Beruflich Dokumente

Kultur Dokumente

Cat Eye

Hochgeladen von

jitu2968Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Cat Eye

Hochgeladen von

jitu2968Copyright:

Verfügbare Formate

4 893.00 Smt Road Marking with Hot applied thermoplastic paints with 496.00 4.96 500.96 Sqm 447357.

28

Reflectorising glass beads on Bitumin surface. Peoviding & Laying a

hot applied Thermoplastic compound 2.5 mm thick including

refflectorising glass beads @ 250 gms. Sqm. Area thickness of 2.5 mm

is excluding of Surface applied glass beads as per IRC :35-2015. The

finished surface to be level , uniform and free from streaks and holes

Zebra patta / bump patta lane / center line / edges/ Cut patta. The

white colour marking should provide leminance coefficient on cermend

road shallbe min. 130 mcd/m2/lux and Ashphalt road shall be

minimum 100 mcd/m2/lux during the service life during the dry time.

The marking should should meet the performance criteria for night

time / reflectivity, wet reflectivitiy and skid reasistance as mentioned in

the section-15 of IRC 35 - 2015.( SOR It. No. 26161 ,P . No. )

5 1555.00 No. Cat Eye / Road Stud / RPM : Providing & fixing raised pavement 303.00 3.03 306.03 No. 475876.65

marker ( Cat Eye / Road Stud ) Complying ASTM 04280 made of high

strength engineering plastic body having at list 13653 Kgs. Load

Bearing capacity in accordance with ASTM D 4280. The Reflective

raised pavement markers shall also confirm to the MORTH circular

No. RW/ NH./ 33023 / 10/ 97 - DO.III and Length / Width of the

marker should be not be more than 130 mm and height should not be

more than 20 mm, having shape so that no water penetration or dust

occumulation takes place on reflective Surface, fitted with

electronically welded tough polycarbonate micro prismatic reflective

panels having not less than 13 Sq.Cmt. surface area of each side having

long distance visibility at night and in wet weather condition. The slope

or retro reflectory Surface shall be 35 + 5 degree to base. Each

reflectore shall have a GL not less values specified in Table of

MORTH circular dated 11.6.97 respectively. The body of the marker

should having finger grip for easy and accurate Placement and

application with epoxy /bituminous Adhesive as recommended by the

manufacture of the marker. The colour of the marker should be as per

the IRC 34-2015 and as directed by Engineer in Charges. ( SOR It. No.

26162 . P. No. )

Das könnte Ihnen auch gefallen

- DemolitionDokument4 SeitenDemolitionLjupka VukicNoch keine Bewertungen

- Constuction of Embankment/ Preparation of Subgrade: Highway ConstructionDokument11 SeitenConstuction of Embankment/ Preparation of Subgrade: Highway ConstructionMohan Mylarappa100% (1)

- Civil Standard & Code No Area Code Standard AstmDokument10 SeitenCivil Standard & Code No Area Code Standard AstmTri SeptaNoch keine Bewertungen

- Method Statement PDFDokument9 SeitenMethod Statement PDFDon Clerance Denzil WeerakkodyNoch keine Bewertungen

- Factors and Elements Guiding Highway Alignment and Cross-Section DesignDokument3 SeitenFactors and Elements Guiding Highway Alignment and Cross-Section DesignRohit BhamareNoch keine Bewertungen

- Geometric Design of HighwaysDokument75 SeitenGeometric Design of Highwayssuman subediNoch keine Bewertungen

- Vol-Ii - Section-I - PMS, Qam & PmaDokument25 SeitenVol-Ii - Section-I - PMS, Qam & PmaAmit Kumar SinghNoch keine Bewertungen

- Construction and Design of MultistoreyDokument37 SeitenConstruction and Design of MultistoreyFawadNoch keine Bewertungen

- Road Intersections-15-4-20Dokument8 SeitenRoad Intersections-15-4-20lakshmidileepNoch keine Bewertungen

- Joint Member Distribution Factor FEM BalanceDokument2 SeitenJoint Member Distribution Factor FEM Balancewe_mbmNoch keine Bewertungen

