Beruflich Dokumente

Kultur Dokumente

Risk Assessment For CABLE TRAY

Hochgeladen von

Anandu AshokanOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Risk Assessment For CABLE TRAY

Hochgeladen von

Anandu AshokanCopyright:

Verfügbare Formate

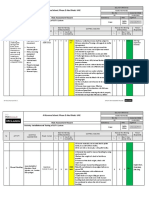

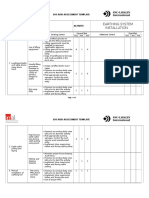

Document Reference

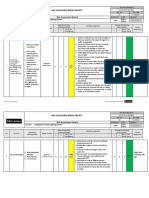

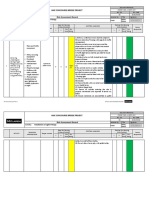

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Delivery/ collection drivers shall be subject to

McLaren induction/Training with regards to traffic

management.

2)Ensure exclusion zone is set up around the

preparation work area and all plant movement

Plant and Traffic and checked by supervisor

movement 3) Always use the pedestrian access with high

visible vest.

Run over by 4) Forklift must be tested and certified by 3rd

vehicles/plants party.

Hit by reversing 5) Daily checklist of forklift must maintained by

Delivering, equipment forklift operator

unloading and Overhead Operatives 6) Forklift Operator /banksman must be trained Site Eng.

storing of Materials

1 obstructions Staff/visitors and certified by 3rd party. Supervisor

using Pickup Van, 4 4 16 High 2 4 8 Low

Forklift, Pallet Vehicle/Forklift 7) Traffic light batons shall be provided for banks Foreman

Trolley and break down man at night

Manual Handling. Property damage 8) All plant to have a fully trained banks man

Collision with present all times.

other vehicles 9) No plant to reverse without banks man.

Falling materials 10) Ensure access route are sufficient and safe to

from Forklift use.

Over loading 11) Do not take rest in or under vehicles

Falling materials 12) Proper barricade and safety signboard

from pallet provided on open excavation

trolley 13) All vehicles must be fitted with reverse alarm

Personal injury / Flashing light.

14) The work place and all access to be well

illuminated.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

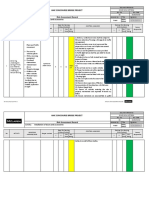

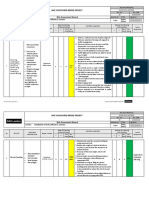

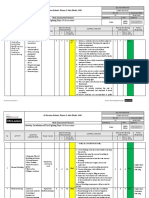

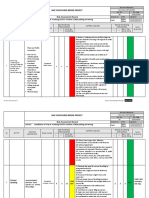

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

15) Ensure close supervision, Effective

Communication & Coordination with McLaren

16) Enforce Speed limit

17) Ensure all vehicles entering the site is

properly maintained and reported if found any

defect

18) Ensure materials are secured/tied in pallet

trolley to avoid fall from trolley.

19) Do not ride or horse play with pallet trolley?

20) All operatives must follow and use their PPE

on site.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

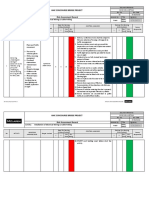

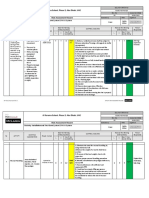

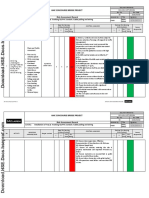

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Eliminate the need for manual handling by

using mechanical aid.

2)Reduce the weight of a load to limit force

exertion

3) If unsure of the load weight, check with

supervisor.

5)Ensure proper manual handling procedure Supervisor,

Manual musculoskeletal

Med

Operatives 6) Identify and eliminate sharp edges before any Foreman,

2 Handling disorders, Hand involved in work

Low

4 3 12 ium manual lift 1 3 3 Site Eng.

injuries, cut , bruises

7) Ensure adherence with sufficient and

Sharp edges

appropriate PPE.

