Beruflich Dokumente

Kultur Dokumente

Hshs

Hochgeladen von

IR MA Al AzharCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hshs

Hochgeladen von

IR MA Al AzharCopyright:

Verfügbare Formate

Pulp & Paper

Applying the Digital Twin

to Kamyr Digesters

Dynamic simulation with Mimic Simulation Software provides a

high-performance solution for operator training and control system

optimization. This Digital Twin technology delivers the complete

Mimic Simulation Software

environment for control system optimization and is an effective tool Train operators on

for teaching process and control engineers the control and operation infrequent and dangerous

process occurrences

of kamyr digesters.

Kamyr Digester Modeling Test control system

enhancements

Solutions for pulp and paper facilities include dynamic models of the

following process areas: Transfer knowledge

from seasoned to

White liquor and chip feeder mixing inexperienced operators

Digester with circulating liquor

Increase overall

Multiple cook zones plant safety

Wash region

Upper and Lower Heaters

Used liquor extraction

Application Capabilities

Continuous Digester

Dynamic real time mass and energy balances for individual chip Tunable reaction rate constants (activation energies, pre-

components including lignin, cellulose, hemicellulose and resins. exponential factors, and reaction orders) for both, forward and

reverse reactions.

Dynamic Vapor Liquid Equilibrium Balance accounting for

reaction mixture interaction with external streams, chemical Flexible Heat Transfer models characterized to actual tube

transformations due to the reaction kinetics. or shell design.

Configurable thermodynamic activities and enthalpy correction Instructor controls for feed composition and digester KPIs

factors to account for mixture non-idealities. (Kappa, etc).

Reaction modeling using the power law dependencies with the

Arrhenius type equation for reaction rate constants.

Pulp & Paper

Instructor Station

Instructor controls in Mimic and instructor screens in Mimic easy access in one location. Typical controls allow instructors to

Component Studio allow your training team to prepare for working manipulate operating conditions, such as boundary conditions and

with the control system and process. Any element in Mimic can compositions, introduce ad-hoc device failures, control scripted

be manipulated or controlled, and instructor screens provide training scenarios, and restore snapshots to steady-state operations.

Operating Conditions Ad-Hoc Process

Manipulate feeds, compositions, and Switches for individual

other boundary conditions. unit failures.

Process Snapshots Scripted Scenarios

Control and restore full Pre-engineered scenarios with

steady-state, cold, or other dynamic representation of

plant conditions. student scores.

Emerson

North America, Latin America:

+1 800 833 8314 or

+1 512 832 3774 ©2019, Emerson. All rights reserved.

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property

Asia Pacific:

of their respective owners.

65 6777 8211

The contents of this publication are presented for informational purposes only, and while diligent efforts

Europe, Middle East: were made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

+41 41 768 6111 or implied, regarding the products or services described herein or their use or applicability. All sales are

governed by our terms and conditions, which are available on request. We reserve the right to modify

www.emerson.com/mimic or improve the designs or specifications of our products at any time without notice.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Lamella Settler E10800Dokument8 SeitenLamella Settler E10800IR MA Al AzharNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Schedule Modify Line To Screen HDTDokument1 SeiteSchedule Modify Line To Screen HDTIR MA Al AzharNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Growing Our Tomorrow Growing Our Tomorrow Growing Our Tomorrow Growing Our TomorrowDokument4 SeitenGrowing Our Tomorrow Growing Our Tomorrow Growing Our Tomorrow Growing Our TomorrowIR MA Al AzharNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- KbiagdcDokument1 SeiteKbiagdcIR MA Al AzharNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- M PL AT E: PRW Pulp SGA Competition 2020Dokument8 SeitenM PL AT E: PRW Pulp SGA Competition 2020IR MA Al AzharNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- FIBERLINE 1 PROGRESS REPORTDokument4 SeitenFIBERLINE 1 PROGRESS REPORTIR MA Al AzharNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- PRW Pulp SGA Competition 2021: Topic: Menurunkan Pemakaian WL Dari 0,328T/TP To 0,309T/TP Selama 6 BulanDokument8 SeitenPRW Pulp SGA Competition 2021: Topic: Menurunkan Pemakaian WL Dari 0,328T/TP To 0,309T/TP Selama 6 BulanIR MA Al AzharNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 28° North: Pt. Indah Kiat Pulp & Paper TBKDokument1 Seite28° North: Pt. Indah Kiat Pulp & Paper TBKIR MA Al AzharNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Schedule Modify Line To Screen HDTDokument1 SeiteSchedule Modify Line To Screen HDTIR MA Al AzharNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Casing Cover: Av, BV, CV, DV Control Unit Assembly CustomerDokument1 SeiteCasing Cover: Av, BV, CV, DV Control Unit Assembly CustomerIR MA Al AzharNoch keine Bewertungen

