine Bewertungen

- Wastewater TreatmentDokument61 SeitenWastewater TreatmentGoutham R100% (1)

- Colloidal StateDokument24 SeitenColloidal Stateakash gargNoch keine Bewertungen

- Cellulose-Based Materials in Wastewater TreatmentDokument13 SeitenCellulose-Based Materials in Wastewater TreatmentNixson Manosalva ElguetaNoch keine Bewertungen

- Application For Discharge Permit: Republic of The Philippines Department of Environmental and Natural ResourcesDokument3 SeitenApplication For Discharge Permit: Republic of The Philippines Department of Environmental and Natural ResourcesDwinix John CabañeroNoch keine Bewertungen

- Vws Oil GasDokument8 SeitenVws Oil GasFabricio TrosarelloNoch keine Bewertungen

- STERILIZATION OF WATER USING BLEACHING POWDER Kartik (12Dokument15 SeitenSTERILIZATION OF WATER USING BLEACHING POWDER Kartik (12Atul AgarwalNoch keine Bewertungen

- Treating Cardboard Plant Wastewater With an Innovative HydroPac SystemDokument3 SeitenTreating Cardboard Plant Wastewater With an Innovative HydroPac SystemBryan Alberto Cueva VásquezNoch keine Bewertungen

- Status of Water Treatment Plants in IndiaDokument110 SeitenStatus of Water Treatment Plants in IndiaRiga Edwards100% (1)

- Design 10,000 m3/d SWRO plantDokument78 SeitenDesign 10,000 m3/d SWRO plantbazediNoch keine Bewertungen

- Exercise 4 Coagulation and Denaturation of Protein: ObjectiveDokument4 SeitenExercise 4 Coagulation and Denaturation of Protein: ObjectiveStephanie Abler AbellanosaNoch keine Bewertungen

- Pressure swing adsorption simulation of air dryingDokument7 SeitenPressure swing adsorption simulation of air dryingAndri SaputraNoch keine Bewertungen

- SBR 2001Dokument11 SeitenSBR 2001Abdul rahmanNoch keine Bewertungen

- How to Purify Water for DrinkingDokument30 SeitenHow to Purify Water for Drinkingpaulo100% (2)

- Treatment of Petroleum Industry Wastewater: Technologies and PerspectivesDokument9 SeitenTreatment of Petroleum Industry Wastewater: Technologies and PerspectivesKemuel MatthewNoch keine Bewertungen

- Chemical Units Chu1Dokument2 SeitenChemical Units Chu1MariusCapraNoch keine Bewertungen

- Environmental Engineering M TECH SYLLABUS JNTUHDokument23 SeitenEnvironmental Engineering M TECH SYLLABUS JNTUHnagasmsNoch keine Bewertungen

- Ice Cream Formation and Stabilization A ReviewDokument17 SeitenIce Cream Formation and Stabilization A Reviewhergofra100% (1)

- Poly Aluminum Chloride ProductionDokument7 SeitenPoly Aluminum Chloride ProductionTermodynamicsNoch keine Bewertungen

- Water Treatment and Waste Water ProcessesDokument14 SeitenWater Treatment and Waste Water ProcessesBhaswar MajumderNoch keine Bewertungen

- 7 T Y B SC Environmental ScienceDokument19 Seiten7 T Y B SC Environmental ScienceRoshan patilNoch keine Bewertungen