- StandardsDokument25 SeitenStandardsJohnlester DelosoNoch keine Bewertungen

- Standard Protactor TestDokument8 SeitenStandard Protactor TestNur ZakariaNoch keine Bewertungen

- Core Drilling ProcedureDokument7 SeitenCore Drilling ProcedureEngineeri TadiyosNoch keine Bewertungen

- Guidelines For Dowel Alignment in Concrete Pavements: Appendix A Review of Literature and Other Relevant InformationDokument41 SeitenGuidelines For Dowel Alignment in Concrete Pavements: Appendix A Review of Literature and Other Relevant InformationEunice Joy Tabucanon Villegas100% (1)

- Design of Beams To BS 8110Dokument14 SeitenDesign of Beams To BS 8110YAHAMPATH ARACHCHIGE PASAN MADURA YahampathNoch keine Bewertungen

- Highway Geometric DesignDokument76 SeitenHighway Geometric DesignNaman DwivediNoch keine Bewertungen

- Highway Geometric Design ElementsDokument93 SeitenHighway Geometric Design ElementsGERA AMITH KUMARNoch keine Bewertungen

- Experiment Atterberg Limits: PurposeDokument8 SeitenExperiment Atterberg Limits: PurposefoidsNoch keine Bewertungen

- Seismic Analysis and Structural Design of Multi-Storied RCC Framed Commercial BuildingDokument55 SeitenSeismic Analysis and Structural Design of Multi-Storied RCC Framed Commercial BuildingYugenNoch keine Bewertungen

- Typical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sDokument6 SeitenTypical Pipe Culvert Capacity: DIA Slope Flow Flow 1:S Velocity Capasity MM M/s M 3/sJennifer PearsonNoch keine Bewertungen

- Industrial Training ReportDokument20 SeitenIndustrial Training Reportch umairNoch keine Bewertungen

- Specification For Pile EmbankmentDokument5 SeitenSpecification For Pile EmbankmentamirriyyahNoch keine Bewertungen

- Review of Permeable Pavement Systems in Malaysia ConditionsDokument10 SeitenReview of Permeable Pavement Systems in Malaysia ConditionsEkki GustiNoch keine Bewertungen

- Specification of D-Wall and Bored PilesDokument34 SeitenSpecification of D-Wall and Bored PilesdonnyNoch keine Bewertungen

- Assignment - 1 OF Project Management Topic-: Submitted To Submitted byDokument13 SeitenAssignment - 1 OF Project Management Topic-: Submitted To Submitted bynaushavaNoch keine Bewertungen

- 7732 Method Statement I v01Dokument75 Seiten7732 Method Statement I v01Nadeeka HerathNoch keine Bewertungen

- Work Section Preambles ExplainedDokument55 SeitenWork Section Preambles ExplaineddophongxdNoch keine Bewertungen

- BS-5950-90 Example 001Dokument7 SeitenBS-5950-90 Example 001Win ThanNoch keine Bewertungen

- PileDokument5 SeitenPileSuman NakarmiNoch keine Bewertungen

- L-Shape Wall Mar13Dokument2 SeitenL-Shape Wall Mar13Wan MahiramNoch keine Bewertungen

- Risk Management Policy SummaryDokument7 SeitenRisk Management Policy SummaryAnilkotNoch keine Bewertungen

- ZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkDokument1 SeiteZHJV W I Si 0167 0 A1 - Abutment Pile Cap FormworkASAALE GLORIANoch keine Bewertungen

- RCC Lecture Series 2 2018-19 PDFDokument41 SeitenRCC Lecture Series 2 2018-19 PDFMansa ArthurNoch keine Bewertungen

- ProfessionalPractice - FAQ (For BEM's Website) PDFDokument17 SeitenProfessionalPractice - FAQ (For BEM's Website) PDFgilbert850507Noch keine Bewertungen

