Beruflich Dokumente

Kultur Dokumente

Formwork Systems: Advanced Options for Speedy Construction

Hochgeladen von

Khan SalimOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Formwork Systems: Advanced Options for Speedy Construction

Hochgeladen von

Khan SalimCopyright:

Verfügbare Formate

Formwork Systems

Advanced

Formwork and

its Management

Systems for Speedy

Construction of

Buildings

Sonjoy Deb, B.Tech, Civil

Associate Editor

B

uilding a high rise, or other large buildings, is typical for concrete construction throughout past few decades. With the

urban areas. High-rise buildings are rapidly becoming development and increasing of population people tend to

a developing nature of urban zones due to increased construct high-rise buildings and construction of a tall building

population and businesses. The core of high-rise buildings was not easy at the early days. With the development, the man

is one of the most important elements in such gigantic made the tasks easy by inventing new machinery and new

structures. Fast and efficient construction of the concrete techniques. One such area related to high-rise construction

core of a high-rise building is essential to maintain phased is the type of the formwork used in the construction. At the

progress on other parts of the building. Formwork is one of early days people used conventional type formwork where

the most important factors in determining the success of a the timber planks were supported on timber columns. With

construction project in terms of speed, quality cost and safety the advancement of the science man used plywood instead

of work as it accounts about 40% of the total project cost of of timber planks and pipe supports with various kinds of jacks

the structure. To minimize the costs the contractor needs to instead of timber supports. Then the man invented small units

complete the project as soon as possible and the client wants of formworks when the same structure is repeating such as

the building to use the building as early as possible for the slab forms, flying forms for the walls etc. finally the greatest

intended purpose. In highrise building construction the most invention came for the complete system. At the

efficient way to speed up the work is by achieving a very short

beginning the system was made out of steel and which was

floor cycle. That directly depends on the selected form work

very heavy. Then the man paid his attention towards reducing

type for the construction.

the weight of the formwork system. Now the materials for

The development of formworks is parallel with the growth of formwork have extended to aluminium, plastic, fiber glass etc.

150 The Masterbuilder - March 2014 • www.masterbuilder.co.in

Formwork Systems

But still the aluminium panel system formwork is not much 4. Type of foundations

explores in developing countreis and most of the contractors 5. Information flows between architect/engineer and contractor

do not like to shift to the latest technology as they have 6. Presence/absence of precast facades; and

the doubt of facing losses in the project and they are very 7. Type of scheme adopted

much familiar with the existing formwork type, the modern

Form work system and its usefulness to optimize the

conventional type. At the same time contactors have a false

construction schedule and speeding it up falls in the type of

belief that aluminium panel system formwork is only suitable

scheme adopted category. This is a very important aspect to

for very tall buildings which are having thirty to forty storeys.

speed up the construction as now a days there are projects

Though the aluminium panel system formwork reduces the

which achieved 3 to 6 days of floor cycle by adopting light

project duration and hence the total project cost, the formwork

assembled form work system.

system is a bit expensive. So this research was carried out to

analyze the cost for each formwork type and compare the Available Formwork Types for High Rise / Mid Rise

values obtained for the total project cost when different types Buildings

of formworks are used in the construction project and find the

least no. of storeys sufficient to use the system formwork in When a project is considered the material requirement is

the construction project. unique as it depends on the design. But the labor requirement

and the duration of the project are totally depending on the

Another important aspect in a high-rise building construction technologies and the construction methods used in the

with reinforced concrete structures is form work effective project. One of the most time consuming activities in a high-

management systems to reduce the duration and cost of rise / mid-rise building construction project is the construction

structural frame work and subsequent activities. A concrete of the main structure. At the same time it requires more labor.

curing management system by adapting a ubiquitous But when the latest technologies are used it can reduce both

computing environment has been developed by researcher’s the time and labor requirement in constructing the main

as a method for effective quality management, which is also structure. In a high-rise building projects formwork plays a

discussed here. major role as it directly affect the floor cycle and hence it will

reduce the time taken to construct the main structure and

Various Work Packages and Work Flow Pattern of a High

because of that the total duration of the project will go down

Rise / Mid Rise Building

drastically. Commonly available formwork system includes:-

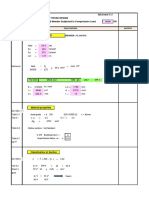

A Typical master program comprises five primary work

packages as shown in Figure 1. Conventional Type of Formwork

This is the most traditional type of formwork and this uses

timber, bamboo, masonry and carpentry to complete

construction. Low initial cost, low experience factor and low

weight are some of the advantages while high floor cycle,

poor finish, and high labor requirement are the disadvantages

of this formwork type. This formwork type is still in practice in

two – three storey building construction projects.

