Beruflich Dokumente

Kultur Dokumente

WeldedBridgeCode ACS 2 12

Hochgeladen von

MAYMODERN STEELCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WeldedBridgeCode ACS 2 12

Hochgeladen von

MAYMODERN STEELCopyright:

Verfügbare Formate

16.1.3 In dynamically loaded structures, 16.3.

3 Fillet welds placed on one side only

flange plates laid end to end shall be joined of the stiffener shall not be used.

by butt welds, and welded cover plates shall

not be used. Joints in flange plates shall be 16.3.4 Intermediate stiffeners carrying

butt welded and dressed flush before cross bracings or diaphragms shall not be

assembling. connected to the web by intermittent fillet

welds.

16.1.4 Where the flange consists of more

than one section, the butt joints shall be 16.3.5 Intermediate stiffeners shall be

staggered. located away from web splices.

16.1.5 Welded cover plates, where used in 17. Strengthening of Existing Bridges

structures not subjected to dynamic loading,

shall have enough welds on either side to 17.1 All provisions of this code, applicable

develop the load 5% more than that of the to new welded bridge work, shall apply

element spliced. equally to strengthening of existing bridges

except as modified by clauses 17.2 to 17.7.

16.1.6 The flange plate, welded directly to

the web plate, shall not be more than 50 17.2 Where a compression member is

mm thick when steel conforms to IS: 2062. strengthened by welding while under load,

the work shall be carried out in such a way

16.2 Web plates - Splices in the webs of that -

plate girders and rolled sections used, as

beams shall be made by butt welds dressed (a) The least radius of gyration is

flush on all faces, in the case of dynamically substantially increased; and

loaded structures. In the case of structures

(b) Large compression shrinkage

not subjected to dynamic loading, splice

stresses are not induced in the

plates may be used independently and not

extreme fibres.

to reinforce a butt-welded splice.

17.3 Strengthening of existing bridges by

16.3 Intermediate stiffeners welding shall not be done unless tests prove

that the parent metal is suitable for the

16.3.1 Where intermediate stiffeners are purpose.

connected to the web by intermittent fillet

welds placed in pairs, one weld on either 17.4 The details of design for

side of the stiffeners, the effective length of strengthening shall be made taking into

each weld shall be not less than four times consideration the weakening effect of stress

the thickness of the stiffeners, subject to the raisers on the fatigue strength of the parent

provisions of clause 6.7. metal.

16.3.2 Where staggered intermittent fillet 17.5 If material is added to a member

welds are used, the effective length of each carrying dead load stress in excess of 19.6

weld shall be not less than 10 times the N/mm2 (2.0 kg/mm2) for strengthening, it is

thickness of the stiffener, subject to the desirable to relieve the member of dead

provisions of clause 6.7. load stress.

IVB-10

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Ground Improvement Method StatementDokument7 SeitenGround Improvement Method StatementMAYMODERN STEELNoch keine Bewertungen

- Method Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)Dokument7 SeitenMethod Statement For Drainage Work at VBC KG Titi Besi (CH 232457.551)MAYMODERN STEELNoch keine Bewertungen

- MS For MLT On 300 Spun Pile Br583Dokument21 SeitenMS For MLT On 300 Spun Pile Br583giyat_prcNoch keine Bewertungen

- Standard VCS 5737,: Volvo Car CorporationDokument9 SeitenStandard VCS 5737,: Volvo Car CorporationWei Yue ZhuanNoch keine Bewertungen

- Quotation Temp - RoadDokument1 SeiteQuotation Temp - RoadMAYMODERN STEELNoch keine Bewertungen

- Pile Driving Analyser Test Method StatementDokument7 SeitenPile Driving Analyser Test Method StatementTrương Văn ĐồngNoch keine Bewertungen

- Sub-Base and Road BaseDokument7 SeitenSub-Base and Road BaseMAYMODERN STEELNoch keine Bewertungen

- UEC-MS-BR466-MLT-006-Load TestDokument18 SeitenUEC-MS-BR466-MLT-006-Load TestMAYMODERN STEELNoch keine Bewertungen

