Beruflich Dokumente

Kultur Dokumente

DCSWM Investigation (Mechanical)

Hochgeladen von

TuTuy An0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten3 SeitenOriginaltitel

DCSWM investigation(mechanical).xlsx

Copyright

© © All Rights Reserved

Verfügbare Formate

XLSX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

29 Ansichten3 SeitenDCSWM Investigation (Mechanical)

Hochgeladen von

TuTuy AnCopyright:

© All Rights Reserved

Verfügbare Formate

Als XLSX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

Job No./ DCSM No.

PACKAGE Section Unit Equipment Equipment

NUMBER No. No. Tag# Description

DCSM1963 3 1.1 14 3-SOW-014- Quill, 014-SP-

3007- 2406, Washing

M2AR01-PG Water

DCSM2304 3 2 087 087-UZV- Vent air to

0021 093H031/131_

Control valve

DCSM2350 3 1.2 042 2”-HBFW- Flange leakage

042-7959-

M1EG-HS

(Upstream

of check

valve)

DCSM2353 3 1.2 042 10”-HPS- Flange leakage

042-7908-

M1EG-HS

DCSM2584 7.2 2 087 087-UZV- HPS-087-1016-

0018 D1AS-HS (087-

UZV-0018).

DCSM7429 3 1.2 044 Block valve Low Voltage

(20) Switchgear and

MCC

(Manufacturer:

ABB and

others)

Job Description Equipment Type Discipline

Remove to check the physical condition of quill in corrosive service Piping MECHANICAL

087-UZV-0021 steam leakage from jacket at welding joint. Control Valve MECHANICAL

2”-HBFW-042-7959-M1EG-HS Piping MECHANICAL

(Upstream of check valve)

SO-012

10”-HPS-042-7908-M1EG-HS Piping MECHANICAL

SO-012

Leakage at bottom plug of 087-UZV-0018. Control Valve MECHANICAL

Leakage at flange joint. (SO-025)

Block valve (20") malfunction Manual Valve MECHANICAL

Comon block valve of 044-P-203B/C leaks continuosly.

(Maintenance already fix 02 time but still leak)

Work Category Initial Scope Marked

Defect - Opening and JGCS

Confirmation by inspection.

NSRP - Cut and weld new

nozzle.

Defect Rectification - Remove. Delete

by NSRP - Repalce new valve

(087-UZV-0021).

Defect Rectification - Remove the Delete

by NSRP clamp.

- Open/close the

flange.

- Check the flange

surface condition.

Defect Rectification -- Remove

Re-facingthe

the Delete

by NSRP clamp.

flange surface if

-necessary.

Open/close the

flange.

- Check the flange

surface condition.

Defect Rectification NSRP will provide

- Re-facing the Delete

by NSRP spare

flangeparts andif do

surface

repair

necessary. NSRP

work.

do overhauling and

testing at

workshop.

Defect Rectification -DCSM

Checkcontractor

and repair , Delete

by NSRP leakage

to do allfrom stem

site work

valve.

activities:

- Remove / Re-

install the valve

from piping.

- Do scaffolding

work, insulation

work, piping

support work

(including

material).

- Do Blind / Deblind

(including material:

Blind gasket, bind

flange, etc.).

- Provide

crane/boom truck

if required.

- Transportation to

Workshop and vice

versa.

- Co-operate with

other parties to

complete whole

task if any

- Reinstate the

valve after NSRP do

overhauling and

testing

- Stroke testing at

side.

- Record in check

sheet at site.

- Etc.