8) Limit load carrying to 20kg per person

9) Supervisor must make sure while manual

handling load individual task and environment to

be considered to reduce the risk of manual

handling.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

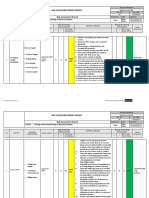

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

1) Ensure accesses are kept clear at all times.

2)Housekeeping to be carried out regularly

throughout the day when required

3)Supervisor to ensure operatives are stacking

material neatly and stacks are stable and in a safe

condition

4)Provide adequate lighting especially during

night hours

Operatives 5) Appropriate space is allowed around storage Supervisor,

Slips, Trips and fall Staff/storekeeper Med areas for employees to move around safely Foreman,

3 Material storing Poor house keeping 3 4 12 without the risk being trapped between stacked

1 4 4 Low

ium Site Eng.

materials.

6) Maintain good housekeeping.

7) Fire Extinguisher in place and do not obstruct

with materials

8) No smoking and no loose connection in storage

area

9) First Aid arrangement in place

Erection and 1) Ensure PTW to be in place.

Incorrect sequence/

4 dismantling of 2) Only trained persons(certified) are authorized

Improper erection

Mobile to build towers in line with manufacturer’s

and dismantling of Supervisor,

scaffolding for All operatives instructions which must then be inspected and

Installation of

scaffold

involved in 4 4 16 High tagged by a competent person (scaffold 1 4 4 Low Foreman,

GI/PVC Conduits work inspector) Site Eng.

Fall of person

and Tray and 3) Ensure that all personnel involved in the task

Falling Objects

Trunking including understand the hazard and risk involved related

cable lying. to the task.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

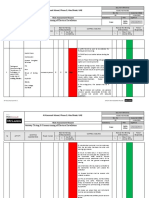

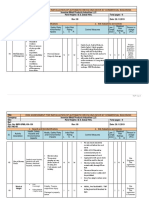

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

4) Area inspected prior to where structure is to

be erected.

5) Guard rails and toe boards to be used for all

working platforms

6) Provide safe access to scaffold platforms

7) Do not climb cross-bracing as a means of

access

8) All operatives working on height must wear full

body harness and hooked in secured place.

Installation of Overturning of Operatives/Staff/ 4 1) Only trained and authorised personnel to carry 1 5 5

Visitors 4 16 out the task.

GI/PVC Conduits Mobile scaffold Low

Others 2) Ensure the PTW in place and task briefing by

and Tray Fall of person

Falling objects supervisor to work force. Supervisors

/Trunking/Cable

Angle Grinder for GI 3) Ensure proper working platform with complete Foreman,

pulling and fall protection

Tray cutting Site Eng.

Laying using 4) Secure the tools and objects kept on the

Hot work

Mobile platform

Entanglement

Scaffolding. 5) Ensure safe access to the working platform.

Using solvent for

5

PVC conduit joints High 6) Ensure Full body harness and 100% tie off

Dust 7) Ensure the scaffold platform is properly

Use of threading Die erected with "Safe to use" tag.

for GI conduit 8) Ensure castor wheels are locked and out rigger

Sharp edge of in place.

existing Tray 10) Hand tools must be secured/tethered

Major injury 11) Hot work permit to be obtained and ensure

that there is no combustible materials near

cutting work.

12) Ensure Fire extinguisher in place with fire

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

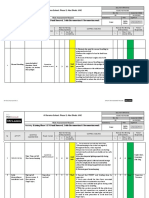

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

blanket to protect the Fire flux

13) Ensure cutting wheel must be from standard

company and inspect before use.

14) Angle grinder must inspected by competent

electrician and maintain record.

.

15) Ensure operatives must alert while using

cutting tools for their clothing to avoid

entanglement with moving parts.

16) Angle grinder must have safety guard and

operatives must use face shield.

17) Dust mask and noise protection must use.