- Zone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)Dokument25 SeitenZone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)MAYMODERN STEELNoch keine Bewertungen

- Dynamic Load Test Method for PilesDokument7 SeitenDynamic Load Test Method for PilesMAYMODERN STEELNoch keine Bewertungen

- Method Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)Dokument6 SeitenMethod Statement For Earthworks at VBC Kg. Titi Besi (CH 232.457)MAYMODERN STEELNoch keine Bewertungen

- Bridge Construction MethodologyDokument11 SeitenBridge Construction MethodologyMAYMODERN STEELNoch keine Bewertungen

- Dynamic Load Test Method for PilesDokument7 SeitenDynamic Load Test Method for PilesMAYMODERN STEELNoch keine Bewertungen

- UEC-MS-BR466-IST-007-Instrumentation TestDokument6 SeitenUEC-MS-BR466-IST-007-Instrumentation TestMAYMODERN STEELNoch keine Bewertungen

- Zone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)Dokument25 SeitenZone 2 Section 4 Method Statement For Dynamic Load Test On Reinforced Concrete 300Mm Diameter Spun Pile at Br562 (Sg. Chenderiang)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangDokument12 SeitenMethod Statement For Construction of Bridge RC Structure at BR 562-Sg. ChenderiangMAYMODERN STEELNoch keine Bewertungen

- Bridge Construction Method StatementDokument14 SeitenBridge Construction Method StatementMAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)Dokument11 SeitenMethod Statement For Bored Pile at RB 012, Temoh - Sg. Lesong (CH 226.000)MAYMODERN STEEL100% (1)

- UEC-MS-BR466-SLT-008-Sonic Logging TestDokument6 SeitenUEC-MS-BR466-SLT-008-Sonic Logging TestMAYMODERN STEELNoch keine Bewertungen

- Pile Driving Analyser TestDokument5 SeitenPile Driving Analyser TestMAYMODERN STEELNoch keine Bewertungen

- Pile Driving Analyser Test-Rev 1Dokument6 SeitenPile Driving Analyser Test-Rev 1MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Dokument11 SeitenMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNoch keine Bewertungen

- Sonic Logging Method for Bored PilesDokument5 SeitenSonic Logging Method for Bored PilesMAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)Dokument14 SeitenMethod Statement For Bored Pile at Rb013: Jalan Air Kuning - Banir (CH 229.424)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Dokument11 SeitenMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)Dokument11 SeitenMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Baharu Pinji (CH 219.500)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)Dokument11 SeitenMethod Statement For Bored Pile at Proposed Pedestrian/Motorcycle Bridge Near Kg. Changkat Melintang (CH 230.900)MAYMODERN STEELNoch keine Bewertungen

- BR570 - Rev 1Dokument15 SeitenBR570 - Rev 1MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)Dokument12 SeitenMethod Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)Dokument12 SeitenMethod Statement For Bored Pile at BR 583 - Sg. Chikus (CH 239.165)MAYMODERN STEELNoch keine Bewertungen

- Method Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)Dokument12 SeitenMethod Statement For Bored Pile at BR 562 - Sg. Chenderiang (CH 226.735)MAYMODERN STEELNoch keine Bewertungen

- PPR Pipe Production Line - Benk Machinery Co LTDDokument6 SeitenPPR Pipe Production Line - Benk Machinery Co LTDazeez engNoch keine Bewertungen

- Intro to Concrete Structures DesignDokument42 SeitenIntro to Concrete Structures DesignTanvirH.ChowdhuryNoch keine Bewertungen

- Technical Catalog Sandwich Panels Paneltech 2020.1Dokument88 SeitenTechnical Catalog Sandwich Panels Paneltech 2020.1cheikh ahmed Mohamed NagimNoch keine Bewertungen

- Catawissa BrochureDokument12 SeitenCatawissa Brochurepacho916Noch keine Bewertungen

- Welding Pipeline HandbookDokument64 SeitenWelding Pipeline HandbookJose Luis Roca Cordova100% (1)

