Beruflich Dokumente

Kultur Dokumente

JSA - Repair-Coating and Finition Work

Hochgeladen von

AMINOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JSA - Repair-Coating and Finition Work

Hochgeladen von

AMINCopyright:

Verfügbare Formate

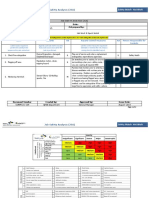

JOB SAFETY ANALYSIS

Ref: – JSA-…….

Facility / Site: TATOUINE 10MW PV Location within Site: Permit No:PTF-19- Permit Type: cold Date:

Task Description : Repair and painting work

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: Company:SOCOBAT

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

Name / Signature: Company:

FALL PROTECTION

FALL RESTRAINT

COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask OTHER (specify):

Work clothes

OTHER PPE (specify): Worker performing task inside to wear Double

Earing Protection (ear plugs and ear muffs)

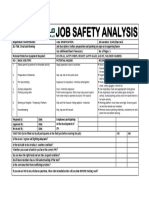

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

- Manual handling Manual handling techniques. Personnel trained. ENI Emergency response

- Sharp objects

Use adequate PPEs. plan

1- Materials prep - Heavy load

- Falling objects Selection of tools (appropriate to the task). Proper fire extinguisher

- Slip, Trip & fall Obtain assistance during manual handling.

-MSDS to be on site explained to crew

- Strains Appropriate PPE to be worn at all time

2- Repair ENI Emergency response

- Exposure to SIKA product TBT conducted prior to job commencement

Foundations plan

- Silica Exposure Read label of the product and avoid contact

using SIKA & Proper fire extinguisher

- Harmful product Storage should be indicated and barricaded

DERBICOTE

- Safety gloves and glasses must be worn

Avoid leak of product by placing containment on the area

- Flying particles To connect safety whip in the air compressor ENI Emergency response

- Unsecured hoses Barricaded area and safety signs to be erected plan

- Incompetent operator Use dust mask while operating Proper fire extinguisher

- Pressurized hose Check hose , valve , nozzle before using equipment

3- Cleaning

- Dust / harmful

foundation using Fire extinguisher must be on place

substances

Hilti and grinder Check the RPM of disc and grinder

- Vibration

machine Inspect cables and plugs before use

- Flying particles

- Damaged power tools Face shield should be worn

Administrative control

Ensure work area is clear of other workers.

User shall wear a hard hat, eye protection, and ear plugs.

Use dust-free power tools in good condition, and

- •Falling/Flying Debris

have dust masks available for workers who might

- • Harmful Dust (Silica)

- • Tool Malfunction want to use one in addition to the other hazard

- • Electrical Shock Controls.

- • Loss of Control Over Inspect and test drill and cord prior to use.

Tool Plug into a protected outlet. ENI Emergency response

4- Work of Piercing - • Vibratory Fatigue Safety whips to be attached at both compressor and pneumatic tools plan

and cleaning - • Excessive Noise Barricaded area and only authorized person to be on site Proper fire extinguisher

- •Looseness Perforator Face shield should be worn

bit Make sure that cords are not lying in water.

- Vibration tools / Power The drill operator should use any auxiliary Handles that are on the drill to

tools

maintain control.

- Pneumatic tools

The drill operator should make sure that he sets his feet properly before

beginning to drill or chip.

Take regular breaks from drilling or switch with another worker (if drilling for

a prolonged period of time) to relieve fatigue.

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

- Hazard to health - Full PPE must be worn + Specials gloves

(Ingestion, inhalation) - Use PPE

- Fire , Spills - Flammable liquid should be properly stored

- Personal injuries, - MSDS for the paint in place

- Irritation and skin - Tool Box Talk

sensitization on contact - Handle chemical in accordance with material safety data sheet

- Irritation to the - Take precaution when tossing asphalt not to spray on fellow workers

ENI Emergency response

respiratory tract - Don’t touch or pick up asphalt with hands

plan

5- Concrete coating - Gastrointestinal damage - Immediately flush eyes with plenty of water. Get medical attention,

Proper fire extinguisher

if swallowed if irritation persists. Remove contact lenses after flushing.

- Fatality. - Wash affected area with soap and water. Get medical attention if

- Fire Hazard: YES irritation develops or persists.

- Reactive Hazard: YES - Remove to fresh air. Seek medical attention if respiratory irritation

- Acute Health Hazard: develops or if breathing becomes difficult.

YES - Give large quantities of water. Never give anything by mouth to an

- unconscious person.