All neccessaries

tool/equipment,

consumable

material, flange

gasket, blind flange

for isolation, etc for

site work are

provided by DCSM

within his scope.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Module 2h - Coursework To Duy AnhDokument2 SeitenModule 2h - Coursework To Duy AnhTuTuy AnNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

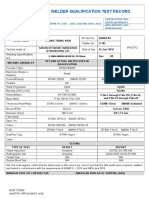

- General Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)Dokument20 SeitenGeneral Information On Welder Certification: No. Welder - ID ID - No Welder - Name Picture Name Company - Name (For Welder)TuTuy AnNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Module 2l - Coursework To Duy AnhDokument3 SeitenModule 2l - Coursework To Duy AnhTuTuy AnNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Module 2k - Coursework To Duy AnhDokument3 SeitenModule 2k - Coursework To Duy AnhTuTuy AnNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- BV Updated Cpp03 Epci6 Dsm1 MPGF Mom 096059 Rev00 PTSC Dsme Noc DNV CA Cabc Monthly.Dokument14 SeitenBV Updated Cpp03 Epci6 Dsm1 MPGF Mom 096059 Rev00 PTSC Dsme Noc DNV CA Cabc Monthly.TuTuy AnNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- SS IND A21 BVX 001 - Welding Procedure Qualification Record (WPQR)Dokument2 SeitenSS IND A21 BVX 001 - Welding Procedure Qualification Record (WPQR)TuTuy AnNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- SS IND A21 BVX 003 - Welder Performance Qualification Record (WPQ) Welding Operator Performance Qualification Record (WOPQ)Dokument2 SeitenSS IND A21 BVX 003 - Welder Performance Qualification Record (WPQ) Welding Operator Performance Qualification Record (WOPQ)TuTuy AnNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- 3.b.11 Application Appendix 2 - Ieng Competence MappingDokument7 Seiten3.b.11 Application Appendix 2 - Ieng Competence MappingTuTuy AnNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- SS Ind A21 BVX002 - Approval of Permanent Joining Procedure and PersonnelDokument1 SeiteSS Ind A21 BVX002 - Approval of Permanent Joining Procedure and PersonnelTuTuy AnNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Comparison of European and Chinese Standard For Structural Steel in Offshore Wind IndustryDokument9 SeitenComparison of European and Chinese Standard For Structural Steel in Offshore Wind IndustryTuTuy AnNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Continuing Professional Development (CPD) Record Sheet: Part A: The Record of ActivityDokument4 SeitenContinuing Professional Development (CPD) Record Sheet: Part A: The Record of ActivityTuTuy AnNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Ceng Uk Spec Evidence FormsDokument6 SeitenCeng Uk Spec Evidence FormsTuTuy AnNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Juan Du - Non-Native English-Speaking Engineers' Writing at The Workplace-Springer (2020)Dokument93 SeitenJuan Du - Non-Native English-Speaking Engineers' Writing at The Workplace-Springer (2020)TuTuy AnNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- 3-WPS Checklist Master PieceDokument3 Seiten3-WPS Checklist Master PieceTuTuy An100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Print 1Dokument11 SeitenPrint 1TuTuy AnNoch keine Bewertungen

- (Package 2 - Pec-Dcsm) NSRP Daily Progress Report - 201910 - 23Dokument21 Seiten(Package 2 - Pec-Dcsm) NSRP Daily Progress Report - 201910 - 23duyanhNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Package 2 & 4 Block 2 (Sec 3 & 4) - Turnaround Daily Work PlanDokument111 SeitenPackage 2 & 4 Block 2 (Sec 3 & 4) - Turnaround Daily Work PlanTuTuy AnNoch keine Bewertungen

- Personal Information Form - Nguyen Van Ly 1Dokument19 SeitenPersonal Information Form - Nguyen Van Ly 1TuTuy AnNoch keine Bewertungen

- WP MonitoringDokument2 SeitenWP MonitoringTuTuy AnNoch keine Bewertungen

- Job List With Planned Date DCSM Rev.2Dokument261 SeitenJob List With Planned Date DCSM Rev.2TuTuy AnNoch keine Bewertungen

- WPS PQR Check List Table 2017Dokument5 SeitenWPS PQR Check List Table 2017TuTuy An89% (19)

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Dokument3 SeitenHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNoch keine Bewertungen

- Vinhomes Central Park (Latest)Dokument20 SeitenVinhomes Central Park (Latest)TuTuy AnNoch keine Bewertungen

- QAQC Organization ChartDokument2 SeitenQAQC Organization ChartTuTuy AnNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- WPS PQR Check List Table 2017Dokument5 SeitenWPS PQR Check List Table 2017TuTuy An89% (19)