Modern Conventional type of Formwork

Modern conventional type formwork is as much the same as

Figure 1: Typical Master Program for High Rise Buildings

the traditional slab formwork method and the only difference

Management strategies for defining these stages as construction is that steel props and various types of jacks (U jacks, T

packages have been proposed to reduce time in the overall jacks) are used as supports in the formwork instead of timber

construction duration. If the construction durations of every supports and ply wood sheets are used instead of timber

phase can be estimated reliably and objectively in the design planks on slab decks, beams and columns. The advantages

stage, time uncertainty will be minimized in the construction of this type are low initial cost, low skilled labor requirement

stage. and can use in places where there are a lot of deviations in

The researchers found that the seven most important variables the structure.

affecting the time schedule of this type of structures are: Various companies have done various researches in the wood

1. Area of external cladding formwork and have come out with H beams and pressed

shuttering plates.

2. Height of the building

3. Ratio of total gross floor area to the number of stories (a)The H-Beam is a unique introduction in construction

www.masterbuilder.co.in • The Masterbuilder - March 2014 151

Formwork Systems

industry to over come the cumbersome process of Semi System Formwork:

procurement of timber. H-Beam is designed and fabricated

This is a more advanced formwork type than the modern

at par with International Standards under strict quality control

conventional type as there are pre-fabricated formwork items.

and Quality assurance to withstand various design loads

For example there are pre-fabricated formworks for slab panels

during Construction of various activities. The members are

and supports and other structural parts. There are several types

made up of Solid Wood Panel making the web, and flange

of semi system formworks and is discussed as below:

sections are made up of well-seasoned Spruce Wood that

makes Timber H Beam stronger and durable. The flange and (A)Fiberglass formwork: The use of fiberglass as a material

web of H-Beam are hot processed by the wedge technology to make forms for concrete work has increased rapidly within

that makes a versatile section by which the whole member the past two years. Among the reasons are:

gives us strong durable and higher load carrying capacity in

various areas of construction Industry. Refer Figure 2 for H - Fiberglass forms provide a means of producing a concrete

Beam application. surface that is architecturally acceptable without rubbing

and grinding.

- Special patterns and designs can be readily molded into

the material.

- Large areas or sections may be made without joints or

seams.

- When repeated usage is possible, fiberglass is often the

most economical form material.

Perhaps most important one is fiberglass forms allow the

architect complete freedom of design.

One advantage of fiberglass forms is it is possible to eliminate

the joints or seams. Also when special conditions dictate

building a form in sections, it is possible to join the units in

such a manner that the several sections may later be sealed

together with additional applications of resin and fiberglass to

Figure 2 produce a seamless mold. Versatility is another advantage.

Fiberglass panels can be 100 percent reversible in any situation.

(b)Shuttering Panel made of Solid Wood have multiple layers Fiberglass is also an excellent insulating material and is

(typically 3), with cross layers consist of two outer skins made impervious to moisture; thus fiberglass forms provide built-

of Spruce wood, oriented parallel to each other and one or in protection against temperature extremes. Although the first

more middle layer oriented crosswise to the grain direction cost of fiberglass forms are relatively high, the durability of

of the outer skins. The build-up of the panels is symmetric the material permits almost unlimited reuses. Consequently,

to the middle layer. The two outer layers with aligned fibers wherever it is possible to make repeated use of the same

and the middle layers are glued with waterproof bonding. form, the cost may be reduced substantially to a point that the

This construction keeps the layers strongly bonded and gives material becomes the lowest cost per use of any form.

more repetition along with high load carrying capacity. For

construction use, the function of the Solid Wood shuttering

panel is the same as Film Faced plywood. Refer Figure 3 for

a typical 3 layered shuttering panel.

Figure 3 Figure 4: Use of fiber glass formwork

152 The Masterbuilder - March 2014 • www.masterbuilder.co.in

Formwork Systems

(B)Plastic Formwork: It comes as a individual structural typical storeys as it can be made in a single storey complete

elements like columns and walls. Various sized columns and formwork set form and a faster floor to floor construction can

walls are available in the market. The formwork is very easy be achieved. (Refer Figure 7)

to install and uninstall and has a very high repetitive nature.

