Beruflich Dokumente

Kultur Dokumente

Precast

Hochgeladen von

AhmadOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Precast

Hochgeladen von

AhmadCopyright:

Verfügbare Formate

City of San Bruno

Technical Specifications

SECTION 33 39 13

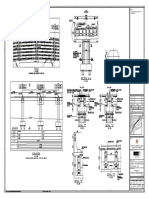

PRECAST CONCRETE MANHOLES

PART 1 – GENERAL

1.01 WORK INCLUDED

A. This section includes materials, testing, and installation of precast concrete

manhole for sewer and appurtenances.

1.02 RELATED REQUIREMENTS AND SPECIFICATIONS

A. City Standard Detail Drawings.

B. Specification Section 33 30 00, Sanitary Sewerage Utilities

C. Specification Section 31 23 33, Trench Excavation and Backfill

1.03 REFERENCE STANDARDS

ASTM A 48 Gray Iron Castings

ASTM C 478 Precast Reinforced Concrete Manhole Sections

ASTM C 923 Resilient Connectors between Reinforced Concrete

Manhole Structures and Pipes

ASTM C 990 Joints for Concrete Pipe, Manholes, and Precast Box

Sections Using Preformed Flexible Joint Sealants

1.04 QUALITY ASSURANCE

All materials furnished under this Section shall be:

A. From a manufacturer who has been regularly engaged in the design and

manufacture of the materials for at least five (5) years; and

B. Approved by the engineer before installation. The Engineer shall verify that the

product and quality is equal to the materials made by those manufacturers

specifically named herein, or if an alternate product manufacturer is proposed.

1.05 SUBMITTALS

The Contractor shall submit for approval by the Engineer the following:

A. Manufacturer’s literature on the materials identified on the City Standard Detail

and this specification. Literature shall include recommended installation

procedures.

B. Certification by the manufacturer that all precast sections furnished under this

specification were manufactured, sampled, tested, and inspected in accordance

with ASTM C 478 or ASTM C361.

C. Mix design of the concrete used for the manhole base.

D. Frame, grates, rings, and covers.

E. Material to be used for pipe connections at manhole walls.

33 39 13 - 1 Precast Concrete Manholes

City of San Bruno

Technical Specifications

PART 2 – PRODUCTS

2.01 MANHOLES

A. Pre-Cast Concrete Manholes

1. All pre-cast concrete manhole sections shall conform to the details shown

on the applicable City Standard Drawings for sewer manhole. Pre-cast

manhole sections shall be manufactured in accordance with ASTM C 478,

"Precast Reinforced Concrete Manhole Sections." Manholes shall be leak

free structures. Structures constructed with precast sections shall be

constructed using a single manufacturers products and/or with products

recommended by the precast section manufacturer.

2. Manhole Sizes

Pipe Diameter Manhole Diameter Cover Diameter

21 inch and smaller 48 inch 24 inch

24 inch and 27 inch 60 inch 24 inch

30, 33 and 36 inch 72 inch 24 inch

B. Manhole Cones

1. Manhole Cones shall be CONCENTRIC.

C. Manhole Bases

1. Manhole bases shall be cast-in-place in accordance with City Standard

Drawing unless specified otherwise. Concrete for manhole base shall be 6-

sack with a 4,000 psi rating. Top of base channel shall be six inches (6”)

above the crown of pipe.

D. Manhole Inlet

1. For manholes with more than one inlet, the invert of the smaller inlet shall

be at or above the centerline of the larger pipe. Channel for the side entry

shall be properly shaped to provide minimum turbulence in the manhole.

E. Ladder Rungs

1. Manhole ladder rungs shall be installed for all manholes deeper than four

feet (4’). Rungs shall be made of one-half inch (½”) diameter grade 60 steel

with Copolymer Polypropylene coating. Steps are to be cast in place during

manufacturing of pre-cast barrels and cones.