- Theory of Shear Transfer Strength of Reinforced ConcreteDokument12 SeitenTheory of Shear Transfer Strength of Reinforced ConcretePremasiri Karunarathna100% (1)

- Septic TanksDokument6 SeitenSeptic TanksJustin MusopoleNoch keine Bewertungen

- Separation and Processing and Transformation of Solid WasteDokument10 SeitenSeparation and Processing and Transformation of Solid WasteKind Red50% (2)

- Distillation Column Case StudyDokument26 SeitenDistillation Column Case Studysachin2010Noch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Дизельные электростанции EMSADokument52 SeitenДизельные электростанции EMSABrizmotorsNoch keine Bewertungen

- IS 428 Washable DistemperDokument10 SeitenIS 428 Washable DistempersunitkghoshNoch keine Bewertungen

- Lecure Two. ReactorsDokument56 SeitenLecure Two. ReactorsSophia WambuiNoch keine Bewertungen

- Gacl Training ReportDokument35 SeitenGacl Training ReportDhruvin Shah100% (1)

- Abhitech Prasad RaoDokument44 SeitenAbhitech Prasad RaoSubhasish mukherjeeNoch keine Bewertungen

- Vice Cosmetics Duo Finish FoundationDokument14 SeitenVice Cosmetics Duo Finish FoundationChunne LinqueNoch keine Bewertungen

- If P 100N T1 T2 58: Design CodesDokument1 SeiteIf P 100N T1 T2 58: Design CodessereNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- What Defines An Industrial GasDokument2 SeitenWhat Defines An Industrial GasYuri YamirnovNoch keine Bewertungen

- ECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Dokument12 SeitenECOTECH Continuous Emissions Monitoring Systems CEMS Brochure 20171113Er Dipak PatelNoch keine Bewertungen

- Heavy Fuel OilsDokument114 SeitenHeavy Fuel Oilsrenatomico2Noch keine Bewertungen

- Paraffin Wax PDFDokument12 SeitenParaffin Wax PDFNurhasanahNoch keine Bewertungen

- Ball MillDokument8 SeitenBall MillHumbulaniNoch keine Bewertungen

- Zincanode 304 pc142Dokument3 SeitenZincanode 304 pc142kushar_geoNoch keine Bewertungen

- Bucky PaperDokument22 SeitenBucky PaperShreyashkumar ZingadeNoch keine Bewertungen

- Insulation CoordinationDokument3 SeitenInsulation CoordinationsujithmohandasNoch keine Bewertungen

- SWB A5 m01 FinalDokument19 SeitenSWB A5 m01 Finalharshal161987Noch keine Bewertungen

- Irr PD 1866 PDFDokument33 SeitenIrr PD 1866 PDFLeia VeracruzNoch keine Bewertungen

- Corrosion Guide Galvanic Chart SummaryDokument1 SeiteCorrosion Guide Galvanic Chart SummaryDan CosacNoch keine Bewertungen

- Mpet FinalDokument12 SeitenMpet FinalShahid Iqbal GorayaNoch keine Bewertungen

- 08 - Chapter 1 PDFDokument63 Seiten08 - Chapter 1 PDFRAMNoch keine Bewertungen

- Feb IssueDokument40 SeitenFeb Issuesppram100% (1)

- Stabilised Mud Block Production With Mardini Block PressDokument16 SeitenStabilised Mud Block Production With Mardini Block PressMahesh ConstructionNoch keine Bewertungen

- Grade Library NITONDokument2 SeitenGrade Library NITONKande RameshNoch keine Bewertungen

- Guide To PavementDokument74 SeitenGuide To PavementCristian GiurgeaNoch keine Bewertungen

- CD6 Prototype Control PlanDokument3 SeitenCD6 Prototype Control Planmpedraza-1Noch keine Bewertungen

- Dolphin WaterCare PDF Presentation 10-16-12Dokument28 SeitenDolphin WaterCare PDF Presentation 10-16-12Fabio Gregorio Beltrán MartínezNoch keine Bewertungen