- Sample BOQDokument150 SeitenSample BOQkanishkaNoch keine Bewertungen

- MOS - PipeBridge SG SebatangDokument13 SeitenMOS - PipeBridge SG Sebatang7e1a8821100% (1)

- In-Situ Concrete CulvertDokument3 SeitenIn-Situ Concrete CulvertBenjamin IpeNoch keine Bewertungen

- Department of Civil Engineering: Guide:Prof. Vishal SapateDokument21 SeitenDepartment of Civil Engineering: Guide:Prof. Vishal SapateshrikantharleNoch keine Bewertungen

- Loads On Industrial BuildingsDokument29 SeitenLoads On Industrial Buildingsmcg_3m100% (1)

- Handril CalculationDokument10 SeitenHandril CalculationGonzalo AnzaldoNoch keine Bewertungen

- List of Test StandardsDokument4 SeitenList of Test StandardsjargalneNoch keine Bewertungen

- Precast Concrete ConstructionDokument28 SeitenPrecast Concrete ConstructionGirl in the CityNoch keine Bewertungen

- 1.technical Specifications (Piling)Dokument15 Seiten1.technical Specifications (Piling)Kunal Panchal100% (2)

- CCIP Errata Worked Examples To Eurocode 2 Jan2012Dokument13 SeitenCCIP Errata Worked Examples To Eurocode 2 Jan2012fan_luc89Noch keine Bewertungen

- Tale of 2 Deep Singapore Basements and How 3D Modeling Led To A Leaner Design and Keener Construction Programme - EiSandaDokument13 SeitenTale of 2 Deep Singapore Basements and How 3D Modeling Led To A Leaner Design and Keener Construction Programme - EiSandablithevincentNoch keine Bewertungen

- Early Thermal Cracking CalculationsDokument1 SeiteEarly Thermal Cracking Calculationsmassive85Noch keine Bewertungen

- Reinforcement Detailing BrochureDokument2 SeitenReinforcement Detailing BrochureAbd Al-Gaffar BajouriNoch keine Bewertungen

- Precast Concrete Pipe Culvert InstallationDokument4 SeitenPrecast Concrete Pipe Culvert InstallationDanny NguNoch keine Bewertungen

- U Drain SpecDokument4 SeitenU Drain Speckenji_sanNoch keine Bewertungen

- Beam Design 1Dokument23 SeitenBeam Design 1kanishkaNoch keine Bewertungen

- Sector 7 Infrastructure Cost AnalysisDokument129 SeitenSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNoch keine Bewertungen

- Crane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVDokument15 SeitenCrane Lifting Optimization and Construction Monitoring in Steel Bridge Construction Project Based On BIM and UAVGogyNoch keine Bewertungen

- PILE ANALYSISDokument4 SeitenPILE ANALYSISRuemu Godwin InikoriNoch keine Bewertungen

- Mesh Fabric BS4483 1998Dokument1 SeiteMesh Fabric BS4483 1998eotp1Noch keine Bewertungen

- 005 - C3 - Scope of WorksDokument11 Seiten005 - C3 - Scope of Workskkodge0% (1)

- Pdc8 Checklist StatusDokument1 SeitePdc8 Checklist StatusNusaibah YusofNoch keine Bewertungen

- Materials & loading details for hospital buildingDokument2 SeitenMaterials & loading details for hospital buildingashishNoch keine Bewertungen

- Thermal Stresses and Temperature Control of Mass ConcreteVon EverandThermal Stresses and Temperature Control of Mass ConcreteNoch keine Bewertungen

- Boq MG RoadDokument3 SeitenBoq MG Roadsushaant pahalwanNoch keine Bewertungen

- Road Safety WorksDokument1 SeiteRoad Safety WorksVannurSwamyNoch keine Bewertungen

- 4 Detailed SpecificationsDokument136 Seiten4 Detailed Specificationsjitu2968Noch keine Bewertungen

- 5 Cons StatementDokument5 Seiten5 Cons Statementjitu2968Noch keine Bewertungen

- Final Ap 2023 24 With Circular 1804202318042023014956Dokument9 SeitenFinal Ap 2023 24 With Circular 1804202318042023014956jitu2968Noch keine Bewertungen