Precast Concrete Manholes 33 39 13 - 2

City of San Bruno

Technical Specifications

F. Joint Sealer

1. Joints in precast manhole sections shall be made of "Ram-Nek" preformed

flexible plastic joint sealant or neoprene gaskets.

2.02 MANHOLE FRAMES AND COVERS

A. Manhole frames and covers shall conform to applicable City Standard Drawing.

Non-pressure type manhole frames and covers shall be Phoenix Iron Works P-

1090 or D&L Supply A-1024, or equal.

B. Pressure type manhole frames and covers shall be Phoenix Iron Works P-1002

(bolt-down), or equal. Both manhole frames and covers shall meet all

requirements of ASTM A 159, "Automotive Gray Iron Castings."

C. Manhole covers shall be labeled “Sanitary Sewer”.

D. Manhole covers shall have at least one center pick hole and one edge pry hole.

E. Adjustment rings shall NOT be used on any sewer manhole. Frames must be

raised.

F. Anchor bolts shall be fabricated as specified by the equipment manufacturer

and, unless otherwise indicated, shall be stainless steel. Cone shall be drilled

to accept three-fourths inch (¾”) stainless steel inserts. Manhole rim is to be

bolted down prior to the pouring of the concrete cap

PART 3 - EXECUTION

3.01 CONNECTIONS TO EXISTING MANHOLES

A. Pipe connections to existing manholes shall be done under the direction of the

Engineer and other applicable requirements specified for new manholes,

including all necessary concrete work, cutting, and shaping of channel.

B. All PVC and HDPE pipe entering or leaving a manhole shall have a rubber

sealing gasket as supplied by the pipe manufacturer, firmly seated

perpendicular to the pipe axis, around the pipe exterior and cast into the

structure base or near the wall center as a water stop. Water stop may also

consist of a manhole coupling with rubber sealing rings cast into the structure

base.

C. Existing flow shall be maintained through a bypass. A bypass plan shall be

submitted and the Contractor shall be solely responsible for maintaining the

33 39 13 - 3 Precast Concrete Manholes

City of San Bruno

Technical Specifications

bypass and shall be liable for any fines levied by any agency as a result of any

spill or overflow.

3.02 ABANDONMENT OF EXISTING MANHOLES

A. Manholes to be abandoned shall have their cones removed, backfilled and

compacted to ninety-five percent (95%) relative compaction. Frames and

covers not to be reused shall be delivered to the City as directed by the

Engineer.

3.03 MANHOLES

A. Manhole Bases

1. Manhole bases shall be “Cast-In-Place” unless specified otherwise.

Manhole bases shall be poured against a minimum of twelve inches (12”)

of three-quarter inch (¾”) drain rock, over undisturbed material, and

excavated to the dimensions shown on the plans. The Contractor shall

not deviate from plan dimensions, notwithstanding over-excavation or

other detrimental field conditions, unless approved by the Engineer. A

forming ring shall be used to form a level joint groove in fresh concrete of

the manhole base to receive the precast barrel section of the manhole.

The metal forming ring shall be removed after the concrete has sufficiently

set to eliminate any slump in the joint groove.

2. Manhole bedding shall be twelve inches (12”) of ¾-inch drain rock shall be

placed under manhole base to be cast-in-place and shall be compacted

to a relative compaction of ninety percent (90%) per ASTM D1557-78 and

ASTM D2922-81.

3. Manhole Channels: Where sewer lines ingress and egress manholes,

construction shall conform to the City Standard Drawings. Pipe shall be

used to form the channel. After the base concrete has set, the channel

shall be shaped to the final required configuration. Perpendicular channel

sides shall not be allowed. All channels shall be approved by the

Engineer.

4. All connections shall provide for a watertight seal between the pipe and

the manhole. The connector shall be the sole element relied upon to

assure a flexible water tight seal of the pipe to the manhole.

5. When connecting new pipe to existing manholes, a channel and bench

walls shall be installed.

6. The pipe up to the structures shall not project beyond the inside wall of

the structure and in no case shall the socket of a vitrified clay pipe be built

into the wall of a structure.