18) Safety data sheet and COSHH assessment

must briefed to the operatives before using any

chemicals and solvent.

19) Maintain good housekeeping.

20) PPE must be in use for every task.

21 While cable pulling activity need close

supervision and with good communication

22) Roller to be use safety to pull the cable and

secured to avoid fall from height.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

Cable glanding and

1. PAT test to be conduct and maintain register.

termination

2) All the power tools must be 110 volt and safe to use

(Not energized)

3.All power supplies should be installed & connected

using drill machine Physical Injuries like

by a competent electrician.

and hole show laceration, foreign

4). RAMS to be briefed to the operatives before start

cutter. parts in eyes, finger

6 the activity and maintain the record. Supervisor,

injury All

5.Hot work permit to be obtained and work area must Foreman,

Entanglement with operatives 4 4 16 High 2 4 8 Low

free from combustible item Safety officer

sharp edge tools involved

6. Fire extinguisher in place with fire blanket.

Noise and dust

7. Noise protection to be use

Spark and Fire

8) Eye protection must be used.

9) Operatives should alert while using sharp edge tools

to avoid entanglement with clothing.

10) Close supervision and necessary PPE.

1. Prepare the working area for a good working

condition.

2.All workers should wear high visibility vest and PPE

Physical injuries,

3. Ensure that the working area is well-ventilated.

Working in poor Slips, trips & falls, Site engg

All personnel in Medi 4.Wear goggles & face mask when working in a dusty

7 visibility/dust Health effects – eye 3 4 12 1 4 4 Low Supervisors,

the work area um place

condition damage/respiratory Foreman

5. TBT conducted by supervisor.

diseases.

6.First aider and first aid kit available on the site

7) Ensure that work area must have proper illumination

8) Maintain good house keeping

Use of Ladder 1) Only light work, off short duration and work in

which the operative can maintain secure hand

Supervisor

Med and foot hold can be undertaken form a ladder

8 Falling from height Operatives 3 4 12 2 4 8 Low Foreman,

ium 2) Never try to overreach with any ladders

3) Check the ladder is of suitable quality for Site Eng.

industrial use and is in good condition

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

4) Check the inclination of the ladder conforms to

the one-in-four rule.

5) Maintain a minimum of 3 points of contact

with stepladders always (feet/thighs/hands)

If possible avoid the use of stepladders at a

working height of 2 meters and more.

6) Check the ladder legs (and stays) are fully

deployed or locked (depending on type) to

maintain maximum base dimensions and the step

ladder is orientated to provide maximum stability.

1) All portable electrical equipment must be PAT

Damaged cable tested and color coded. Make sure the test dates

insulation, are visible on the equipment.

Sockets. 2)Ensure all power tools are in good condition

Electrocution and appropriately maintained

Electric shock 3) PTW to be obtained, prior to commencing the

Use of power Short circuit task

tools such as Electric burn 4) Damaged industrial sockets and power cables Supervisor

Operatives

9 angel grinder, Trip/Fall 4 5 20 High must be removed. 1 5 5 Low Foreman

Drill machine, Noise

and staff

5) Ensure the electrical cable is not damaged and Site eng.

Jack Hammer Hearing loss

has not been repaired with insulating tape or

Vibration

unsuitable connectors.

Dust

6) Ensure cables from power tools shall be

organized so as not to present a tripping hazard

7) Only trained competent operatives to operate

the power tools.

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

8) Ensure proper and regular maintenance of

equipment that takes account of noise

9) Ensure proper hearing protection always.

10) Make sure people use the right tool for the

job and are trained to use it correctly

11) Ensure defective tools that requires

maintenance is reported for repair or

replacement.

12) Instruct workers to keep their hands warm

and dry, and to not grip a vibrating tool too

tightly. Workers should allow the tool or machine

to do the work.

13) Ensuring proper job rotation and limiting

time operatives working with power tools and

hand tools.