- Optimized D2 P&ID overviewDokument34 SeitenOptimized D2 P&ID overviewIR MA Al AzharNoch keine Bewertungen

- LT 123LC536 123FC681Dokument13 SeitenLT 123LC536 123FC681IR MA Al AzharNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Fiberline 1 - SD Mmf-Os Job List Progress Report Apr 2021Dokument23 SeitenFiberline 1 - SD Mmf-Os Job List Progress Report Apr 2021IR MA Al AzharNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Spanner 24mm 2Pc, Spanner 30mm 2Pc, Hammer 2pcDokument1 SeiteSpanner 24mm 2Pc, Spanner 30mm 2Pc, Hammer 2pcIR MA Al AzharNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Fl1a El SD Joblist 20210406Dokument8 SeitenFl1a El SD Joblist 20210406IR MA Al AzharNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

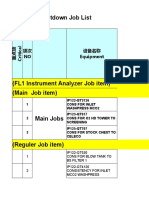

- SH Utd Ow N Job ListDokument6 SeitenSH Utd Ow N Job ListIR MA Al AzharNoch keine Bewertungen

- 2021 FL1 Shutdown Job List: Unit: MTD-MIADokument114 Seiten2021 FL1 Shutdown Job List: Unit: MTD-MIAIR MA Al AzharNoch keine Bewertungen

- FL1A SD Joblist Januari FRP 20210406Dokument11 SeitenFL1A SD Joblist Januari FRP 20210406IR MA Al AzharNoch keine Bewertungen

- Spanner 24mm 2Pc, Spanner 30mm 2Pc, Hammer 2pcDokument1 SeiteSpanner 24mm 2Pc, Spanner 30mm 2Pc, Hammer 2pcIR MA Al AzharNoch keine Bewertungen

- Maintenance Division Head, MIF Unit HeadDokument1 SeiteMaintenance Division Head, MIF Unit HeadIR MA Al AzharNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Rules of Thumb: Tanks and VesselsDokument4 SeitenRules of Thumb: Tanks and VesselsIR MA Al AzharNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- KbiagdcDokument1 SeiteKbiagdcIR MA Al AzharNoch keine Bewertungen

- Brown Stock Screening EquipmentDokument15 SeitenBrown Stock Screening EquipmentIR MA Al AzharNoch keine Bewertungen

- FIBERLINE 1 PROGRESS REPORTDokument4 SeitenFIBERLINE 1 PROGRESS REPORTIR MA Al AzharNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- 248-AprosDemo Installation GuideDokument12 Seiten248-AprosDemo Installation GuideIR MA Al AzharNoch keine Bewertungen

- IP120Dokument51 SeitenIP120IR MA Al AzharNoch keine Bewertungen

- Valmet: Wastewater GuideDokument45 SeitenValmet: Wastewater GuideIR MA Al AzharNoch keine Bewertungen

- PM1A washer equipment functional descriptionsDokument54 SeitenPM1A washer equipment functional descriptionsIR MA Al AzharNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- IP124Dokument90 SeitenIP124IR MA Al AzharNoch keine Bewertungen

- IP121Dokument33 SeitenIP121IR MA Al AzharNoch keine Bewertungen

- MCQ Electromagnetism Self-AssessmentDokument2 SeitenMCQ Electromagnetism Self-AssessmentJunaidKhanNoch keine Bewertungen

- STAAD Service Stage and Seismic Analysis ResultsDokument14 SeitenSTAAD Service Stage and Seismic Analysis ResultsVikasNoch keine Bewertungen

- Thermodynamics of Weak Electrolytes Including H3PO4Dokument10 SeitenThermodynamics of Weak Electrolytes Including H3PO4buhalnitaNoch keine Bewertungen

- Hamilton-Jacobi-Bellman Equation ExplainedDokument7 SeitenHamilton-Jacobi-Bellman Equation ExplainedMakinita CerveraNoch keine Bewertungen

- Heat Transfer Chapter 1 IntroductionDokument68 SeitenHeat Transfer Chapter 1 IntroductionsubratorajNoch keine Bewertungen

- 85 Describing Motion OrganizerDokument10 Seiten85 Describing Motion OrganizerFernando Sorto50% (2)

- Stp417-Eb 5820 PDFDokument219 SeitenStp417-Eb 5820 PDFS R Kumar KonathalaNoch keine Bewertungen