The ease of application makes it very useful where faster

completion of work is a criteria. Refer Figure 5 for Plastic

formwork in columns.

Figure 5: Plastic formwork in columns

(C) Fiber-reinforced polymer (FRP) formwork system: FRP

formwork is used where unique configuration required for

the arches and columns or any other structural parts. The

FRP formwork pieces were produced using the hand layup

method using molds fabricated by means of a computer

numerical control (CNC) machine. On site, the size and weight

of the formwork required the use of forklifts and scissor lifts for

assembly. After the forms were assembled (Refer Figure 6)

and the reinforcement was placed, selfconsolidating concrete

was used to produce the required smooth, uniform finish.

Figure 7: Various Form work assembly system for High Rise Buildings

Figure 6: FRP Formwork system

Jump Form System to Construct Concrete Core Walls of

Aluminium Panel System Formwork:

High Rise / Mid Rise Buildings

System formwork has prefabricated modular components

The use of a climbing formwork systems (Refer Figure 8) to

with casting panels. The system formwork can suit the

construct the core walls of tall buildings has been successful

required shape of concrete structure. The speedy and quality

in different countries in reducing construction times, primarily

construction is the biggest advantage in this type while high

because the process become repetitive through the whole

initial cost is the main disadvantage and hence this is not

height of the building.

economical to use in low-rise buildings. But this is the most

economical form of formwork type to be used in high-rise Basically it consists of a frame constructed from structural

building construction when it is having few (more that 10) steel members over the score wall. Steel formwork panels

154 The Masterbuilder - March 2014 • www.masterbuilder.co.in

Formwork Systems

Figure 8: Climbing Formwork System

continues, which is normally four days. Faster times have been

achieved. However, the limiting factor to faster times is usually

the construction of floor slabs, which usually are done as a

separate process. Refer Figure 9 for climbing procedure.

Form Work Management Based On Ubiquitous Computing

Form work significantly influences successful project

Figure 9: Climbing Procedure

completion in high-rise / mid-rise building construction with

are hung from this frame, some supported on rollers. After reinforced concrete structures. One of the effective ways for

the concrete walls are poured, the formwork is released and reducing the form work duration is to strip the forms without

rolled back from the concrete face. Jacks then lift or climb delay when concrete placed in the form is sufficiently cured to

the whole frame up one level. All the formwork panels are stand by itself. In order to strip the forms at the appropriate time,

attached to the frame. This process takes approximately one it is important to estimate the concrete strength development

and a half hours. The moulds are cleaned after being lifted at the early stage of the curing process. The concrete maturity

out of the finished unit and then re-assembled. A thin layer method can determine the concrete strength more accurately

of a steel mould-releasing agent is then applied by spraying and consistently than other conventional methods such

it onto the surface of the steel mould in contact with concrete as using test cylinders or a Schmidt hammer. A ubiquitous

prior to reinforcing bar placement. Inspection of the moulds computing environment can facilitate the application of the

is then carried out. Once the climbing formwork is in its concrete maturity method on the construction site, and a

approved position, the next concrete wall is poured. The cycle wireless temperature monitoring system has been recently

developed in Korea. The system is discussed below.

Figure 10: Wireless temperature monitoring system

www.masterbuilder.co.in • The Masterbuilder - March 2014 155

Formwork Systems

Wireless Temperature Monitoring System In order to shorten the learning period and smooth flow of

works on site, full-scale factory pre-assembly is recommended

Figure 10 shows the constitution of the wireless temperature

for each set of system formwork prior to the delivery to site. In

monitoring system developed in Korea. The system transmits

addition, an on-site mock-up is also mandatory to verify the

the temperature data measured from the sensors wirelessly

integrity of the system formwork as well as for coordination

in real-time into the personal computer in the site office,

among different trades. It is necessary to strike the beam and

and estimates the maturity and concrete strength. The data

slab formwork earlier than the specified period to achieve

are also stored in the computer server, and information is

the learning period to avoid any delay. The approval of such

shared with related experts for technical support. However,

operation should be supported by concrete mix with early

there are some limitations on the application for form work

strength development. In addition, the formwork should be

management in a structural frame work in highrise building

designed in a way to absorb the construction tolerance of the

projects as follows:

concrete flooring.