14) use dust mask

Improper selection 1) Hand tools should be visually inspected for Site engg

of hand tools. defects, prior to use. Supervisor

Damaged and Operatives/Staf 2) Never use damaged, blunt or broken tools to Foreman

Defective Hand f avoid injury.

tools 3) Select right tools for right Job

Hand injuries Med 4) Ensure no Homemade or makeshift tools to be

10 Use of Hand tools 3 3 9 2 2 4 Low

Pinch point ium used at site

Ergonomics 5) Remove from service any tool that shows signs

Repetitive strain of damage or defect

injury 6) Ensure Hand tools are Stored in accordance

with the manufacturer’s instructions.

7) Ensure hands are not in direct line of fire while

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

Document Reference

AMC CONCOURSE BRIDGE PROJECT MCL-ME-A-MST-MSS-004

Rev. No. Rev. Date

00 20/02/02019

Risk Assessment Record Assessed by Title Signature

Activity: Installation of Tray & Trunking/GI/PVC Conduit /Cable pulling and wiring Safety

Prabir

Officer

Base Risk Ranking Residual Risk Ranking

CONTROL MEASURES

IDENTIFIED (Without Controls) (With Controls) Person

No ACTIVITY People Involved

HAZARDS/RISKS Risk Risk Risk Risk Responsible

L S L S

Score Rating Score Rating

working with hand tools

6) Ensure appropriate PPE always.

Approved By: Name PRABIR KUMAR Position _HSE_________ Signature _____ ____

SAF-010 (UAE) 03/18 Rev D SPECIFIC RISK ASSESSMENT RECORD

RISK ASSESSMENT & CONTROL GUIDELINES

1. Executing Steps:

1.1. Planning

a) Construction and HSE team must ensure that hazard identification is complete.

b) Construction and HSE team must prioritize the hazard issues, which are of significant in nature. (It means that risks have well

established legal requirements, potentially high risks).

c) Construction and HSE team to prepare the risk assessment plan for the priorities identified hazards for these potential high

risks.

1.2. Risk Assessment

Risk is the probability of an event occurring in a given set of circumstances. The ‘event’ is an exposure to hazard. The hazard is the

potential to cause harm. The risk assessment is the technique of evaluating not just the likelihood of an event occurring, but also the

outcome will be in terms of injury, loss, damage or harm.

1.3. Risk Assessment Process

The process of carrying out a risk assessment should be as follows.

1. Identify the hazards.

2. Identify who might be harmed and how.

3. Evaluate the risk and implement the control measures.

4. Record the significant findings.

5. Review the assessment and update if necessary.

1.4. Examination of the Hazards and Risk Associated

Competent staff must be used in examining the risk associated with the identified hazard.

Competent staff should examine following aspect to determine the risk involved:

o Examine the existing control measures in place.

o Identify employees at risk.

o Likelihood of risk.

o Severity

o Risk level and their tolerability.

1.5. Evaluating the risk:

Once the necessary information has been obtained on the hazards encountered by work activities, next stage is to access the risks.

1.5.1. Risk Rating Score

Risk rating score is a combination of two factors.

The severity of the risk that could injure persons or cause damage to plant.

The likelihood of the risk that it could happen (Probability).

RISK RATING = LIKELIHOOD X SEVERITY

NOTE: Each activity has to be assessed for the risk value for determining the level of Severity and likelihood are mentioned in the table

below.

No Injury Minor Moderate Major

Catastrophic (5)

(1) Injury (2) Injury (3) Injury (4)

1 2 3 4 5

Rarely (1)

Unlikely (2) 2 4 6 8 10

LIKELIHOOD Possible (3) 3 6 9 12 15

Likely (4) 4 8 12 16 20

Almost

5 10 15 20 25

RISK LEVEL: Certain (5)

Low Medium High

SAF-010 (UAE) 03/18 Rev C SPECIFIC RISK ASSESSMENT RECORD

Das könnte Ihnen auch gefallen

- Risk Assessment For Installation of Drainage PipesDokument17 SeitenRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Drainage PipesDokument17 SeitenRisk Assessment For Installation of Drainage PipesAnandu Ashokan97% (34)

