Beruflich Dokumente

Kultur Dokumente

Datasheet (API 610 - 1 Page)

Hochgeladen von

Rudin Fahrudin Rahman0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten8 SeitenDatasheet API610

Originaltitel

Datasheet (API 610 -1 page)

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDatasheet API610

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten8 SeitenDatasheet (API 610 - 1 Page)

Hochgeladen von

Rudin Fahrudin RahmanDatasheet API610

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

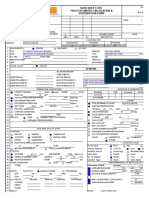

MECHANICAL DATA SHEET

LPG LOADING PUMP Rev. No. : 1

TAG NO. Page : 1 of 3

PEMBERI KERJA :…………………………….

KONTRAKTOR : …………………………………

NAMA PROYEK : …………………………….

LOKASI : …………………………………………..

0 Issued for Approval

REV DATE DESCRIPTION PREP'D CHECKED APP'D

1 of 3

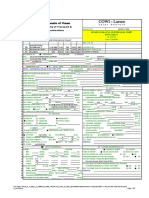

MECHANICAL DATA SHEET

LPG LOADING PUMP Rev. No. : 1

TAG NO. Page : 2 of 3

REVISION RECORD SHEET

Rev No. Date Description

Issued For Approval

2 of 3

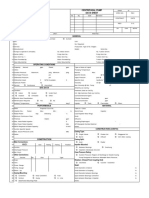

MECHANICAL DATA SHEET

LPG LOADING PUMP Rev. No. : 1

TAG NO. Page : 3 of 3

Nama Proyek : Project Number :

Lokasi : Tag Number :

Service Fluid : Item Number :

P & ID Number : Number Required :