1) time for installing the sensors and connecting wires with

Conclusion

recording devices,

2) identification of the data into the PC in the site office, and Buildings are becoming higher and higher nowadays in

3) gap between the time when the estimated strength of maximizing land use and investment return. Construction of

concrete reaches the required standard and form stripping residential developments are considered as focal point of

time due to a planned schedule in structural frame work. the construction industry in view of its huge labor contents

and turnovers evolved due to its own nature of works and

However research have been carried out and the above investments involved from the investors. Investors tend to

bottlenecks were overcomes. The research proposes a build everything possible in a small piece of land to increase

method which integrates a sensor and recording device with a their return from their investment in the quickest possible

form, and the sensor and recording device can be separated manner. Practitioners in the construction industry are looking

from the form in the case of a problem such as failure in the for different means and methods in enhancing efficiency

sensor or discharge in the recording device. The installing time and meeting requirements from the statutory bodies and the

may then be reduced considerably. Next, the construction Clients. All these will be met with if the construction is planned

manager can identify acquired data and estimated strength and achieved at a faster pace. Efficient formwork design and

on the PC in the site office. However, this could cause proper adoption helps considerably in achieving this target. However

and timely actions to be delayed according to the changes in sufficient attention to be given in the safety aspect of the

the site condition, even though the system has the function adopted system as this involves work at height.

of sending the warning message to the managers. Mobile

devices, such as smart phones and web pads, can be offered Reference

as useful tools for timely management. Form stripping work

1. Form Work Management Based On Ubiquitous Computing For High-

could be delayed at the time when the required concrete Rise Building Construction Taehoon Kim, Hunhee Cho, and Kyung-In

strength is gained. This is because the time of resources input Kang School of Civil, Environmental and Architectural Engineering,

needs to be adjusted if the time taken to reach the required Korea University, Seoul, Korea

strength for form stripping is inconsistent with the time 2. Cost Effective and Speedy Construction for High-Rise Buildings

in Sri Lanka by Using Aluminium Panel System Formworks,

planned in advance. Thus, daily work management needs D.M.Wijesekara, Department of Civil Engineering, University of

to be managed effectively through predicting the concrete Moratuwa, Bandaranayake Mawatha, Katubadda, Moratuwa, Sri

strength development and form stripping time. Lanka

3. Construction Planning For High-Rise Residential Building David C W

Considerations Required for Adoption of Formwork Systems Kwok Gammon Building Construction (Macau) Ltd

4. h t t p : / / w w w . c t b u h . o r g / L i n k C l i c k .

In planning for the adoption of handset system formwork aspx?fileticket=L4CdffQlVlQ%3D&tabid=1413&language=en-US

for high-rise / mid-rise residential building construction, the 5. http://dspace.mit.edu/bitstream/handle/1721.1/ 80646/48271919.

followings consideration should be taken care of: pdf?sequence

6. http://personal.cityu.edu.hk/~bswmwong/photo_lib/formwork_

1. Building design must be frozen at early stage application/formwork_application.pdf

7. http://www.navnirman.in/shuttering_panel.html

2. Sufficient time shall be allowed for fabrication, factory pre- 8. http://www.concreteconstruction.net/concrete-articles/fiberglass-

assembly and learning period for adopting necessary day forms-a-progress-report.aspx

cycle as required for the project. 9. http://www.siscon.co.in/slide/colum%20work.png

3. Allowance should be made for change from typical floor 10. h t t p : / / w w w. s t a r p a c . i n / i n d e x . p h p / p r o d u c t s / p l a s t i c

-formwork-system/wall-formwork

to non-typical floor, such as refuge floor or plant rooms, 11. http://www.metsawood.com/materialarchive/MaterialArchive/

and vice versa. MetsaWood-Concrete-Formwork.pdf

156 The Masterbuilder - March 2014 • www.masterbuilder.co.in

Das könnte Ihnen auch gefallen

- Modernisation, Mechanisation and Industrialisation of Concrete StructuresVon EverandModernisation, Mechanisation and Industrialisation of Concrete StructuresNoch keine Bewertungen

- Advance Formwork Management SystemDokument6 SeitenAdvance Formwork Management SystemPandula MaddumageNoch keine Bewertungen

- Steel Structures Design Based on Eurocode 3Von EverandSteel Structures Design Based on Eurocode 3Bewertung: 3 von 5 Sternen3/5 (1)

- Materials Today: Proceedings: Mohan Sai Gaddam, Aravindan AchuthanDokument5 SeitenMaterials Today: Proceedings: Mohan Sai Gaddam, Aravindan AchuthanAshutosh BorageNoch keine Bewertungen