- Price 16.10.2022Dokument1 SeitePrice 16.10.2022jitu2968Noch keine Bewertungen

- Judicial Quarter d1 Category JesarDokument7 SeitenJudicial Quarter d1 Category Jesarjitu2968Noch keine Bewertungen

- Price 01.11.2022Dokument1 SeitePrice 01.11.2022jitu2968Noch keine Bewertungen

- Steel GRDokument3 SeitenSteel GRjitu2968Noch keine Bewertungen

- 6 InfoDokument11 Seiten6 Infojitu2968Noch keine Bewertungen

- Information Pertaining To Lease TenureDokument1 SeiteInformation Pertaining To Lease Tenurejitu2968Noch keine Bewertungen

- Classification of Cities GR 12-10-2022Dokument13 SeitenClassification of Cities GR 12-10-2022jitu2968Noch keine Bewertungen

- Request For Change in Policy Details20march13Dokument1 SeiteRequest For Change in Policy Details20march13jitu2968Noch keine Bewertungen

- Hindustan Colas price offer for emulsion productsDokument1 SeiteHindustan Colas price offer for emulsion productsjitu2968100% (1)

- Price 16.10.2022Dokument1 SeitePrice 16.10.2022jitu2968Noch keine Bewertungen

- Pages From NEW SIGNAGE ITEMSDokument3 SeitenPages From NEW SIGNAGE ITEMSjitu2968Noch keine Bewertungen

- Product Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net PriceDokument1 SeiteProduct Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net Pricejitu2968Noch keine Bewertungen

- Product Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net PriceDokument1 SeiteProduct Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net Pricejitu2968Noch keine Bewertungen

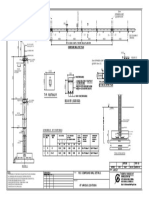

- Compound Wall Type CDokument1 SeiteCompound Wall Type Cjitu2968Noch keine Bewertungen

- Schematic Boundary WallDokument1 SeiteSchematic Boundary Walljitu2968Noch keine Bewertungen

- Product Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net PriceDokument1 SeiteProduct Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net Pricejitu2968Noch keine Bewertungen

- Product Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net PriceDokument1 SeiteProduct Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net Pricejitu2968Noch keine Bewertungen

- Product Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net PriceDokument1 SeiteProduct Supply Location Unit Current Assessable Value SGST SGST Amount CGST CGST Amount Igst Igst Amount Net Pricejitu2968Noch keine Bewertungen

- Compound Wall Type BDokument1 SeiteCompound Wall Type Bjitu2968Noch keine Bewertungen

- Sakhi One Stope CenterDokument116 SeitenSakhi One Stope Centerjitu2968Noch keine Bewertungen

- Compound Wall Type ADokument1 SeiteCompound Wall Type Ajitu2968Noch keine Bewertungen

- 4.3 Item 7 Soil Subbase Stabilization With TS+ZB Specs Using RotavatorDokument7 Seiten4.3 Item 7 Soil Subbase Stabilization With TS+ZB Specs Using Rotavatorjitu2968Noch keine Bewertungen

- Providing Stabilized Base Course with NanotechnologyDokument10 SeitenProviding Stabilized Base Course with Nanotechnologyjitu2968Noch keine Bewertungen

- Cement QUO JuneDokument6 SeitenCement QUO Junejitu2968Noch keine Bewertungen

- QTN - Executive Engineer - PalanpurDokument4 SeitenQTN - Executive Engineer - Palanpurjitu2968Noch keine Bewertungen

- Hindustan Colas price offer for emulsion productsDokument1 SeiteHindustan Colas price offer for emulsion productsjitu2968100% (1)

- Waterproofing of Subgrades and ShouldersDokument4 SeitenWaterproofing of Subgrades and Shouldersjitu2968Noch keine Bewertungen

- Gabriel S OboeDokument4 SeitenGabriel S Oboeisabeletaestatequeta100% (1)