- Performance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameDokument7 SeitenPerformance-Based Plastic Design and Energy-Based Evaluation of Seismic Resistant RC Moment FrameARJafariNoch keine Bewertungen

- University of Engineering and Technology Peshawar, PakistanDokument54 SeitenUniversity of Engineering and Technology Peshawar, PakistanJoachim GardNoch keine Bewertungen

- Physics Questions Part 3Dokument8 SeitenPhysics Questions Part 3Muhammad HuzaifaNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Controls Exit OTDokument13 SeitenControls Exit OTJeffrey Wenzen AgbuyaNoch keine Bewertungen

- BelowsDokument35 SeitenBelowstejassidhpuraNoch keine Bewertungen

- Radar PlottingDokument23 SeitenRadar Plottingthugsdei100% (2)

- Thermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KDokument17 SeitenThermodynamic Study On Density and Viscosity of Binary Mixtures of Ethyl Acetoacetate With (C4-C9) Aliphatic Ketones at (303.15 and 308.15) KInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Parameter Estimation of Single Diode PV Module Based On GWO AlgorithmDokument12 SeitenParameter Estimation of Single Diode PV Module Based On GWO AlgorithmFelicia Itusaca CcariNoch keine Bewertungen

- Harmonic Oscillator & Rigid Rotor ModelsDokument14 SeitenHarmonic Oscillator & Rigid Rotor ModelsJisu RyuNoch keine Bewertungen

- Information Folder LUCCON PDFDokument9 SeitenInformation Folder LUCCON PDFASHOKKUMAR ENoch keine Bewertungen

- Interference PatternsDokument8 SeitenInterference PatternsAsa mathewNoch keine Bewertungen

- Testing of Rigid Plastic ContainersDokument22 SeitenTesting of Rigid Plastic ContainersBhupendra Singh100% (12)

- GannZilla User GuideDokument20 SeitenGannZilla User GuideNiladri Jana100% (26)

- Applying IGBTs - 5SYA 2053-04 PDFDokument22 SeitenApplying IGBTs - 5SYA 2053-04 PDFbacuoc.nguyen356Noch keine Bewertungen

- Slide Micro Teaching 5.3Dokument18 SeitenSlide Micro Teaching 5.3Mastura MohamadNoch keine Bewertungen

- Love My LifeDokument5 SeitenLove My LifeLinda Veronica0% (1)

- Engineering Failure Analysis: Ayad Subhy, Davide Lo Presti, Gordon AireyDokument11 SeitenEngineering Failure Analysis: Ayad Subhy, Davide Lo Presti, Gordon AireyMohamed BoudabbousNoch keine Bewertungen

- IOE, TU Questions and Solutions: Engineering Physics (for BE first yearDokument235 SeitenIOE, TU Questions and Solutions: Engineering Physics (for BE first yearRajeev PaudelNoch keine Bewertungen

- LECTURE 3 - Shear Stress & Allowable StressDokument15 SeitenLECTURE 3 - Shear Stress & Allowable StressIhab OmarNoch keine Bewertungen

- SPE 122225 Gas Condensate Productivity Improvement by Chemical Wettability AlterationDokument12 SeitenSPE 122225 Gas Condensate Productivity Improvement by Chemical Wettability AlterationGabriel EduardoNoch keine Bewertungen

- Mean Deviation - Wolfram MathWorldDokument4 SeitenMean Deviation - Wolfram MathWorldbraulio.dantas-1Noch keine Bewertungen

- 4363 111 Machine Design IDokument6 Seiten4363 111 Machine Design Iyogesh_b_k100% (2)

- 4439testing MultipleDokument4 Seiten4439testing MultipleSonny RamosNoch keine Bewertungen

- Why We Die: The New Science of Aging and the Quest for ImmortalityVon EverandWhy We Die: The New Science of Aging and the Quest for ImmortalityBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Summary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisVon EverandSummary: Limitless: Upgrade Your Brain, Learn Anything Faster, and Unlock Your Exceptional Life By Jim Kwik: Key Takeaways, Summary and AnalysisBewertung: 5 von 5 Sternen5/5 (8)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (57)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingVon EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingBewertung: 5 von 5 Sternen5/5 (4)

- The Comfort of Crows: A Backyard YearVon EverandThe Comfort of Crows: A Backyard YearBewertung: 4.5 von 5 Sternen4.5/5 (23)

- The Obesity Code: Unlocking the Secrets of Weight LossVon EverandThe Obesity Code: Unlocking the Secrets of Weight LossBewertung: 5 von 5 Sternen5/5 (4)