- Document 2 GobR 07042017Dokument5 SeitenDocument 2 GobR 07042017Rahul KumarNoch keine Bewertungen

- Comparative Analysis of Alluformwork and Conventional Formwork in Pune RegionDokument8 SeitenComparative Analysis of Alluformwork and Conventional Formwork in Pune RegionleovinNoch keine Bewertungen

- CET402 Design - of FormworkDokument49 SeitenCET402 Design - of FormworkGautam PoddarNoch keine Bewertungen

- Doca Formwork PDFDokument7 SeitenDoca Formwork PDFvasudevangurusamyNoch keine Bewertungen

- Design and Cost Analysis of Advanced Shuttering: NtroductionDokument8 SeitenDesign and Cost Analysis of Advanced Shuttering: Ntroductionsri projectssNoch keine Bewertungen

- Modern Formwork Systems Speed ConstructionDokument10 SeitenModern Formwork Systems Speed ConstructionvishaliNoch keine Bewertungen

- Innovating Formwork Systems ReviewDokument8 SeitenInnovating Formwork Systems ReviewJasmine TsoNoch keine Bewertungen

- M1.3Form WorkDokument44 SeitenM1.3Form WorkShubhaNoch keine Bewertungen

- Research AluformDokument7 SeitenResearch AluformPartth JayyNoch keine Bewertungen

- A Comparative Study For Evaluation of Different Form Work Systems Utilization in Construction ProjectsDokument10 SeitenA Comparative Study For Evaluation of Different Form Work Systems Utilization in Construction ProjectsJitri DriveNoch keine Bewertungen

- Form WorkDokument10 SeitenForm WorkJitri DriveNoch keine Bewertungen

- Ads Microproject HHHDokument10 SeitenAds Microproject HHHSk songNoch keine Bewertungen

- Architectural Formwork in High Rise ConstructionDokument59 SeitenArchitectural Formwork in High Rise ConstructionShivaraju HNoch keine Bewertungen

- Cost Savings Analysis The Use of Alform Formwork On Beams, Columns & Floor Slab For Typical BuildingsDokument8 SeitenCost Savings Analysis The Use of Alform Formwork On Beams, Columns & Floor Slab For Typical BuildingsInternational Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- High Rise BuildingsDokument19 SeitenHigh Rise BuildingsVivek Majik50% (2)

- Advanced Methods of Building ConstructionDokument10 SeitenAdvanced Methods of Building ConstructionsnehaNoch keine Bewertungen

- Comparisonal Analysis of Formwork Costs ConventionDokument7 SeitenComparisonal Analysis of Formwork Costs Conventionanildondapati1Noch keine Bewertungen

- Introduction of Tilt-Up Structures in The Philippines - VaDokument10 SeitenIntroduction of Tilt-Up Structures in The Philippines - VaRichard FallegaNoch keine Bewertungen

- A Brief Study On The Types of Shuttering PDFDokument3 SeitenA Brief Study On The Types of Shuttering PDFRahul KumarNoch keine Bewertungen

- Introduction of Innovative Construction SystemDokument3 SeitenIntroduction of Innovative Construction Systemgarima0303Noch keine Bewertungen

- 9 4 Comparative Study and Decision Making For A FormworkDokument5 Seiten9 4 Comparative Study and Decision Making For A Formworknazi nazNoch keine Bewertungen

- Precast Technology Mini Project Sid 1111Dokument33 SeitenPrecast Technology Mini Project Sid 1111jai sri ramNoch keine Bewertungen

- Pre Engineered Buildings 410Dokument8 SeitenPre Engineered Buildings 410Vinit KondapureNoch keine Bewertungen

- Dissertation 17001006024Dokument35 SeitenDissertation 17001006024gunjan barejaNoch keine Bewertungen

- Peb 2Dokument6 SeitenPeb 2Ayush GargNoch keine Bewertungen

- Mivan Vs ConvDokument5 SeitenMivan Vs ConvAkhil SurendranNoch keine Bewertungen

- IbrahimandHamzeh2015Role of FormworkDokument11 SeitenIbrahimandHamzeh2015Role of FormworkUday SrinivasNoch keine Bewertungen

- Mivan ShutteringDokument4 SeitenMivan ShutteringWanda BeasleyNoch keine Bewertungen

- Presentation On ShutteringDokument29 SeitenPresentation On ShutteringMukul KumarNoch keine Bewertungen

- Forms and Materials For Speedy Construction: Submitted byDokument44 SeitenForms and Materials For Speedy Construction: Submitted byChetna BhanwalNoch keine Bewertungen