- Flexural Behaviour of Reinforced Lightweight Foamed Concrete Beams - Augustus Jun Hui, TanDokument6 SeitenFlexural Behaviour of Reinforced Lightweight Foamed Concrete Beams - Augustus Jun Hui, TanTJH_1211Noch keine Bewertungen

- Pickling Paste 101Dokument2 SeitenPickling Paste 101George BogdanNoch keine Bewertungen

- 20IN027 - Arslan AhmedDokument12 Seiten20IN027 - Arslan AhmedArsalan SidikiNoch keine Bewertungen

- Material Metallurgy - Descriptive TypesDokument53 SeitenMaterial Metallurgy - Descriptive TypesSushant GhurupNoch keine Bewertungen

- Epoxy ResinDokument17 SeitenEpoxy ResinIrfan AliNoch keine Bewertungen

- Narrative ReportDokument4 SeitenNarrative ReportMichael Adrian Magbanua100% (1)

- Passive Block Foundation DrawingDokument1 SeitePassive Block Foundation Drawingapi-426990805100% (1)

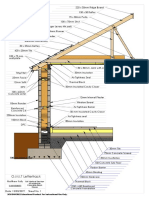

- Drainage, Water Supply & InsulationDokument56 SeitenDrainage, Water Supply & InsulationRiddhi PatelNoch keine Bewertungen

- Design of Slabs-on-GradeDokument36 SeitenDesign of Slabs-on-GradeMohan Manickam100% (1)

- Waffle Slab Joint DetailsDokument6 SeitenWaffle Slab Joint DetailsReymond Longtable100% (1)

- MARAFIQ Pipe Specification Rev 1Dokument17 SeitenMARAFIQ Pipe Specification Rev 1jaseelNoch keine Bewertungen

- Engineering Utilities 2Dokument8 SeitenEngineering Utilities 2Vanissa MontillaNoch keine Bewertungen

- Tubing Data-Engineered Combinations MS-06-117Dokument7 SeitenTubing Data-Engineered Combinations MS-06-117kirlaniano@gmail.comNoch keine Bewertungen

- Steel Reviewer 1.1 Steel ConstructionDokument4 SeitenSteel Reviewer 1.1 Steel ConstructionCharmie Cabeltera CuelloNoch keine Bewertungen

- Determining The Time of Setting of Portland CementDokument3 SeitenDetermining The Time of Setting of Portland CementRizette PaloganNoch keine Bewertungen

- 8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralDokument5 Seiten8.19.3 Laying: 8.20 Curtain W T T ALL W W With Aluminium Composite Panels (Acp) Cladding P P 8.20.1 GeneralAnshuman RathNoch keine Bewertungen

- DLL Science 8 Q3 WK - 9 - JUDYDokument7 SeitenDLL Science 8 Q3 WK - 9 - JUDYAlrei MeaNoch keine Bewertungen

- The "Carbon Footprint" of Aluminum and Magnesium Die Casting Compared To Injection Molded ComponentsDokument40 SeitenThe "Carbon Footprint" of Aluminum and Magnesium Die Casting Compared To Injection Molded ComponentsPaolo BartoliNoch keine Bewertungen

- Vernacular Terms Used in ConstructionDokument6 SeitenVernacular Terms Used in ConstructionJe CiroNoch keine Bewertungen

- CC Block Pavement EstimateDokument3 SeitenCC Block Pavement EstimateTeng MarakNoch keine Bewertungen

- TDS - Power Metcut S-PlusDokument1 SeiteTDS - Power Metcut S-PlusVaidya Mahesh ManoharNoch keine Bewertungen

- Transparent (Light Transmitting) ConcreteDokument3 SeitenTransparent (Light Transmitting) Concretevenkateswara rao PothinaNoch keine Bewertungen

- Ccip Worked Examples Ec2Dokument224 SeitenCcip Worked Examples Ec2HerrMeier4221100% (20)

- Spiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesDokument6 SeitenSpiral-Wound-Gaskets ASME B16 20 2012 Spiral Wound Gaskets For ASME B16.5 FlangesAntonio CardosoNoch keine Bewertungen