- Risk Assessment For Installation of Fire Fighting SystemDokument20 SeitenRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (32)

- Cable PullingDokument4 SeitenCable Pullingmykelrenz90% (10)

- Risk Assessment For Installation of Fire Fighting SystemDokument20 SeitenRisk Assessment For Installation of Fire Fighting SystemAnandu Ashokan91% (32)

- Risk Assessment For Installation of Water Supply PipeDokument18 SeitenRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Installation of Water Supply PipeDokument18 SeitenRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Risk Assessment For Structured CablingDokument7 SeitenRisk Assessment For Structured CablingAnandu Ashokan67% (6)

- Risk Assessment For Installation of Ducts and AccessoriesDokument17 SeitenRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- Risk Assessment For Installation of Ducts and AccessoriesDokument17 SeitenRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan85% (13)

- Risk Assessment For Installation of Light FittingsDokument11 SeitenRisk Assessment For Installation of Light FittingsAnandu Ashokan88% (8)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDokument13 SeitenRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For Testing and Commissioning of Electrical SystemDokument8 SeitenRisk Assessment For Testing and Commissioning of Electrical SystemAnandu Ashokan100% (8)

- Risk Assessment For Testing and Commissioning of Electrical SystemDokument7 SeitenRisk Assessment For Testing and Commissioning of Electrical Systemvo100% (2)

- Risk Assessment For Installation and Testing of CCTVDokument11 SeitenRisk Assessment For Installation and Testing of CCTVAnandu Ashokan100% (5)

- Method Statement For Structured Cabling System InstallationDokument9 SeitenMethod Statement For Structured Cabling System InstallationAnandu Ashokan50% (2)

- Risk Assessment For Installation & Testing Commissioning of PumpsDokument17 SeitenRisk Assessment For Installation & Testing Commissioning of PumpsAnandu Ashokan75% (8)

- Risk Assessment For MEP Isolation WorksDokument8 SeitenRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Risk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control BuildingDokument14 SeitenRisk Assessment - Cable Pulling Laying, Glanding and Termination From RT Bay Outdoor Enclosure To RT Control Buildingnsadnan91% (82)

- Risk Assessment For Installation of Grill, Diffuser and LouversDokument13 SeitenRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Grill, Diffuser and LouversDokument13 SeitenRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- Risk Assessment For Installation of Fan Coil UnitsDokument18 SeitenRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation & Testing of BMS UnitDokument15 SeitenRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Risk Assessment For Installation of Fan Coil UnitsDokument18 SeitenRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of Air Handling UnitsDokument19 SeitenRisk Assessment For Installation of Air Handling UnitsAnandu Ashokan100% (8)

- Risk Assessment For Installation of HVAC Systems (RA34)Dokument19 SeitenRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment For Installation of Fire Alarm System & PAVA SystemDokument11 SeitenRisk Assessment For Installation of Fire Alarm System & PAVA SystemAnandu Ashokan88% (8)

- Risk Assessment For Installation of Sanitary WaresDokument14 SeitenRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of SMDB&DBDokument15 SeitenRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Risk Assessment For Installation of Toilet Exhaust FanDokument11 SeitenRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Risk Assessment For Cable InstallationDokument15 SeitenRisk Assessment For Cable InstallationKaruppu Samy86% (7)

- Risk Assesment For Electrical Testing and Commissioning.Dokument6 SeitenRisk Assesment For Electrical Testing and Commissioning.Francis Enriquez Tan83% (12)

- Testing and Commissioning of BMS Rev ADokument8 SeitenTesting and Commissioning of BMS Rev Aanish7785100% (3)

- Risk Assessment For Testing & Commissioning of Fire Fighting SystemDokument17 SeitenRisk Assessment For Testing & Commissioning of Fire Fighting SystemAnandu Ashokan92% (12)