- Pre-Engineered Building Systems A Promising FutureDokument27 SeitenPre-Engineered Building Systems A Promising FutureDivya PunjabiNoch keine Bewertungen

- EQUIP Semifi TopicsDokument144 SeitenEQUIP Semifi Topicsshelmar yan panisalesNoch keine Bewertungen

- Foreign Literature and Study - FormworksDokument3 SeitenForeign Literature and Study - FormworksKent OcenarNoch keine Bewertungen

- Advance construction techniques summaryDokument12 SeitenAdvance construction techniques summaryMoïsës TavarexNoch keine Bewertungen

- Building Construction Report-1Dokument39 SeitenBuilding Construction Report-1Kanak YadavNoch keine Bewertungen

- Structural Precast Concrete Frame DesignDokument13 SeitenStructural Precast Concrete Frame DesignpapasterevskiNoch keine Bewertungen

- Literature Study 17001006024 DissertationDokument30 SeitenLiterature Study 17001006024 Dissertationgunjan barejaNoch keine Bewertungen

- Introduction to Advantages of Pre-Engineered BuildingsDokument7 SeitenIntroduction to Advantages of Pre-Engineered BuildingsDrGanesh KameNoch keine Bewertungen

- Structural Systems in HousingDokument9 SeitenStructural Systems in HousingzuhaNoch keine Bewertungen

- E3sconf Icemee2021 03020Dokument4 SeitenE3sconf Icemee2021 03020Akanksha PendharkarNoch keine Bewertungen

- Construction Technology (Technical Report)Dokument35 SeitenConstruction Technology (Technical Report)Shady DokhanNoch keine Bewertungen

- Group 5 - Construction Methods and Operations-1Dokument6 SeitenGroup 5 - Construction Methods and Operations-1Donna Cece MelgarNoch keine Bewertungen

- QC 222 - Building Construction Iii: Formwork and False WorkDokument10 SeitenQC 222 - Building Construction Iii: Formwork and False Workkefapaul21Noch keine Bewertungen

- Seminar Report On Aluminium FormworkDokument34 SeitenSeminar Report On Aluminium FormworkSandip JagdaleNoch keine Bewertungen

- Mivan TechnologyDokument24 SeitenMivan TechnologyArjun MNoch keine Bewertungen

- Formwork Analysis Analysis of Formwork Types for Cost Optimization in Multistory BuildingsDokument3 SeitenFormwork Analysis Analysis of Formwork Types for Cost Optimization in Multistory BuildingsCIVIL DEPARTMENT MMANTCNoch keine Bewertungen

- Precast Concrete Construction: Benefits and Design ConsiderationsDokument12 SeitenPrecast Concrete Construction: Benefits and Design ConsiderationsRemya R. KumarNoch keine Bewertungen

- Research Work 2Dokument6 SeitenResearch Work 2flor minozaNoch keine Bewertungen

- Prefabricated Structures NotesDokument23 SeitenPrefabricated Structures Notesjss_devNoch keine Bewertungen

- Advantages of Prefabricated ConstructionDokument7 SeitenAdvantages of Prefabricated ConstructionShubhaang GoelaNoch keine Bewertungen

- PSG College Report on Modern Prefabrication TechniquesDokument6 SeitenPSG College Report on Modern Prefabrication TechniquesMASILAMANI TNoch keine Bewertungen

- Modern Methods of ConstructionDokument3 SeitenModern Methods of ConstructionTony Anderson Quiro CarrascoNoch keine Bewertungen

- Research PaperDokument28 SeitenResearch PaperGladdelyn PiencenavesNoch keine Bewertungen

- Housing Assignment - 1: Vamshi Krishna.A BA15ARC059Dokument27 SeitenHousing Assignment - 1: Vamshi Krishna.A BA15ARC059vamshikrishNoch keine Bewertungen

- Civil Engineering Seminar on Mivan Formwork TechnologyDokument17 SeitenCivil Engineering Seminar on Mivan Formwork TechnologyNikhil ThoteNoch keine Bewertungen

- Stiffness Modifiers - Anurag UpadhyayDokument20 SeitenStiffness Modifiers - Anurag UpadhyayKhan SalimNoch keine Bewertungen

- Authoring Page Updates - Guidelines FinalDokument11 SeitenAuthoring Page Updates - Guidelines FinalKhan SalimNoch keine Bewertungen