1 Client Project Item

2 Service Location No.

3 Parallel operation Auto start & stop Continuous Intermittent Manufacturer : Mfr's

4 No. of units : Main 0 driven by Motor Model

5 Spare 0 driven by Pump serial No. : TBA

6 OPERATING CONDITIONS CONSTRUCTION

`

7 Liquid : LPG Pump type OH2

8 PT (pumping temp) °C Casing support ✘ Centerline Foot Bracket

9 Sp Gr at PT 0.54 Impeller mount Overhung Between brgs

10 Vap. press. at PT 6.09 Bar Case split ✘ Radial Axial

11 Viscosity at PT 0.1 cp No. of stages Single Two Multi

12 Corr. / eros caused by Impeller type Closed Single Double suction

13 Capacity : normal Volute type Single Double Diffuser

14 rated 35 t/h Nozzles : Size Rating Facing Lo

15 Differential head 114.720 m Suction 8" Class 300# RF

16 Discharge press. at Nozzle 11.339 BarA Discharge 6" Class 300# RF

17 Suction press 6.128 BarA Misc. Conn : Size Rating Facing Re

18 Diff. press 5.211 Bar Vent VTA

19 Hydraulic HP 19.1 kW Drain VTA

20 Max. Suction press. 6.745 BarA Threaded Socket weld Valved Flanged

21 NPSH avail, 2.719 m C.W. In & Out

22 PERFORMANCE Inlet / Outlet valve ✘ Sight flow

23 NPSH req'd m Flushing Plan 11+52+61

24 Efficiency % Quenching

25 BHP at rated cap. kW

26 Min. Cont. flow : Thermal / Stable m3/hr / Imp. dia. Min. / Rated / Max. mm, in /

27 Max. Head rated imp. m Bearing No. / Type radial /

28 Max. BHP rated imp. kW thrust /

29 Max. Allow. work press. Barg Lubrication type

30 Hydrotest press. Barg Coupling : Mfr. / type VTA /

31 Design press. / temp. Barg / °C Packing : Mfr. / No. size /

32 Rotation viewed from coupling end Mechanical seal ; API code

33 Rotating speed rpm Mfr. / size, model No. /

34 S.S.S. at BEP m3/hr-m-rpm API plan : flush / aux seal /

35 Max. Allow Sound Level / Expected dB(A) 85 @ 1 m Baseplate

36 Vertical Pumps : MATERIALS

37 Pit depth / Base to pump bottom m Casing Throat bush

38 Min. Submergence req'd m / Inner case parts Shaft

39 Pump length (Imp. to disch. nozzle) m Impeller Case gasket

40 SHOP TESTS Required Witnessed Case wear, ring Wet bolt / nut

41 Performance YES NO YES NO Imp, wear, ring

42 NPSH YES NO YES NO

43 Hydrotest YES NO YES NO Cooling water : API c.w. pipe plan :

44 MOTOR DRIVE In : kg/cm2G , psig/°C, °F /

45 Motor : Supplied by ✘ Pump Mfr Purchaser Out : kg/cm2G , psig/°C, °F /

46 Mfr. HP: kW Design : kg/cm2G , psig/°C, °F /

47 Phase / Volt / Cycle 3 ph 400 Volt 50 Hz Consumption Pump / Flushing cooler / Lube oil cooler / Total

48 Type Squirrel cage motor m3 / hr , gpm / /

49 Starting Method Softstarter External flush / Quench

50 Location Indoor Outdoor Under roof Fluid name :

51 Heated Unheated In : kg/cm2G , psig / °C, °F

52 Area Class : Ex nA Consumption m3/hr , gpm

53 Winterization Tropicalization Lubricant Bearing : Grade / Qty l,

54 Tandem / Double seal : Grade / Qty l,

55 NOTES :

56 * = Vendor to Advise ** = Process to Advise

57 1. NPSH test shall be carried out only if NPSHa-NPSHr<1meter

58 2. Manufacturer's data report is required

59 3. Vendor waranty for complete unit test at commisioning

60 4. Vibration test

61

`

Semi Open

Location

END

TOP

Remarks

FLANGED

FLANGED

Check &

needle valve

/

ANTIFRICTION

ANTIFRICTION

Flexible Spacer

gal

gal

Das könnte Ihnen auch gefallen

- Stored EnergyDokument38 SeitenStored EnergySajid SattarNoch keine Bewertungen

- K-Flex ST Class 0 CatalogueDokument6 SeitenK-Flex ST Class 0 CatalogueBac VuNoch keine Bewertungen

- DatasheetDokument71 SeitenDatasheetRhadityo Shakti BudimanNoch keine Bewertungen

- Classics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowDokument8 SeitenClassics in Chemical Neuroscience: Diazepam (Valium) : Nicholas E. Calcaterra and James C. BarrowEga Trikuntianti100% (1)

- Quintessence of The PhilosophersDokument32 SeitenQuintessence of The PhilosopherstravellerfellowNoch keine Bewertungen

- PLC Programming With RSLogix 5000Dokument168 SeitenPLC Programming With RSLogix 5000HuangRuanJin100% (19)

- CoDeSys Manual V2p3Dokument388 SeitenCoDeSys Manual V2p3Akula VeerrajuNoch keine Bewertungen

- TQ - Air Fin Cooler (CS) - ModificationDokument6 SeitenTQ - Air Fin Cooler (CS) - ModificationAvinash ShuklaNoch keine Bewertungen

- Forced Evaporation Ponds DesignDokument10 SeitenForced Evaporation Ponds Designfotikos100% (1)

- Horizontal KO PotDokument4 SeitenHorizontal KO Pothk168Noch keine Bewertungen

- Datasheet Flame Detector FL4000H PDFDokument2 SeitenDatasheet Flame Detector FL4000H PDFRudin Fahrudin RahmanNoch keine Bewertungen

- 24191000-2, Gas Metering Skid As BuiltDokument6 Seiten24191000-2, Gas Metering Skid As BuiltAtty AttyNoch keine Bewertungen

- Input From Simulation Result From Table or Chart AssumptionDokument31 SeitenInput From Simulation Result From Table or Chart AssumptionMohamed Mamdouh AbdelHameed100% (1)

- Elm Pul PR XXX 034 Agc FinalDokument16 SeitenElm Pul PR XXX 034 Agc Finaljagiprem123Noch keine Bewertungen

- Effect of Viscosity On PumpsDokument4 SeitenEffect of Viscosity On PumpsChemkhiNoch keine Bewertungen