- The Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4Dokument2 SeitenThe Manuals Com Cost Accounting by Matz and Usry 9th Edition Manual Ht4ammarhashmi198633% (12)

- Risk Assessment of Installation of Chilled Water PipesDokument19 SeitenRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- Risk Assessment For Installation of HVAC Duct and AccessoriesDokument15 SeitenRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment (Electric Works)Dokument4 SeitenRisk Assessment (Electric Works)Raza Muhammad Soomro100% (3)

- Risk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEDokument18 SeitenRisk Assessment For .TESTING AND COMMISSIONING OF 11 KV CABLEarun kurlan89% (9)

- Risk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Dokument12 SeitenRisk Assessment For Testing & Commissioning of Electrical Installation (Modefied)Anandu Ashokan100% (1)

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Dokument6 Seiten012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Method Statement For Cable Tray and Truncking InstallationDokument9 SeitenMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For Water Heaters InstallationDokument9 SeitenMethod Statement For Water Heaters InstallationAnandu Ashokan100% (1)

- Risk Assessment For MEP Services in P6 Existing ParkingDokument16 SeitenRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Dokument12 SeitenRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk Assessment For Installation and Testing of ACS (RA33)Dokument11 SeitenRisk Assessment For Installation and Testing of ACS (RA33)Anandu Ashokan100% (3)

- Amc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineDokument8 SeitenAmc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineEm Niax100% (1)

- Risk Assessment For Installation of Grill, Diffuser & Louvers RA 36Dokument12 SeitenRisk Assessment For Installation of Grill, Diffuser & Louvers RA 36Anandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting Pipe & AccessoriesDokument15 SeitenRisk Assessment For Installation of Fire Fighting Pipe & AccessoriesAnandu Ashokan83% (6)

- Risk Assessment For Integration of FACP, PAVA & ELV SystemDokument11 SeitenRisk Assessment For Integration of FACP, PAVA & ELV SystemAnandu Ashokan100% (1)

- Electrical Risk AssessmentDokument6 SeitenElectrical Risk AssessmentRaul Moyo100% (2)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDokument8 SeitenRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDokument9 SeitenRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Method Statement For Earthing and Lightning ProtectionDokument12 SeitenMethod Statement For Earthing and Lightning ProtectionAnandu Ashokan100% (1)

- Method Statement For Drainage Pipes InstallationDokument11 SeitenMethod Statement For Drainage Pipes InstallationAnandu Ashokan100% (4)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDokument11 SeitenMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Method Statement LV Distribution Boards InstallationDokument9 SeitenMethod Statement LV Distribution Boards InstallationAnandu Ashokan100% (1)

- Method Statement For Wiring Accessories InstallationDokument9 SeitenMethod Statement For Wiring Accessories InstallationAnandu AshokanNoch keine Bewertungen

- RAMS EvaluationDokument3 SeitenRAMS EvaluationAnandu AshokanNoch keine Bewertungen

- MS For Installation of Grills, Diffuser & LouversDokument21 SeitenMS For Installation of Grills, Diffuser & LouversAnandu AshokanNoch keine Bewertungen

- Course Recorder (Paperless) MDR290Dokument4 SeitenCourse Recorder (Paperless) MDR290Jay SanchaniyaNoch keine Bewertungen

- Risk Assessment For Installation of SMDB DBDokument12 SeitenRisk Assessment For Installation of SMDB DBRAMA100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDokument12 SeitenRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Toilet Exhaust Fan (New)Dokument12 SeitenRisk Assessment For Installation of Toilet Exhaust Fan (New)Anandu AshokanNoch keine Bewertungen

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDokument17 SeitenRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- MS For Installation of Light FittingsDokument11 SeitenMS For Installation of Light FittingsAnandu Ashokan100% (2)

- Risk Assessment For Installation of MDBSMDB DB (Modified)Dokument15 SeitenRisk Assessment For Installation of MDBSMDB DB (Modified)Anandu Ashokan100% (1)