Precast Concrete Manholes 33 39 13 - 4

City of San Bruno

Technical Specifications

7. Flexible connection at manhole tie-in shall be in accordance with

applicable City Standard Drawings.

B. Joints in pre-cast manhole sections shall be filled using "Ram-Nek" or approved

equal in the joint space between matching parts. After placement of the

subsequent section, excess sealant squeezed from joint shall be removed and

the joint area troweled smooth. Special precautions shall be taken to ensure that

the entire joint space is filled with sealant. Apply mortar to all joints.

C. Apply concrete sealant “XYPEX Concentrate” 2 coats to manhole base and 1

coat to inside and outside of barrels.

.

3.04 WORKING ON EXISTING MANHOLES

A. When work is to be performed above the flow channel of existing manholes,

plywood shall be used to cover the entire channel and a drop cloth shall be

used to cover the entire base and prevent any debris from entering the flow-

channel. Noncompliance will result in the suspension of that portion of the

Contractor’s work for the day until the precautionary measures are put in place.

No contract time extensions will be granted due to said suspension of work.

This precaution shall be taken to prevent debris from entering or obstructing the

flow to the Collection System.

B. Sanitary sewer connections to existing manholes shall be core-drilled and

made using a flexible rubber seal/waterstop. Saw cutting and hammer

through taps are prohibited.

3.05 ADJUSTING EXISTING FRAMES AND COVERS TO GRADE

A. General

1. Before any work is performed on existing manholes, plywood shall be

used to cover entire channel and a drop cloth be used to cover the entire

base. This precaution shall be taken to prevent debris from entering the

Collection System. Existing frames, covers, or adjustment rings removed

during adjustments may be reinstalled only if the materials are

undamaged and only if approved in advance by the Engineer.

2. All City manholes shall be raised to grade within ten (10) calendar days

after street resurfacing.

3. Manholes shall be raised flush with the finished grade of the new road

surface. The maximum allowable tolerance shall be one-fourth inch (¼”)

measured with a straightedge.

33 39 13 - 5 Precast Concrete Manholes

City of San Bruno

Technical Specifications

4. Manhole frame and cover shall be shimmed. The void between the top of

manhole cone or ring and the cover frame shall be filled with cement

mortar.

5. No bricks, shims or any other device shall be left as part of final

construction.

6. Manhole covers shall have no other holes, other than the center pick hole

and side pry hole.

B. Downward Adjustments

Downward adjustments can be made by removal of grade rings, mortar,

concrete or brick. At no time shall the cone be modified in any way.

C. Manhole Surface Block

Manhole surface blocks (collars) are required on all manholes. A block is to be

poured around each adjusted frame. The block is to be eighteen inches (18”)

wide as measured from the outside edge of the cover and twelve inches (12”)

thick. Concrete is to be poured no more than two inches (2”) from final grade

and rough finished to accept asphalt overlay. Frame is then to be grouted to

grade to grade rings and cone.

3.06 TESTING

A. The Contractor shall conduct an exfiltration test or vacuum test on each

manhole constructed. The test shall be conducted by the Contractor in the

presence of the Engineer.

B. Exfiltration tests shall consist of plugging incoming and outgoing sewer lines

and filling the manhole with water up to the rim. After initial absorption (15

minutes), if the water loss exceeds one inch in depth in five minutes, the

manhole shall have failed the test. Each manhole which fails the test shall be

carefully inspected to determine the problem and then resealed and retested

until the water loss is less than one inch in five minutes.

C. Vacuum tests shall consist of drawing a vacuum on a sealed manhole and

measuring the time for the vacuum to drop to a predetermined level. The

actual test procedure shall be provided by the manufacturer of the test

equipment and approved by the Engineer. Each manhole which fails the test

shall be carefully inspected to determine the problem and then resealed and

retested until the manhole passes.