- Design of Unistrut Farming SystemDokument256 SeitenDesign of Unistrut Farming Systemjudaspriest21100% (1)

- (P&id1) PDFDokument1 Seite(P&id1) PDFHatem FaroukNoch keine Bewertungen

- Stress QuizDokument8 SeitenStress QuizNagarjuna SeellaNoch keine Bewertungen

- Chemical Control of Turfgrass Diseases 2020Dokument34 SeitenChemical Control of Turfgrass Diseases 2020Zakhar PikulytskyiNoch keine Bewertungen

- XX X XXXX XX XXXX 1rev XX Tank Farm Sleeper DesignDokument44 SeitenXX X XXXX XX XXXX 1rev XX Tank Farm Sleeper Designg4gohar0% (1)

- Bài Tập Kỹ Thuật Điện TửDokument13 SeitenBài Tập Kỹ Thuật Điện TửNguyenCanhBaoNoch keine Bewertungen

- Unfired Pressure VesselDokument30 SeitenUnfired Pressure VesselSrinivasan RajenderanNoch keine Bewertungen

- Loadsheet Demin Water Pump PU-1202 ABDokument13 SeitenLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarNoch keine Bewertungen

- 00000-UDS-001 (Chemical Injection Unit) Rev 0Dokument2 Seiten00000-UDS-001 (Chemical Injection Unit) Rev 0sithulibraNoch keine Bewertungen

- Method Statement For ACC BHELDokument7 SeitenMethod Statement For ACC BHELHsebepl NkNoch keine Bewertungen

- Equipment DatasheetDokument9 SeitenEquipment DatasheetBimal DeyNoch keine Bewertungen

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Dokument5 SeitenSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNoch keine Bewertungen

- Oil & Gas Facilities: Thai Nippon Steel Engineering and Construction CorporationDokument43 SeitenOil & Gas Facilities: Thai Nippon Steel Engineering and Construction CorporationDư Trần HưngNoch keine Bewertungen

- Rolling Threads DetailsDokument0 SeitenRolling Threads DetailsfastenersworldNoch keine Bewertungen

- Presentation Copy - Transfer, Storage and Distribution Solutions in LNGDokument86 SeitenPresentation Copy - Transfer, Storage and Distribution Solutions in LNGRudin Fahrudin RahmanNoch keine Bewertungen

- Calculate Pressure Drop in Basket & Tee Strainers ReferenceDokument5 SeitenCalculate Pressure Drop in Basket & Tee Strainers Referencebrock100% (1)

- TO-HQ-02-036 Rev 00 Philosophy For Flare Relief & Blowdown - OnshoreDokument28 SeitenTO-HQ-02-036 Rev 00 Philosophy For Flare Relief & Blowdown - OnshoreKthiri WaelNoch keine Bewertungen

- Cover TEG Contactor (V-1100)Dokument1 SeiteCover TEG Contactor (V-1100)Elias EliasNoch keine Bewertungen

- Wet Crude Tank CorrectedDokument36 SeitenWet Crude Tank CorrectedssheafiNoch keine Bewertungen

- A716-08 (2014) Standard Specification For Ductile Iron Culvert PipeDokument5 SeitenA716-08 (2014) Standard Specification For Ductile Iron Culvert PipejuegyiNoch keine Bewertungen

- 22-DS-R-001 Rev 1 API 617 GTCPsDokument25 Seiten22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Philosophy of OperationDokument30 SeitenPhilosophy of Operationfehmi-fjr4696Noch keine Bewertungen

- Data Sheet For Flare Package (PK-720)Dokument3 SeitenData Sheet For Flare Package (PK-720)samynatha PrasathNoch keine Bewertungen

- EIEPD Design CriteriaDokument125 SeitenEIEPD Design CriteriaLale AğayevaNoch keine Bewertungen

- Compressed Air System For Chemical and Industrial PlantsDokument23 SeitenCompressed Air System For Chemical and Industrial Plantsjkhan_724384Noch keine Bewertungen

- Mechanical Tender CNG PDFDokument161 SeitenMechanical Tender CNG PDFAWANI SRIVASTAVANoch keine Bewertungen