-

• Bites • Job rotation to be applied and share outdoors activities between all

• Poisonous insects workers

• Slip, trips and fall • Big and fresh quantity of water to be displayed

• Dehydration • Manual technique

6- Adverse weather • Heat struck • Awareness session to workers to aware them about hazards ENI Emergency response

condition: • Dizziness associated with poisonous insects plan

Scorpions and • MSD • First aid kit and first aider should be available Proper fire extinguisher

snakes • Fatigue • Frequent breaks to be taken for recovery

• Working in extreme • Workers should wear adequate coverall

temperature • Time management culture among work force

Name Position Date Signed

Prepared By HSSE

Checked By Area HSSE Supervisor

Approved By

Das könnte Ihnen auch gefallen

- JSA Confined Sapce EntryDokument1 SeiteJSA Confined Sapce EntryprasongNoch keine Bewertungen

- JSA - Blasting & PaintingDokument11 SeitenJSA - Blasting & PaintingRajuNoch keine Bewertungen

- Tanks Confined Space JSADokument5 SeitenTanks Confined Space JSAkosoko100% (1)

- 4-JSA - Unloading Under Inert - F9030 B NewDokument6 Seiten4-JSA - Unloading Under Inert - F9030 B NewAde RahmadiNoch keine Bewertungen

- JSA For Coating and Raping Activity in TankDokument7 SeitenJSA For Coating and Raping Activity in TankEslam lotfy- Eslam elsadatNoch keine Bewertungen

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Dokument1 SeiteJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JHA - To Carry Out Reinstate of Interlock StonesDokument7 SeitenJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- PVCMS-BMV-HSE-JSA-001 InsulationDokument6 SeitenPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNoch keine Bewertungen

- JSA - Installation of U G PipingDokument11 SeitenJSA - Installation of U G PipingOws Anish100% (1)

- JS A Excavation Work For Electrical CableDokument3 SeitenJS A Excavation Work For Electrical CableMohammed MinhajNoch keine Bewertungen

- Jsa Insulation WorkDokument20 SeitenJsa Insulation WorkazerNoch keine Bewertungen

- PaintingDokument1 SeitePaintingReynaldo PesqueraNoch keine Bewertungen

- JSA Pipe Installation 2012Dokument2 SeitenJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- JSA Machinal PipingDokument7 SeitenJSA Machinal PipingNaitik Desai48100% (1)

- Jsa For Intallation of Sub Pipe RackDokument7 SeitenJsa For Intallation of Sub Pipe RackMohammed Minhaj100% (2)

- Job Safety Analysis: Manual ExcavationDokument2 SeitenJob Safety Analysis: Manual Excavationfdfddf dfsdfNoch keine Bewertungen

- Jsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested byDokument3 SeitenJsa For Painting Operation: S.N o Scope of Activity Hazard Control Measures Requested bywahyu nugroho100% (2)

- Jsa Grinding Welding Gas CuttingDokument3 SeitenJsa Grinding Welding Gas CuttingRyanNoch keine Bewertungen

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDokument1 SeiteJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNoch keine Bewertungen

- 003-JSA Pipe Loading and OffloadingDokument8 Seiten003-JSA Pipe Loading and OffloadingMoaatazz NouisriNoch keine Bewertungen

- JSA Hydro TestingDokument1 SeiteJSA Hydro TestingZeyad RezkNoch keine Bewertungen

- JSA For Lifting of RebarsDokument5 SeitenJSA For Lifting of RebarsNiraNoch keine Bewertungen

- Jsa For Installation of Bracket in Phase 1Dokument4 SeitenJsa For Installation of Bracket in Phase 1Mohammed Minhaj100% (1)

- JSA Earthpit Construction GeneralDokument4 SeitenJSA Earthpit Construction Generalmukka88Noch keine Bewertungen

- JSA For HDPE SLEEVING DEL 89Dokument3 SeitenJSA For HDPE SLEEVING DEL 89Mohammed Minhaj100% (1)

- JHA Vessel EntryDokument2 SeitenJHA Vessel EntryRiyadh SalehNoch keine Bewertungen

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7Dokument4 SeitenThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 7abhijit janaNoch keine Bewertungen

- JSA - CivilDokument5 SeitenJSA - CivilRajuNoch keine Bewertungen

- Job Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentDokument5 SeitenJob Safety Analysis Worksheet: JSA No: JSA For Chemical Cleaning of WWT TreatmentlokreddiNoch keine Bewertungen

- Jsa Loading and Unloading of Pile PipesDokument4 SeitenJsa Loading and Unloading of Pile PipesOsiobe Ewomazino100% (1)

- SINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONDokument12 SeitenSINOPEC JSA For HDPE PIPE & ACCESSORIES INSTALLATIONtusharDJNoch keine Bewertungen

- JSA For Blower Cyclone and Duct Installation - Revision 004Dokument8 SeitenJSA For Blower Cyclone and Duct Installation - Revision 004WilsonNoch keine Bewertungen

- Jsa n2 Purging PDF FreeDokument1 SeiteJsa n2 Purging PDF FreeSKH CultureNoch keine Bewertungen

- JSA-020-Safety Watch-Hot WorkDokument2 SeitenJSA-020-Safety Watch-Hot WorkNishad MuhammedNoch keine Bewertungen

- JSA - Dismantling CM ShedDokument4 SeitenJSA - Dismantling CM ShedvivekaramanaNoch keine Bewertungen

- Jsa Working at Height (Maintenance & Cleaning)Dokument2 SeitenJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Jsa PaintDokument2 SeitenJsa PaintKhalid NaseemNoch keine Bewertungen

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDokument14 SeitenElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- JSA For Painting Works-Hazards ControlDokument4 SeitenJSA For Painting Works-Hazards Controlkaleem0% (2)

- Copy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksDokument7 SeitenCopy (4) of JSA For HDPE Liner Fusion Welding Includes Night WorksMohammed Minhaj80% (5)

- Excavation and TrenchingDokument2 SeitenExcavation and TrenchingvikasNoch keine Bewertungen

- Job Safety Analysis (JSA) : Description Hazard ControlDokument3 SeitenJob Safety Analysis (JSA) : Description Hazard ControlRidha BennasrNoch keine Bewertungen

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDokument4 SeitenPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Noch keine Bewertungen

- Jsa For Civil Confined Space EntryDokument11 SeitenJsa For Civil Confined Space EntryKhuda BukshNoch keine Bewertungen

- JSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling ActivityDokument12 SeitenJSA For Civil Work Activity Including Installation of Shuttering, Rebar, Formwork, Concrete Work, and Backfilling Activitybagas prakoso100% (1)

- JSA For Foundation Concrete RepairDokument6 SeitenJSA For Foundation Concrete RepairOvais FarooqNoch keine Bewertungen

- JSA For Flare Pit Area Including Night WorksDokument4 SeitenJSA For Flare Pit Area Including Night WorksMohammed MinhajNoch keine Bewertungen

- JSA Cable Laying PDFDokument2 SeitenJSA Cable Laying PDFManoj WaskelNoch keine Bewertungen

- JOB SAFETY ANALYSIS - Structural PaintingDokument1 SeiteJOB SAFETY ANALYSIS - Structural PaintingSajith C PauloseNoch keine Bewertungen

- JSA FOR Concerate PlacementDokument1 SeiteJSA FOR Concerate Placementwahyu nugrohoNoch keine Bewertungen

- Job Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityDokument2 SeitenJob Safety Analysis (Jsa) : Title of Activity / Work: Hot Work ActivityJayendra PatelNoch keine Bewertungen

- JSA For Road BarrierDokument3 SeitenJSA For Road BarrierMohammed MinhajNoch keine Bewertungen

- Jsa Pipe Cutting at Fire PumpDokument5 SeitenJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNoch keine Bewertungen

- Manual Tig Welding (RRC) - Job ProcedureDokument3 SeitenManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDokument6 Seitenjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNoch keine Bewertungen

- JSA - Repair-Coating and Finition Work THDokument3 SeitenJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNoch keine Bewertungen

- JSA-Use of Temporary Energization (Power Generator)Dokument4 SeitenJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- Electrical InstallationDokument3 SeitenElectrical InstallationWalid KhelfaNoch keine Bewertungen

- Cutting ActivitiesDokument3 SeitenCutting ActivitiesWalid KhelfaNoch keine Bewertungen

- Job Safety Analysis: Required References Jsa ReviewDokument3 SeitenJob Safety Analysis: Required References Jsa ReviewMajdiSahnounNoch keine Bewertungen

- Travaux Genie Civil MTR JSADokument5 SeitenTravaux Genie Civil MTR JSAAMINNoch keine Bewertungen

- Topography SurveyDokument2 SeitenTopography SurveyAMIN100% (2)

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDokument3 SeitenLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNoch keine Bewertungen

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDokument3 SeitenLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINNoch keine Bewertungen

- JSA - Drilling ActivitiesDokument4 SeitenJSA - Drilling ActivitiesAMIN100% (1)