- Generic Design Assessment - Step 4 - Assessment of Westinghouse AP1000 - Civil Engineering and External Hazards PDFDokument244 SeitenGeneric Design Assessment - Step 4 - Assessment of Westinghouse AP1000 - Civil Engineering and External Hazards PDFKhan SalimNoch keine Bewertungen

- Comparison of ANSYS Elements SHELL181 and SOLSH190: September 2014Dokument54 SeitenComparison of ANSYS Elements SHELL181 and SOLSH190: September 2014Sunil ReddyNoch keine Bewertungen

- Vendor Test GuidelinesDokument8 SeitenVendor Test GuidelinesKhan SalimNoch keine Bewertungen

- Formulas For Mechanical Properties of Elastomeric Bearings PDFDokument2 SeitenFormulas For Mechanical Properties of Elastomeric Bearings PDFKhan SalimNoch keine Bewertungen

- Effects of SSI On EPR In-Structure Response For A Rock Site - Coherent and Incoherent High Frequency Ground Motion PDFDokument11 SeitenEffects of SSI On EPR In-Structure Response For A Rock Site - Coherent and Incoherent High Frequency Ground Motion PDFKhan SalimNoch keine Bewertungen

- Outrigger Design For High-Rise Buildings by Hi Sun Choi PDFDokument89 SeitenOutrigger Design For High-Rise Buildings by Hi Sun Choi PDFafifdaudNoch keine Bewertungen

- Nureg 7253 PDFDokument113 SeitenNureg 7253 PDFKhan SalimNoch keine Bewertungen

- Seismic Response Impact of Incoherent SSI Analysis by New Hard-Rock Coherency Model PDFDokument9 SeitenSeismic Response Impact of Incoherent SSI Analysis by New Hard-Rock Coherency Model PDFKhan SalimNoch keine Bewertungen

- QSCT Sheets PDFDokument7 SeitenQSCT Sheets PDFKhan SalimNoch keine Bewertungen

- Hosts UmbrellaDokument1 SeiteHosts UmbrellaFabsor SoralNoch keine Bewertungen

- A04 QSCT PDFDokument1 SeiteA04 QSCT PDFKhan SalimNoch keine Bewertungen

- SD-III Group PDFDokument2 SeitenSD-III Group PDFKhan SalimNoch keine Bewertungen

- GraphDokument15 SeitenGraphKhan SalimNoch keine Bewertungen

- A01 QSCT PDFDokument1 SeiteA01 QSCT PDFKhan SalimNoch keine Bewertungen

- Application of Genetic Algorithm To Structural Dynamic Parameter IdentificationDokument14 SeitenApplication of Genetic Algorithm To Structural Dynamic Parameter IdentificationKhan SalimNoch keine Bewertungen

- Pune PWD DSR 2016-17Dokument448 SeitenPune PWD DSR 2016-17GaneshZombade96% (95)

- Reactor Engineering Division, Bhabha Atomic Research Centre, Bombay 400085, IndiaDokument12 SeitenReactor Engineering Division, Bhabha Atomic Research Centre, Bombay 400085, IndiaKhan SalimNoch keine Bewertungen

- FreemanDokument1 SeiteFreemanKhan SalimNoch keine Bewertungen

- Fa Q 201727 MarchDokument2 SeitenFa Q 201727 MarchKhan SalimNoch keine Bewertungen

- Incremental Dynamic AnalysisDokument24 SeitenIncremental Dynamic Analysismarin_sNoch keine Bewertungen

- Indian Institute of Technology, Bombay IITB HospitalDokument1 SeiteIndian Institute of Technology, Bombay IITB HospitalKhan SalimNoch keine Bewertungen

- Cost and Time Estimation For Conventional, Aluminium &tunnel FormworkDokument4 SeitenCost and Time Estimation For Conventional, Aluminium &tunnel FormworkAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Medical201122june PDFDokument1 SeiteMedical201122june PDFKhan SalimNoch keine Bewertungen

- Lecture PDF IIT BombayDokument593 SeitenLecture PDF IIT BombayKhan SalimNoch keine Bewertungen

- MatixDokument3 SeitenMatixKhan SalimNoch keine Bewertungen

- Plinth BeamDokument3 SeitenPlinth BeamKhan SalimNoch keine Bewertungen

- Elnimeiri 2008Dokument77 SeitenElnimeiri 2008Khan SalimNoch keine Bewertungen

- Powder Chopped Stand Mats: General PurposeDokument1 SeitePowder Chopped Stand Mats: General Purposehamza OUADINoch keine Bewertungen