- Risk Assessment For Temporary ServicesDokument15 SeitenRisk Assessment For Temporary Servicesfaizan khan100% (2)

- NPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemDokument15 SeitenNPCL Project Chennai Risk Assessment Record: Activity: Installation of Fire Fighting SystemabbasNoch keine Bewertungen

- Risk Assessment For Modification of Phase 1 Existing Building GPR TankDokument15 SeitenRisk Assessment For Modification of Phase 1 Existing Building GPR TankAnandu Ashokan100% (1)

- Risk Assessment For Dismantling of Temporary ServicesDokument17 SeitenRisk Assessment For Dismantling of Temporary ServicesAnandu AshokanNoch keine Bewertungen

- Risk Assessment of Conduit Pipe InstallationDokument17 SeitenRisk Assessment of Conduit Pipe InstallationJayson Escamillan75% (4)

- Risk Assessment For .TESTING AND COMMISSIONING OF LV CABLEDokument19 SeitenRisk Assessment For .TESTING AND COMMISSIONING OF LV CABLEarun kurlan100% (3)

- 63 Risk Assesments Testing and Pre-Commissioning WorksDokument18 Seiten63 Risk Assesments Testing and Pre-Commissioning WorksEngr.Syed Amjad100% (3)

- For CABLE TRAY AssessmentDokument10 SeitenFor CABLE TRAY AssessmentIliyanPetrovNoch keine Bewertungen

- Risk-Assessment Ducts & AccessoriesDokument13 SeitenRisk-Assessment Ducts & AccessoriesMohammed Amer PashaNoch keine Bewertungen

- Risk Assessment of Installation of Chilled Water PipesDokument20 SeitenRisk Assessment of Installation of Chilled Water PipesJomy JohnyNoch keine Bewertungen

- RA For Cable Pulling and WiringDokument11 SeitenRA For Cable Pulling and Wiringnikhilsingh1087Noch keine Bewertungen

- Method Statement For PPR Pipes and Fittings InstallationDokument9 SeitenMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For GI Conduits InstallationDokument9 SeitenMethod Statement For GI Conduits InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For PEX Pipes and Fittings InstallationDokument9 SeitenMethod Statement For PEX Pipes and Fittings InstallationAnandu AshokanNoch keine Bewertungen

- Method Statement For Fire Alarm and Emergency System InstallationDokument9 SeitenMethod Statement For Fire Alarm and Emergency System InstallationAnandu Ashokan100% (1)

- Method Statement For PVC Conduits InstallationDokument9 SeitenMethod Statement For PVC Conduits InstallationAnandu AshokanNoch keine Bewertungen

- MS For Installation of Sanitary WaresDokument22 SeitenMS For Installation of Sanitary WaresAnandu AshokanNoch keine Bewertungen

- MS For Installation of Duct & AccessariesDokument21 SeitenMS For Installation of Duct & AccessariesAnandu Ashokan100% (1)

- MS - Installation of Water Supply PipeDokument20 SeitenMS - Installation of Water Supply PipeAnandu Ashokan100% (1)

- MS For Installation of FCUDokument20 SeitenMS For Installation of FCUAnandu AshokanNoch keine Bewertungen

- MS For Installation of Drainage PipesDokument20 SeitenMS For Installation of Drainage PipesAnandu Ashokan100% (1)

- MS For Installation of Toilet Exhaust FanDokument20 SeitenMS For Installation of Toilet Exhaust FanAnandu AshokanNoch keine Bewertungen

- MS For Installation of FF Pipes FittingsDokument23 SeitenMS For Installation of FF Pipes FittingsAnandu Ashokan100% (1)

- Goldwallet 2.1.1Dokument16 SeitenGoldwallet 2.1.1yanuarNoch keine Bewertungen

- Non Domestic Building Services Compliance GuideDokument76 SeitenNon Domestic Building Services Compliance GuideZoe MarinescuNoch keine Bewertungen