- Diesel RefuelingDokument3 SeitenDiesel RefuelingAMINNoch keine Bewertungen

- Diesel RefuelingDokument3 SeitenDiesel RefuelingAMINNoch keine Bewertungen

- Material Safety Data Sheet For Hobas PipeDokument3 SeitenMaterial Safety Data Sheet For Hobas Pipejunhe898Noch keine Bewertungen

- Fire Warden Monthly ChecklistDokument3 SeitenFire Warden Monthly ChecklistTichaona KwazvichasvikaNoch keine Bewertungen

- HSE Training Matrix PDFDokument3 SeitenHSE Training Matrix PDFNizar KhalidNoch keine Bewertungen

- NEBOSH International DiplomaDokument2 SeitenNEBOSH International DiplomaMohammed Khatib70% (10)

- Engineerrahim Ullah: Village Shahderai, Tehsil Kabal, District Swat, 19200, KPK, PakistanDokument3 SeitenEngineerrahim Ullah: Village Shahderai, Tehsil Kabal, District Swat, 19200, KPK, PakistanAnsarNoch keine Bewertungen

- ANSI Fall Protection Standards WebDokument8 SeitenANSI Fall Protection Standards WebMohamedSaidNoch keine Bewertungen

- iCS - L01 - Course IntroDokument36 SeiteniCS - L01 - Course IntroAli IrtazaNoch keine Bewertungen

- ZIC Royal Grease 3Dokument10 SeitenZIC Royal Grease 3UtkarshNoch keine Bewertungen

- PpeDokument7 SeitenPpeylaala8010Noch keine Bewertungen

- 5-Pole Erection & Stringing PDFDokument2 Seiten5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- Job Hazard Analysis Sample Tag Confined SpaceDokument1 SeiteJob Hazard Analysis Sample Tag Confined Spaceomer1980100% (1)

- MSDS Karl FischerDokument8 SeitenMSDS Karl FischerShelvia YunisegaNoch keine Bewertungen

- HazmatDokument55 SeitenHazmatMatthew Citta100% (4)

- Istilah-Istilah Dalam Dunia K3Dokument3 SeitenIstilah-Istilah Dalam Dunia K3MasNoch keine Bewertungen

- Monthly Fire Prevention ChecklistDokument1 SeiteMonthly Fire Prevention ChecklistgkNoch keine Bewertungen

- JSA Cable Laying PDFDokument2 SeitenJSA Cable Laying PDFManoj WaskelNoch keine Bewertungen

- Installation of Electrical Earthing System REV 2Dokument15 SeitenInstallation of Electrical Earthing System REV 2amal100% (1)

- JOB HAZARD ANALYSIS (JHA) Risk Assessment Tier (RAT 1) : Preparation of Work Documents and Work EquipmentDokument2 SeitenJOB HAZARD ANALYSIS (JHA) Risk Assessment Tier (RAT 1) : Preparation of Work Documents and Work EquipmentDarmawan OnradNoch keine Bewertungen

- Control of Exposure Through Intervention (Final)Dokument62 SeitenControl of Exposure Through Intervention (Final)Lauro CanceranNoch keine Bewertungen

- Petrofac Limited Hsseia StandardDokument15 SeitenPetrofac Limited Hsseia Standardrodman823Noch keine Bewertungen

- Example Health and Safety Policy: Setting The SceneDokument12 SeitenExample Health and Safety Policy: Setting The SceneĐiệp TítNoch keine Bewertungen

- COSHH Assessment FormDokument2 SeitenCOSHH Assessment Formmohamed atefNoch keine Bewertungen

- GSK Interview Preparation (Repaired)Dokument8 SeitenGSK Interview Preparation (Repaired)MirNoch keine Bewertungen

- Risk Assessment For Temporary ServicesDokument15 SeitenRisk Assessment For Temporary Servicesfaizan khan100% (2)

- MSDS - REINZOSIL - 70 31414 10 - (v11 GB EN) PDFDokument5 SeitenMSDS - REINZOSIL - 70 31414 10 - (v11 GB EN) PDFJuju JusmanNoch keine Bewertungen

- Method Statement TemplateDokument3 SeitenMethod Statement TemplateKayNoch keine Bewertungen

- IS 14889 JSR 2019 Safety AuditDokument4 SeitenIS 14889 JSR 2019 Safety AuditjitsssNoch keine Bewertungen

- OSHA Wallet CardsDokument2 SeitenOSHA Wallet CardsbsiofncNoch keine Bewertungen

- Health Committee MinutesDokument2 SeitenHealth Committee Minutesnqh2009100% (1)

- HIRA 008 Height Work.Dokument4 SeitenHIRA 008 Height Work.srinibas mohapatraNoch keine Bewertungen