- Centrifugal Pump Lab ReportDokument3 SeitenCentrifugal Pump Lab ReportManu KumarNoch keine Bewertungen

- ENGINEERING DESIGN GUIDELINES Flare Systems Rev3.4webDokument25 SeitenENGINEERING DESIGN GUIDELINES Flare Systems Rev3.4webAngie Paola Sanabria Martinez100% (1)

- 100-T-1100 Methanol Tank SampleDokument3 Seiten100-T-1100 Methanol Tank SampleSachinl PatelNoch keine Bewertungen

- Saddle - Analysis by PV-EliteDokument17 SeitenSaddle - Analysis by PV-EliteSunilNoch keine Bewertungen

- Design Calculations of Elevated Cylindrical Flare StackDokument5 SeitenDesign Calculations of Elevated Cylindrical Flare StackSuarez Romero Gabino AuxibioNoch keine Bewertungen

- ClearanceDokument6 SeitenClearanceAGBARAOLUWA OLADIRANNoch keine Bewertungen

- Head Surface AeaDokument7 SeitenHead Surface AeaShashi Kant KumarNoch keine Bewertungen

- PV EliteDokument4 SeitenPV EliteRININoch keine Bewertungen

- ProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFDokument37 SeitenProcessBuildingVentilationSystemDesignDescription - CM A ME 001 R6 PDFShaimaa SaadNoch keine Bewertungen

- Leak TestingDokument5 SeitenLeak Testingogie_0513Noch keine Bewertungen

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsDokument19 SeitenGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRANoch keine Bewertungen

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Dokument5 Seiten18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNoch keine Bewertungen

- Enquiry: Bharat Heavy Electricals LimitedDokument21 SeitenEnquiry: Bharat Heavy Electricals LimitedanjnaNoch keine Bewertungen

- MEP R ES 006 Corrugated Plate Intercept SeparatorDokument6 SeitenMEP R ES 006 Corrugated Plate Intercept SeparatorimyourscinNoch keine Bewertungen

- Calgary 2011 Nozzle Loads PresentationDokument10 SeitenCalgary 2011 Nozzle Loads PresentationpexyNoch keine Bewertungen

- Thermal Power Plants IEE Checklist FormatDokument17 SeitenThermal Power Plants IEE Checklist FormatAlathea DonneNoch keine Bewertungen

- Nozzle LoadDokument8 SeitenNozzle LoadDam VoNoch keine Bewertungen

- Index - Amendment To TBPDokument4 SeitenIndex - Amendment To TBPVineet 01Noch keine Bewertungen

- 15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)Dokument22 Seiten15250-194-EN04-SP-005-Rev 0 (Specification For Atmospheric Storage Tank)sudokuNoch keine Bewertungen

- Pressure Releaving StationDokument11 SeitenPressure Releaving StationSreejesh Sundaresan100% (1)

- Fire Jockey Pump. Rev B1Dokument3 SeitenFire Jockey Pump. Rev B1Pump SpesialistNoch keine Bewertungen

- Tank DesignDokument2 SeitenTank DesignkamleshyadavmoneyNoch keine Bewertungen

- Technical Clarification For SHOP FABRICATING PIPINGDokument3 SeitenTechnical Clarification For SHOP FABRICATING PIPINGChaerul AnwarNoch keine Bewertungen

- Deep Well Submersible Pump - HydraulicsDokument1 SeiteDeep Well Submersible Pump - HydraulicsImran AzizNoch keine Bewertungen

- Cyclic Service - Intergraph CADWorx & AnalysisDokument2 SeitenCyclic Service - Intergraph CADWorx & Analysisisrar khanNoch keine Bewertungen

- Caesar IiDokument2 SeitenCaesar Iicena3135Noch keine Bewertungen

- Drain Philosophy Rev BDokument26 SeitenDrain Philosophy Rev BAnonymous nxWj29Noch keine Bewertungen

- Sick Tanker Unloading PumpDokument3 SeitenSick Tanker Unloading PumpSumantrra ChattopadhyayNoch keine Bewertungen

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDokument6 SeitenPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNoch keine Bewertungen

- General: Centrifugal Pump Data SheetDokument3 SeitenGeneral: Centrifugal Pump Data Sheetfaraujodff10Noch keine Bewertungen