- Seminarski RadDokument32 SeitenSeminarski RadAdmir KlinčevićNoch keine Bewertungen

- Topaz Towers In-Building DASDokument25 SeitenTopaz Towers In-Building DASSudheera IndrajithNoch keine Bewertungen

- Chapter 17, E-Learning: 2001 Prentice Hall, Inc. All Rights ReservedDokument22 SeitenChapter 17, E-Learning: 2001 Prentice Hall, Inc. All Rights ReservedmarianNoch keine Bewertungen

- A Handbook of Livestock and Poultry Best Management PracticeDokument87 SeitenA Handbook of Livestock and Poultry Best Management PracticeRaymond Katabazi100% (2)

- Bus Bar Schemes: Submitted By: Under Guidance ofDokument26 SeitenBus Bar Schemes: Submitted By: Under Guidance ofHumeraNoch keine Bewertungen

- Unit of Work Football Y9Dokument5 SeitenUnit of Work Football Y9api-282209830Noch keine Bewertungen

- 7GCBC PohDokument75 Seiten7GCBC PohEyal Nevo100% (1)

- Sony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Dokument94 SeitenSony Chassis Ba-4 (C-TV KV-13M40 - 50 - 51, KV-14MB40, KV-20M40, KV-20S40 - 41, KV-20V80, Kv-21se80, Kv-21se40, Kv-21me40... Service Manual)Mauro Mendez100% (1)

- Total Productive Maintenance WorksheetDokument2 SeitenTotal Productive Maintenance WorksheetSeda De Drasnia100% (1)

- PDFDokument7 SeitenPDFJose JohnNoch keine Bewertungen

- 12556/gorakhdham Exp Third Ac (3A)Dokument2 Seiten12556/gorakhdham Exp Third Ac (3A)Lovkesh GoyalNoch keine Bewertungen

- Position PaperDokument7 SeitenPosition PaperClem CollantesNoch keine Bewertungen

- Model 7691Dokument1 SeiteModel 7691Khiết trầnNoch keine Bewertungen

- Thrust Bearing Design GuideDokument56 SeitenThrust Bearing Design Guidebladimir moraNoch keine Bewertungen

- Ds Lm5006 en Co 79839 Float Level SwitchDokument7 SeitenDs Lm5006 en Co 79839 Float Level SwitchRiski AdiNoch keine Bewertungen

- Committee Report PDFDokument72 SeitenCommittee Report PDFVivek BadkurNoch keine Bewertungen

- Introducing Maf and Mef Frameworks: Exploring Managed Addin FrameworkDokument9 SeitenIntroducing Maf and Mef Frameworks: Exploring Managed Addin Frameworkkris2tmgNoch keine Bewertungen

- RSC 406 (English)Dokument11 SeitenRSC 406 (English)Tuấn DũngNoch keine Bewertungen

- Lesson13ToeIn ToeOut PDFDokument5 SeitenLesson13ToeIn ToeOut PDFNurSafitriNoch keine Bewertungen

- Colebrook EquationDokument3 SeitenColebrook EquationMuhammad Ghufran KhanNoch keine Bewertungen

- EPA 2010 ATS and DEF Modification GuideDokument30 SeitenEPA 2010 ATS and DEF Modification GuideRodolfo Alberto Muñoz CarcamoNoch keine Bewertungen

- Remuz TreeDokument608 SeitenRemuz TreeEdward JonesNoch keine Bewertungen

- Technical Data: Digital and Millivolt Gas HeatersDokument2 SeitenTechnical Data: Digital and Millivolt Gas HeatersDenis CuraNoch keine Bewertungen

- Filtration 2Dokument5 SeitenFiltration 2Ramon Dela CruzNoch keine Bewertungen

- 1213-23-Si-Og RR GecDokument8 Seiten1213-23-Si-Og RR Gecvkj5824Noch keine Bewertungen

- Harley DavidsonDokument40 SeitenHarley Davidsonristosk100% (1)