- END OF SECTION -

Precast Concrete Manholes 33 39 13 - 6

Das könnte Ihnen auch gefallen

- Laattalattia Ontelolaataston Pã Ã LlãDokument28 SeitenLaattalattia Ontelolaataston Pã Ã LlãAhmadNoch keine Bewertungen

- Comparison of Concrete Road Vs Asphalt RoadDokument6 SeitenComparison of Concrete Road Vs Asphalt RoadAhmadNoch keine Bewertungen

- Sheetrock Mold Tough Gypsum Liner Panels TDSDokument2 SeitenSheetrock Mold Tough Gypsum Liner Panels TDSAhmadNoch keine Bewertungen

- Concrete & Asphalt Roads - Pros & ConsDokument4 SeitenConcrete & Asphalt Roads - Pros & ConsAhmadNoch keine Bewertungen

- Notes: 1-All Dimensions Are Given in Millimeters .: A B C DDokument1 SeiteNotes: 1-All Dimensions Are Given in Millimeters .: A B C DAhmadNoch keine Bewertungen

- Finite Elements in Autodesk Robot Structural AnalysisDokument2 SeitenFinite Elements in Autodesk Robot Structural AnalysisAhmadNoch keine Bewertungen

- Drain Repairs: Should The Word Drainage Be Replaced by Pipework?Dokument1 SeiteDrain Repairs: Should The Word Drainage Be Replaced by Pipework?AhmadNoch keine Bewertungen

- Precast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityDokument3 SeitenPrecast Concrete Catch Basins and Inlets: Unmatched Strength and DurabilityAhmadNoch keine Bewertungen

- Bearing Replacement STUs M4 Hambrook ViaductDokument1 SeiteBearing Replacement STUs M4 Hambrook ViaductAhmadNoch keine Bewertungen

- CIVL2360 Cheat Sheet CIVL2360 Cheat SheetDokument3 SeitenCIVL2360 Cheat Sheet CIVL2360 Cheat SheetAhmadNoch keine Bewertungen

- Voided and Ribbed SlabsDokument17 SeitenVoided and Ribbed SlabsAhmadNoch keine Bewertungen

- Watertight Shotcrete For Swimming Pools: ASA Pool and Recreational Shotcrete CommitteeDokument2 SeitenWatertight Shotcrete For Swimming Pools: ASA Pool and Recreational Shotcrete CommitteeAhmadNoch keine Bewertungen

- Bison Hollowcore Floors Bearing DetailsDokument4 SeitenBison Hollowcore Floors Bearing DetailsAhmadNoch keine Bewertungen

- Down - Tecnospan Dossier - Recycled Aggregates in Concrete For PrecastDokument2 SeitenDown - Tecnospan Dossier - Recycled Aggregates in Concrete For PrecastAhmadNoch keine Bewertungen

- Ascon Design Department: Comparision Based On Value Engineered OptionDokument5 SeitenAscon Design Department: Comparision Based On Value Engineered OptionAhmadNoch keine Bewertungen

- A B C D: General Arrangement PHASE "1"Dokument1 SeiteA B C D: General Arrangement PHASE "1"AhmadNoch keine Bewertungen

- Manhole Installation Guide-PDF-rev2Dokument68 SeitenManhole Installation Guide-PDF-rev2AhmadNoch keine Bewertungen

- Cat Lifting Devices 2Dokument1 SeiteCat Lifting Devices 2AhmadNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Water Meter Installation, Maintenance and Replacement GuidelineDokument10 SeitenWater Meter Installation, Maintenance and Replacement GuidelineAugustine NgwaleNoch keine Bewertungen

- External Coating For Corrosion ProtectionDokument142 SeitenExternal Coating For Corrosion ProtectionMajid Dixon100% (1)

- Skid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CDokument8 SeitenSkid Weight Calculation HHI-RAR-SD-SCAL-004. REV.CAgus MarpaungNoch keine Bewertungen

- Flame ControlDokument56 SeitenFlame ControlFabio Peres de LimaNoch keine Bewertungen