- Omnigrad M TR 11: RTD Temperature SensorDokument16 SeitenOmnigrad M TR 11: RTD Temperature SensorRudin Fahrudin RahmanNoch keine Bewertungen

- XNX Specs Universal TransmiterDokument2 SeitenXNX Specs Universal TransmiterRudin Fahrudin RahmanNoch keine Bewertungen

- Itemp Hart TMT182 With 4... 20 Ma Output Signal: Functional Safety Manual ® ®Dokument16 SeitenItemp Hart TMT182 With 4... 20 Ma Output Signal: Functional Safety Manual ® ®Rudin Fahrudin RahmanNoch keine Bewertungen

- 1756 Um001 - en P PDFDokument210 Seiten1756 Um001 - en P PDFAlafael AraújoNoch keine Bewertungen

- Logix 5000 Controllers Import/Export: Reference ManualDokument304 SeitenLogix 5000 Controllers Import/Export: Reference ManualRudin Fahrudin RahmanNoch keine Bewertungen

- Datasheet Flame Detector FL3100HDokument2 SeitenDatasheet Flame Detector FL3100HRudin Fahrudin RahmanNoch keine Bewertungen

- Logix 5000 Controllers Security: Programming ManualDokument60 SeitenLogix 5000 Controllers Security: Programming ManualRudin Fahrudin RahmanNoch keine Bewertungen

- 1756 Um001 - en P PDFDokument210 Seiten1756 Um001 - en P PDFAlafael AraújoNoch keine Bewertungen

- 1789 Um002 - en PDokument272 Seiten1789 Um002 - en P1meander23Noch keine Bewertungen

- 1756 Um051 - en P PDFDokument122 Seiten1756 Um051 - en P PDFRudin Fahrudin RahmanNoch keine Bewertungen

- 1756 pm019 - en PDokument100 Seiten1756 pm019 - en PGuilhermeNoch keine Bewertungen

- 1756 pm019 - en PDokument100 Seiten1756 pm019 - en PGuilhermeNoch keine Bewertungen

- Logix 5000 Controllers Program Parameters: Programming ManualDokument42 SeitenLogix 5000 Controllers Program Parameters: Programming ManualRudin Fahrudin RahmanNoch keine Bewertungen

- 1756-Analog HartDokument264 Seiten1756-Analog HartPrasanna KaushikNoch keine Bewertungen

- Logix 5000 Controllers Program Parameters: Programming ManualDokument42 SeitenLogix 5000 Controllers Program Parameters: Programming ManualRudin Fahrudin RahmanNoch keine Bewertungen

- 1756 Controllogix and Guardlogix Controllers: Technical DataDokument52 Seiten1756 Controllogix and Guardlogix Controllers: Technical DataMaricruz OlivarNoch keine Bewertungen

- Logix 5000 Controllers Import/Export: Reference ManualDokument304 SeitenLogix 5000 Controllers Import/Export: Reference ManualRudin Fahrudin RahmanNoch keine Bewertungen

- 1756 Um022 - en P PDFDokument172 Seiten1756 Um022 - en P PDFumair arifNoch keine Bewertungen

- Logix 5000 Controllers Security: Programming ManualDokument60 SeitenLogix 5000 Controllers Security: Programming ManualRudin Fahrudin RahmanNoch keine Bewertungen

- Modul Analog Output 1756Dokument4 SeitenModul Analog Output 1756Rudin Fahrudin RahmanNoch keine Bewertungen

- Logix 5000 Controllers Ladder Diagram Programming Manual PDFDokument24 SeitenLogix 5000 Controllers Ladder Diagram Programming Manual PDFthepinetreesNoch keine Bewertungen

- 1756 Controllogix Controllers: Product InformationDokument2 Seiten1756 Controllogix Controllers: Product InformationRudin Fahrudin RahmanNoch keine Bewertungen

- 1756 Um001 - en P PDFDokument210 Seiten1756 Um001 - en P PDFAlafael AraújoNoch keine Bewertungen