- 9.9 Diaphragms-With-Interior-Shearwalls PDFDokument4 Seiten9.9 Diaphragms-With-Interior-Shearwalls PDFnickNoch keine Bewertungen

- Assignment 3Dokument9 SeitenAssignment 3api-335365905Noch keine Bewertungen

- Water Bound Macadam-WbmDokument11 SeitenWater Bound Macadam-WbmCheng EngiNoch keine Bewertungen

- Tabla 310.15 (B) (16) - Ampacidades PDFDokument1 SeiteTabla 310.15 (B) (16) - Ampacidades PDFDettagli GuateNoch keine Bewertungen

- Front Frame Rail Inner Reinforcement RepairDokument29 SeitenFront Frame Rail Inner Reinforcement RepairDong NguyenNoch keine Bewertungen

- Geyser Mounting Horizontal Vs VerticalDokument1 SeiteGeyser Mounting Horizontal Vs VerticalRussell Collett0% (1)

- Heat Transfer RadiationDokument7 SeitenHeat Transfer RadiationJerico MikesellNoch keine Bewertungen

- 5 6138727946501751075Dokument3 Seiten5 6138727946501751075Xkarr RastaNoch keine Bewertungen

- CEHYDRA Notes on Headloss Equations Using Friction FactorDokument12 SeitenCEHYDRA Notes on Headloss Equations Using Friction FactorAngel Lisette LaoNoch keine Bewertungen

- METROLOGY & MEASUREMENTSDokument12 SeitenMETROLOGY & MEASUREMENTSmirztrNoch keine Bewertungen

- High-Performance Cold Work Tool Steel K110Dokument2 SeitenHigh-Performance Cold Work Tool Steel K110Greg SanjayaNoch keine Bewertungen

- Science Fair ExperimentDokument3 SeitenScience Fair Experimentapi-303001234Noch keine Bewertungen

- Domestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaDokument24 SeitenDomestic Timber Deck Design: Technical Design Guide Issued by Forest and Wood Products AustraliaHaibo LVNoch keine Bewertungen

- YORK Mini VRF ODU - JDOH (040 To 060) - Installation Manual - FAN-1707 201602Dokument36 SeitenYORK Mini VRF ODU - JDOH (040 To 060) - Installation Manual - FAN-1707 201602Douglas Rodriguez100% (1)

- Astm A560Dokument5 SeitenAstm A560MAX ALBERTO JUAREZ AVALOSNoch keine Bewertungen

- Dry EtchingDokument12 SeitenDry EtchingMosaddekNoch keine Bewertungen

- SG653PB1 ADokument5 SeitenSG653PB1 ADANILO MEDINA OSORIONoch keine Bewertungen

- Trestles Design 1Dokument10 SeitenTrestles Design 1Anonymous sfkedkymNoch keine Bewertungen

- Mom 1Dokument25 SeitenMom 1Husnain ShahidNoch keine Bewertungen

- Disc Check ValvesDokument2 SeitenDisc Check Valvessuresh tNoch keine Bewertungen

- Princesa Bridge Narrative ReportDokument9 SeitenPrincesa Bridge Narrative ReportRodelo OngNoch keine Bewertungen

- Upright Sprinkler VK300Dokument4 SeitenUpright Sprinkler VK300james alfarasNoch keine Bewertungen

- Circuit Breaker Configuration of LTB245E1-1PDokument2 SeitenCircuit Breaker Configuration of LTB245E1-1PThành Danh100% (1)

- Cable-Stayed Roof Structure InspectionDokument1 SeiteCable-Stayed Roof Structure Inspectionbenjamin swokaNoch keine Bewertungen

- Shackelford 7e 13ADokument44 SeitenShackelford 7e 13AaznapnNoch keine Bewertungen

- Astm A 403 / A 403M - 06Dokument7 SeitenAstm A 403 / A 403M - 06negg 348100% (1)

- Overtime AccomplishmentDokument9 SeitenOvertime AccomplishmentKate PerezNoch keine Bewertungen

- 250-122 (F) Equipment-Grounding Conductors For Parallel RunsDokument3 Seiten250-122 (F) Equipment-Grounding Conductors For Parallel RunsJOSE LUIS FALCON CHAVEZNoch keine Bewertungen

- NortonCatalog PortableBeltsDokument2 SeitenNortonCatalog PortableBeltsherysyam1980Noch keine Bewertungen