- In New SampleDokument9 SeitenIn New Samplearun neupaneNoch keine Bewertungen

- All Unity Source CodeDokument16 SeitenAll Unity Source CodeMohamed AlashramNoch keine Bewertungen

- Service System Design MatrixDokument4 SeitenService System Design MatrixSanica FernandesNoch keine Bewertungen

- Free To Air, Indian TV, Free TV, Satellite TV, FTA Channels PDFDokument18 SeitenFree To Air, Indian TV, Free TV, Satellite TV, FTA Channels PDFchidambaram kasi100% (1)

- Lifebook E Series E8310 ManualDokument4 SeitenLifebook E Series E8310 ManualpraetorianblNoch keine Bewertungen

- McGill Music Course Covers FundamentalsDokument3 SeitenMcGill Music Course Covers FundamentalsMauriceNoch keine Bewertungen

- Strategic Management Task 1Dokument31 SeitenStrategic Management Task 1Niculescu IrinaNoch keine Bewertungen

- The TempestDokument1 SeiteThe TempestAnna CTNoch keine Bewertungen

- Walmart Vs AmazonDokument13 SeitenWalmart Vs AmazonSimone AdamiNoch keine Bewertungen

- Blank 5e Sheet DNDDokument3 SeitenBlank 5e Sheet DNDPhil Fantastic D'AnjouNoch keine Bewertungen

- Booklet PDFDokument6 SeitenBooklet PDFJossNoch keine Bewertungen

- Heidi Lesson Plan Good One-2Dokument8 SeitenHeidi Lesson Plan Good One-2api-295566333Noch keine Bewertungen

- Pros and Cons of Project SchedulingDokument5 SeitenPros and Cons of Project SchedulingTashio ShiotaNoch keine Bewertungen

- The Catcher in the Rye Chapters 1-26 SummaryDokument4 SeitenThe Catcher in the Rye Chapters 1-26 SummaryRav Rah0% (1)

- Transfering From Bed To ChairDokument3 SeitenTransfering From Bed To ChairJoyce Madarang100% (1)

- Beef Jerky RecipesDokument3 SeitenBeef Jerky Recipeszeem buoNoch keine Bewertungen

- Total body workouts & Superman circuitDokument3 SeitenTotal body workouts & Superman circuitAlberto LaraNoch keine Bewertungen

- 120B Final PaperDokument8 Seiten120B Final PaperKhanh MaiNoch keine Bewertungen

- Getting Ripped EbookDokument14 SeitenGetting Ripped EbookBrent Koboroff100% (1)

- The Tale of Mrs Tiggy-WinkleDokument14 SeitenThe Tale of Mrs Tiggy-WinkleGglupps Gglupps GgluppsyNoch keine Bewertungen

- The Story of Sangkuriang and Tangkuban Perahu MountainDokument2 SeitenThe Story of Sangkuriang and Tangkuban Perahu MountainVester Ryan Pratama PutraNoch keine Bewertungen

- The Ant and The Dove: ComprehensionDokument14 SeitenThe Ant and The Dove: ComprehensionSčol LërNoch keine Bewertungen

- Breezy Peasy Crochet CardiganDokument5 SeitenBreezy Peasy Crochet CardiganRoganNoch keine Bewertungen

- Tarea de Refuerzo y Recuperación Unit 2Dokument7 SeitenTarea de Refuerzo y Recuperación Unit 2LuisNoch keine Bewertungen

- Audition Notice Wizard of OzDokument3 SeitenAudition Notice Wizard of OzTJerome BakerNoch keine Bewertungen

- Arduino IntroductionDokument8 SeitenArduino IntroductionSedrex De Veas CastilloNoch keine Bewertungen

- EdamameDokument3 SeitenEdamameEdy SutiarsoNoch keine Bewertungen

- Formulas and Logical FunctionsDokument8 SeitenFormulas and Logical FunctionsKeisi RojasNoch keine Bewertungen

- Mopar Oil Filters Application GuideDokument40 SeitenMopar Oil Filters Application GuidebasquenNoch keine Bewertungen