- Logix5000 Controllers Common Procedures: Programming ManualDokument1 SeiteLogix5000 Controllers Common Procedures: Programming ManualAdhitNoch keine Bewertungen

- 1756 Controllogix Controllers: Product InformationDokument2 Seiten1756 Controllogix Controllers: Product InformationRudin Fahrudin RahmanNoch keine Bewertungen

- 1756-Pm004 - Logix 5000 Controllers IO and Tag DataDokument88 Seiten1756-Pm004 - Logix 5000 Controllers IO and Tag DataHenryNoch keine Bewertungen

- M05 SpecificationsDokument97 SeitenM05 SpecificationsLê Văn TrườngNoch keine Bewertungen

- ECOSIADokument8 SeitenECOSIAaliosk8799Noch keine Bewertungen

- Egyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDokument13 SeitenEgyptian Blue Cuprorivaite A Window To Ancient Egyptian TechnologyDοмenıκ CaesarNoch keine Bewertungen

- Orgo Naming RulesDokument7 SeitenOrgo Naming Ruleskirtmartinreyes14Noch keine Bewertungen

- Designing Concrete For Exposure To Seawater - tcm45-342265Dokument3 SeitenDesigning Concrete For Exposure To Seawater - tcm45-342265Ignatius Samraj100% (2)

- Project ReportDokument67 SeitenProject ReportDivyanshu DkNoch keine Bewertungen

- EBT 335 Polymer Blends: Presented By: PL TehDokument23 SeitenEBT 335 Polymer Blends: Presented By: PL TehTarani TharanNoch keine Bewertungen

- Goldmix PC110 TDS PDFDokument1 SeiteGoldmix PC110 TDS PDFRafael Obusan IINoch keine Bewertungen

- Electroanalytical Methods: Presented ToDokument36 SeitenElectroanalytical Methods: Presented ToSyed UmairNoch keine Bewertungen

- SSRN Id4492574Dokument16 SeitenSSRN Id4492574Sai KrishnaNoch keine Bewertungen

- PT - PhytoAct Golden Sericin - B2 - Customer VersionDokument11 SeitenPT - PhytoAct Golden Sericin - B2 - Customer VersionNishikino MakiryNoch keine Bewertungen

- Methods For Testing Antioxidant Activity: The Analyst February 2002Dokument17 SeitenMethods For Testing Antioxidant Activity: The Analyst February 2002Boas WayneNoch keine Bewertungen

- Energy and Power Ib2Dokument24 SeitenEnergy and Power Ib2Gkid GkidNoch keine Bewertungen

- Chem PD LabDokument2 SeitenChem PD LabNia-Amoi CurrieNoch keine Bewertungen

- SealXtra PU FR - BaseDokument3 SeitenSealXtra PU FR - BasehazelNoch keine Bewertungen

- Lec 6Dokument21 SeitenLec 6Loganathan SelvamNoch keine Bewertungen

- Transes Act 7 CC LabDokument7 SeitenTranses Act 7 CC LabCiara PamonagNoch keine Bewertungen

- Types of Dosage Forms Lecture2,2Dokument34 SeitenTypes of Dosage Forms Lecture2,2Bhuvana TejaNoch keine Bewertungen

- Amino Crosslinkers: Product Guide - Cymel Resins - WorldwideDokument20 SeitenAmino Crosslinkers: Product Guide - Cymel Resins - WorldwidejoseNoch keine Bewertungen

- Recruitment and Selection Bharathi CementsDokument73 SeitenRecruitment and Selection Bharathi Cementskum124267% (3)

- Colloid Chemistry and Phase Rule 4022146-1: (Essentials of Physical Chemistry - Arun Bahl & B.S. Bahl) Chapter 19 and 22Dokument51 SeitenColloid Chemistry and Phase Rule 4022146-1: (Essentials of Physical Chemistry - Arun Bahl & B.S. Bahl) Chapter 19 and 22Razan khalidNoch keine Bewertungen

- Comparitive of Waterproofing WorkDokument12 SeitenComparitive of Waterproofing WorkReshik KannanNoch keine Bewertungen

- Bruice Organic Chemistry 6eDokument26 SeitenBruice Organic Chemistry 6esdfasf asdasdasd100% (1)