- GenusDokument68 SeitenGenussmokefieldNoch keine Bewertungen

- ASME Joint EfficiencyDokument49 SeitenASME Joint Efficiencygateauxboy95% (39)

- Part List DIESEL-PARTS-DIRECT CUMMINS NT-855 BIG CAMDokument15 SeitenPart List DIESEL-PARTS-DIRECT CUMMINS NT-855 BIG CAMDouglas Duarte0% (1)

- TBA 19 Production Monitoring Sheet FinalDokument4 SeitenTBA 19 Production Monitoring Sheet FinalAtish Kissoon67% (3)

- Shree Shakti Engineering (G) Pvt. Ltd.Dokument16 SeitenShree Shakti Engineering (G) Pvt. Ltd.Krunal JaniNoch keine Bewertungen

- United States Patent (19) : Helderle Et AlDokument14 SeitenUnited States Patent (19) : Helderle Et AlabodolkuhaaNoch keine Bewertungen

- Daily Calling AutosavedDokument335 SeitenDaily Calling AutosavedShubh SahooNoch keine Bewertungen

- Technical-THSDokument163 SeitenTechnical-THSgenciNoch keine Bewertungen

- Nfpa 22 IndexDokument5 SeitenNfpa 22 Indexsaladin1977Noch keine Bewertungen

- ALFA LAVAL Fittings CatalogDokument76 SeitenALFA LAVAL Fittings Catalogjesus casas garayNoch keine Bewertungen

- Rolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2Dokument33 SeitenRolls-Royce RB211 Trent 700 UCPG (Full Permission) - 2ArabyAbdel Hamed Sadek100% (1)

- 2nd Year - Fluid Mechanics 2 - SheetDokument3 Seiten2nd Year - Fluid Mechanics 2 - SheetAhmedTaha100% (1)

- B-LINE PIPE Hangers & SupportsDokument393 SeitenB-LINE PIPE Hangers & SupportsROGER CHNoch keine Bewertungen

- Manual de O&M Blackmer PumpsDokument16 SeitenManual de O&M Blackmer PumpsArturo VillenaNoch keine Bewertungen

- QDB Ethiopia Matchmaking 2020Dokument29 SeitenQDB Ethiopia Matchmaking 2020Neville Trindade100% (1)

- Specification For Dual-Layer FBEDokument19 SeitenSpecification For Dual-Layer FBEali saidNoch keine Bewertungen

- 1.MS Start Up & Comm of Fuel Oil PumpDokument11 Seiten1.MS Start Up & Comm of Fuel Oil Pump721917114 47Noch keine Bewertungen

- Bite Type FittingsDokument42 SeitenBite Type FittingsWilson JustinoNoch keine Bewertungen

- Isolation Valve Chamber - 900 MM Diameter PipeDokument47 SeitenIsolation Valve Chamber - 900 MM Diameter PipeAnonymous 3kDy7e100% (1)

- Petroplas Installation Manual UsDokument34 SeitenPetroplas Installation Manual UsRogerio Pinto AndradeNoch keine Bewertungen

- Mixing, Aeration and Heat & Mass TransferDokument40 SeitenMixing, Aeration and Heat & Mass TransferDr. Akepati Sivarami Reddy100% (5)

- Cat General Torque SpecificationsDokument48 SeitenCat General Torque SpecificationsRicardo Aguirre100% (7)

- Table 6 - Mechanical Products PDFDokument18 SeitenTable 6 - Mechanical Products PDFSharad NanapureNoch keine Bewertungen

- Hydrophore Set (Mectron Engineering)Dokument2 SeitenHydrophore Set (Mectron Engineering)KelvinNoch keine Bewertungen

- Hose Reel Catalogue 2018Dokument12 SeitenHose Reel Catalogue 2018FrancisNoch keine Bewertungen

- Behringer CatalogDokument36 SeitenBehringer Catalogyazanof4Noch keine Bewertungen